2

APPLICATION

The instruction manual and labels applied to the product provide

information for avoiding injury or death from unsafe practices

related to setting up and operating this machine. It is critical that all

personnel involved with the use of this machine understand these

hazards and unsafe practices. The three levels (Danger, Warning,

and Caution) define the severity of the hazard.

DANGER: Immediate hazards that if not avoided WILL result

in severe injury or death.

WARNING: Serious injury or death COULD occur if proper

attention is not observed.

CAUTION: Injury or property damage MAY occur if proper

attention is not observed.

The product has safety related labels securely adhered to it

in several locations. They serve to highlight the areas of this

machine that have the potential to cause injury if the operator

does not use caution. The labels include internationally

recognized symbols that are described below.

Read and understand the instruction sheet before

setting up or operating this machine.

Body parts are in danger of being crushed by

moving or moveable parts.

Body parts are in danger of being entangled in rope.

Read instruction sheet before operation.

1. Do not use the cable puller for any other purpose or

application beyond its intended use. It is intended for pulling

wire or cable through fixed conduit, with the conduit adaptor

engaged in the conduit and fastened to the cable puller.

2. Do not operate the cable puller in poorly lit areas.

3. Do not exceed the maximum rated 10,000 lbs. pulling force.

4. Inspect all cable puller components prior to operation.

5. Keep the pull rope away from the operator’s feet. Gather the

tailing rope in an area where the operator or crew cannot

become entangled.

6. Never stand directly under a vertical pull or directly in line

with pull rope under tension.

7. Never use general purpose rope; always use double braided

polyester rope and inspect the rope for damage after each

pull. Do not use damaged rope for pulling cable.

