Prebena KT-3500 User manual

PREBENA Wilfried Bornemann GmbH & Co. KG

Seestr. 20 – 26, 63679 Schotten, Germany

Tel.: +49 (0) 60 44 / 96 01 – 0, Fax: +49 (0) 60 44 / 96 01 – 80

email: info@prebena.com

www.prebena.de, www.kartuschen-tausch.de

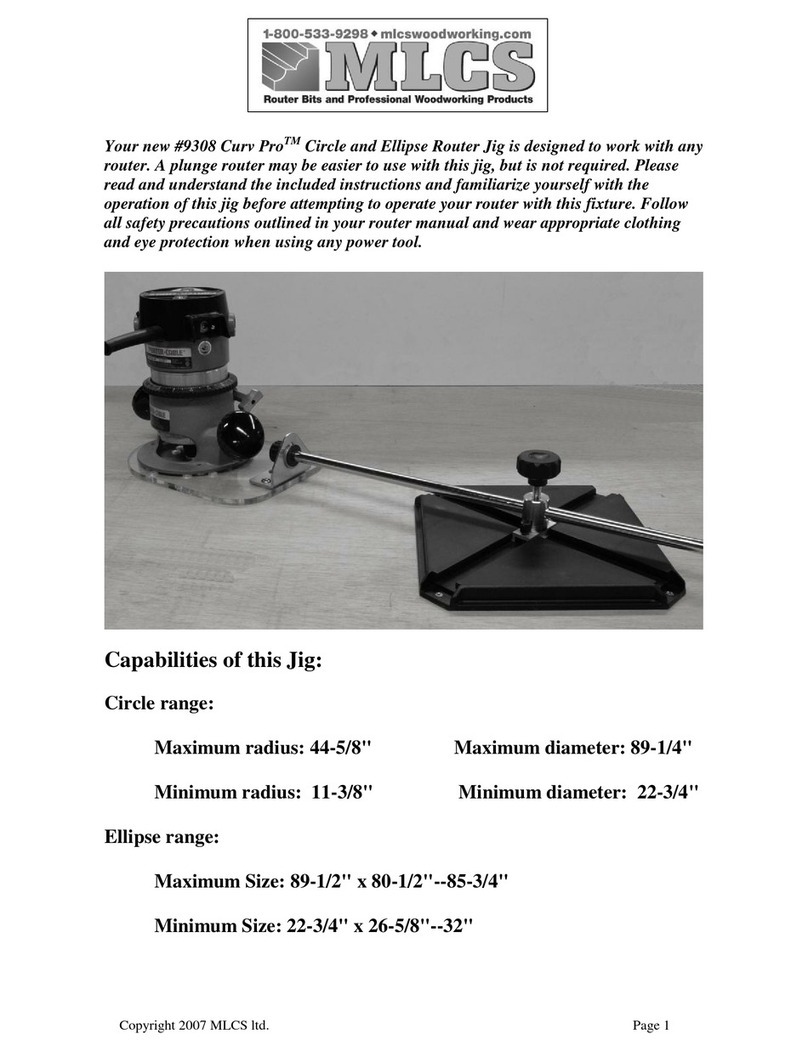

Operating Manual for the Cartridge

PREBENA KT-3500

98678701

Introduction

This operating manual is provided as an aid for

•proper,

•safe, and

•economical

use of the KT-3500 cartridge, or also referred to as just cartridge.

We assume that every user of the cartridge has experience handling

pressure vessels and devices powered by compressed air. Persons

lacking this knowledge must be instructed in the use of the cartridge

by an experienced user.

Every person who

uses,

fills,

cleans or

disposes

of this cartridge must have read and understood this operating

manual.

This operating manual is considered as a component of the product.

Always keep this operating with the cartridge. If you sell the

cartridge, or provide it to another party, ensure that the operating

manual is included with the cartridge.

