GAS Gasmaster User manual

1 to 4 channel gas detection control panel

Gasmaster

Installation, Operation and

Maintenance Manual

The equipment described in this manual may have mains voltages applied to it. Ensure correct safety procedures are adopted

before working on the equipment. The equipment described in this manual is designed for the detection of ammable and/

or toxic gases. Detectors may be sited in hazardous areas. Ensure local safety procedures are adopted before carrying out any

maintenance or calibration work. The equipment described in this manual may be connected to remote alarms and/ or shutdown

systems. Ensure that local operating procedures are adopted before carrying out any maintenance or calibration work.

This product has been tested and found to comply with the European Directive 2004/108/EC and the EMC requirements of

EN50270. It also complies with the Council Directive 2006/95/EC relating to electrical safety and the Low Voltage Directive. It

conforms to the CE Marking Directive 93/68/EEC.

Contents

1. Introduction. .............................................................................................................................1

1.1 About Gasmaster ....................................................................................................................1

1.2 About this manual ..................................................................................................................1

1.3 Instructions for use as part of an ATEX approved system.........................................2

2. Installation .................................................................................................................................3

Please read this rst................................................................................................................3

2.1 Before installation ...................................................................................................................4

2.1 General........................................................................................................................................4

2.3 Mounting....................................................................................................................................5

2.4 Cabling requirements............................................................................................................5

2.5 Installing gas and re detectors.........................................................................................6

2.6 Installing output devices......................................................................................................6

2.7 Connecting mains power..................................................................................................... 6

2.8 Connecting input devices....................................................................................................7

2.9 Connecting output devices.................................................................................................11

2.10 Applying power .......................................................................................................................13

2.11 Battery back-up times............................................................................................................13

2.12 Commissioning........................................................................................................................14

3. Operation...................................................................................................................................17

3.1 Gasmaster Operator Panel...................................................................................................17

3.2 Gasmaster start up sequence .............................................................................................19

3.3 How to adjust display contrast...........................................................................................19

3.4 How to display Instrument serial number and system identity .............................19

3.5 Using the menu system ........................................................................................................20

3.6 Inhibiting channels.................................................................................................................20

3.7 Using the Control Panel in Supervisor Mode................................................................21

3.8 In the event of an alarm........................................................................................................22

3.9 mV channels: Pellistor saver mode ...................................................................................22

3.10 In the event of a fault.............................................................................................................23

3.11 System Conguration ............................................................................................................23

4. Maintenance .............................................................................................................................35

4.1 Functional Testing...................................................................................................................35

4.2 System Inhibi ............................................................................................................................35

4.3 Detector Calibration...............................................................................................................36

4.4 Changing Batteries .................................................................................................................36

4.5 Module Replacement ............................................................................................................36

4.6 Event logging............................................................................................................................36

4.7 Service card ..............................................................................................................................36

4.8 Cleaning......................................................................................................................................36

5. Adding an input module......................................................................................................37

Appendix A: Specications..................................................................................................38

Appendix B: Spare Parts and Accessories.......................................................................39

Appendix C: Display characters..........................................................................................40

Warranty Statement ...............................................................................................................41

1

1.1 About Gasmaster

Gasmaster is a gas and re control panel, designed

to monitor remote gas and re detectors.

Gasmaster can also monitor ame detectors as

well as GAS’s ESU product. The status of each input

is displayed on a large, clear LCD display, and

alarms or faults are indicated by clear LEDs and an

integral sounder.

Relay outputs are provided for alarms and faults, as

well as dedicated outputs for audible visual alarms.

An RS-485 Modbus output is provided for two-wire

transfer of all data to industry-standard control

systems.

Gasmaster logs all alarm and fault events so that

they can be investigated at a later stage using

Gasmaster PC software.

There are two versions of Gasmaster:

• Gasmaster 1 - single channel unit for one gas

detector, re zone or ESU sampling device.

• Gasmaster 4 - four channel unit for one to

four gas detectors, re zones or ESU sampling

devices.

Gasmaster 1 is identiable from Gasmaster 4 by

having only a single channel display (see gure

3.2, page 18) and a de-populated terminal PCB. All

operating functions are identical to Gasmater 4.

Gasmaster is designed for simple operation, and all

day-to-day functions can be performed from the

front panel. Please refer to section 3 for details on

display operation.

1.2 About this manual

The manual is divided into sections which

detail procedures for installing, operating and

maintaining Gasmaster. Gasmaster is a safety

system and it is essential that all instructions are

correctly followed.

Details of the types of device that can be

connected to Gasmaster are shown in section 2,

along with typical connection diagrams. Section

3 provides instructions for day-to-day operation

of Gasmaster as well as detailed information on

system conguration.

Warning

Regular maintenance of any safety system is essential,

and failure to maintain the system according to these

instructions could result in failures which could lead to

harm to plant and/or personnel or even death. Details of

the requirements for Gasmaster systems are provided in

section 4.

There are separate appendices for systems

specication and spare parts identication.

1. Introduction

2

1. Introduction

1.3 Instructions for use as part of

an ATEX approved system

Gasmaster is approved according to the 94/9/EC

ATEX Directive when used as part of a system with

intrinsically safe gas detectors and I.S. barriers.

