Slug Out™ Knockout Driver instruction manual

6

PUNCHING 3/4" TO 3" HOLES

1. Follow instructions for drilling guide hole and punching a 1/2" hole. DO NOT DRILL

A 1/2" HOLE.

2. Drive mechanical knockout driver till the 3/4" draw stud receiver is slightly exposed.

3. Thread the 3/4" draw stud into the mechanical knockout driver's 3/4" draw stud

receiver till it bottoms out. (fig. 5).

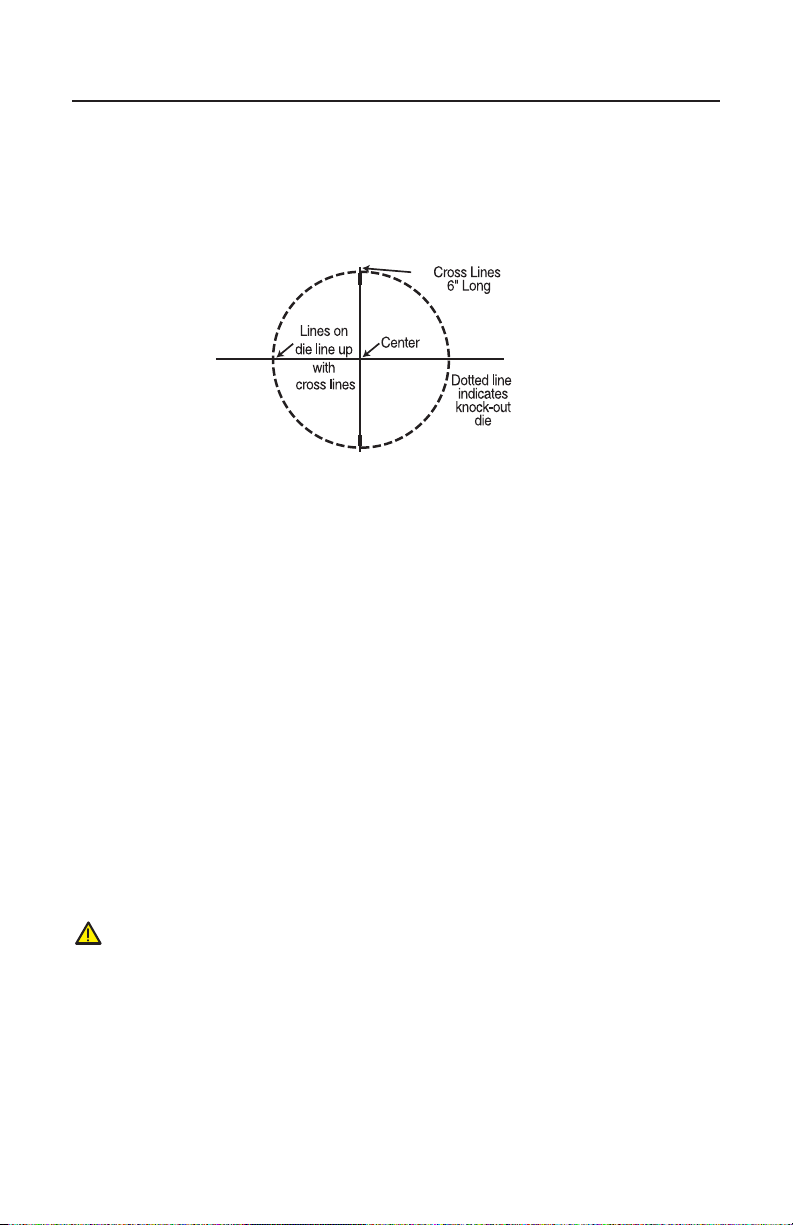

4. Select the punch and die set needed (3/4"–3"). Slide the die over the pull rod, flat

side toward the mechanical knockout driver.

5. Place 3/4" draw stud into the guide hole.

6. Thread the punch onto the 3/4" draw stud.

7. Insert square drive bit into the square drive bit receiver (fig. 6)

CAUTION: Use one hand to firmly grip the knockout driver handle and use the

other hand to firmly grip the driver drill. Brace yourself for a torque reaction. Failure

to observe this caution may result in injury or lossing your balance and falling.

8. Holding the mechanical driver in position, keep drill driving until punch completely

penetrates the metal.

9. Remove the punch set from the hole. Reverse the driver drill until draw stud is

exposed. Remove punch form draw stud. Slide the die off the draw stud. To

remove the slug, turn over and tap lightly on a solid wooden object.

NOTE: To avoid excessive wear and tear on the draw stud threads during punching,

center the pull rod accurately so that it does not rest against the metal edge of the

guide hole. Also, be sure that all points of the punch are in uniform contact with the

metal surface when starting to punch.

PUNCHING 3-1/2" AND 4" HOLES

1. Larger punch sizes require a 1-15/16" diameter guide hole (use 1-1/2" punch and

die) and a KC3540 converter.

2. Follow all the instructions for drilling guide hole (page 4). Punch a 1/2" hole per

instructions on page 4. Punch a 1-1/2" hole per instructions above.

3. Remove the 1-1/2" punch and die. Install the 3-1/2" or 4" die over the draw stud. (fig. 7)

4. Install the KC3540 converter on the inside of the punch. (fig. 7)

CAUTION: Do not install the converter (KC3540) on outside of punch. Damage to

the draw stud would result from incorrect converter installation.

5. Place the draw stud into the guide hole. Thread the punch on the draw stud and

turn until the converter is into the guide hole.

6. Place 3/4" draw stud into the guide hole.

7. Thread the punch onto the 3/4" draw stud.

8. Insert square drive bit into the square drive bit receiver (fig. 6)

CAUTION: Use one hand to firmly grip the knockout driver handle and use the

other hand to firmly grip the driver drill. Brace yourself for a torque reaction. Failure

to observe this caution may result in injury or lossing your balance and falling.