GASDNA DA-770 User manual

Smart Digital-Process Gas Detector

Auto-Suction Type

DA-770

http://www.gasdna.com

GASDNA Co.,Ltd

http://www.gasdna.com

101, Bukhang-ro 193beon-gil, Seo-gu, Incheon, 22856, Republic of Korea

CONTENTS

■

1. Introduction

■

2. Parts and Discription

■

3. Display Discription

3

3

3

4

5

6

7

8

8

9

11

12

13

14

15

16

10

GASDNA.co.,ltd.

Best Detectors,

Best Service

17

■

4. Dimension 18

1. Introduction

2. Features

1. Parts Discription

2. Board discription

3. Specification

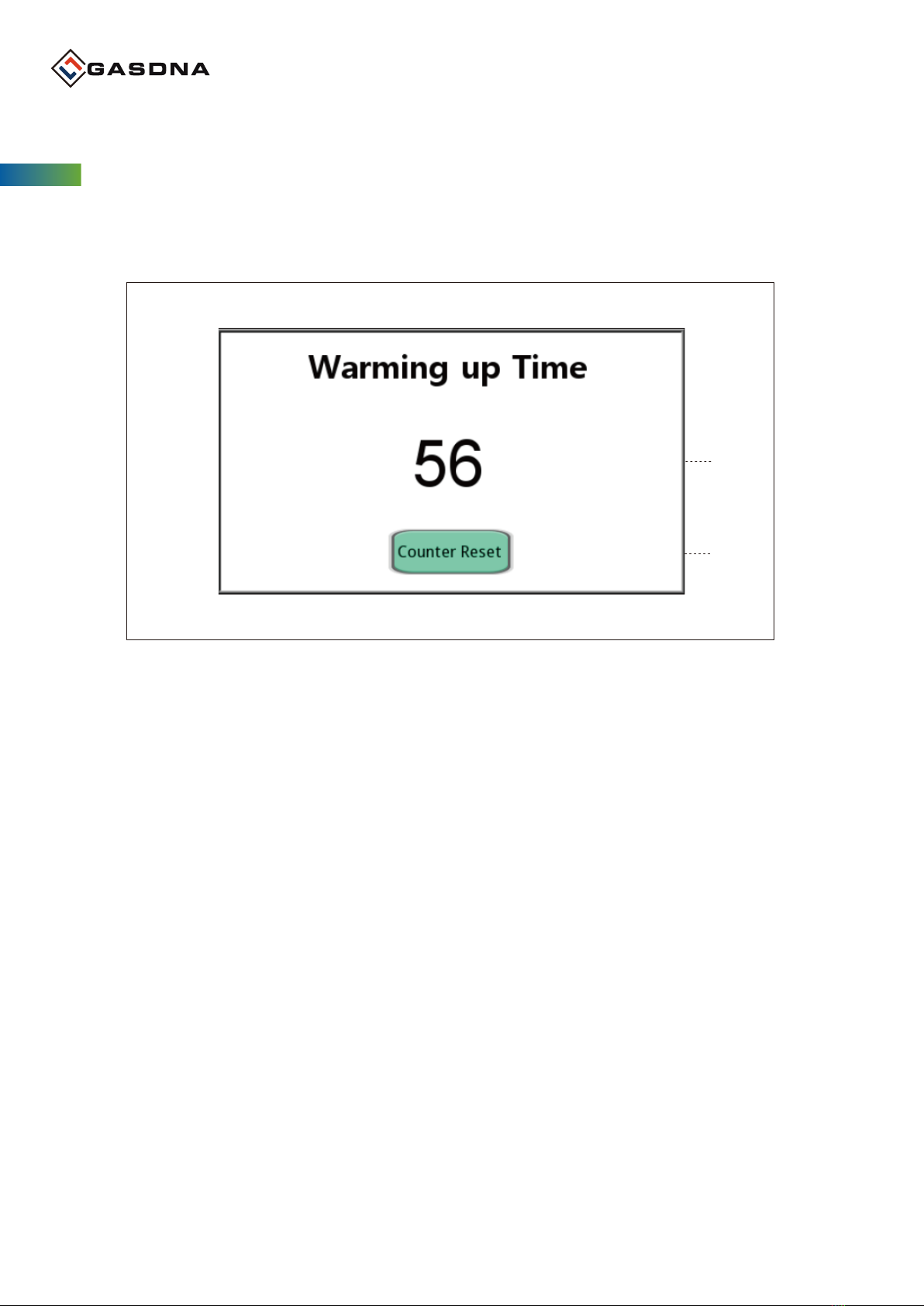

1. Warming up Time

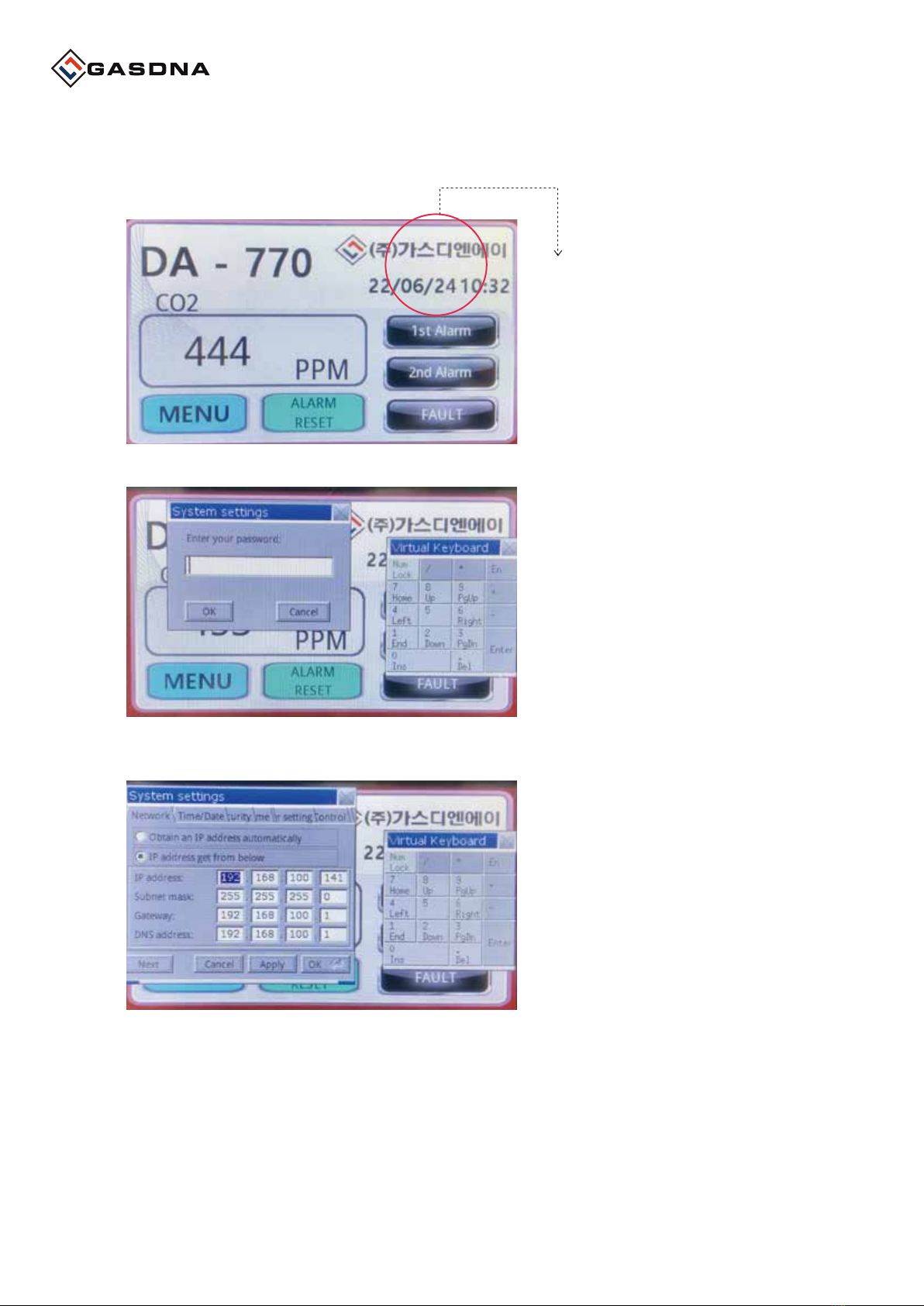

2. DA-770 MAIN

4. MENU

3. IP Setting

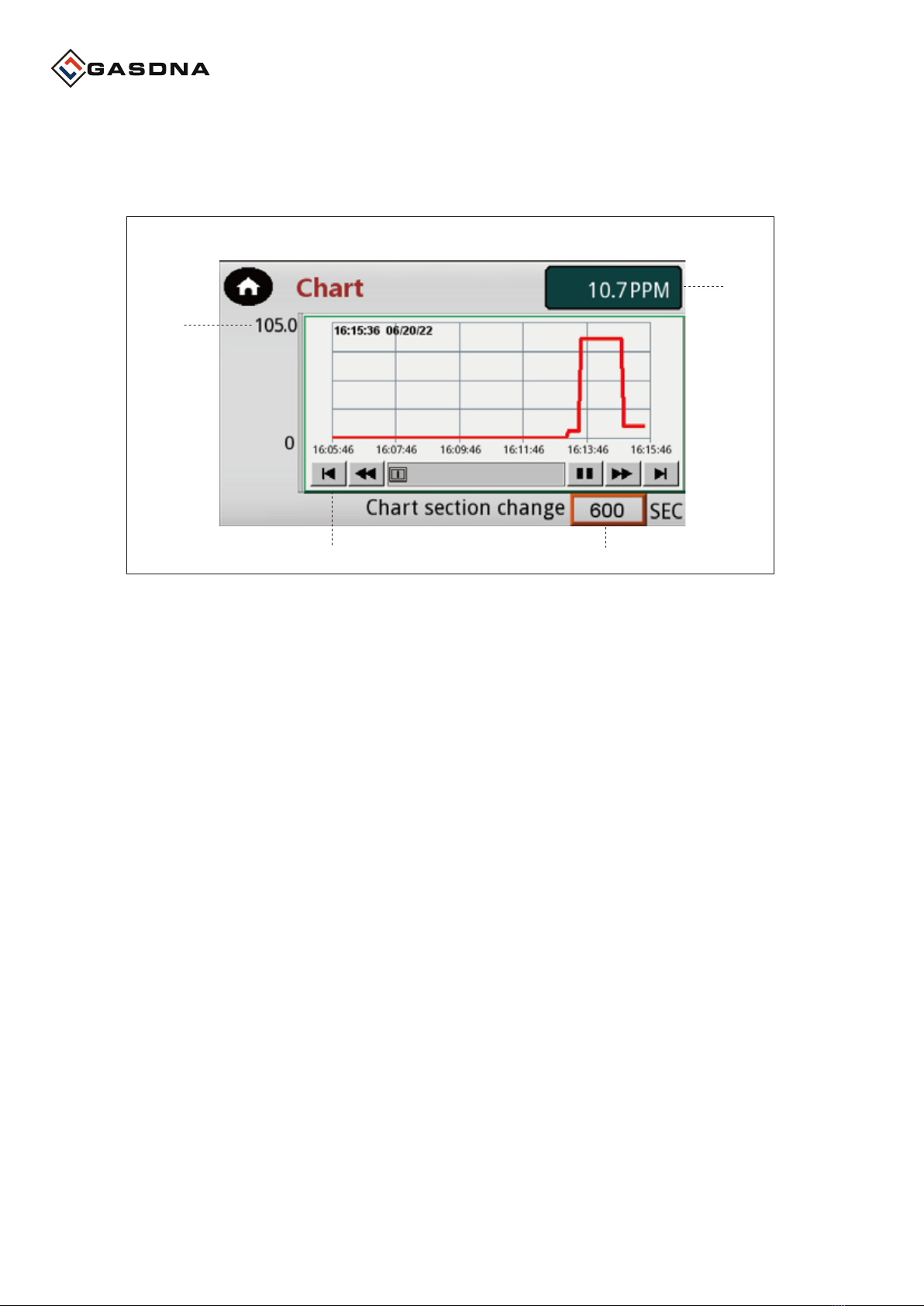

5. Chart

6. Calibration value setup

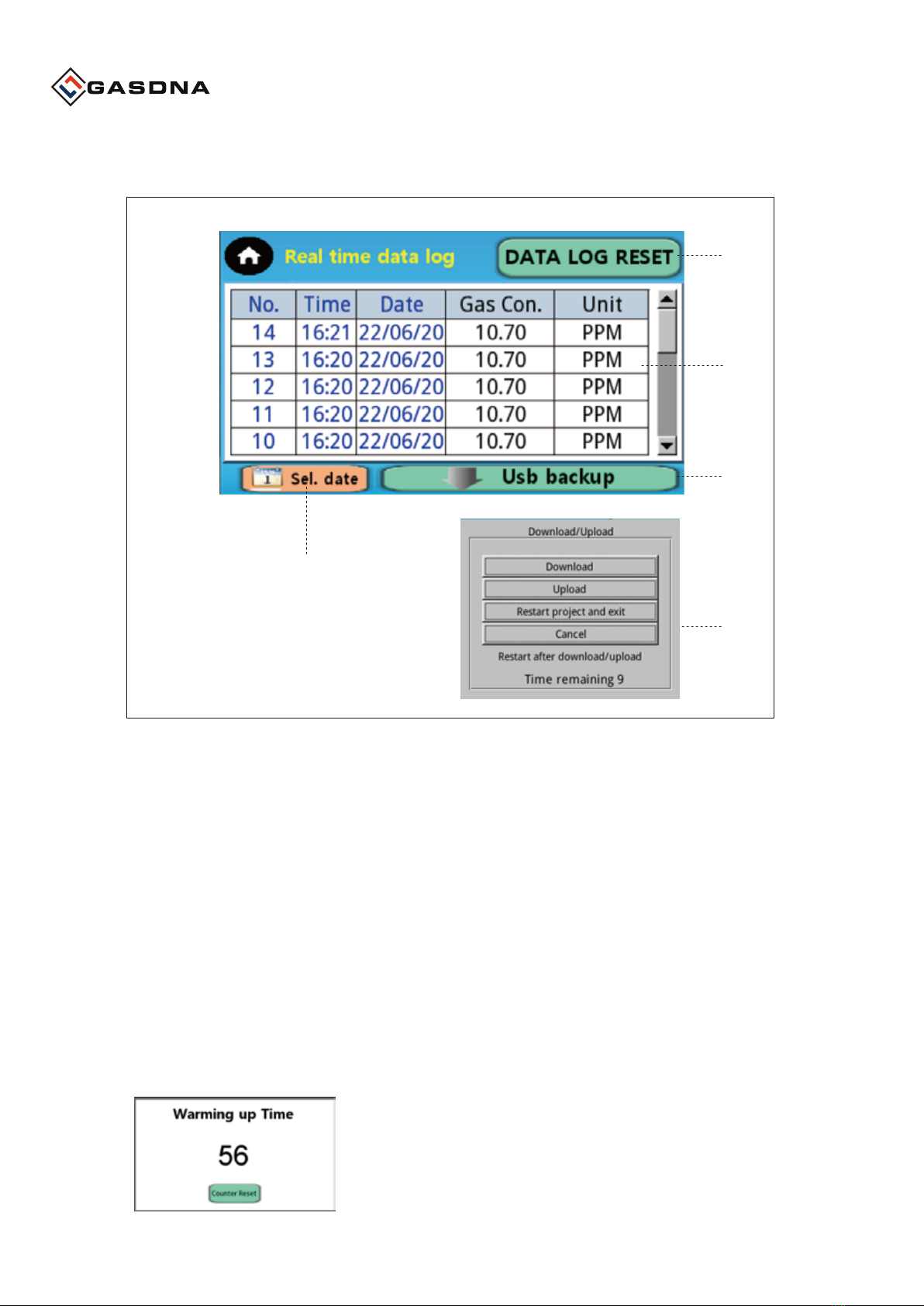

7-1. Data history(When using internal HMI memory)

7-2. Data history(When using external USB memory)

8. Sensor Setup

9. Manager Setup

3

DA-770

Best Detectors,

Best Service

1. Introduction

The Oxygen Analyzer is a product that can measure oxygen concentrations quickly and

quickly in a variety of locations, including a firing furnace, secondary battery laboratory,

process quality control, and TMS.

Continuous measurements can be made using the BLDC motor.