Gasmaster has been certied according to

EN60079- 25:2010 Explosive atmospheres -

Intrinsically safe electrical systems. Certicate

reference: Baseefa05Y0090/1 Gasmaster must

be installed in the safe area only, but is certied

for connection to Intrinsically Safe gas detectors

installed in Zone 0, 1 or 2 hazardous areas when

connected by a safety barrier. Installation must be

in accordance with the instructions shown below.

3

Please read this rst

Before commencing the installation and commisioning

of your Gasmaster system, please read through the

following information which will guide you through

the whole process.

The installation instructions contained in this section

are for a pre-congured Gasmaster. For instructions on

installing and commissioning gas and re detectors,

please follow the user manual instructions supplied

with the detectors. Alternatively contact Gas Alarm

Systems for advice.

To complete the installation of your Gasmaster system

you will need to use the Operator panel and Menu. Full

instructions can be found in section III. Operation, you

are advised to familiarise yourself with the operator

buttons on the front panel and the menu structure, see

page 25. Some conguration steps may require you to

enter Supervisor mode. Gas Alarm Systems advises that

personnel familiar with installing and commisioning

gas and re detection systems carry out this part.

If you have purchased a Gasmaster 1

Please follow the instructions in this section but ignore

the reference to additional channels.

If you have purchased a non-congured

Gasmaster 4

Please follow the installation instructions for a pre-

congured Gasmaster 4. Additional information

on setting-up your Gasmaster system can be found in

section III. Operation.

Step-by-step instructions

The installation and commissioning of your Gasmaster

system is presented in easy to follow instructions. A

summary table of contents detailing a typical sequence

of installation steps is shown below. Depending on

your conguration some or part of each step may be

omitted.

Warning:

Gasmaster is not certied for use in hazardous

areas, but may be connected to detectors

and/or alarm devices which are installed in a

hazardous area. Instructions for eld devices

must be closely observed when installing a

Gasmaster system.

2.1 Before installation

2.2 General

2.3 Mounting

2.4 Cabling requirements

2.5 Installing gas and re detectors

2.6 Installing output devices

2.7 Connecting mains power

2.8 Connecting input devices

2.8.1 Two wire 4-20mA devices

2.8.2 Three wire 4-20mA devices

2.8.3 mV bridge pellistor detectors.

2.8.4 Heat/smoke detectors

2.8.5 Environmental Sampling Unit

(ESU)

2.8.6 Flame detectors

2.8.7 Remote inhibit and accept/

reset inputs

2.9 Connecting output devices

2.9.1 Audible visual alarms

2.9.2 Common relay connections

2.9.3 Channel relay connections

2.9.4 Analogue outputs

2.9.5 RS485 communications

2.10 Applying power

2.11 Battery back-up time/power calculations

2.12 Commissioning

2.12.1 Commissioning mV pellistor

detectors

2.12.2 Zero adjustment and calibration

2.12.3 Testing re channels

2.12.4 Testing ESU channels

2. Installation

4

2.1 Before installation

Before carrying out any installation work, ensure that

local regulations and site procedures are followed.

Further advice is available from Gas Alarm Systems if

required.

Gasmaster is intended for use in non hazardous areas.

Gas and re detectors may be mounted in potentially

ammable atmospheres using appropriate barrier

devices where necessary. Check the equipment to be

installed is suitable for the area classication. Please

refer to instrument installation manuals for information

on location.

Gas Alarm Systems recommends the installation of

Gasmaster be carried out by people with experience of

installing electrical equipment in potentially hazardous

areas.

2.2 General

This section describes how to get started with a

Gasmaster 4 or Gasmaster 1 system that has been pre-

congured for the detectors supplied. Figures 2.1, 2.2

and 2.5 show the internal structure of Gasmaster.

See the Specication and Inspection Certicate

provided with your system for full details of its

conguration.

Figure 2.1 shows the internal arrangement of a

Gasmaster system. The front cover ➀is removed

by unscrewing the four screws ➁and carefully

disconnecting the two-pole sounder connector

from the display PCB ➂. The front cover can either

be supported by the case using one of the retaining

screws, or removed completely and placed in a safe

location. Two separate chassis support the display PCB

and batteries which supports the display PCB ➂and

batteries ➃. The terminal PCB ➆contains the input

modules, and all of the input and output terminals. The

display PCB ➂is connected to the terminal PCB ➆via

a 50-way ribbon connector, and is hinged on the left

side so that it can be moved to provide access to the

detector input terminals. Most terminals are accessible

once the display PCB is moved and the batteries are

removed. If necessary the two chassis can be removed

for easier terminal access.

In order to remove the display chassis, the display PCB

ribbon connector must rst be carefully unplugged.

Care should be taken when re-tting the display PCB so

as not to damage the connector or ribbon cable.

Six punched cable gland knock-outs are provided

on the top and bottom of the enclosure. The knock-

outs are suitable for M20, 1/2”NPT or PG13.5 cable

glands. To remove Knock-outs,tap around the edge

of the recessed ange using a small hammer and a

screwdriver. The knocks outs should then come away

from the enclosure

Knock-outs should be removed prior to mounting

Gasmaster and great care must be taken to avoid

damaging internal components.

Power supply

Gasmaster comes tted with an auto-ranging power

supply suitable for 100-240 V ac 50-60 Hz operation.

This provides a nominal 24 V dc supply with a

maximum power of 60 W. Alternatively Gasmaster

can be powered from an external 24 V dc supply, a

maximum 60 W supply is required. Gasmaster must

never be connected to ac and dc supplies at the same

time.

