After Sales Support TEL: 1300 130 579 WEB: www.rossmac.com

4

Before you put the dirty water pump into operation,

carefully read the following safety regulations and the

operating instructions.

If you give the equipment to any other persons, give

them the operating instructions as well.

Keep these instructions in a safe place.

Packaging

The unit is supplied in packaging to prevent it from

being damaged in transit. The raw materials in this

packaging can be reused or recycled.

1. Safety instructions

Caution!

In stagnant water bodies, garden ponds,

swimming ponds and their surrounding areas the

pump may only be used with an earth-leakage

circuit breaker with an actuating rated current of

up to 30 mA (acc. to VDE 0100 part 702 and 738).

The pump is not designed for use in swimming

pools and paddling pools of any kind or other

bodies of water in which people or animals may

be present during operation.

It is prohibited to operate the pump if a person or

animal is in the danger area.

Ask your electrician!

●Before starting to run your new pump, please have

the following items checked by an expert:

- Ground connection

- Zero conductor

●Safety circuit breaker switch must correspond

to the safety regulations of the power plants

and they must work faultlessly.

●The electrical connections must be protected from

moisture.

●If there is danger of flooding, the electrical

connections must be taken to higher ground.

●Circulation of aggressive fluids, as well as the

circulation of abrasive materials must be avoided

at all costs.

●The pump must be protected from frost.

●The pump must be protected from running dry.

●Access on the part of children should also be

prevented with appropriate measures.

2. Layout (Fig. 1)

1 Handle

2 Integrated cable rewind

3 Universal hose connection

4 Venting

5 Floating switch

6 Cable holder

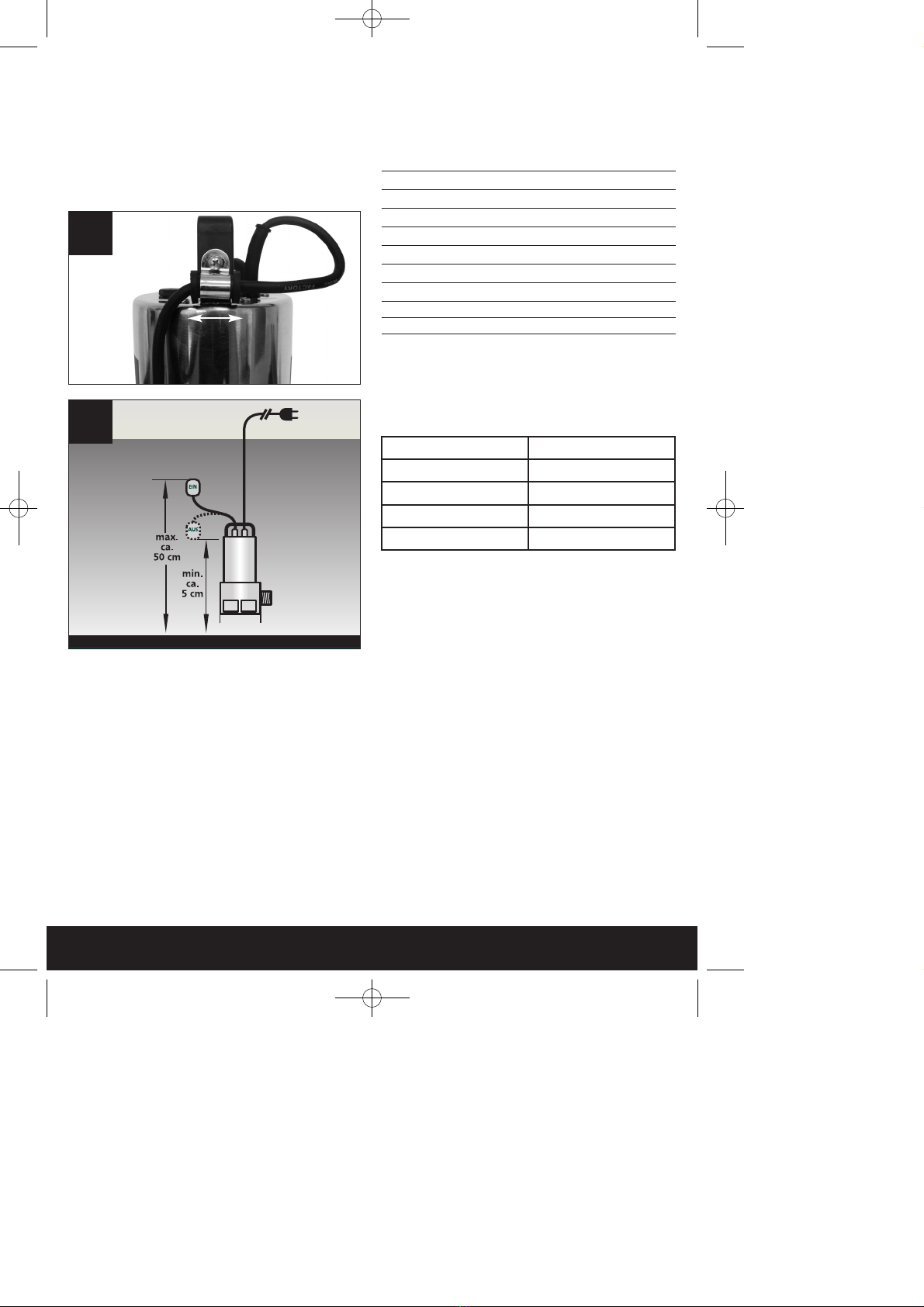

3. Installation (Fig. 2)

The pump is installed as follows:

●In a stationary position with fixed pipeline

or

●In a stationary position with a flexible hose pipe.

You should never install the pump by suspending it

unsupported from its delivery pipe or power cable.

The pump must be suspended from the specially

provided handle or be placed on the bottom of the

shaft. To guarantee that the pump works properly,

the bottom of the shaft must be kept free of sludge

and dirt of all kinds.

If the water level becomes too low, any sludge in the

shaft will dry out quickly and stop the pump from

starting up. It is necessary, therefore, to check the

submersible motor pump regularly (by carrying out

start-up tests).

The float is adjusted in a way that the pump can

immediately be started

The pump shaft should have minimum dimensions of

40 x 40 x 50 cm, so that the floating switch can move

freely.

2