ㆍAutomatic suction: Continuous measurement using a micro pump

ㆍVarious signal outputs: 4-20mA, 2 Step-Relay, RS-485

ㆍOptical sensors are available in the presence of flammable gases

ㆍOxygen concentration can be measured in various environments because

it is not affected by other gases

ㆍData LOG USB Backup

1. Introduction

2. Feature

4

DA-770

Best Detectors,

Best Service

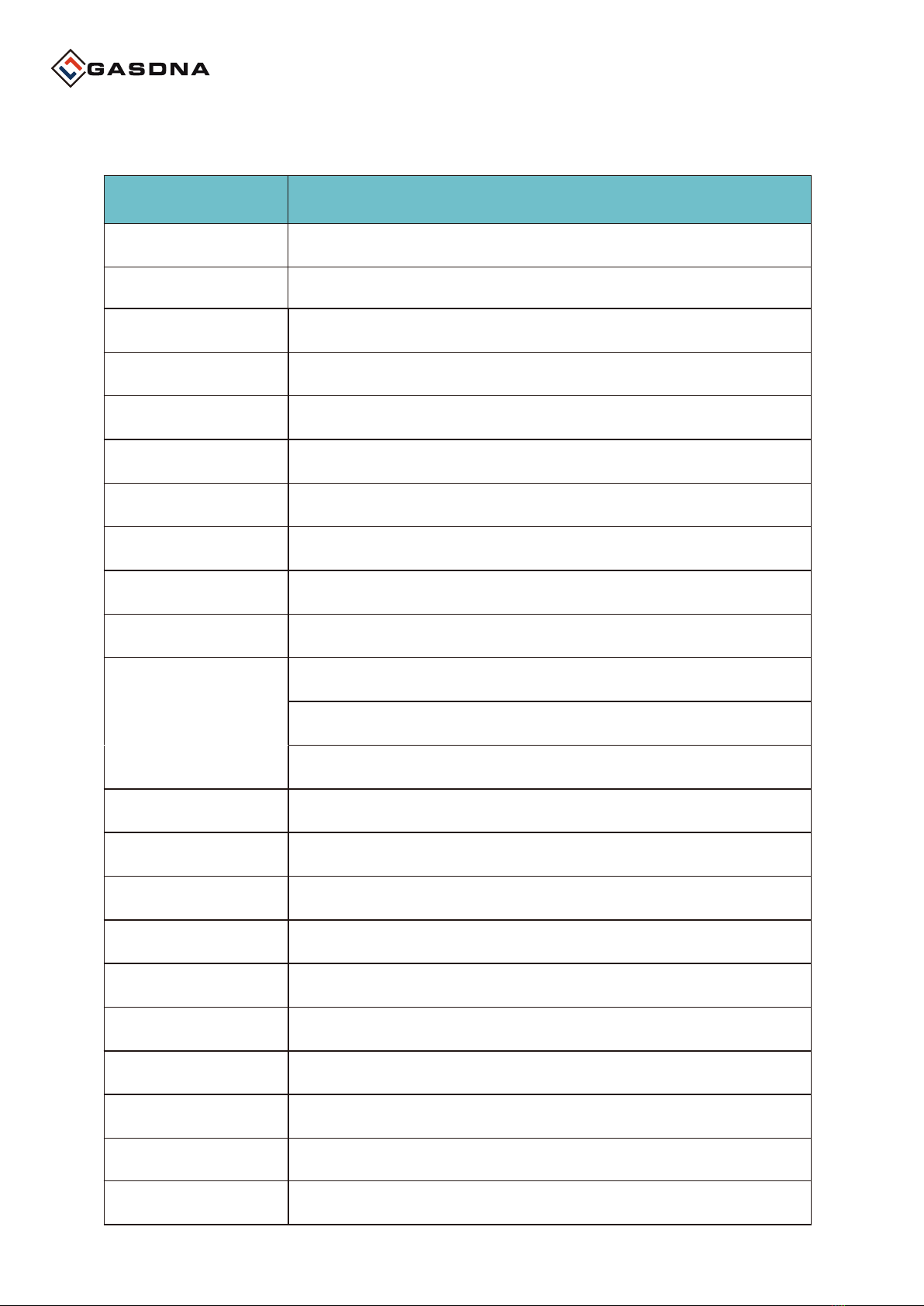

3. Specification

Gas Sampling Suction Type

Input Power AC 110 ~220 V (2.4W)

Sample Gas Volume 0.2 L/min ~ 3 L/min

Accuracy ≤ ±0.5% / Full Scale

Output Signal 4-20㎃ DC/F.S

Display 7” TFT LED (800 X 480)

Alarm Indication

Alarm 1 – AL1 LCD (YELLOW)

Alarm 2 – LCD (RED)

Fault Alarm – LCD FAULT(RED)

Setting of Alram Value AL2/AL1 2 stages Alarm-User can optionally set

Alarm Delay Time 0~99 seconds with user adjustable

Alarm Clearing Manually or Automatically

Alarm Output 2 Step Alarm Relay Contact

Operating Temperature -10℃ ~ 60℃

Operating Humidity 5 ~ 95%RH (Non-Condensing)

How to install Tabletop type

Inhalation of gas Female 1/4”

Output Option RS-485

USB Host USB 2.0 (data log download)

Gas Oxygen

Detection Principal Optical

Range 0.00 ~ 100%

Response Time T90(within 15 seconds)

Sortation Contents

5

DA-770

Best Detectors,

Best Service

5

2. Parts and Discription

④

⑨

⑩

⑧

⑥

⑦

①

② ③

⑤

1. Parts discription

6

DA-770

Best Detectors,

Best Service

① Cover Case

▷ It protects the sensor, pump, and PCB boards mounted inside from external shocks

and environmental changes.