2. Installation

5

The Gasmaster power supply contains no user

replaceable fuses.

Short circuit protection

Each detector input is short-circuit protected. Self-

resetting‘polyfuses’ are tted to the 24 V power supply

which will cut power in the event of a cabling fault,

and automatically reset when the fault is corrected.

Detectors with a maximum consumption of 500 mA

may be connected.

Circuit breaker

If the equipment is permanently connected to a

mains supply then a dedicated circuit breaker must be

included in the installation, to comply with EN 61010-

1. The circuit breaker must be close to Gasmaster, in

easy reach of the operator. It must be marked as the

disconnecting device for the Gasmaster system, and

the ON and OFF positions must be clearly marked.

The circuit breaker must comply with the relevant

requirements of IEC60947-1 and IEC60947-3. The

protective earth must not be disconnected even when

the breaker is activated.

Figure 2.2 Gasmaster chassis plate with display PCB

board and batteries.

2.3 Mounting

All Gasmaster systems should be installed in a safe area.

Consider location, cabling and earthing requirements.

Figure 2.3 provides a dimensional view of Gasmaster.

To access the mounting points, rst remove the front

cover by unscrewing the xings labelled ➁in gure

2.1. Carefully remove the sounder connector from

the display PCB. The cover should be placed in a

secure location. It is recommended that Gasmaster is

positioned by hand in the desired location, and a pencil

used to mark the mounting hole positions. Gasmaster

should be removed before drilling the mounting

holes. Nylon bushes suitable for up to 5mm screws are

tted within the Gasmaster mounting points. Ensure

these bushes are present when mounting as they are

essential to maintain the ingress protection of the

enclosure.

Figure 2.3 Dimensional view of Gasmaster with

mounting holes shown

2.4 Cabling requirements

Cabling to Gasmaster and detectors must be in

accordance with the recognised standards of the

appropriate authority in the country concerned, and

must meet the electrical requirements of the detector.

• Explosion-proof (Exd) devices

Gas Alarm Systems recommends the use of steel wire

armoured (SWA) cable. Suitable explosionproof glands

must be used.

• Intrinsically Safe (I.S.) devices

Gas Alarm Systems recommends the use of twisted

pair cable with overall screen and sheath. Suitable

weatherproof glands must be used. I.S. devices must be

used with a suitable Zener Barrier or Galvanic Isolator

when used in a hazardous area.

2. Installation

6

• Fire detectors

Gas Alarm Systems recommends the use of twisted-pair

cable, screened with an overall protective sheath that

is reproof, for example, Pirelli FP200 or similar. A 1K8

end-of-line resistor must be tted to the last detector

on each conventional smoke or heat detector loop.

Alternative cabling techniques, such as steel conduit,

may be acceptable provided that appropriate

standards are met. The minimum acceptable supply

voltage measured at the detector and the maximum

current drawn by that detector is dierent for each

device. Please refer to the relevant Installation,

Operating and Maintenance Instructions provided

with each detector to calculate the maximum cable

distances allowed for dierent cable types.

The maximum cable distance allowed is dependent

upon the installation, for example, whether Zener

Barriers or Galvanic Isolators are required (for I.S.

devices) or not.

When calculating maximum cable distances for

detectors, assume a minimum supply of 19 V and

a sense resistance of 98 Ω (39 Ω for convential re

channels).

Table 1: Typical cable characteristics

c.s.a (mm2)* Resistance (Ω per km)

Cable Loop

0.5 (20) 39.0 78.0

1.0 (17) 18.1 36.2

1.5 (15) 12.1 24.2

2.5 (13) 8.0 16.0

*Approximate c.s.a. in awg given in brackets.

Cable lengths should be calculated according to the

equations dened in the detector instructions sheet

and the cable and Gasmaster characteristics specied

above.

There are a number of suitable ways of terminating

cables and glands to Gasmaster dependant on the

cable and gland type:

– Steel wire-armoured (SWA) cable and glands with

electrical termination of the armour to the enclosure

via the gland.

– Screened cable with the screen terminated inside the

enclosure via a metal tag attached to the gland.

– Screened cable using an EMC gland where the screen

is terminated to the enclosure via the gland.

– For detectors, 4-20 mA outputs and RS- 485

terminations: screened cable where the screen is

connected to the SCR terminal on the appropriate

terminal strip.

2.5 Installing gas and re detectors

Install gas and re detectors as per instrument

installation manuals, paying attention to location and

cabling requirements. For ESU devices please refer to

installation manual provided.

2.6 Installing output devices

Gasmaster can drive 12 V dc or 24 V dc audible visual

alarms directly via the Audible Visual drive terminals

on the terminal PCB. Relays are provided for switching

additional outputs, and 12 V dc or 24 V dc 200 mA

auxiliary supplies are available adjacent to each

block of relay terminals for switching low power

devices. Section 2.9 provides detailed information on

connections to output devices.

2.7 Connecting mains power

Connect the external power supply using the two part

screw terminals, refer to Figures 2.4 and 2.5.

Gasmaster must be earthed either at the power

connector earth terminal (see Figure 2.4) or using the

stud on top of the enclosure.

