HYD-7-610 EN-7

EN

SYNTHETIC COMPRESSOR LUBRICANT MATERIAL COMPATIBILITY

LIST

COMPATIBILITY LIST SUITABLE :

FKM (Fluoroclastomer), PTFE, Epoxy (Glass Filled), Oil Resistant Alkyd,

Fluorosilicone, Fluorocarbon, Polysulde, 2-Component Urethane,

Nylon, POM (Polyoxymethylene/Polyacctel), High Nitrile Rubber (Buna

N. NBR more than 36% Acrylonitrile), Polyurethane, Polyethylene,

Epichlorohydrin, Polyacrylate, Melamine, Polypropylene, Baked

Phenolics, Epoxcy, Modied Alkyds (® indicates trademark of DuPont

Corporation).

NOT RECOMMENDED :

Neoprene, Natural Rubber, SBR Rubber, Acrylic Paint, Lacquer, Varnish,

Polystyrene, PVC, ABS, Polycarbonate, Cellulose Acetate, Low Nitrile

Rubber (Buna N. NBR less than 36% Acrylonitrile), EPDM, Ethylene Vinyl

Acetate, Latex, EPR, Acrylics, Phenoxy, Polysulfones, Styrene Acrylonitrile

(San), Butyl.

GENERAL REQUIREMENTS

The piping, ttings, air receiver tank, etc. must be certied safe for at least

the maximum working pressure of the unit. Use hard-welded or threaded

steel or copper pipes and cast iron ttings that are certied safe for the

unit’s discharge pressure and temperature. DO NOT USE PVC PLASTIC. Use

pipe thread sealant on all threads, and make up joints tightly to prevent air

leaks.

DRIVE OPTIONS

• DIRECT DRIVE

A 1100 series ange is available to direct drive the GD 70. The following

guidelines should be followed:

• Compressor shaft and PTO shaft should be parallel within 2 degrees.

• Maximum compound drive angle must be no greater than 11 degrees.

• Install a “U” bolt hanger for safety in case of a driveshaft failure.

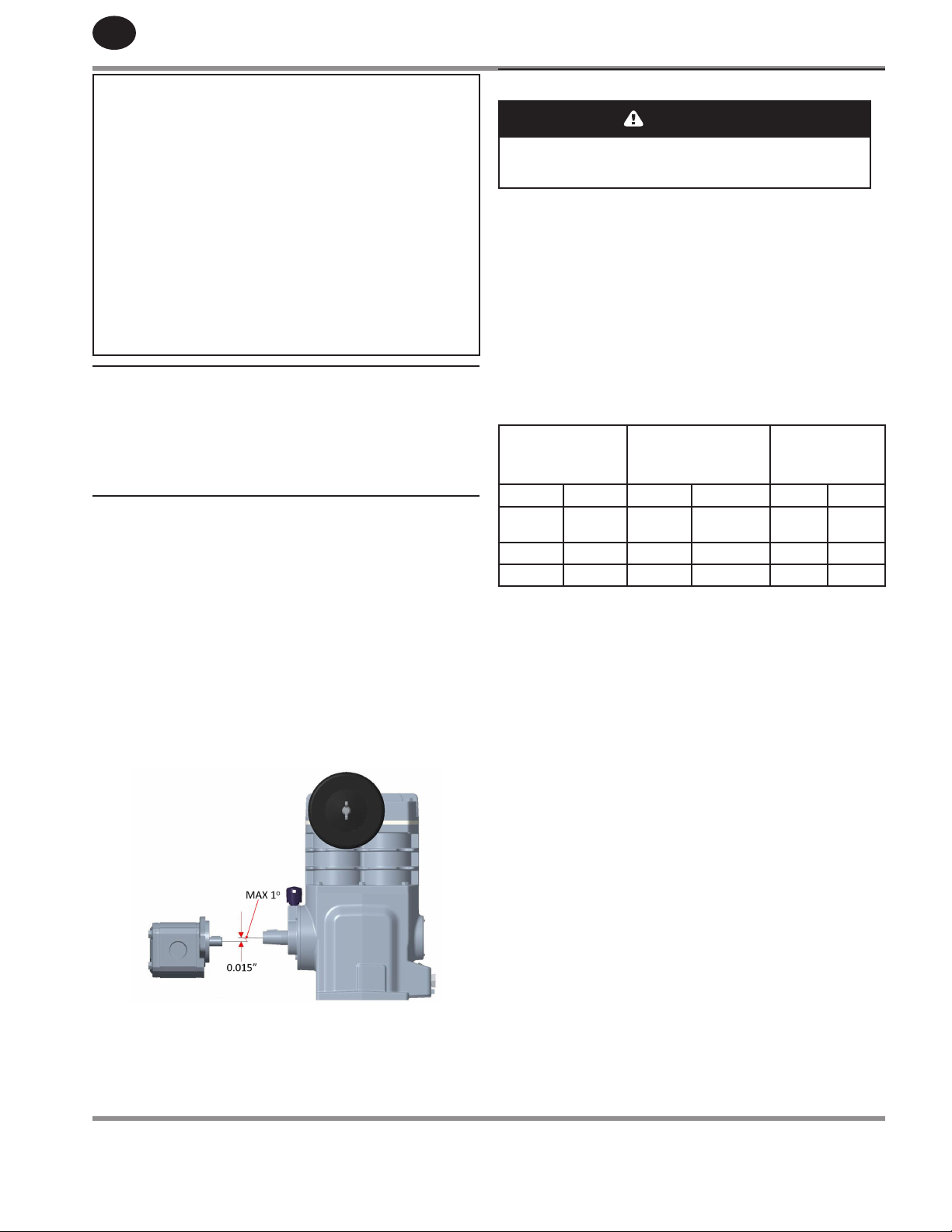

• HYDRUALIC DRIVE

If the unit is to be driven by hydraulic motor, the shafts must be aligned as

follows:

• Shaft oset of no more than 0.015”.

• Shafts parallel within 1 degree.

COMPRESSOR LUBRICATION

CAUTION

Do not operate without lubricant or with inadequate lubricant.

Gardner Denver is not responsible for compressor failure caused

by inadequate lubrication.

SYNTHETIC COMPRESSOR LUBRICANT

We recommend AEON AC-SY compressor lubricant from start-up. See the

WARRANTY section for extended warranty information.

ALTERNATE LUBRICANTS

You may use AEON AC-HC or a comparable petroleum-based lubricant that

is premium quality, does not contain detergents, contains only anti-rust,

anti-oxidation, and anti-foam agents as additives, has a ashpoint of 440°F

(227°C) or higher, and has an auto-ignition point of 650°F (343°C) or higher.

See the petroleum lubricant viscosity table below. The table is intended

as a general guide only. Heavy duty operating conditions require heavier

viscosities. Refer specic operating conditions to Gardner Denver for

recommendations.

Temperature

Around Compressor

Viscosity at 100°F

(37.8 °C)

Viscosity Grade

°F °C SUS Centistokes ISO SAE

40 &

below

4.4 &

below

150 32 32 10

40-80 4.4-26.7 500 110 100 30

80-125 26.7-51.0 750 165 150 40