Note: T he follo wing procedure assumes boom

lift switc hes are installed on the mac hine . F or

mac hines without boom lift switc hes or if y ou

ha v e not already installed the switc hes from the

Electric Boom Lift Kit, install those switc hes no w

as described in the instr uctions with that kit. Do

not install the wire har ness than comes with the

Electric Boom Lift Kit.

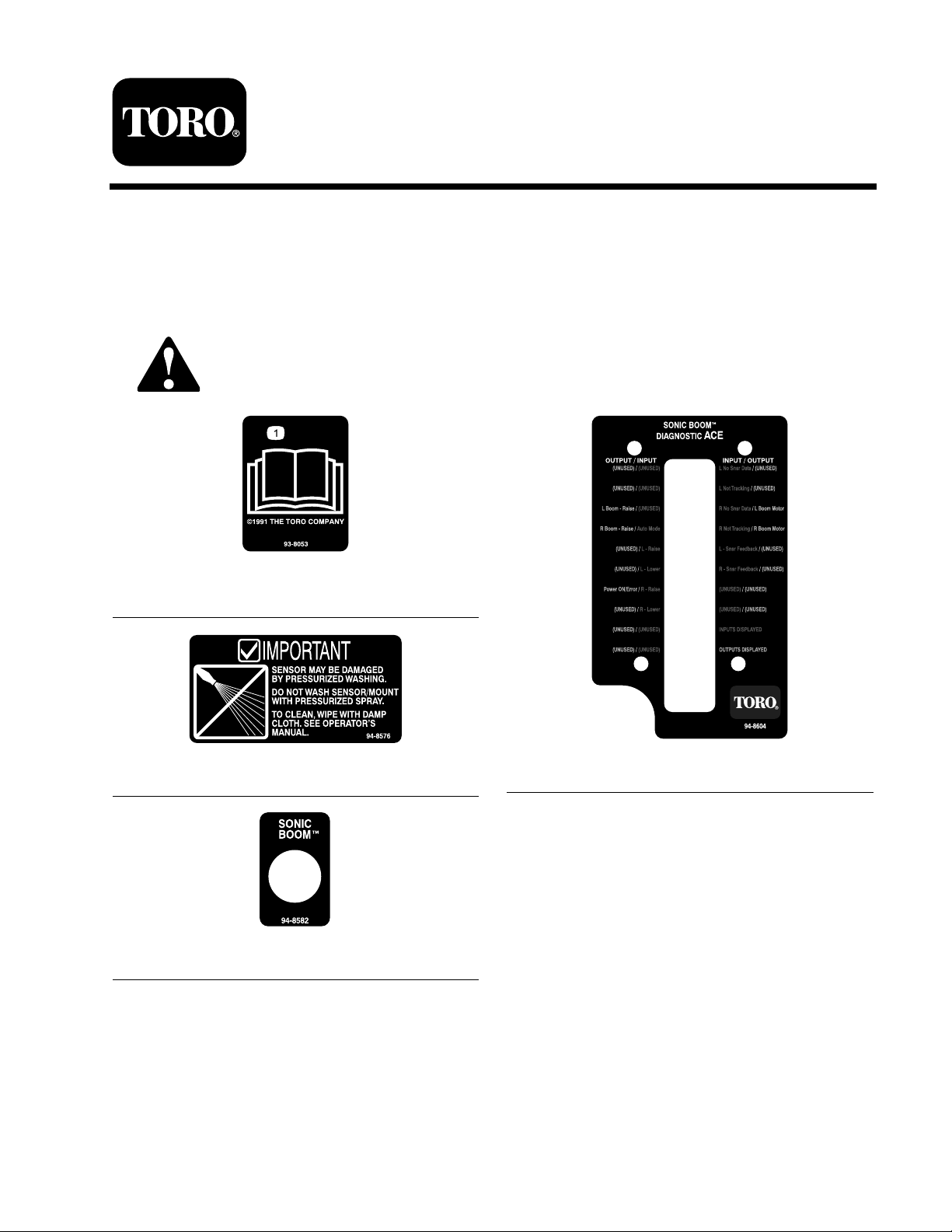

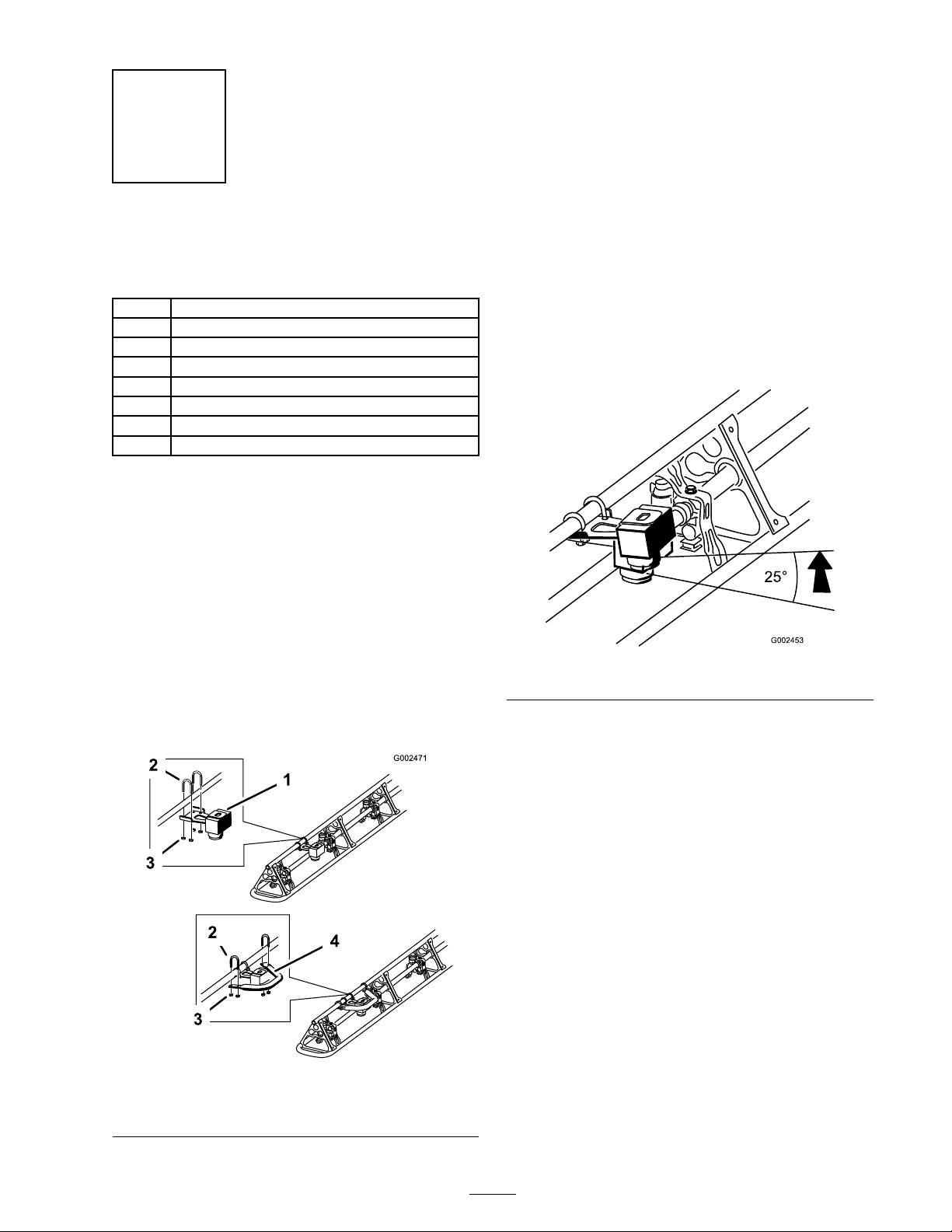

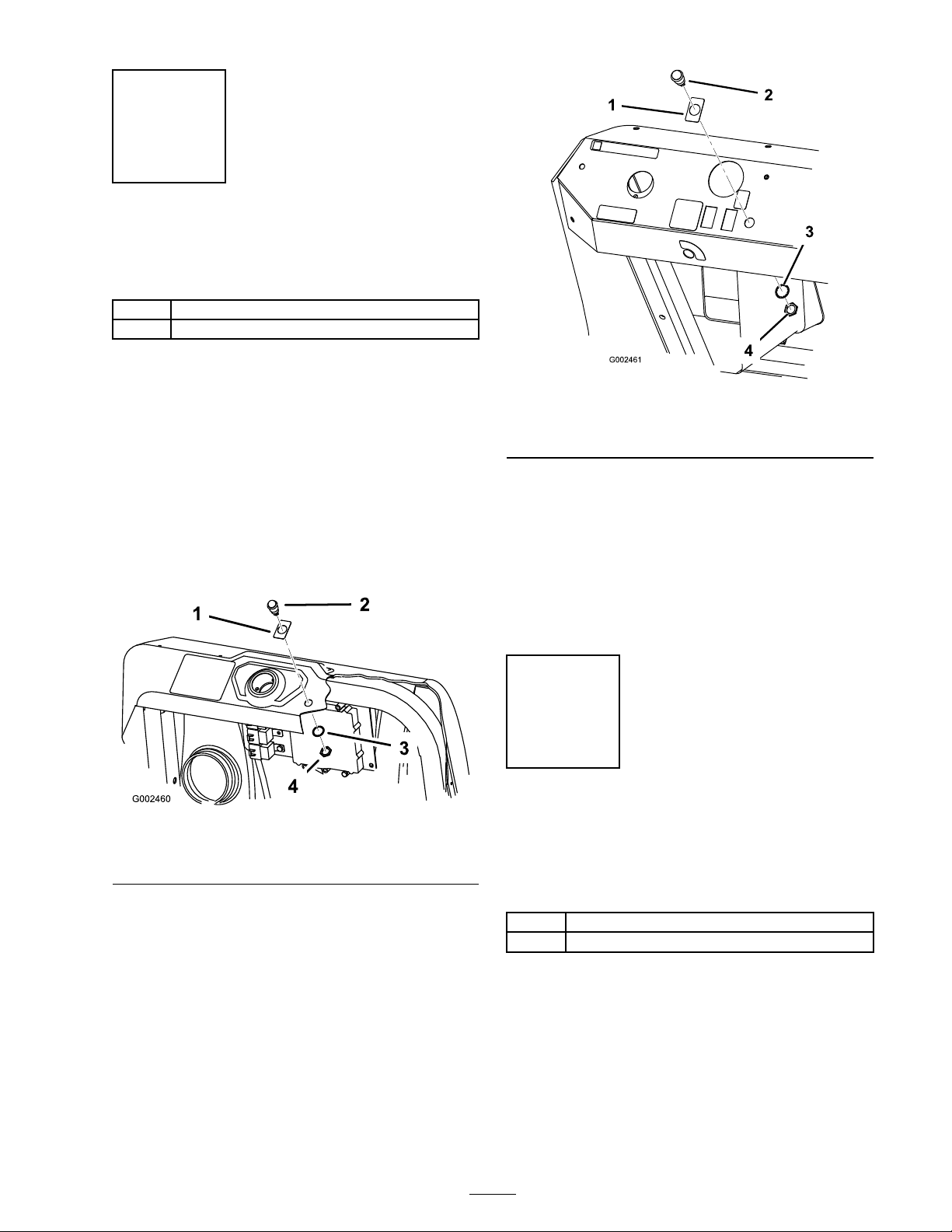

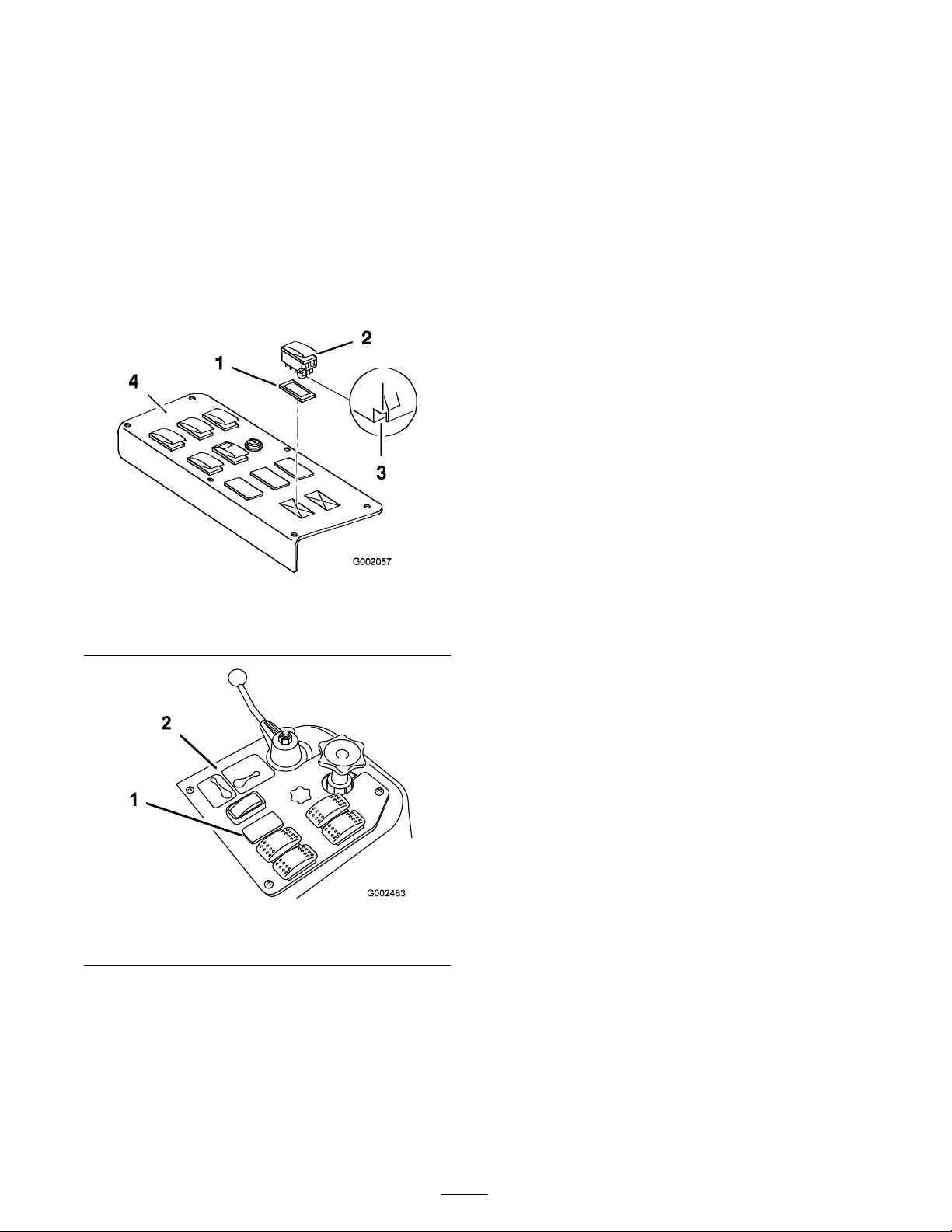

1. R emo v e the spra y control panel to expose the

bottom side ( Figure 13 for the 1250 and Figure

14 for the 1200).

Figure 13

1. Plug

3. Notch (at back)2. Switch 4. Spray control panel

Figure 14

1. Sonic boom switch location 2. Spray control panel

2. R emo v e the plug in the sonic boom slot from

the spra y control panel on the v ehicle and

install the roc k er switc h pro vided in its place

( Figure 13 for the 1250 and Figure 14 for the

1200).

Note: Ensure that the orientation of the

switc h matc hes what is sho wn in Figure 13 ,

with the notc h pointing to w ard the rear of the

v ehicle .

