Table of Contents

6

Low I Range DC Calibration .................................................................................................................. 38

Cable Calibration .................................................................................................................................. 39

Procedure to calibrate the cable .................................................................................................... 40

Chapter 6: Cell Connections ......................................................................................................................... 43

Cell Cable Overview ............................................................................................................................. 43

Ancillary Apparatus ....................................................................................................................... 43

AE Connections ............................................................................................................................. 43

Fuses in the Cell Cable .......................................................................................................................... 43

Normal Cell Connections ...................................................................................................................... 43

ZRA Mode Cell Connections ................................................................................................................. 45

Stack Mode Cell Connections ................................................................................................................ 46

Membrane Cell Connections ................................................................................................................. 46

Fuses in the Cell Cable .......................................................................................................................... 47

In-line Fuse-Holders and Fuses ...................................................................................................... 47

Fuses Located in the Cable Hood .................................................................................................. 48

Testing For Open Fuses ................................................................................................................. 50

Chapter 7: Panel Indicators and Connectors .................................................................................................. 53

Front Panel ........................................................................................................................................... 53

Counter/Working Connector ......................................................................................................... 53

Sense Inputs Connector ................................................................................................................. 54

Power LED .................................................................................................................................... 54

USB LED ....................................................................................................................................... 56

Cell On LED .................................................................................................................................. 56

Overload LED ............................................................................................................................... 56

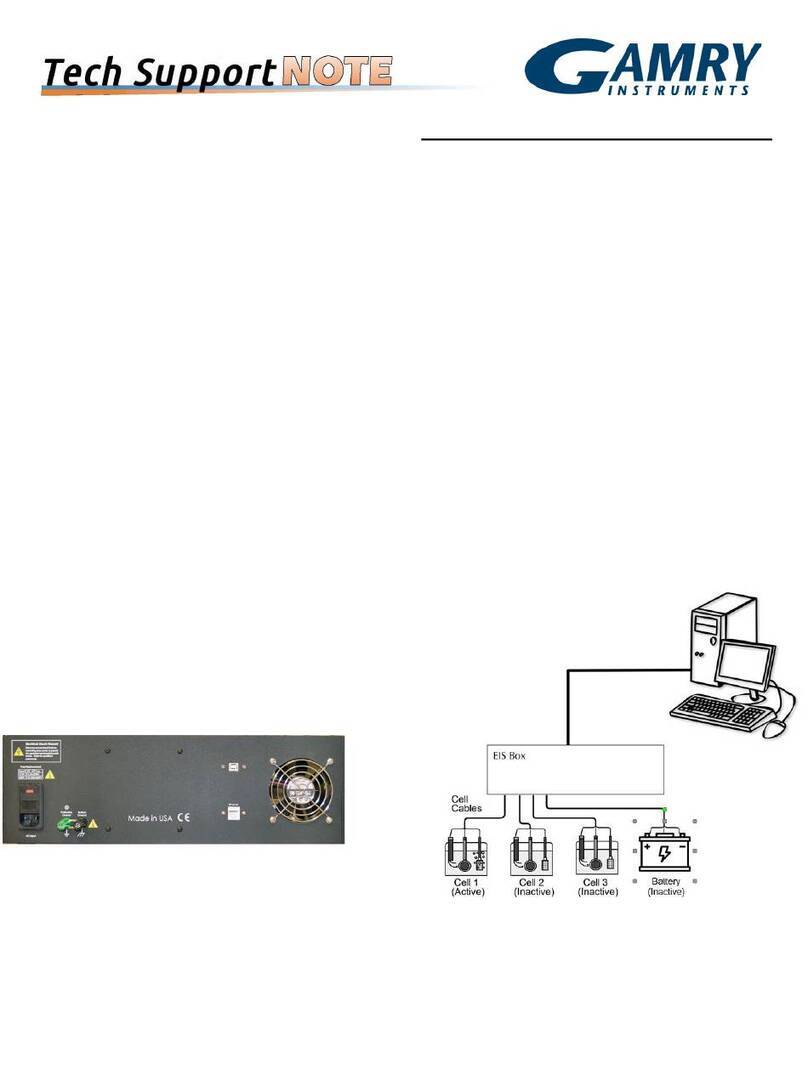

Rear Panel ............................................................................................................................................ 58

Power In Jack ................................................................................................................................ 58

Power Switch ................................................................................................................................ 59

Chassis Ground ............................................................................................................................. 60

USB Port ....................................................................................................................................... 60

Thermocouple Input ..................................................................................................................... 61

Misc. I/O Connector ...................................................................................................................... 61

I Monitor BNC .............................................................................................................................. 62

E Monitor BNC.............................................................................................................................. 63

Ext. Sig. In BNC ............................................................................................................................. 63

Sig Gen. Out BNC ......................................................................................................................... 64

Aux. In BNC .................................................................................................................................. 64

Expansion Interface ....................................................................................................................... 64

Chapter 8: Auxiliary Electrometer Option ...................................................................................................... 65

Overview .............................................................................................................................................. 65

AC Performance and CMRR .................................................................................................................. 65

Experiments .......................................................................................................................................... 66

Connections Using Standard Cables ...................................................................................................... 66

Connections Using Custom Cables ........................................................................................................ 67

AE Specifications ................................................................................................................................... 67

Chapter 9: Stability in Potentiostat Mode ...................................................................................................... 69

Capacitive Cells and Stability ................................................................................................................. 69

Improving Potentiostat Stability ............................................................................................................. 69

Chapter 10: Measurement of Small-current Signals ........................................................................................ 73

Overview .............................................................................................................................................. 73

Description of the Problem ................................................................................................................... 73

Measurement System Model and Physical Limitations ............................................................................ 73

Johnson Noise in Zcell ................................................................................................................... 74