Figure 2.4 Mains connection terminals on terminal PCB

2. Installation

7

2.8 Connecting input devices

Gasmaster may be tted with between one and four

input modules (one only for Gasmaster 1) of the

following types:

• 4-20mA/Fire module for 4-20mA type detectors,

conventional smoke/heat detectors or ESU.

• mV Pellistor module for mV bridge type ammable

gas detectors.

Details of hardware congurations and link settings can

be found in section 2.8.1 to 2.8.6.

4-20 mA Inputs

Gasmaster provides analogue 4-20 mA inputs with a

sensor supply voltage of 19 to 28 V dc and measures the

signal across a 98 Ω sense resistor.

Inputs can be gas detectors or ame detectors in 4-20

mA 2-wire sink, or 3-wire sink or source congurations.

Gasmaster will track inputs from 3 to 21.5 mA at which

point an ‘over-range’ fault will be indicated. Connection

details are shown in section 2.8.1 and 2.8.2.

2. Installation

8

Conventional re detectors

A loop of up to 20 conventional smoke/heat detectors

(for example Apollo Series 65 or Orbis devices’) can

be connected to each Gasmaster input channel.

A re loop can also comprise switched devices such as

manual alarm call points or ame detectors, and devices

can be mixed on the same loop provided electrical

characteristics are compatible and re regulations allow.

Switched devices require a 470 Ω series resistor. Each re

loop must be terminated with a 1K8 end-of-line resistor,

which is monitored to provide indication of open circuit

or short circuit faults. Connection details are shown in

section 2.8.3.

Environmental Sampling Unit (ESU)

Each Gasmaster input can monitor a Gas Alarm Systems

Environmental Sampling Unit (ESU), which enables

detection of ammable or toxic gases over a wide area

using a sample draw technique. It is essential that the

sampling device on the ESU is operating correctly, and

Gasmaster provides this monitoring function to ensure

a sample is being drawn. Gasmaster provides a 2-wire 24

V dc supply to the sampling device. Separate Gasmaster

input channels are required to monitor the gas detector

or detectors tted to the ESU. Connection details are

shown in section 2.8.5.

mV bridge pellistor detectors

Some ammable gas detectors provide a mV bridge

type signal rather than a 4-20mA signal. Example Gas

Alarm Systems products are Xgard Type 3 and Xgard

Type 4. The procedure for setting-up these detectors is

dierent from 4-20mA devices: refer to section 2.12.1 for

detailed instructions on commissioning mV bridge type

detectors

Please contact Gas Alarm Systems for specic wiring

details for Gas Alarm Systems detectors

2.8.1. Two wire 4-20mA devices

Figure 2.6 shows a typical wiring conguration for a

2-wire current sink detector for safe area use only.

Figures 2.7 and 2.8 show typical wiring congurations

for I.S. detectors installed in hazardous areas using Zener

Barriers or Galvanic isolators. Refer also to section 1.3.

Set the link on the 4-20 mA/Fire input module to SINK

in all cases.

Figure 2.6 Connections for 2 wire detector 4-20mA/Fire

input module

Figures 2.7 and 2.8 show typical wiring congurations for

a 2 wire sink I.S.detector with Zener barrier or Galvanic

Isolator. Set the link for the appropriate channel as

shown in each diagram.

2.8.2. Three wire 4-20mA devices

Figure 2.9 shows a typical wiring conguration for a

3-wire detector. Set the link on the 4-20 mA/ Fire input

module to SOURCE for a current source detector, and

SINK for a detector congured as current sink.

Figure 2.9 Connections for 3 wire detector 4-20mA/Fire

input module

2.8.3. mV bridge pellistor detectors.

Detectors such as Gas Alarm Systems’s Xgard Type 3 or

4 should be connected as shown. Refer to section 2.12.1

for instructions on detector set-up.

Refer to Figure 5.1 on page 37 for wiring details.

Important: to avoid signal interference, it is essential

that detector cables do not lay over mV pellistor input

modules (hatched area on diagram).

2. Installation

9

2. Installation

10

2.8.4. Heat/smoke detectors

Conventional re detectors for safe area use should be

setup according to Figures 2.10 and 2.11. Conventional

re detectors for hazardous area use should be setup

according to Figure 2.12.

Figure 2.11 shows connections for manual alarm call

points.

2.8.5. Environmental Sampling Unit

(ESU)

Figure 2.13 shows the wiring conguration for

monitoring the ESU sampling device. Gas detectors

tted to the ESU should be cabled separately to the

appropriate input channels on the Gasmaster or other

control panel. For connections, details are shown on

the instructions provided with the ESU.

2.8.6. Flame detectors

Figure 2.14 shows a typical wiring conguration for a

4-20 mA 3 wire Flame detector. Set the detector type

link appropriate for the type of ame detector, refer to

Figure 2.5. Do not set link to FIRE.

2.8.7. Remote inhibit and accept/reset

inputs

Gasmaster has inputs for the connection of remote

switches to inhibit alarm outputs or accept and reset

alarms. Inputs are activated when pulled down to 0 V,

the open circuit voltage is 5 V dc.

2. Installation

11

Warning

Gas Alarm Systems strongly recommends that remote

inhibit switches be key operated only, and that

access to the key should be restricted to authorised

personnel. A Gasmaster system that has been inhibited

without other safety precautions being in place may

not provide the protection for which it was designed.

Steps should be taken to ensure that all appropriate

personnel are aware when a Gasmaster system is

inhibited.