② Flow Meter

▷ It indicates the flow rate of sample gas and you can adjust the flow rate to the position

of the ball.

③ Display(7”TFT 800X480)

▷ It displays the gas concentration values and setting parameters measured by the sensor.

④ USB PORT

▷ USB PORT only for DATA LOG BACKUP

⑥ Sample Gas Out

Sample gas vent port(1/4”)

⑦ Alarm Terminal + RS485 Terminal

▷ Fault,Alarm1,Alarm2 Relay outpur, terminal for data communication

⑧ 4-20mA Terminal(mA+,mA-)

▷ Terminal connecting 4-20mA output.

⑤ Motor Power Switch

▷ Motor Power ON/OFF Switch

⑨ Sample Gas Inlet

Sample gas inlet port(1/4”)

⑩ AC Power Switch

▷ AC Power ON/OFF Switch

2. Board Discription

7

DA-770

Best Detectors,

Best Service

Indicator or PLC

DA-770 Terminal Block

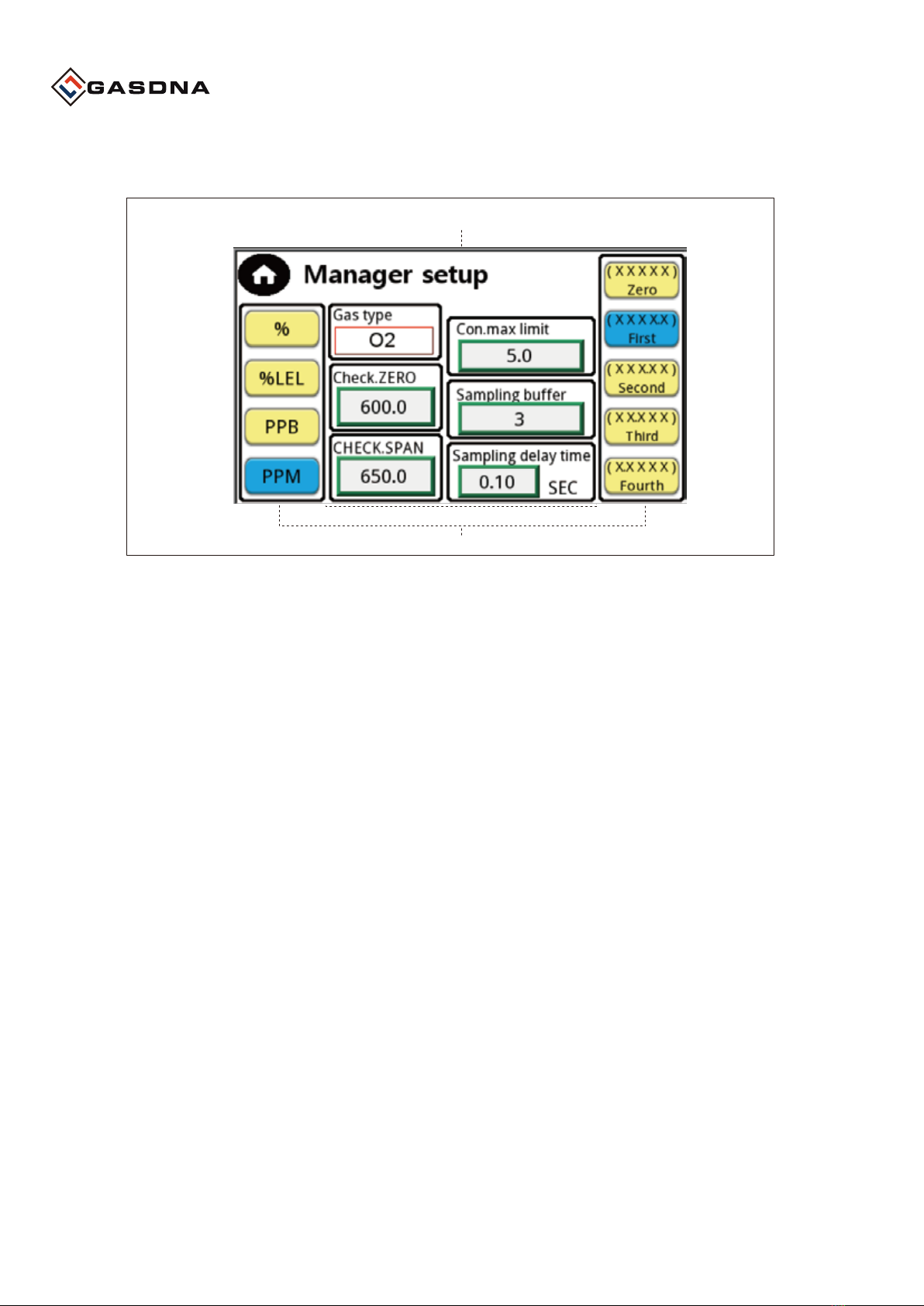

1. Warming up Time

① Warming up Time

▷ It shows the number of warm-up time at first boot. When the value reaches zero,

it automatically switches to the main screen.

② Counter Reset

▷ Force the number to initialize to zero and switch to the main screen.

8

DA-770

Best Detectors,

Best Service

3. Display Discription

①

②

④

⑤

⑥

②③

③ Menu

▷ Go to the selectable screen for the settings, data history, and chart for the detector.

▷ Press the MENU button select a language and enter

⑤ Menu and Alarm Reset

▷ When selecting the MANUAL mode in the setting alarm reset mode,

the menu and the Alarm Reset button are activated.