3

Table of Contents

Organizational features................................................................... 4

General organizational features ...................................................4

Features of the safety instructions ...............................................4

Basic safety instructions.......................................................5

Proper use ....................................................................................5

Avoid explosion hazards...............................................................6

Avoid damage to the cartridge......................................................6

Description .......................................................................................7

Scope of supply ............................................................................7

Rating plate information................................................................7

Using the cartridge .......................................................................... 8

Check the condition ......................................................................8

Connecting the cartridge ..............................................................8

Disconnecting the cartridge from the pneumatic tool. ..................9

Transporting and storing the cartridge .......................................10

Maintaining the cartridge ..............................................................10

Cleaning the cartridge ................................................................10

Filling the cartridge .....................................................................11

Having the cartridge tested.........................................................12

Troubleshooting ............................................................................12

Cartridge disposal .........................................................................13

Technical data................................................................................14

Manufacturer's address ................................................................14

Guarantee .......................................................................................15

Organizational features

4

Organizational features

General organizational features

Different elements of the operating manual have specific

organizational features. These features make it easy to differentiate

normal text,

listings or

action steps.

These instructions contain additional information, such as

special tips on economical use of the cartridge.

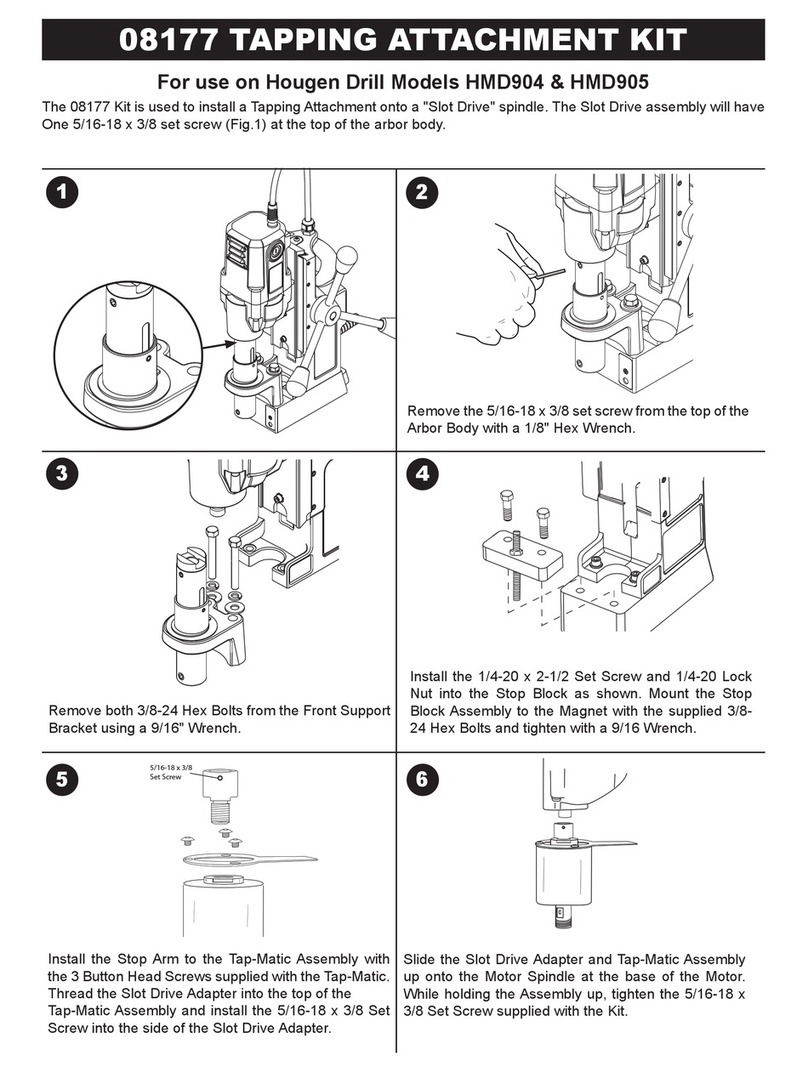

Features of the safety instructions

All safety instructions contained in this operating manual are

structured on the same pattern. To the left is the hazard symbol. To

the right a signal word that indicates the seriousness of the hazard.

Below there is a description of the hazard source and instructions on

how you can avoid this hazard.