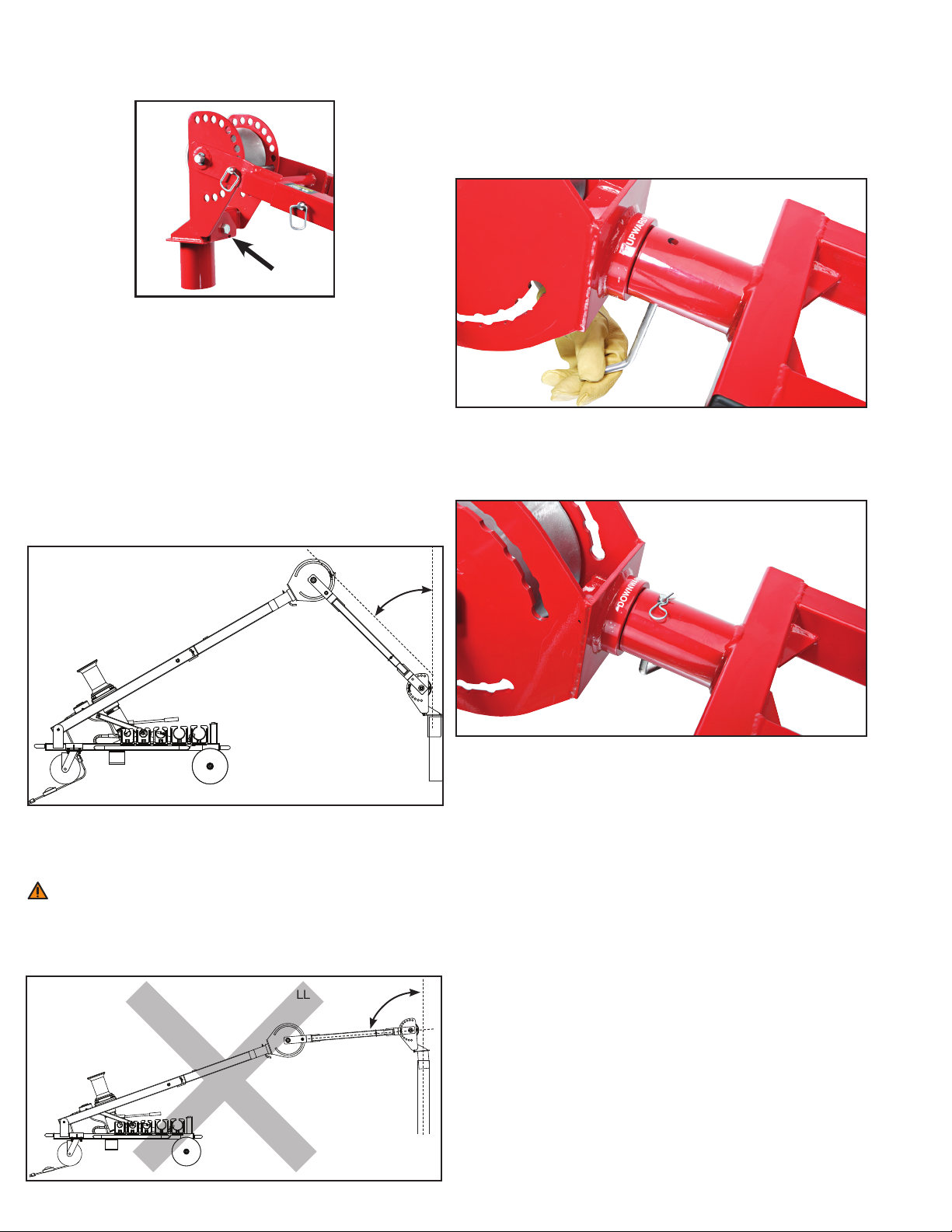

8. Do not allow the rope coils to overlap on the Capstan.

9. Keep bystanders away from operations. Distractions

increase chances of injury.

10. Do not use the cable puller while under the influence of

drugs, alcohol or medication.

11. Do not operate near water or other liquids.

12. Do not wear jewelry or loose-fitting clothes. Long hair, clothing,

body parts and gloves should be clear of moving parts.

13. Always use all personal safety equipment, including eye

protection and a hard hat.

14. Do not wrap rope around legs, arms or torso of body.

15. Do not plug Power Cord directly into power source. Power

Cord must be plugged into the Footswitch.

Grounding

A three pronged grounded plug is included in the Footswitch

and must be plugged into a three hole, properly wired grounded

socket. Do not use a three prong to two prong adaptor. Never

connect the ground wire to a live terminal.

