Document #: GAR_IOM_4605246 – 1/21 9

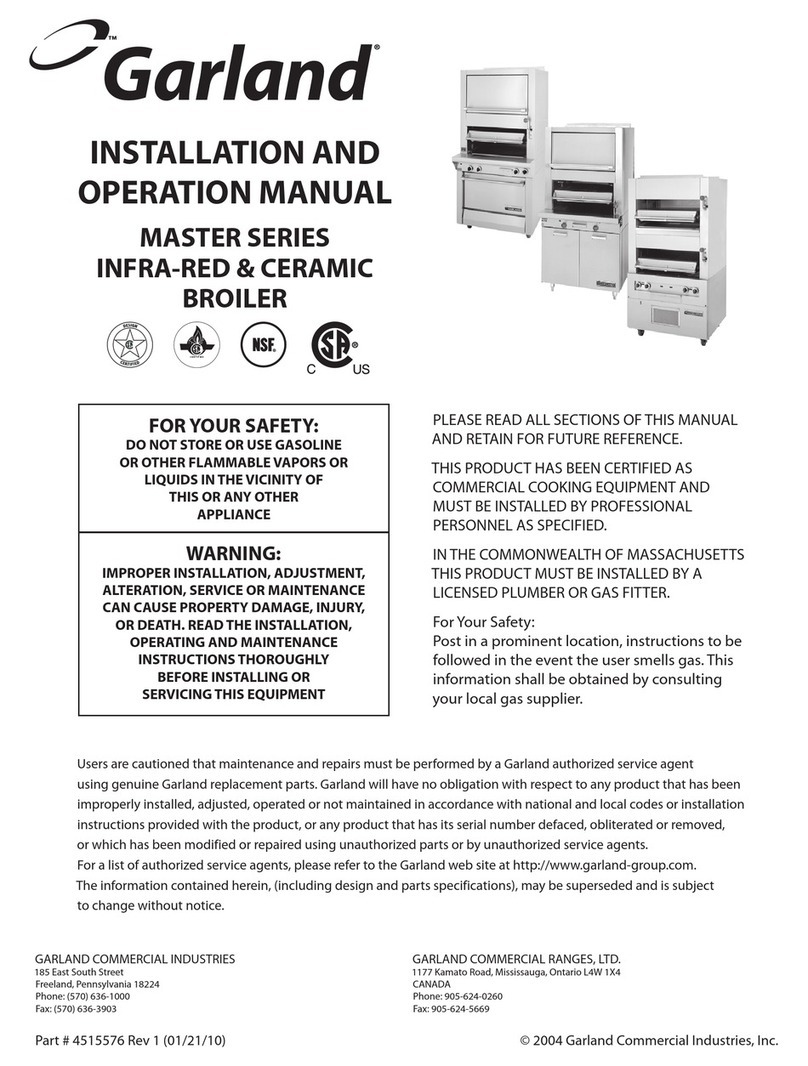

Read This Manual

Garland has developed this manual as a reference guide

for the owner/operator and installer of this equipment.

Please read this manual before installation or operation of

the appliance. A qualified service technician must perform

installation and start-up of this equipment, consult Section 5

within this manual for troubleshooting assistance.

If you cannot correct a service problem, call your Service

Agent or Distributor. Always have your model and serial

number available when you call.

Your Service Agent ____________________________

Service Agent Telephone Number _________________

Your Local Garland Distributor ____________________

Distributor Telephone Number ____________________

Model Number _______________________________

Serial Number ________________________________

Installation Date ______________________________

Unit Inspection

Thoroughly inspect the unit upon delivery. Immediately

report any damage that occurred during transportation to

the delivery carrier. Request a written inspection report from

a claims inspector to document any necessary claim.

Purchaser’s Responsibility

It is the responsibility for the purchaser:

1. To see that the gas and electric services for the grill are

installed on site in accordance with the manufacturer’s

specification.

2. To see that the gas and electric services are connected

properly by a qualified installer of your choice. For

installation in the State of Massachusetts: Installation

of this grill must be performed by a licensed plumber or

gas fitter. All such connections must be in accordance

with applicable code requirements. Refer to “Installation

Requirements” section for specific information.

3. Garland advises that you season the cooking bars

before placing any food on them; this will remove any

manufacturing oils and also smooth the natural pitting

created from freshly cast mouldings. Seasoning your

cooking bars with a light oil, such as vegetable oil, can

smooth out the pitting and stop any food from sticking.

Fresh, unoiled cast iron cooking bars are also prone to

rust if you do not season them from the start. Rusting of

cooking bars from lack of seasoning will not be covered

by warranty.

4. Arrange for an Authorized Sevice Technician to inspect

and confirm correct operation of the unit. Do not

attempt to operate the grill until connection of utility

service has been fully inspected by an Authorized

Service Technician or a Garland Foodservice Products,

LLC Service Representative. This service is required by

Garland Foodservice Products, LLC in order to assist the

purchaser in proper start-up of the grill on site. Please

note the specific details on the Warranty and make

certain connections are made to proper utility services.

5. The warranty shall not apply if the unit is operated prior

to installation being inspected by an Authorized Service

Technician or a Garland Foodservice Products, LLC

Service Representative.

Additional Requirements

• It is required that the unit be installed under a ventilation

hood to provide for adequate air supply and ventilation.

• Minimum clearances must be maintained from all

walls and combustible materials. See “Clearance

Requirements” section for more information.

• Keep the grill free and clear of combustible material.

• Do not obstruct ventilation holes on the unit, as these

provide cool air for the electronics and fresh air for

combustion.

• Only connect and operate the unit on the type of gas

and/or electricity listed on the rating plate.

• This manual should be retained for future reference.

• This appliance is for professional use only and should be

used by qualified people.

Section 1

General Information