WARNING

Instructions with the word WARNING warn of

hazards that could possibly result in serious or

fatal injuries.

CAUTION

Instructions with the word CAUTION warn of

hazards in which light to medium severity

injuries, property damage, or damage to the

environment can possibly occur.

Basic safety instructions

5

Basic safety instructions

When handling the cartridge heed and comply with all warning and

instructions in this operating manual and on the cartridge.

Proper use

The cartridge is used exclusively for supplying compressed air to

those PREBENA pneumatic tools for which this cartridge type is

expressly prescribed in the operating manuals for those pneumatic

tools. Using the cartridge on other devices is only permitted after

consultation with the manufacturer. Proper use also includes

compliance with accident prevention regulations and legal guidelines

and standards applicable at the site of implementation. Any other

use is considered to be improper use and can result in property

damage, or even personal injury.

Operation

on non-approved devices,

with oxygen or with other flammable gasses or gas mixtures, or

operation by persons lacking knowledge of implementation of

pressure vessels and pneumatic tools

particularly constitutes improper use.

PREBENA WILFRIED BORNEMANN GMBH & CO. KG assumes no

liability for damage that occurs due to improper use.

Basic safety instructions

6

Avoid explosion hazards

Only fill the cartridge with the PREBENA PKT-FILLMASTER 350

compressor

Only fill the cartridge with compressed air.

Only fill the cartridge to the maximum filling pressure of 300 bar

Do not fill damaged cartridges.

Never expose the cartridge to temperatures in excess of 60 °C, or

to direct sunlight.

Only use the cartridge until the maximum service life, as specified

on the rating plate, has expired.

Disconnect the cartridge from the pneumatic tool prior to every

transport.

Store the pneumatic tool where it is inaccessible to children and

other unauthorized persons.

Avoid damage to the cartridge

Never open the cartridge. Only have qualified specialists perform

repair work.

Do not use the cartridge if it has fallen or if it is damaged. Have

the cartridge checked by qualified, specialized personnel before

you place it in service again.

Prevent the cartridge from coming into contact with the following

substances:

-

Aggressive solvents

-

Fuels and lubricants

-

Acids

-

Cleaning agents

-

Chemicals of any type.

Description

7

Description

Scope of supply

The cartridge is supplied in a metal transport case for two cartridges

(KT-3500-S). The scope of supply includes two protective caps for

the valves of the cartridges.

