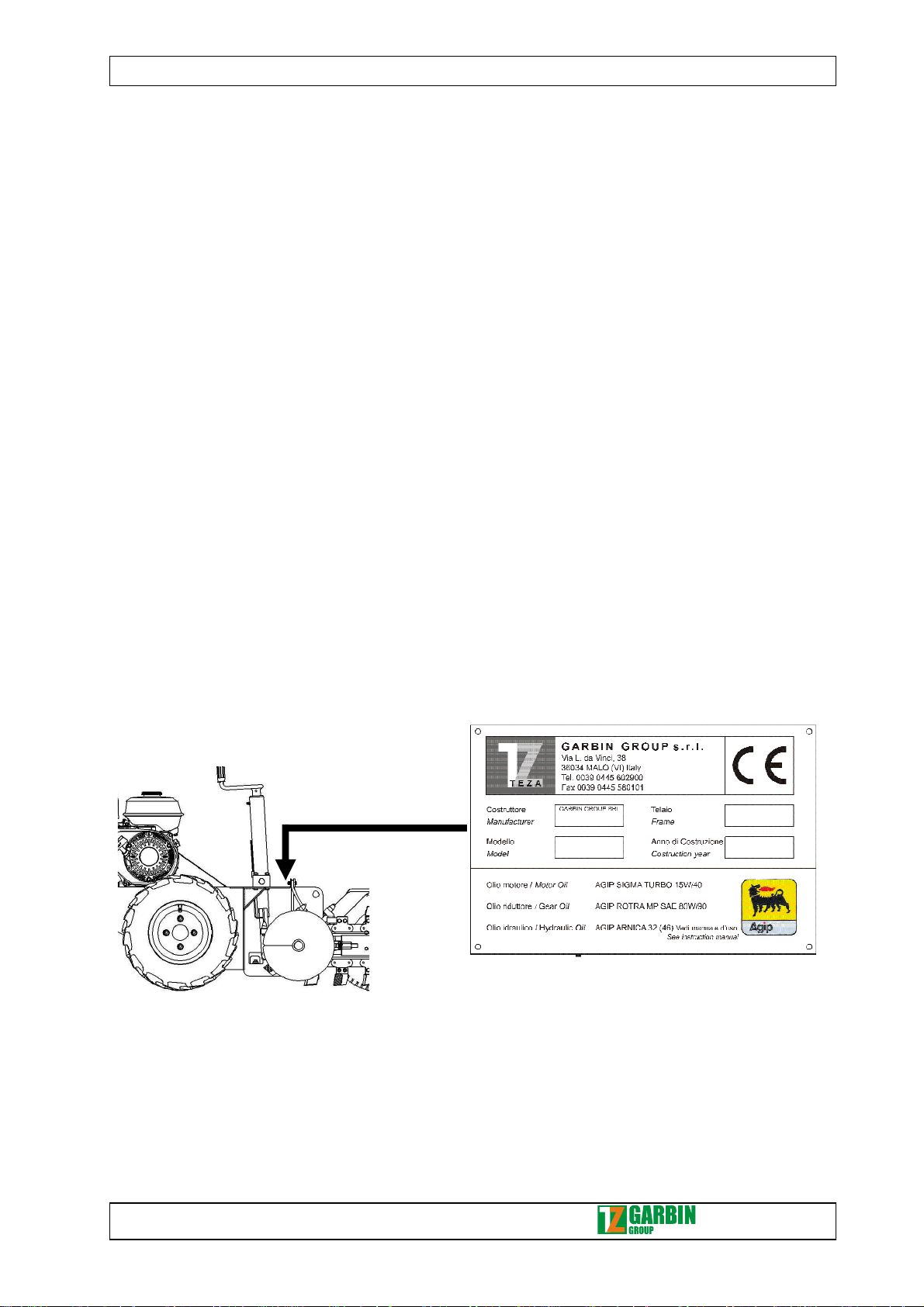

TRENCHER TZ S

Use and maintenance instructions – Spare parts Via L.da Vinci,32/

Rev. 01.2013 - EN (translation of the original instructions)

5

36034 Malo (VI) Italy

T E Z A

WARRANTY

The sale of any trencher, of its accessories and spare parts is governed by following essential and

mandatory conditions:

a) The order is a simple proposal of sale and is therefore subject to acceptance by GARBIN GROUP SRL.

The order may also be accepted simply through execution by GARBIN GROUP SRL.

b) Sold goods are delivered at the conditions established in the contract of sale. In any case, goods travel at

the Customer's own risk, even if the purchase price includes freight.

c) The lead time, if agreed, has only an approximate value and GARBIN GROUP SRL therefore declines all

liability for any delays caused by third parties, force majeure or chance.

d) Any packaging is charged to the Customer at cost.

e) The entire range of the GARBIN GROUP SRL is guaranteed for six months from the date of delivery.

The warranty only covers parts found and recognised by GARBIN GROUP SRL to be faulty as regards

construction, and does not cover any other charges. The faulty part must be sent carriage paid to GARBIN

GROUP SRL in Malo (VI) Italy and collected within 15 days of replacement; failure to do so authorises

GARBIN GROUP SRL to proceed with invoicing. The warranty does not cover motors, electronic

components and parts subject to wear. The diesel engine is directly guaranteed by the engine manufacturer

for twelve months from the date of delivery.

f) The warranty shall become invalid if the machine is tampered with or partially or totally dismounted by

people who have not been authorised in advance by GARBIN GROUP SRL or if it is used incorrectly or not

in conformity with GARBIN GROUP SRL instructions, or if it has not been sufficiently or correctly serviced.

g) Any faults must be notified in writing within 8 days from delivery; failure to do so will invalidate the

Purchasers' rights as per this warranty. Hidden not easily recognisable faults must be notified in writing to

GARBIN GROUP SRL not later than eight days from their discovery, provided this occurs within six months

from delivery. In no case may such notifications entitle the Customer to suspend payment of the agreed

price.

h) GARBIN GROUP SRL reserves the right to make technical or aesthetic changes at its sole discretion, at

any time and without the obligation to notify the Purchaser in advance.

i) If the goods are not paid for on delivery, payment must be made within sixty days from the invoice date.

l) Payment is always made at the head office of GARBIN GROUP SRL in Malo (VI) Italy, even if by means

of promissory notes or drafts. Though the latter are payable elsewhere, in no case shall this affect the

territorial jurisdiction of the Court of Vicenza, it being exclusively competent to interpret and execute the

contract. Consequently, the place in which the obligation arose or the goods were delivered shall not be

taken into account.

m) In case of payment by instalments, the purchaser loses its rights as per art. 1186 of the Italian Civil Code

if even one of the instalments remains unpaid at the date of expiry. In case of late payment, interest shall be

applied at a rate of 2% per month, as agreed between the parties.

n) The order may not be fully or partially revoked. If the Purchaser is unable to collect the goods owing to

Force Majeure, if recognised as such by GARBIN GROUP SRL, it shall reimburse 20% of the total value of

the supply, unless the supply includes goods built to the Purchaser's specification and in case definable as

non-standard goods, in which case any further damage shall also be payable.

o) Any disputes arising between the Parties shall be exclusively submitted to the Court Schio (VI).