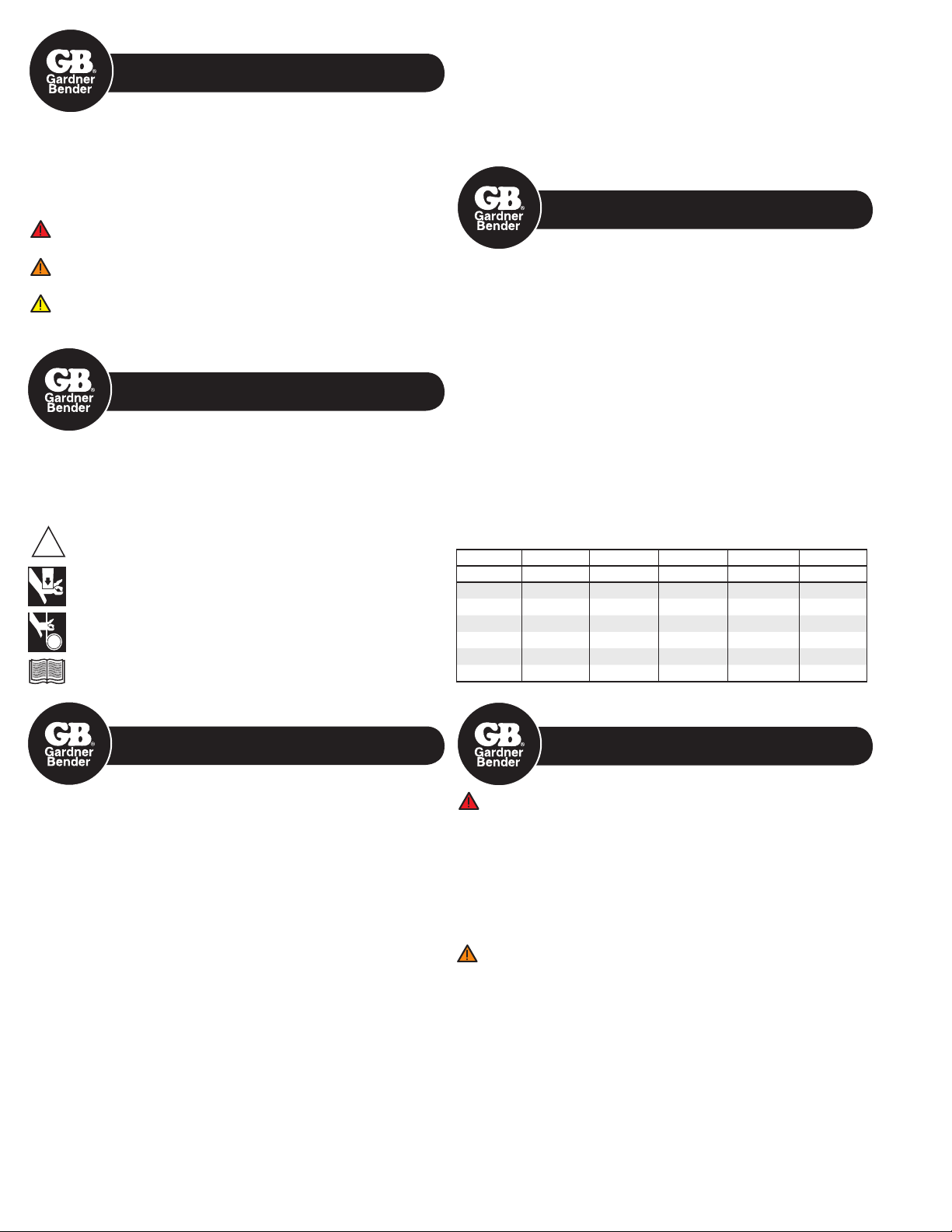

Extension Cords

1. Using an extension cord reduces the voltage supply to the

Motor. Select the appropriate wire size for extension cord

length from Table 1.

2. Only extension cords with the suffix W-A following the cord

type designation are allowed for outdoor use.

3. Extension cords must have a three prong plug and three

prong receptacles.

4. Do not use machine if extension cord has been damaged or

abused.

DANGER

1. Never expose machine to wet conditions due to electric shock.

2. Do not use or store this machine near exposed live circuits or

overhead wires.