Remote ACCEPT/RESET

Close the contact momentarily to accept alarms and

cancel audible alarms. Close the contact again when

the hazard is cleared to reset alarms.

Remote INHIBIT

Closing the contact will inhibit alarms on all input

channels. Channels will remain inhibited until the

contact is opened; the Gasmaster will then return

to its original state (any channels that have been

set to inhibit using the Supervisor menu will remain

inhibited). Figure 2.15 shows wiring congurations for

remote inputs.

Gas Alarm Systems recommends screened cables for

connecting remote switches. The screen should be

terminated at the appropriate‘SCR’ terminal.

2.9 Connecting output devices

WARNING: After accounting for internal power

consumption, the maximum power available for input

and output devices is 48 W

2.9.1. Audible visual alarms

Figure 2.16 shows a typical wiring diagram for audible

& visual (A/V) alarms, in this example a two-tone

sounder is depicted. The A/V drive from Gasmaster is

capable of providing up to 650mA, which equates to

two general purpose A/V alarm devices using xenon

type beacons. A greater number of LED-based beacons

may be powered; contact Gas Alarm Systems for

advice. Gasmaster is compatible with 12 V dc or 24 V dc

A/V alarms: refer to Figure 2.16 for link settings.

Gasmaster is compatible with A/V alarms which require

a common 0V supply (+VE switched), or a common

+VE DC supply (0V or ‘-VE’switched). Connect the A/V

device to the‘AV +VE SWITCHING’or ‘AV -VE SWITCHING’

terminals as appropriate.

Two separate sounder outputs are provided to activate

on level 1 and level 2 alarms respectively (terminal

AV2 becomes active on alarm level 1; AV3 becomes

active on alarm level 2). If a single tone sounder is

used, connections should be to terminal AV2 (and the

common terminal) only. T

erminal AV1 is intended to drive a visual alarm and

activates on a level 1 alarm.

2.9.2. Common relay connections

Double-Pole-Change-Over (DPCO) relays with contact

rating of 250 V ac 8 A (non-inductive), 5 A (inductive)

are provided for Alarm 1, Alarm 2 and Fault. Each relay

can be set in its non-active state as energised (Fail safe)

or de-energised. It is common practice to set the Fault

relay as Fail Safe so in the event of power loss, the fault

relay will change state. See Figure 2.5 for Common

Relay terminal location and Figure 2.17 for contact

denitions. Terminals are tted adjacent to all relay

blocks to provide 12 V or 24 V dc supplies for switching

low power devices. The dc auxiliary output terminals

may be set to either 12 V dc or 24 V dc by moving the ‘V

AV’ link. Refer to Figure 2.5 on page 7 for details.

2. Installation

12

Common Alarm and Fault relay congurations can be

set using the User Control Panel and Menu System. See

Section 3 “Operation” on page 17 for details.

2.9.3. Channel relay connections

Gasmaster 4 provides Double-Pole-Change-Over

(DPCO) relays for each channel. The relays provide

a contact rating of 250 V ac 8 A (non-inductive), 5 A

(inductive) for Alarm 1 and Alarm 2. Each relay can be

set in its non-active state as energised (Fail safe) or de-

energised. Refer to Figure 2.5 for location of Channel

Relay terminals and Figure 2.17 for contact denitions.

Terminals are tted adjacent to all relay blocks to

provide 12 V or 24 V dc supplies for switching low

power devices. The dc auxiliary output terminals may

be set to either 12 V dc or 24 V dc by moving the ‘V AV’

link. Refer to Figure 2.5 on page 7 for details Channel

Alarm thresholds and congurations can be set using

the User Control Panel and Menu System. See Section

“3. Operation” on page 17 for details.

Fire Channels

Conventional re channels will activate both Alarm

1 and Alarm 2 relays on the aected channel in the

event of an alarm. The Common Alarm 2 relay only

will activate. 4-20 mA ame detectors will activate two

levels of alarm as per a gas detector.

ESU Channels

If the ESU sampling device slows signicantly causing

reduced sample ow the Alarm 1 relay for that channel

will activate. If the sampling device stops the Alarm 2

relay will activate. The Common Alarm relays will not

activate if the sampling device slows or stops. If the

cable to the sampling device is open or short-circuited

the Common Fault relay will activate.

2.9.4. Analogue outputs

Gasmaster provides an analogue output for each

channel which can be set as either 4-20 mA or 1-5

V dc by tting a link (see Figure 2.18). These signals

can be used to drive PLC/DCS/SCADA systems or

remote displays. 4-20 mA outputs are current source

(resolution 0.1 mA) and can drive a maximum load of

700 Ω, 1-5 V outputs require a minimum load of 50 KΩ.

Analogue outputs will function in the following way:

4-20 mA gas detectors: the output will track the input

from 3 to 21.5 mA, the signal will drop to 0 mA if the

input rises above 21.5 mA to signal a fault. A sensor

signal that is greater than 110% of range is designated

by Gasmaster as a fault condition. The signal will be set

to 2 mA to indicate when a channel is inhibited, and 0

mA when a channel is in fault.

Fire channels: a signal of between 4 and 12 mA

indicates a‘no-re’ condition, 12-20 mA indicates a re,

0mA indicates a fault (open or short circuit). A 2 mA

signal indicates that a channel is inhibited.