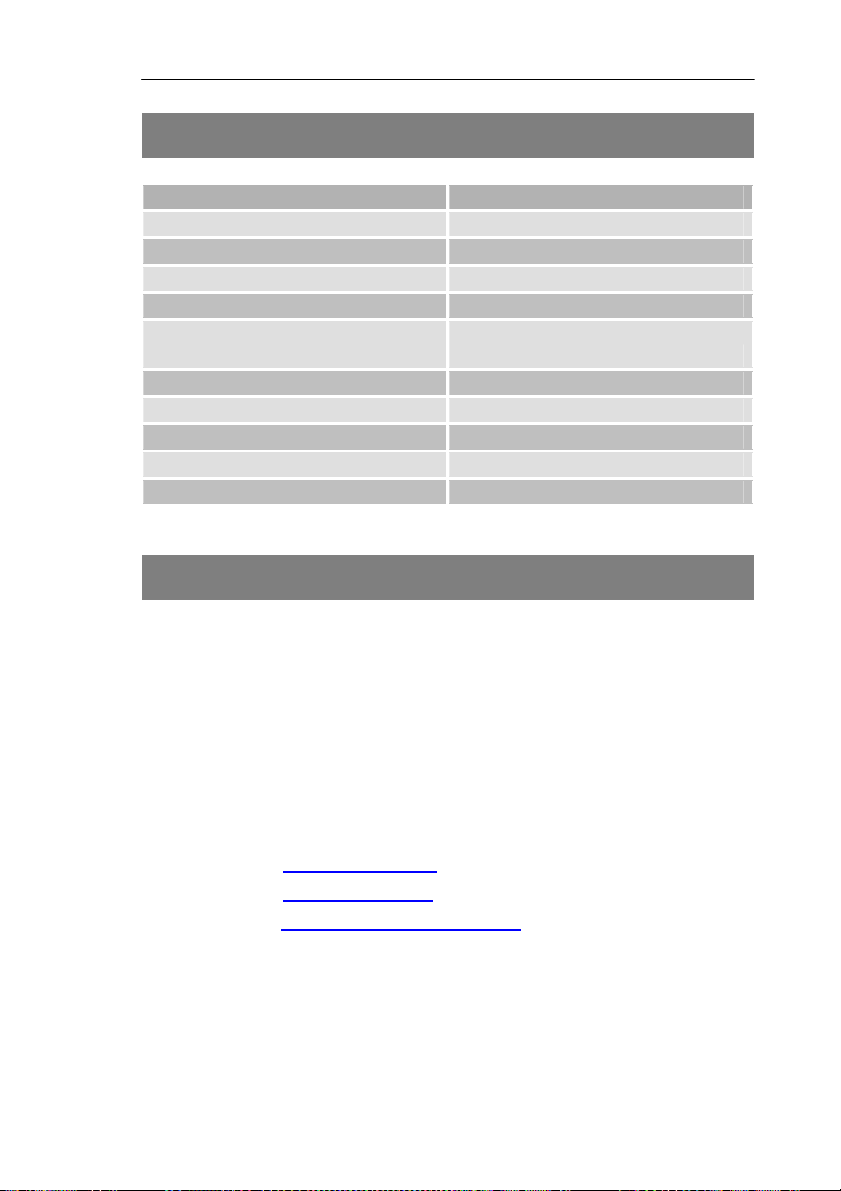

Rating plate information

A sticker is affixed to the cartridge. The following important

information is provided on this sticker:

No.

Explanation

1

Maximum service life:

2

Serial number of the cartridge

3

Date of manufacture (month and year)

4

Year of the first periodic test

5

Type designation of the cartridge

6

Country

of origin

7

Company name

8

Date of the last periodic test performed

Do not remove or cover this rating plate.

Using the cartridge

8

Using the cartridge

Check the condition

WARNING

There is an explosion hazard when operating a

damaged cartridge.

Check the condition of the cartridge before

each connection.

Only connect the cartridge if it is trouble-

free condition.

Check the following points in particular:

-

The valve should not be damaged, fouled, or loosely seated.

-

The cartridge should not show any external damage such as

scratches or dents.

-

The last periodic test of the cartridge should not be more than

five years in the past.

-

Do not exceed the service life of the cartridge.

Do not connect a damaged cartridge to a pneumatic tool.

Have PREBENA specialized personnel repair a damaged

cartridge before you connect it.

Connecting the cartridge

Take the cartridge out of the transport case.

Keep the transport case for transport of the cartridge.

Only transport the cartridge in the transport case.

Using the cartridge

9

WARNING

Explosion hazard when exceeding the

maximum operating pressure (see the

operating manual for the pneumatic tool).

In this case immediately disconnect the

cartridge from the pneumatic tool.

Unscrew the sealing cap from the valve.

Check that the valve is free of foreign objects and fouling.

Clean the valve if necessary (see page 11).

Check the condition of the cartridge (see page 8).

WARNING

Operation on unsuitable devices can result in

damage to the cartridge, and to the tool.

Only connect the cartridge to devices that

have been approved by the manufacturer.

Slide the cartridge, with the valve in front, into the pneumatic

tool's holders.

Screw the cartridge hand-tight into the thread on the connection

element of the pneumatic tool.

Disconnecting the cartridge from the pneumatic tool.

Execute the steps described below after operation, or if you

anticipate longer interruptions in operation.

Unscrew the cartridge from the connecting thread.

Pull the cartridge from the rear out of the holder on the pneumatic

tool.

Screw the sealing cap onto the valve of the cartridge.

Keep the cartridge in the supplied transport case where it will be

protected from bumps and impact.

Transporting and storing the cartridge

10

Transporting and storing the cartridge

CAUTION

Damage due to chemicals or impact is

possible.

Pack the cartridge in such a manner that is

protected from impact for transport and

storage.

