After Sales Support TEL: 1300 130 579 WEB: www.rossmac.com 5

30. Never use replacement parts or accessories

which are not recommended by the

manufacturer.

31. Pull out the power plug before carrying out

any inspection, cleaning or other work on the

shredder and whenever it is not being used.

32. Before you begin your work, examine the

material you want to shred. Remove any

foreign bodies. Continue to watch out for

foreign bodies while you are working. If you

come across any foreign bodies while

shredding, shut down the machine and remove

the items in question.

33. Keep the machine away from other persons,

particularly children and pets.

34. Use the machine only in the way described in

these operating instructions.

35. Only ever connect the device to a shock-proof

socket which has been installed in accordance

with regulations and which is protected by a

16A fuse as a minimum.

36. The efciency of the machine will be greatly

reduced if a connecting cable with too small

a cross section is used. A conductor cross

section of at least 3x1.5 mm2is required for

cables up to 25 m long, and one of at least

3x2.5 mm2for cables longer than 25 m.

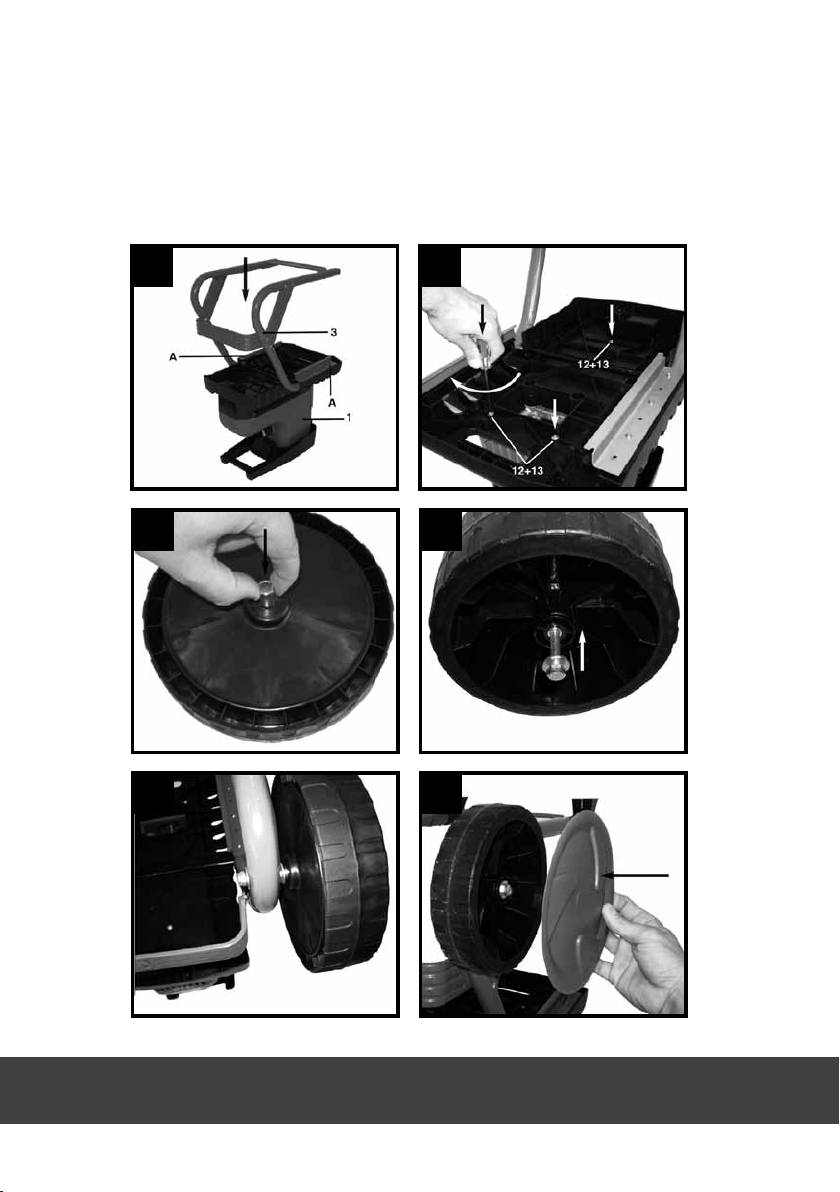

37. If the machine has to be lifted for transporting,

be sure to switch off the motor rst and wait

for the cutter to come to a standstill. Each

time before you leave the machine, switch off

the motor and pull out the power plug. Before

you connect the machine to the power supply,

make sure that the loading funnel is properly

connected to the motor housing and the

release screw tightened.

38. If the garden refuse shredder vibrates

excessively, turn off the motor, pull out the

power plug, and nd out immediately what is

causing the vibrations. Intensive vibration is

usually a sign that something is wrong.

39. Do not wear loose clothing or clothing with

hanging belts or cords.