3. Do not use a damaged or worn extension or Footswitch cord.

FAILURE TO OBSERVE THESE DANGERS WILL RESULT IN

SEVERE INJURY OR DEATH

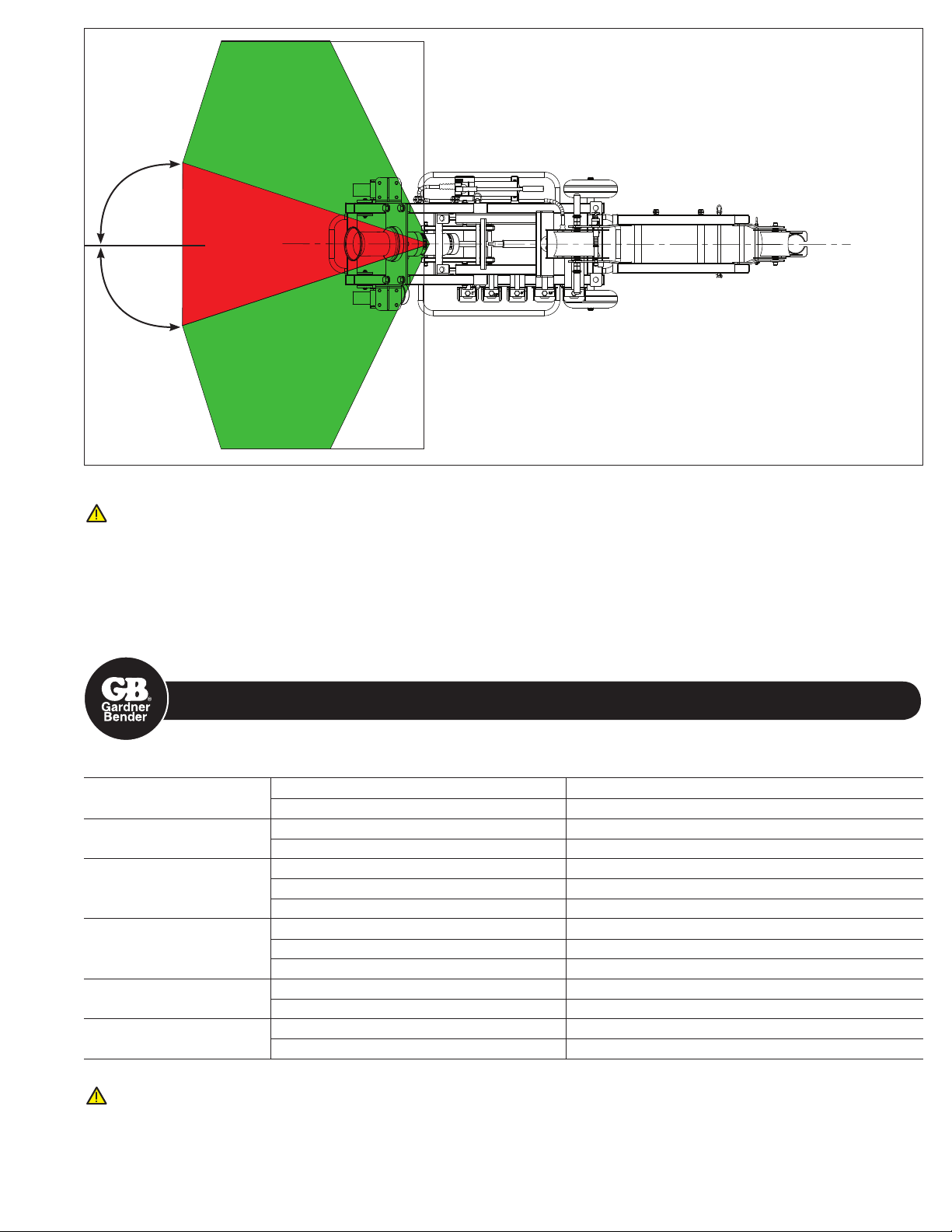

WARNING

1. The maximum pulling capacity must not be exceeded.

2. Use the recommended size rope for pulling load. See

6.0 Puller Specifications.

3. Rope may beak or pulling grip may come loose under tension.

Stand in the safe zone which is at least 30 degrees to either

side of rope. (See Figure 1)

4. Rope must be replaced if the strands are worn or cut.

5. Use the correct size Conduit Adaptor.

FAILURE TO OBSERVE THESE WARNINGS COULD RESULT

IN SEVERE INJURY OR DEATH

1.0 SAFETY SYMBOL DEFINITIONS

2.0 WARNING LABELS

ON PRODUCT

3.0 KEY SAFETY INFORMATION

Total Amps: 0-5.0 5.1-7.0 7.1-12.0 12.1-16.0 16.1-20.0

Length (ft.) Wire Gauge Wire Gauge Wire Gauge Wire Gauge Wire Gauge

25 18 18 16 14 12

50 18 16 14 12 10

75 18 14 12 10 8

100 18 12 10 8 8

150 16 12 8 8 6

200 16 10 8 6 4

4.0 ELECTRICAL SAFETY

INFORMATION

Table 1. Extension Cord Minimum Wire Gauge Guide

5.0 SAFE PULLING

GUIDELINES

!