Protect the cartridge from chemicals during

transport and storage.

Pack the cartridge in the transport case or in a stable shipping

box prior to storage or transport.

Transport the cartridge to the desired location.

Store the cartridge at room temperature in a dry and dust-

protected area.

Maintaining the cartridge

The cartridge should only be maintained by personnel who have the

necessary skill, capability, and experience. All tasks not described

here should only be performed by the manufacturer's customer

service organization, or in the manufacturer's facilities.

Cleaning the cartridge

Clean the shell and the valve of cartridge after each use.

CAUTION

Non-suitable cleaning agents can damage the

cartridge.

Use a dry or slightly damp cloth, or a cloth

that is slightly moistened with a mild soap

solution to clean the cartridge.

Maintaining the cartridge

11

Proceed as follows to remove light fouling from the shell:

Wipe off the cartridge with a cloth that has been slightly

dampened with a mild soap solution.

Then wipe the cartridge with a cloth that has been slightly

dampened with tap water.

Wipe off the pneumatic tool with a dry soft cloth.

Proceed as follows to clean the valve:

WARNING

There is an explosion hazard if the valve is

damaged.

Do not use hard or sharp objects to clean

the valve.

Blow out the inside of the valve.

Wipe the outside with a cloth that has been slightly dampened

with a mild soap solution.

Then wipe the outside of the valve with a cloth that has been

slightly dampened with tap water.

Wipe off the cartridge with a dry soft cloth.

Only use the cleaning agents described to clean the cartridge.

If you cannot clean the cartridge as described, then send the

cartridge to the manufacturer.

Filling the cartridge

You can fill the cartridge with the PKT-FILLMASTER 350

compressor, which is available as an accessory.

Read the operating manual supplied with the compressor.

You can also exchange an empty cartridge when purchasing a full

cartridge from your dealer.

Troubleshooting

12

Having the cartridge tested

WARNING

Explosion hazard due to untested cartridges.

Only use properly tested cartridges.

The cartridge must pass a pressure test at PREBENA every five

years. This test must be documented in the proper field on the label

of the cartridge.

Check the date of the last periodic test on the rating plate.

If the date shows that five years or more have elapsed, proceed as

follows:

Pack the cartridge in a stable shipping box (see page 10).

Send the cartridge in to PREBENA for testing.

Troubleshooting

Symptom

Possible cause:

Reme y

Air audibly escapes

on

the safety valve of the

pneumatic tool.

Operating pressure is

set too high or the

pneumatic tool is

damaged.

Disconnect the cartridge

from the pneumatic tool

(see page 9).

Send the cartridge and

the device to PREBENA

via your dealer (see page

9).

Cartridge disposal

13

Symptom

Possible cause:

Reme y

Air audibly escapes on

the connection for the

cartridge.

The cartridge has

loosened due to

vibration.

Screw the cartridge hand

tight into the connection

(see page 8).

The seals on the

connections for the

cartridge are defective

Connect a new cartridge

(see page 8).

Send the cartridge to

PREBENA via your

dealer (see page 14).

If the problem persists

Send the pneumatic tool

to PREBENA via your

dealer (see page 8).

Release is not possible.

Insufficient operating

pressure.

Connect new cartridge

(see page 9).

If a malfunction cannot be resolved in spite of these instructions,

notify your dealer or the manufacturer (see page 14).

Cartridge disposal

CAUTION

Improper disposal can be harmful to the

environment.

Clean the cartridge prior to disposal.

Comply with the applicable regulations for

disposal of oil.

Never dispose of the cartridge in normal

household waste containers.

Send the cartridge to the manufacturer for

disposal (see page 14).

Technical data

14

Technical data

Length:

410 mm!

Diameter:

87 mm!