④ Enable Menu Button

▷ When selecting the AUTO mode in the setting alarm reset mode,

only the menu button is activated.

⑥ Gas

▷ It is an indication of the gas being detected.

9

DA-770

Best Detectors,

Best Service

①

2. DA-770 MAIN

① Relay Alarm Display

▷ The lamp is operated by the primary and secondary settings of the sensor alarm.

In case of failure, the lamp operates on the fault

② Alarm Reset

▷ It resets the lamp operation for the alarm and fault. However,

it is used when manually selecting it in the Reset setting.

3. IP Setting

10

DA-770

Best Detectors,

Best Service

Press the company logo for 5 secs.

Press password “111111” and

press “OK”

Set the IP address assigned

to the site and press the “OK” button

④

⑤

⑥

①

②

③

③ Sensor Setup

▷ It is moved to the screen where the user can change the settings for the detector.

⑤ Data history

▷ It is moved to the screen that analyzes the data on the concentration value by time.

④ Chart

▷ It is moved to a screen composed of a chart graph format by the concentration value.

⑥ Manager setup

▷ It is moved to the administrator-only setting screen, not the user's permission.

▷ Initial Password : 7420

4. MENU

① Main Screen

▷ It is moved to the main screen of the DA-770

② Calibration Value Setup

▷ It is moved to the screen that calibrates analog ZERO and SPAN.

11

DA-770

Best Detectors,

Best Service

④

①

②③

③ Chart

▷ It is expressed in graph form according to the concentration value.

The data period measurement time is 5 seconds, and the time to check the past data

is about 1 hour and 20 minutes.

④ Chart Concentration Maximum Representation

▷ It shows the maximum value for checking the concentration value on the chart.

5. Chart

① Current Concentration Value

▷ Displays the current concentration value for comparison with the chart.

② Setting the chart interval time

▷ You can check the time units displayed in the chart according to the set time zone.

The time unit consists of SEC units, and the first time the product is booted is every

one minute (expressed as a value of 0 from boot to change the setting)

After that, when changing in the section setting, it appears as the changed time zone.

12

DA-770

Best Detectors,

Best Service

④

①

② ③

③ After setting the concentration value to be calibrated, it is the final calibration button,

and you can select OK in the reconfirmation message.

④ The results after ZERO and SPAN calibration are shown.

6. Calibration Value Setup

② The ZERO calibration setting is a fixed zero value,

and only the SPAN calibration setting needs to be adjusted.

① It is the concentration value that appears now.

▷ This is where the concentration value for sensor calibration is set.

When you click the button on the concentration value notation, the keypad appears

on the screen.

The current value appears on the keypad, and you can enter a value to change it.

It is a screen that can calibrate ZERO and SPAN according to the current concentration value.

Calibration should be performed according to the current concentration value and

Check ZERO and SPAN values.