ESU channels: a signal of between 4 and 12 mA

indicates the sampling device is operating correctly,

12-20 mA indicates a sampling device failure, 0 mA

indicates a fault (open or short circuit). A 2 mA signal

indicates that a channel is inhibited.

2. Installation

13

2.9.5. RS-485 communications

Gasmaster can provide alarm and system information

to PLC/DCS/SCADA systems via a two-wire link using

the Modbus RTU protocol (9600 baud, 8 data bits, no

parity, 1 or 2 stop bits). Up to 16 Gasmaster systems

can be ‘multi-dropped’ on a single two-wire link with a

maximum cable length of 1 Km, two-core twisted pair

cable is recommended. Single Gasmaster systems that

are to communicate via the RS-485 link should have the

RS485 TERM link made, which connects a terminating

resistor. For multi-dropped systems the RS485 TERM

link should be removed from all Gasmasters except the

last unit on the line.

A Modbus specication document is available from Gas

Alarm Systems on request.

The RS-485 terminals on Gasmaster systems ordered

with the optional local communications connector will

be used for terminating the connector leads. These

leads must be removed if a remote RS-485 serial link is

required.

2.10 Applying power

Before applying power ensure that any control

or shutdown systems to which the Gasmaster is

connected are inhibited. Once all eld cables have

been installed, the batteries can be connected as

per the diagram attached to the chassis plate. (Refer

to section 4.4.) Gasmaster will not power up until an

external power supply is applied.

Apply power to Gasmaster from either the AC or 24 V

dc external supplies. Outputs are inhibited for a preset

time after power-up, and the system will perform a

start up sequence testing alarm indicators and the

internal sounder. If after a settling period faults are

reported, check the sensor connections again or refer

to“Faults menu”on page 24.

When power is applied the green Power LED will

illuminate and ash every 5 seconds to indicate that

the system is operational.

If the external supply fails, Gasmaster will continue to

operate from its internal batteries and the Power LED

will ash every second. Depending on conguration,

Gasmaster will display either a Warning (Warning LED

lights and the sounder will beep every 5 seconds) or a

fault (the Fault LED and sounder will activate, and the

fault relay will change state).

Gasmaster should display all channels being

monitored. Allow sensors to settle before commencing

calibration, refer to sensor instructions supplied with

detectors for recommended settling times.

Note: your Gasmaster is supplied pre-congured, refer

to the Specication and Inspection Certicate provided

with your system. If no channels are congured,

Gasmaster will display the following screen:

To congure your system go to page 25.

2.11 Battery back-up times

Gasmaster is tted with 1.2 Ah batteries to provide

continued operation in the event of a power loss.

Examples of typical back-up times are provided

below for a system in a non-alarm state, relays set as

de-energised and with the 4-20mA outputs unused

(system current consumption without detectors is

approximately 50mA):

2. Installation

14

Gasmaster 1

with a toxic gas detector (2-wire): 21 hours

Gasmaster 1

with an oxygen detector (2-wire): 16 hours

Gasmaster 1

with a mV pellistor ammable gas detector:

12 hours

Gasmaster 4

with four toxic gas detectors (2-wire):

10 hours

Gasmaster 4

with four oxygen detectors (2-wire): 4 hours

Gasmaster 4

with four mV pellistor ammable gas

detectors: 3 hours

Gasmaster incorporates protection to prevent

the internal batteries being damaged by being

deeply discharged. When operating from internal

batteries, Gasmaster will display a “Warning -

battery low” fault message when the battery

voltage drops to 22 V. When the voltage drops

to approximately 20 V, the batteries will be

automatically disconnected. The batteries will only be

re-connected when the external power supply is

re-instated, and will take approximately 18 hours

to fully re-charge.

Note: The internal batteries may not be charged

eciently when Gasmaster is powered from an

external dc supply, and therefore the back-up

function may not work if the external supply fails

Please contact Gas Alarm Systems for further advice.

2.12 Commissioning

Note: it is strongly recommended that persons

intending to commission a Gasmaster system rst

read and understand the Operating instructions

provided in section III. Operation.

When all eld devices have been connected and

powered-up, commissioning can commence. Gas

detectors should be calibrated according to their

instructions, re detectors should be tested using

appropriate tools.

Alarms should be simulated and actions noted to

ensure that the system operates as intended. All

warning devices should be checked, and interfaces

with auxiliary equipment should also be veried. The

test and View menu’s are provided for this purpose (see

page 24 on page 27.

2.12.1. Commissioning mV pellistor

detectors

It is essential for these types of detectors that the

correct ‘head voltage’ and balance is set before

attempting to zero and calibrate the sensor.

To set the head voltage, measure the voltage across the

‘+’ and‘-‘ terminals at the detector and adjust the ‘HEAD

VOLTAGE’ potentiometer on the appropriate Gasmaster

input module. Check the detector instructions for

voltage settings: 2 V dc is typical for an Xgard Type 3 or

4 detector.

Allow the sensor to warm-up for 1 hour and then adjust

the amplier balance as follows: connect a meter set

in the dc mV range to test-points TP12 and TP13 on

the Gasmaster mV pellistor input module. Adjust the

‘BALANCE’ potentiometer until the meter reads‘300

m V ’.

The sensor is now ready for zeroing (having rst

checked no ammable gas is present) and calibration.

2.12.2. Zero adjustment and calibration

Calibration must be carried out separately on individual

gas detectors on Gasmaster. Follow calibration

instructions supplied with each detector. Ensure at all

times the local legislation and codes of practice are

complied with.