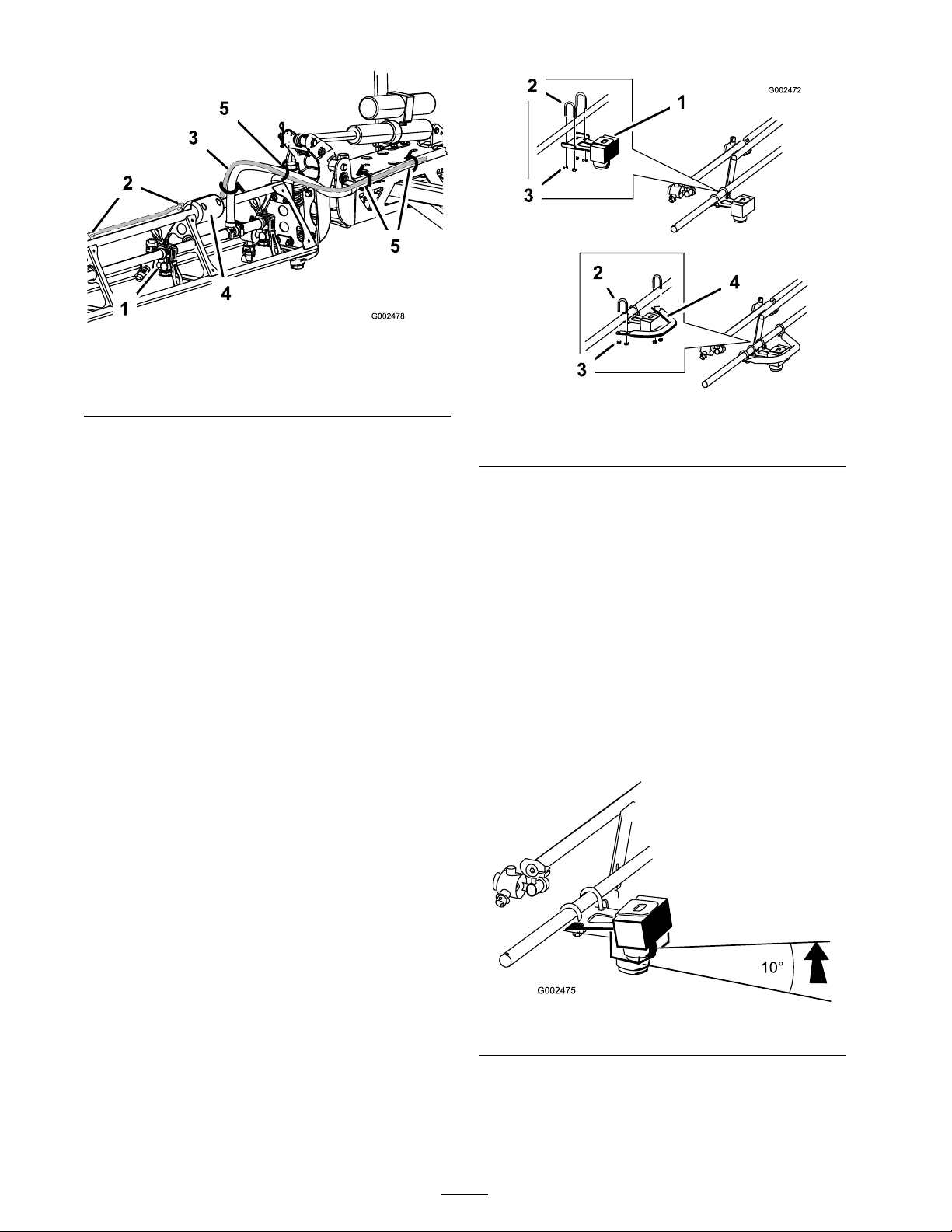

W iring the Switches

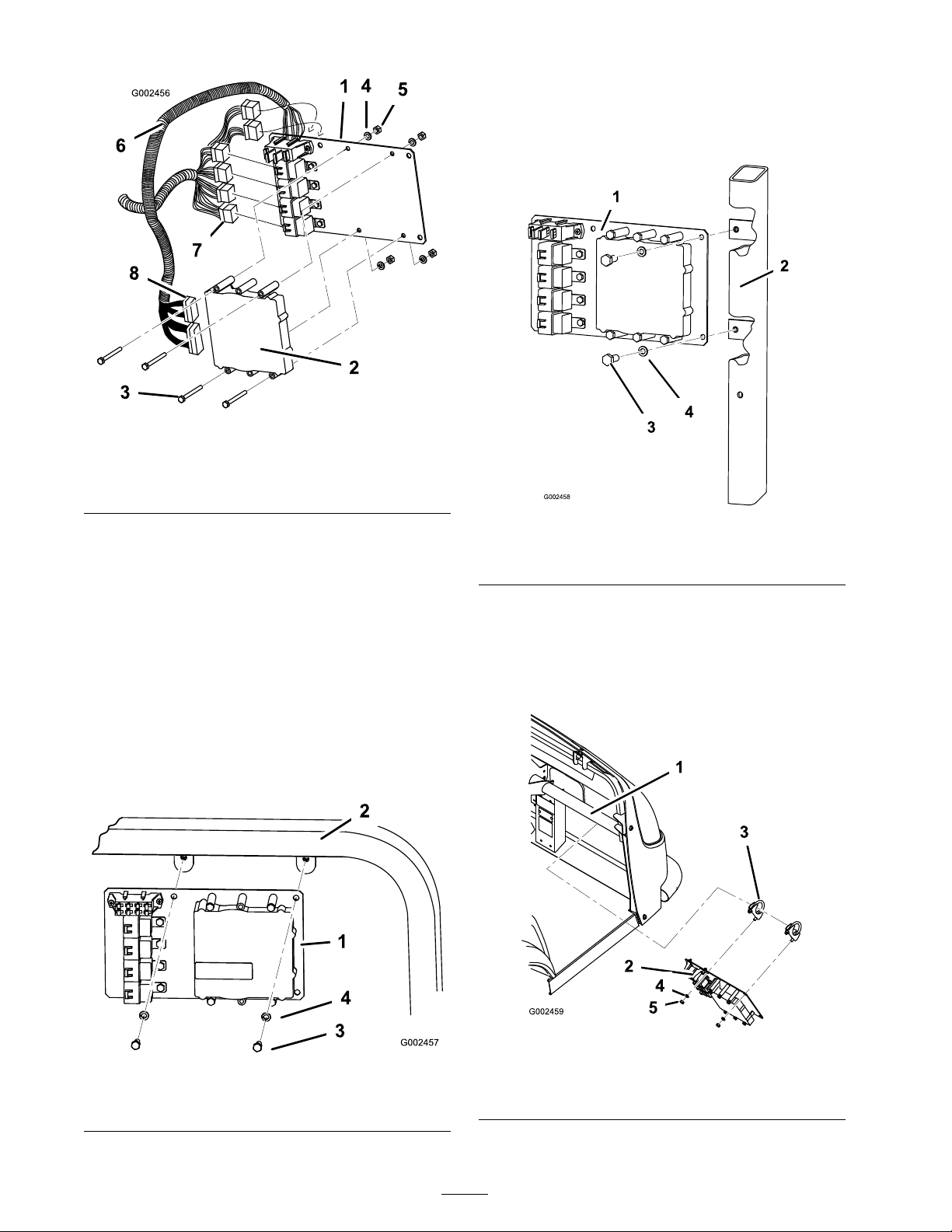

1. R oute the branc h of the sonic boom wire

har ness with the three larg e connectors into

the control panel area.

2. If boom lift switc hes are installed remo v e

any existing connectors plug g ed into the lift

switc hes .

3. Connect the connector with g reen and white ,

g reen and blac k, and blac k wires to the bottom

of the right boom lift switc h.

4. Connect the connector with blue and white ,

blue and blac k, and blac k wires to the bottom

of the left boom lift switc h.

5. Connect the connector with pur ple , yello w ,

and blac k wires to the bottom of the sonic

boom switc h.

6. R oute the free end of the wiring har ness do wn

through the floor and rearw ard, follo wing the

spra y system wire har ness to the center boom

assembly at the bac k of the v ehicle . Use cable

ties to secure the wiring har ness to the other

wiring har nesses a w a y from the engine and

mo ving par ts .

7. Install the spra y control panel and secure it

with the fasteners remo v ed previously .