13

DA-770

Best Detectors,

Best Service

④

①

②

③

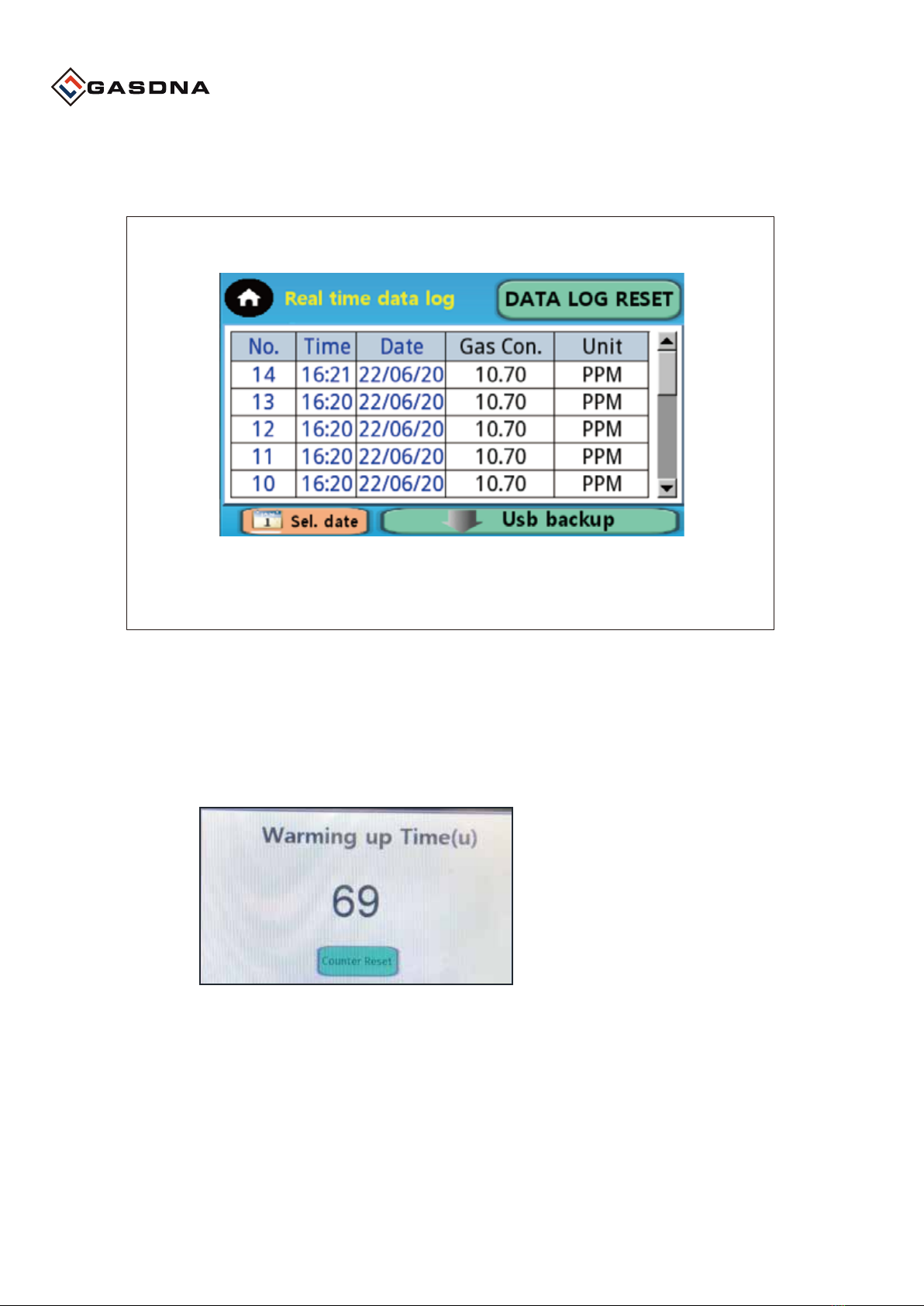

③ USB Backup

▷ The past history data may be loaded into an Excel file using USB.

Connecting method (USB port terminal – system recognition (cont. 4)

– click the usb backup button) USB path (USB / datalog / DA-770 LOG / Excel file)

Backup files load up to 10 days of data to store in internal memory.

④ Select a date

▷ You can check the date of the past history by selecting it in real time.

⑤ USB Connect System

▷ When USB is connected, the system window must appear before it can be connected.

the system window disappears after 10 seconds of cancellation

※ If there is no (u) indication on the warm-up time screen

afterpower-on, the data log is stored using the internal HMI memory.

7-1. Data history (when using internal HMI memory)

① DATA LOG RESET

▷ Not only data that appears in real time, but also data records stored inside are deleted.

If data is reset, historical data cannot be backed up.

② DATA LOG

▷ It is a screen that stores data by date and time in real time. Data is stored in 15 seconds.

⑤

14

DA-770

Best Detectors,

Best Service

※ If there is no (u) mark on the warm-up time screen after power-on, save the

data log using an external USB memory.

If you want to use data log recording, you must plug an external USB memory

into a USB port. (Maximum USB memory capacity: 32GB)

7-2. Data history (when using external USB memory)

15

DA-770

Best Detectors,

Best Service

④

⑤

①

②

③

③ High Scale

▷ 20mA setting compared to Full Scale

⑤ Alarm Reset and Automatic Control

▷ AUTO - Motor control is operated at all times.

When the value rises and ALARM occurs, it is automatically released when

it returns to a normal value.

▷ MANUAL - Press the motor button to operate.

When the value rises and returns to the normal value after ALARM occurs, the user

must RESET it on the main screen.

④ ALARM Setting

▷ Set numerical values for ALARM1/2

ex) ALARM TYPE H&H on AL1, if the display value is more than 23

when setting the numerical value, AL1 action

① ALARM TYPE

▷ High and Low settings for ALARM 1 and 2

High – Alarm above set value / Low – Alarm below set value

② data log unit indication

▷ Unit input for display in the data history log should be specified at initial boot time

