After Sales Support TEL: 1300 130 579 WEB: www.rossmac.com

4

Before you put the water pump into operation,

carefully read the following safety regulations and the

operating instructions.

If you give the equipment to any other persons, give

them the operating instructions as well.

Keep these instructions in a safe place.

Packaging

The unit is supplied in packaging to prevent it from

being damaged in transit. The raw materials in this

packaging can be reused or recycled.

1. Safety information

Please read the instructions for use very carefully

and observe the information they contain. By

referring to these instructions, familiarise yourself

with the appliance, learn how to use it correctly,

and note the safety precautions to be taken.

Take the appropriate steps to ensure that children

have no access to the appliance.

The user of the appliance is responsible for any

third parties in the work area.

Before using the appliance for the first time, an

electrician must check that the necessary

electrical protection measures have been taken.

In stagnant water bodies, garden ponds,

swimming ponds and their surrounding areas the

pump may only be used with an earth-leakage

circuit breaker with an actuating rated current of

up to 30 mA (acc. to VDE 0100 part 702 and 738).

The pump is not designed for use in swimming

pools and paddling pools of any kind or other

bodies of water in which people or animals may

be present during operation.

It is prohibited to operate the pump if a person or

animal is in the danger area.

Ask your electrician!

Inspect the appliance before each use. Do not

use the appliance if the safety devices are

damaged or worn. Never deactivate the safety

devices.

Use the appliance only for the purposes specified

in these instructions for use.

You are responsible for safety in the work area.

Should the pump cable or plug be damaged by

external influences, the cable must not be

repaired! The cable must be replaced with a new

one. This work is to be performed only by an

electrician. (See section “Replacing the mains

cable“)

Your mains supply must comply with the voltage

of 240 V alternating voltage specified on the type

plate.

Never lift, transport or secure the pump by its

power cable.

Make sure the appliance is plugged into a socket

in a place where there is no risk of flooding and

which is protected against moisture.

Always remove the plug from the socket before

doing any work on the pump.

Avoid exposing the pump to a direct jet of water.

The operator is responsible for any local safety

and installation regulations. (Ask your electrician

for advice.)

Rule out any indirect damage caused by the

flooding of rooms following the failure of the pump

by adopting the appropriate measures (e.g. the

installation of an alarm system, a reserve pump or

the like).

Use only original spare parts

Never let the pump run dry and never operate it

with fully closed intake power. The manufacturerʼs

warranty shall lapse if the pump is damaged due

to it being allowed to run dry.

The pump must not be used to operate swimming

pools.

The pump must not be installed in the drinking

water pipe line.

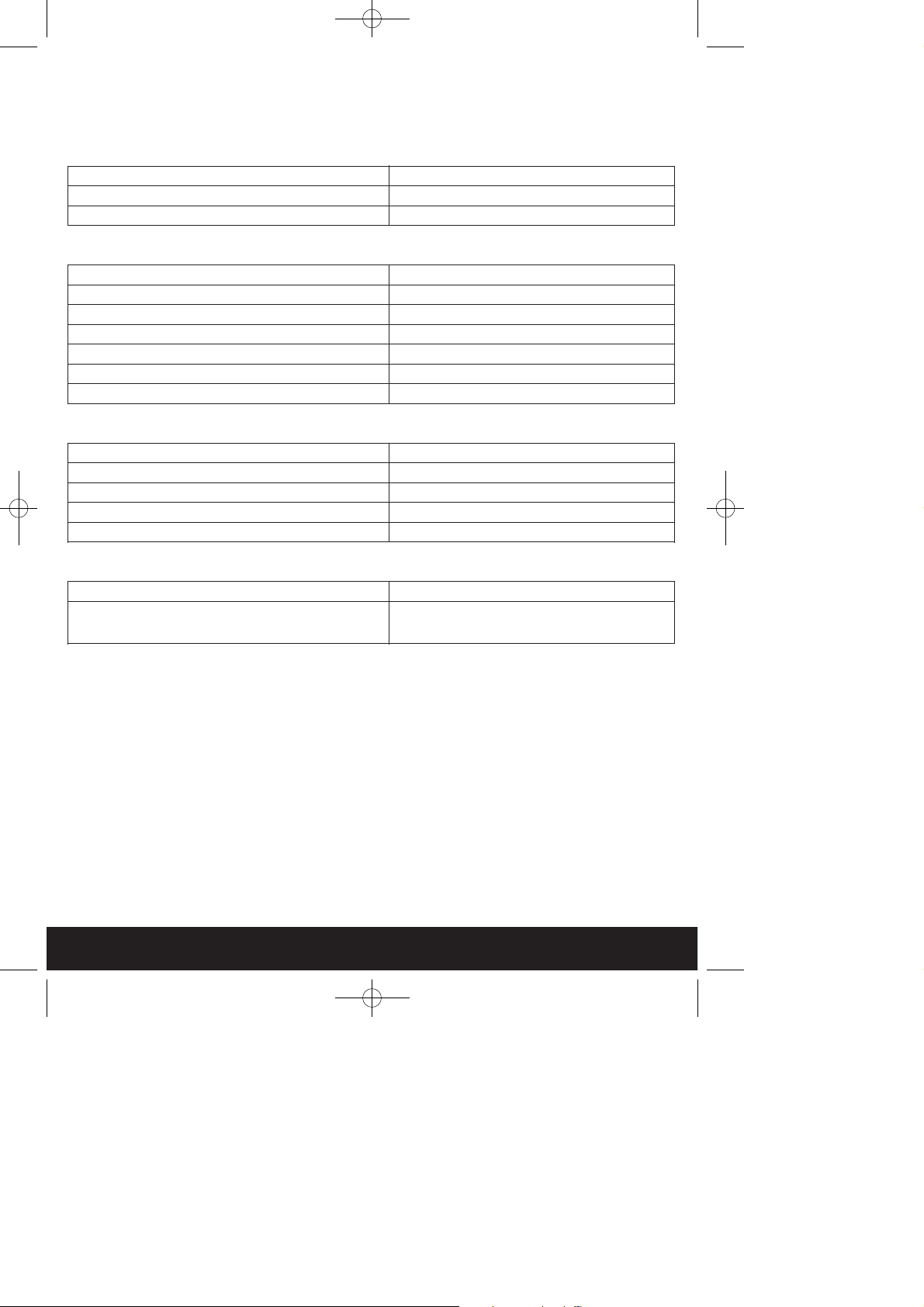

2. Layout (see Fig. 1)

1. ON/OFF switch

2. Carry handle

3. Water filler screw

4. Water drain screw

3. Proper use

Areas of use:

For irrigating and watering parks, vegetable

patches and gardens

For operating lawn sprinklers

With a prefilter, for drawing water from ponds,

streams, rain-butts, rain-water cisterns and wells.