Allow detectors to stabilise for at least one hour before

commencing calibration. Refer to detector manual for

more information.

Gasmaster provides Zero and Calibration Wizards to

enable you to carry out calibration easily. These are

accessed through the Operator Display Panel and

Menu System. Section III. Operation provides detailed

information on the menu structure and operator

buttons.

Zero adjustment

1. From the normal operating display, press the

Continue button to enter the menu system.

2. Use the Up and Down buttons as necessary to

select Supervisor and press Continue .

2. Installation

15

3. You will be asked to enter a password, press

Continue .

The default password is ZZZ (uppercase), use the Up

and Down buttons to enter the rst character

of the password.

Note: Double click the Up or Down button to

move to the top or bottom of the alphabet list. To

enter numbers or lower case characters, continue

pressing the Up or Down button.

When you have selected the correct character,

press Continue , the cursor will move to the next

character position. Continue entering the rest of

the password. When you have nished press the

Continue button twice.

(See 3.7 in section III. Operation for details of

entering text strings).

4. The Zero Wizard oers temporary Inhibit but

you may wish to Inhibit all channels during the

calibration process.

How to set global inhibit:

From the Supervisor menu, scroll down to Inhibit

and press Continue . Select All and press Continue

. Use the Up and Down button to set inhibit

to INHIBIT=ON, press Continue to accept. Use

the Back button to return to the Supervisor

menu. The Inhibit icons will appear on the channel

display.

How to set channel inhibit:

Channel inhibit can be selected from the Inhibit

menu or within the Zero or Calibrate menu.

Follow the instructions provided above, selecting

the Channel #n (where n represents the channel

number) in place of All.

5. From the Supervisor menu, use the Up and Down

buttons to select Zero by pressing the Continue

button .

6. Select the channel to apply zero. Press the Continue

button to step through the Zero Wizard.

7. Press Continue when ‘…Only continue if in clean

air!…’is displayed, ensure the detector has been

correctly zeroed rst (i.e. 4 mA) Press Continue to

apply Zero now.

Gasmaster will display‘Pass’ when zero is successful

or ‘Fail’ if the detector zero is out of range.

8. Use the Continue button to Zero other channels

or Back button to the Supervisor menu to continue

calibration.

Calibration

1. Follow points 1 to 3 above in Zero adjustment to

enter Supervisor mode.

2. Before you commence calibration, ensure the

channels are inhibited prior to applying gas.

Channels can be inhibited globally or individually.

Follow the instructions given in step 4 in Zero

Adjustment.

3. From Supervisor menu, scroll down and select

Calibrate.

4. Select the channel to calibrate. Press the Continue

button to step through the Calibrate Wizard.

Ensure the channels are inhibited prior to applying

gas.

5. The next wizard screen displays the default

calibration gas concentration as 50% of range. If

necessary this calibration gure must be adjusted to

match the concentration of the calibration gas used.

Adjust the value using the Up or Downbuttons

as necessary and press Continue .

6. When“Apply Gas”is displayed, apply gas to the

detector and press Continue , allow readings to

settle.

7. Press Continue when the reading on the appropriate

channel is stable, and the detector has been

calibrated according to its instructions.

Gasmaster will display ‘Pass’ when successful or

‘Fail’ if the detector signal is out of range.

8. Calibration is complete when ‘Purge’ is displayed,

remove the gas from the detector.

Use the Continue button to calibrate another

channel or Back button to exit Supervisor mode

and return to the main display.

9. Ensure that all channel inhibits are removed after

calibration is complete.

2. Installation

16

2.12.3. Testing re channels

To test smoke detectors, inhibit the relevant FIRE

channel and use a smoke test aerosol to test each

detector on a loop in turn. The channel display will

indicate FirE when the detector activates.

Each detector on a loop should be reset before testing

the next to ensure that all detectors activate the alarm.

Heat detectors can be tested with a heat-gun using

the same method as described above.

Flame detectors can either provide a signal using

contacts, or a 4-20 mA signal.

A contact type detector will be connected as a

conventional re loop using 470 Ω series resistors

and a 1K8 end of line resistor and will only indicate

FIRE or FAULT. A 4-20 mA detector will be connected

directly as a 4-20 input, and may have various alarm

levels to indicate UV or IR activation (please refer to

the instructions supplied with the device for details).

Flame detectors require a UV or IR torch (depending on

detector type) to simulate alarms. Inhibit the relevant

channel, shine the torch at the detector and check that

FIRE is shown on the Gasmaster display. For 4-20 mA

detectors, also check that the appropriate alarm level is

displayed.

2.12.4. Testing ESU channels

To test a channel monitoring an ESU sampling device,

inhibit the channel and manually slow the device,

check that Alarm Level 1 is activated.

Manually stop the device and check that Alarm Level 2

is activated. If the alarms do not activate the thresholds

may need changing, refer to section 3.10 for details on

how to change alarm levels.

When commissioning is complete ensure that the

system is left fully functional with no faults present

and no channels inhibited.

2. Installation

17

Every Gasmaster system is pre-congured by Gas

Alarm Systems, please refer to the Specication and

Inspection Certicate provided with the product

for conguration details. This section describes the

operation of pre-congured units, and includes

procedures for altering settings.