Packaging dimensions (L × B × H):

KT

-

3500

-

S: 270 × 115 × 435

mm

Weight empty cartridge

1.3 kg

Weight filled cartridge

1.7 kg

Weight KT

-

3500

-

S

with transport case: 7 kg

Content:

1.5 l compressed air

Maximum container air pressure

300

bar

Implementation temperature:

–

5 to +45 °C

Storage/transport temperature:

Room temperature maximum 60°C

Maximum service life:

15 years after manufacturing

Manufacturer's address

PREBENA

Wilfried Bornemann GmbH & Co. KG

Fastening Technology

Seestr. 20–26

D-63679 Schotten

Telephone: +49 (0) 60 44 96 / 01 0-0

Fax: +49 (0) 60 44 / 96 01-80

E-mail: info@prebena.de

Homepage: www.prebena.de

www.kartuschen-tausch.de

Guarantee

15

Guarantee

For the designated device PREBENA provides a 1-year guarantee

starting from the date of purchase in accordance with the following

guarantee conditions. PREBENA guarantees no-charge resolution of

defects that are attributable to material or manufacturing errors.

Malfunction or damage that has been caused by improper use is not

considered eligible for the no-charge guarantee.

Moreover only original PREBENA fasteners may be used; if this

condition is not complied with, then PREBENA assumes no product

liability, and thus there is no guarantee claim. The guarantee does

not extend to parts subject to wear, such as O-rings, etc. Prebena

will either repair the defective part or ship a replacement at its

discretion. More extensive claims do not exist.

To claim the guarantee, the completely filled- out guarantee card

with dealer stamp and purchase date must be provided, or a receipt

that shows the dates and information in accordance with the

guarantee card must be provided.

Shipping: The device in question must be carefully packed so that it

cannot be damaged during transport, and sent at customer's

expense to PREBENA.

Guarantee card

Model designation: Purchase date:

Dealer: (Stamp)