40. Do not use the machine on a paved area that

has been graveled where discharged material

may cause injuries.

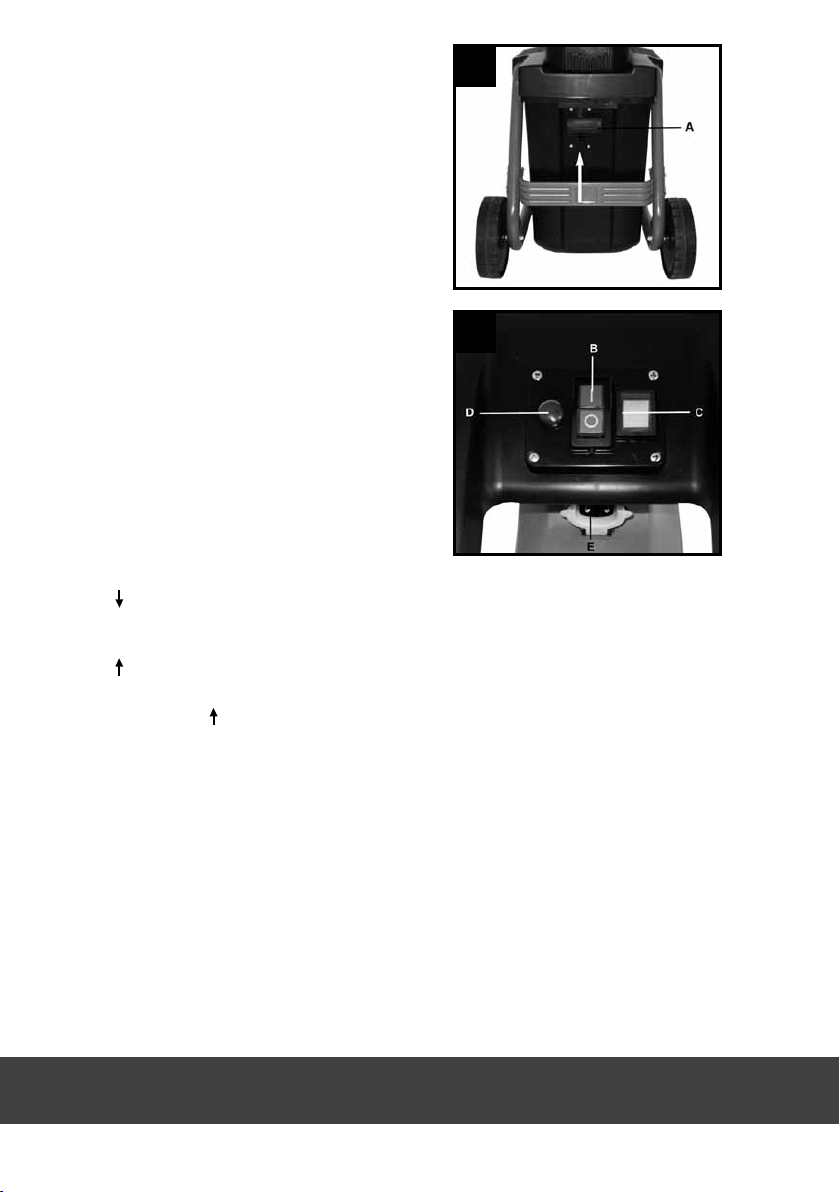

41. Ensure that the loading funnel inlet is empty

before you start the machine.

42. Keep your head and body away from the

infeed opening.

43. Do not move your hands, other body parts or

clothing into the infeed chamber, ejector

chute or near other moving parts.

44. Make sure that you are balanced and standing

on a rm surface at all times. Do not stretch

forwards. Never stand higher than the

machine when feeding material into it.

45. Keep away from the discharge zone when you

start the machine.

46. If foreign bodies get into the cutting tool or

the machine generates unusual noises or

vibrates in a strange way, switch off the motor

immediately and allow the machine to come

to a standstill. Pull the plug and carry out the

following work:

• Check the machine for signs of damage

• Check that all the parts are secure and

tighten them if necessary.

• Have any damaged parts replaced or

repaired, but use only spare parts of the

same type and equivalent quality

47. If the machine is blocked switch off the motor

and pull the plug before you start the cleaning

procedure. Ensure that the motor is clear

of waste and other accumulations to protect

the motor from suffering damage or possibly

catching re.

48. Ensure that all the covers and guards are in

position and in good working order.

49. Do not tip the machine whilst the motor is

running.

50. Switch off the machine before you t or

remove the collection container.

51. The tool may only be used outdoors (i.e. not

in the vicinity of a wall or any other ridged

object)

52. Damaged or illegible labels must be replaced

53. Allow the tool to cool before carrying out any

main tenance work, adjustments, etc.

54. Never use the machine while other people are

nearby