3.1 Gasmaster Operator Panel

The Operator Panel allows you to communicate

with Gasmaster. Use it to monitor the status of all

attached eld devices, determine system settings and

conguration of eld devices. Figure 3.1 shows the

Operator Panel and typical display under normal, non-

alarm monitoring conditions.

Gasmaster Display

The User display provides continuous readings for up

to 4 eld devices plus a display area for user messages

and channel number summary. Gasmaster 1 provides

display for one eld device plus the message area.

Message display area

In normal, non-alarm condition, the message area

displays the channel numbers and detector types, e.g.

CH4 refers to methane detector, see following example.

The # symbol represents the channel number (i.e. #1 is

channel 1).

In the event of an alarm, this message area will display

the channels in alarm and their location. See section 3.8

for more information on alarm conditions.

In the case of a fault (or warning), brief details of

the fault will be displayed. See section 3.9 for more

information on fault conditions. Detailed fault and

warning messages can be found in section 3.10.

Note: User messages longer then sixteen characters are

displayed as scrolling text. If fault and alarm conditions

are present at the same time, alarm messages take

priority.

Channel display area

Gasmaster 4 has a large clear display which shows all

gas levels simultaneously. Gasmaster 1 has a display

for one gas level only, see gure 3.2. The image below

shows details of the channel display area and icons that

are used on Gasmaster.

3. Operation

This manual suits for next models

2

Table of contents

Popular Control Panel manuals by other brands

Bentel

Bentel Omnia installation manual

Controls

Controls XE-9501-AS product manual

Panasonic

Panasonic AK-HRP1005G Operation guide

Chamberlain

Chamberlain LiftMaster CB11 Instructions and electrical set up

Aprilaire

Aprilaire Zoned Comfort Control 6203 Safety & installation instructions

Honeywell

Honeywell THOR VM1 instruction manual

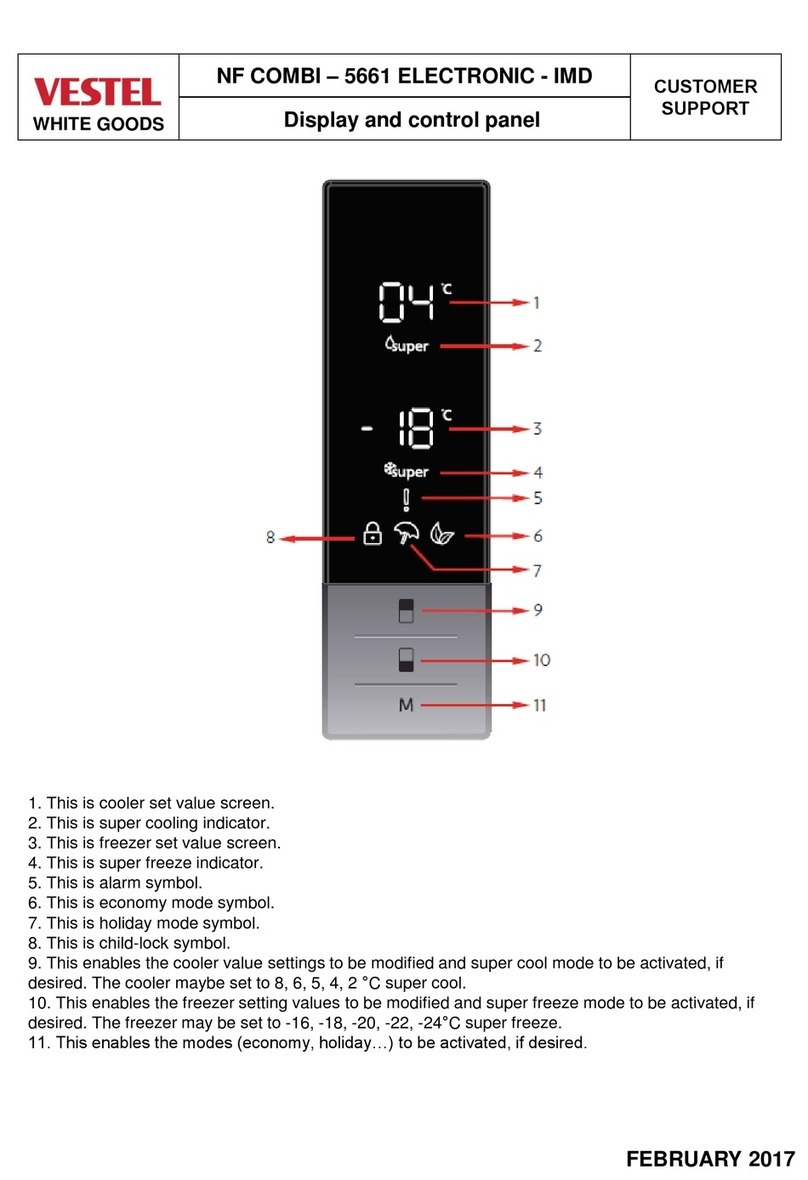

VESTEL

VESTEL NF COMBI 5661 ELECTRONIC IMD Customer support information

Danfoss

Danfoss TS715Si installation guide

QOLSYS

QOLSYS IQ PANEL installation manual

Soundoff Signal

Soundoff Signal ENGSCP7141 quick start guide

Panasonic

Panasonic AV-HS60C3G operating instructions

Helo

Helo WE-50 User and installation manual