PREBENA Wilfried Bornemann GmbH & Co. KG

Seestr 20 – 26, 63679 Schotten, Germany

Tel.: +49 (0) 60 44 / 96 01 – 0, Fax: +49 (0) 60 44 / 96 01 – 80

email: info@prebena.com

www.prebena.de, www.kartuschen-tausch.de

Created by

KONTECXT GmbH

www.kx-doku.de

ISO 9001:2000

Other manuals for KT-3500

1

This manual suits for next models

1

Table of contents

Other Prebena Power Tools Accessories manuals

Popular Power Tools Accessories manuals by other brands

Axminster

Axminster PROFESSIONAL AP254SB Original instructions

dehn

dehn HVI head holder Instruction leaflet

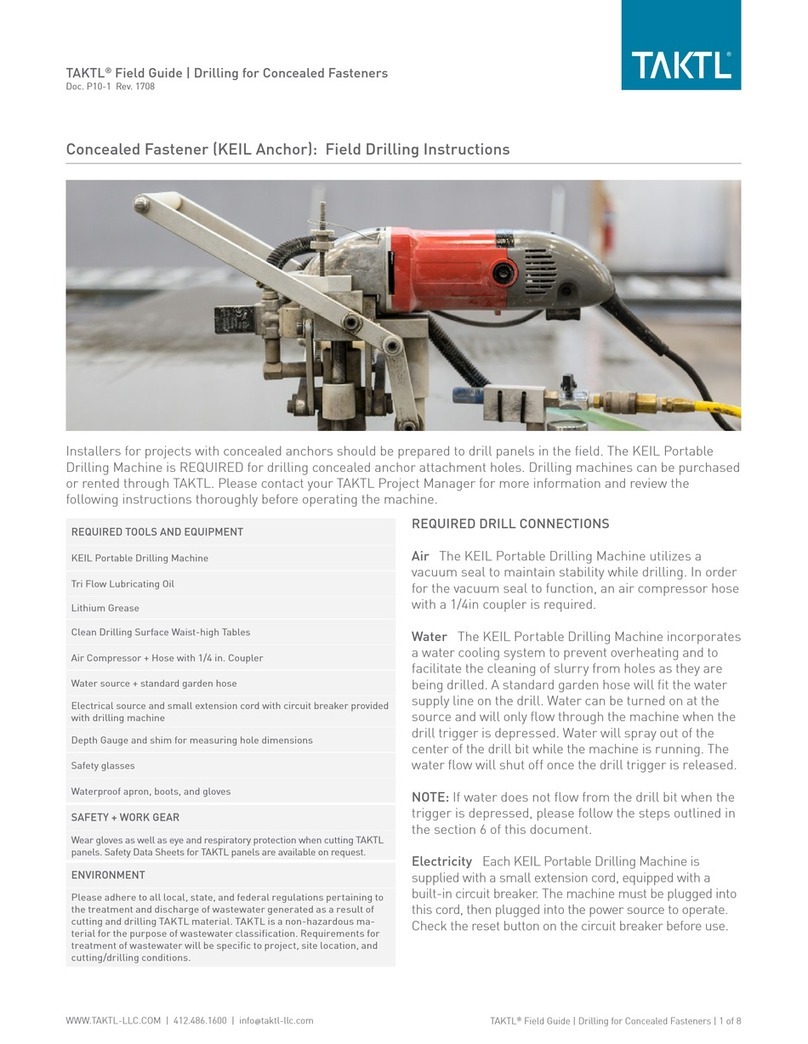

TAKTL

TAKTL KEIL Anchor Field guide

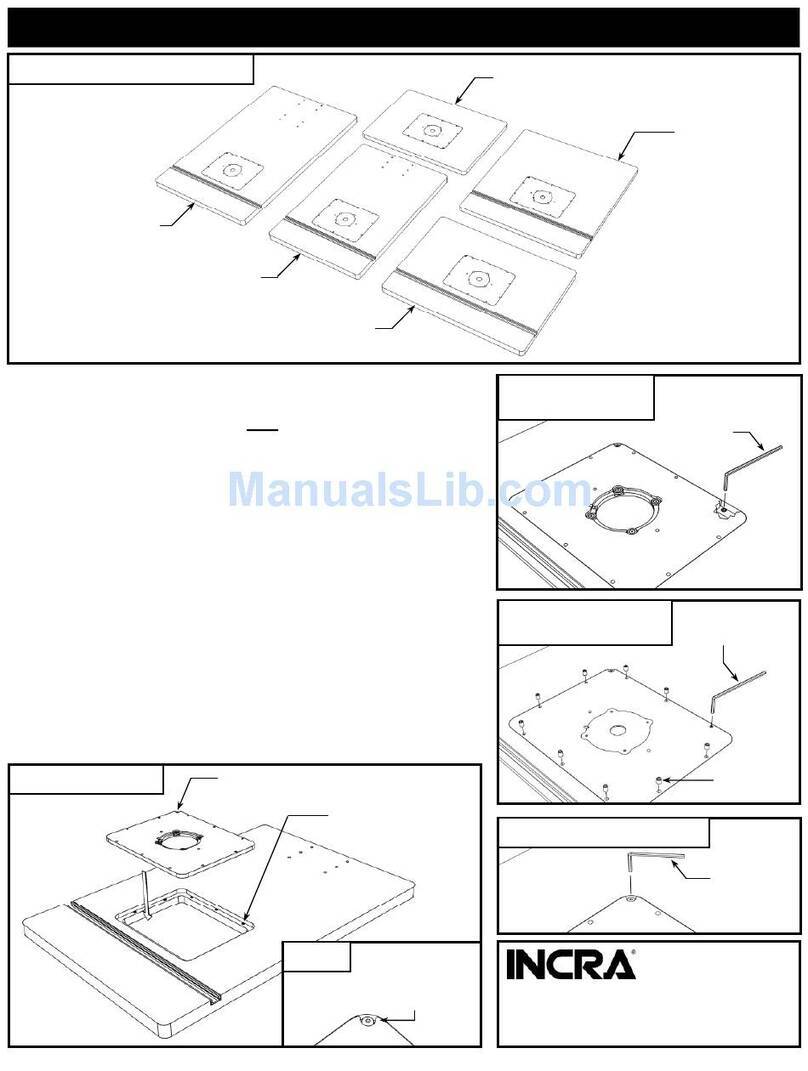

Taylor

Taylor Router Tables & MagnaLOCK Plates installation guide

Craftex

Craftex CX series manual

SCHUNK

SCHUNK TENDO E compact HSK-A63 Assembly and operating manual