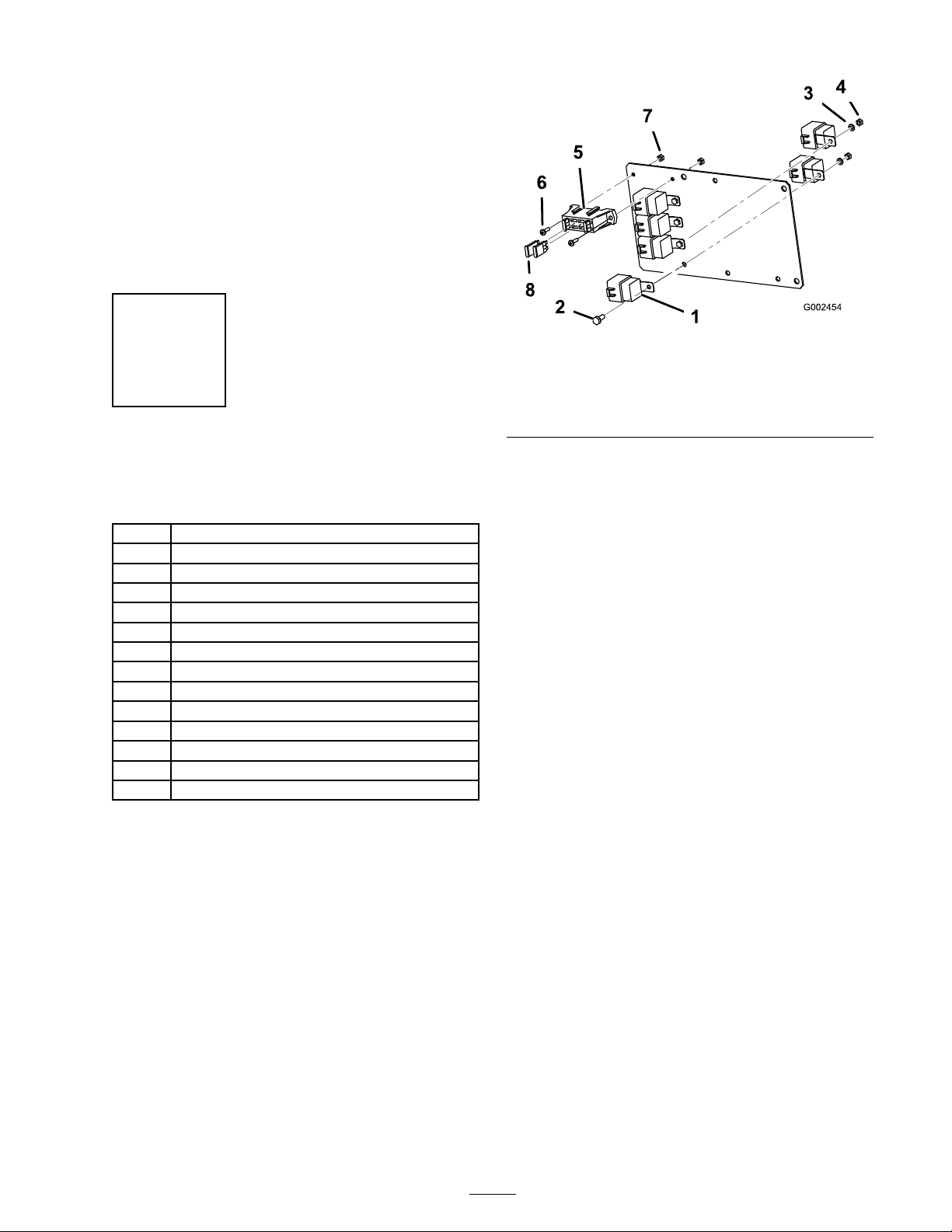

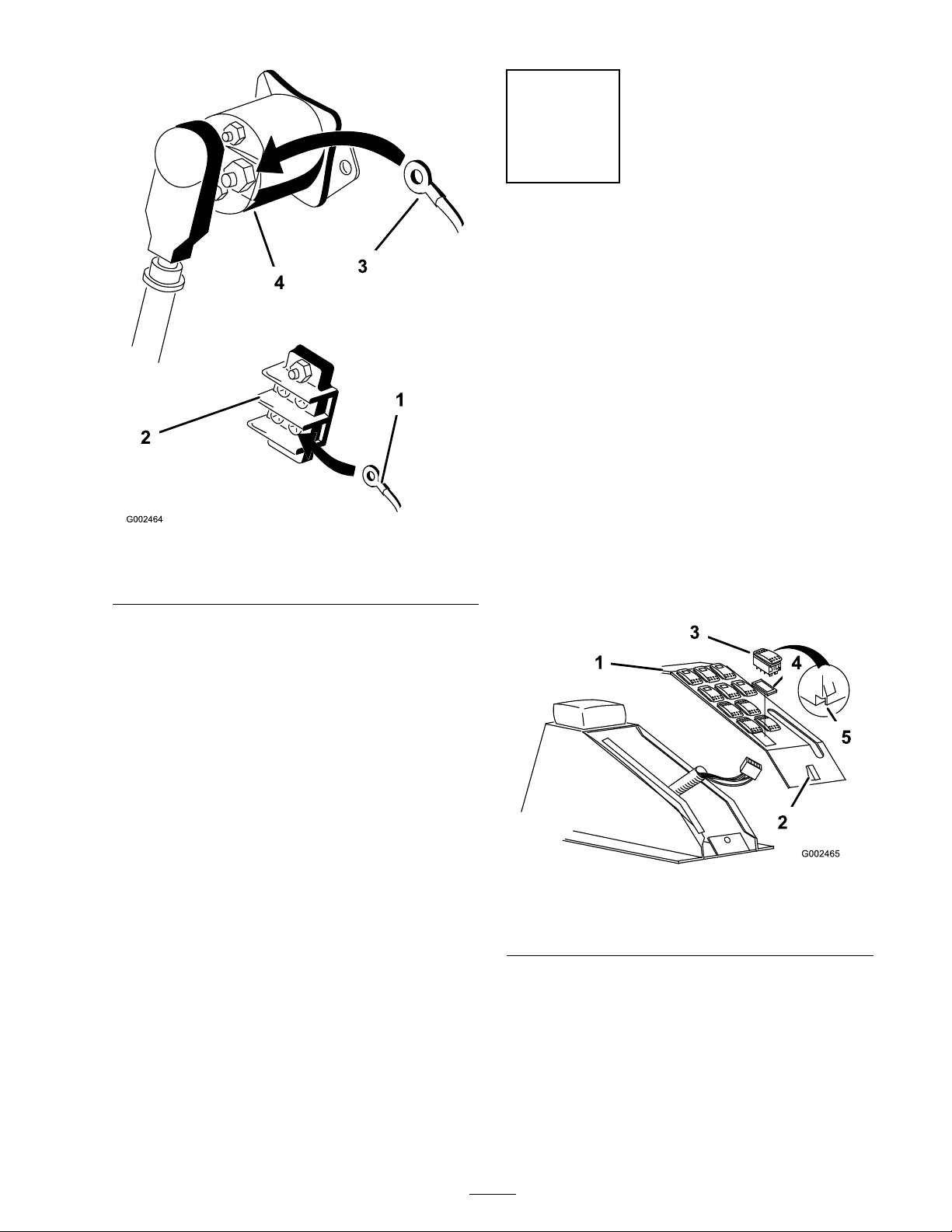

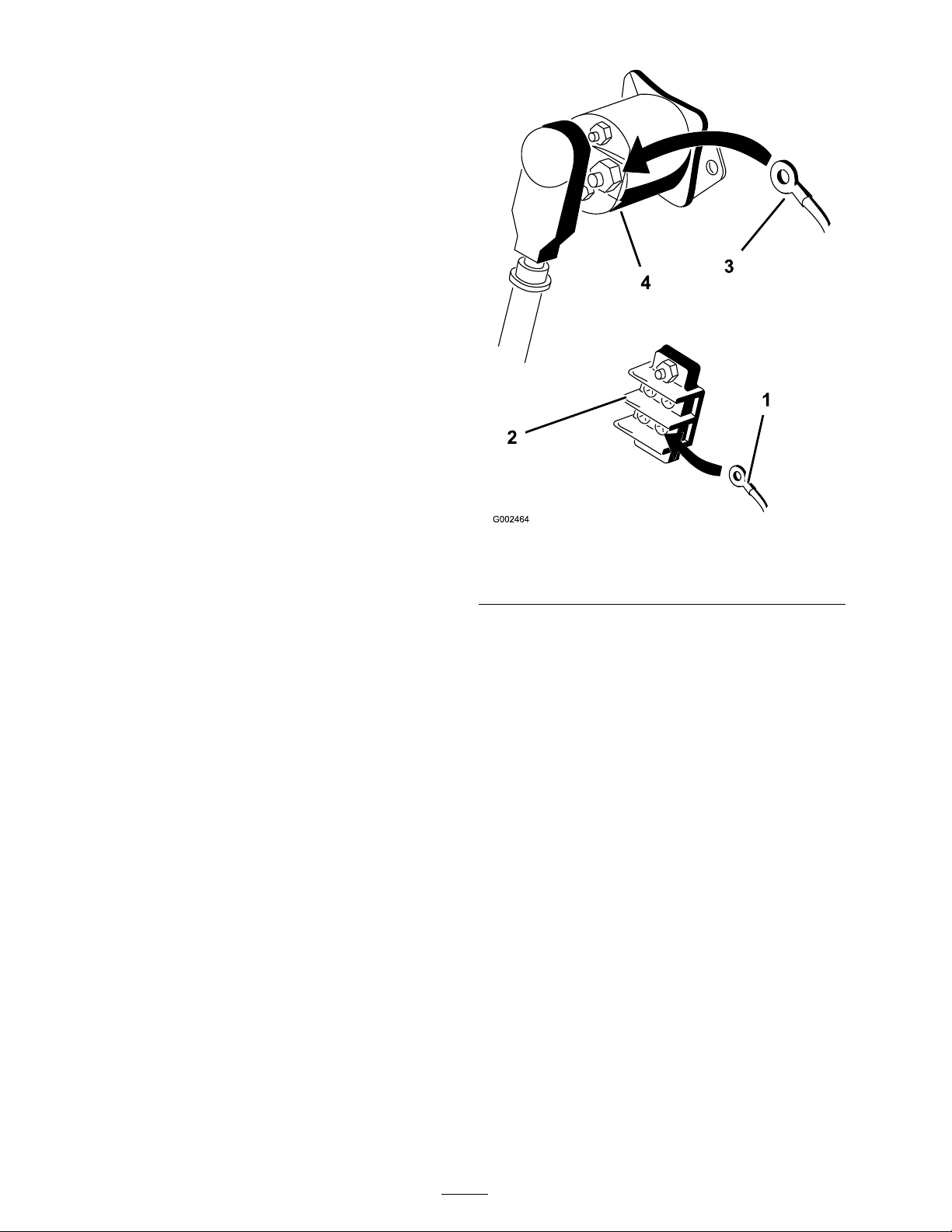

Connecting the W iring to the Fuse Block

1. R oute the branc h of the sonic boom wiring

har ness with the small spade connector and a

ring or fork ter minal into the seat bo x and to

the fuse area.

2. Lift the seat to access the fuse area. Locate the

auxiliar y solenoid and g round ter minal bloc k.

3. Connect the ring labeled g round on the blac k

wire to the g round ter minal bloc k ( Figure 15 ).

8