OFFSET

▷ Adjusting errors for measurements

▷ Current value that appears at warm-up time

Dead Band

▷ Invalid range for alarm return recognition

Dead Time

▷ Time elapsed from alarm recognition until relay output change is recognized

Warming Time

▷ Specify the time for the initial current to stabilize

Initial current value

16

DA-770

8. Sensor setup

①

②

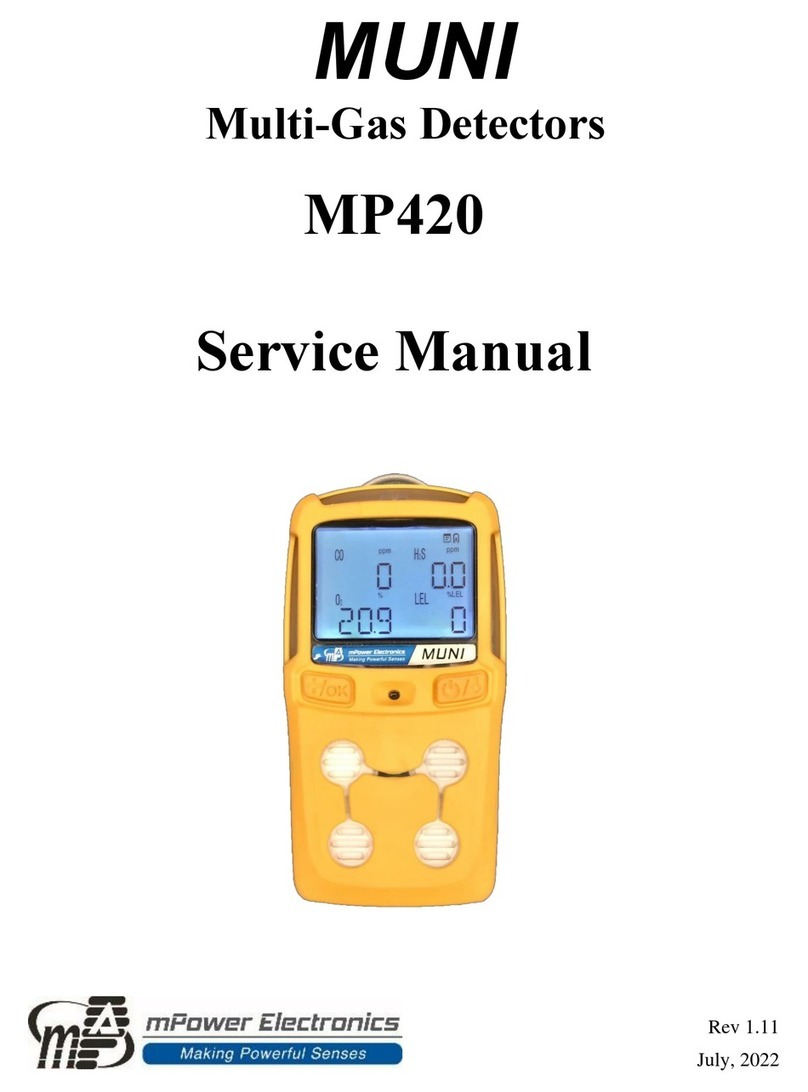

① Gas type

▷ It is a button to input the name of the gas being measured for each channel .

② Unit.

▷ Gas unit setting .

The color of the presence or absence of operation is displayed in blue .

Decimal display

Gas concentration decimal place setting .

Operation status is displayed in blue color .

Check Zero

▷ It is a button to input the name of the gas being measured for each channel .

Check Span

▷ Range limit setting during span calibration.

Calibration is performed when the gas concentration is higher than the set value.

Con.max limit

▷ This is a setting that adds an additional maximum density value above the High Scale value.

Number of sampling buffers

▷ Users can use the range from 1 to 50 .

Just calculate the average value as many as the number of sampling buffers.

Sampling delay time

▷Users can use it in the range of 0.00 ~ 3.00sec.

ex) 1 msec when 0.00 sec is set Sampling

10 msec at 0.01 sec setting Sampling

Best Detectors,

Best Service

17

DA-770

9. Manager setup

Best Detectors,

Best Service

Dimension

Front View Side View

18

DA-770

Table of contents

Other GASDNA Gas Detector manuals

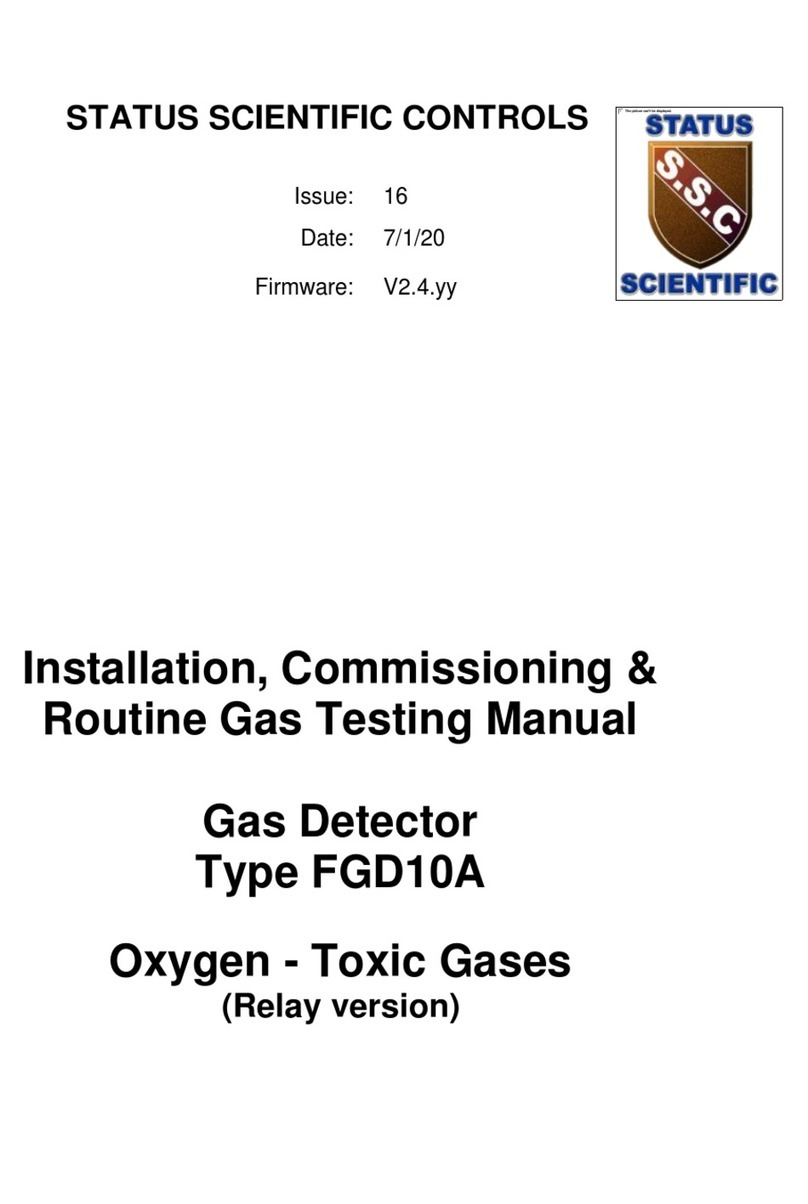

Popular Gas Detector manuals by other brands

STATUS SCIENTIFIC CONTROLS

STATUS SCIENTIFIC CONTROLS FGD10A Installation, Commissioning & Routine Gas Testing Manual

WatchGas

WatchGas POLI quick start guide

SENSIT Technologies

SENSIT Technologies GOLD G3 instruction manual

Compur Monitors

Compur Monitors Statox 560 Getting started

mPower Electronics

mPower Electronics MUNI Service manual

GasTech

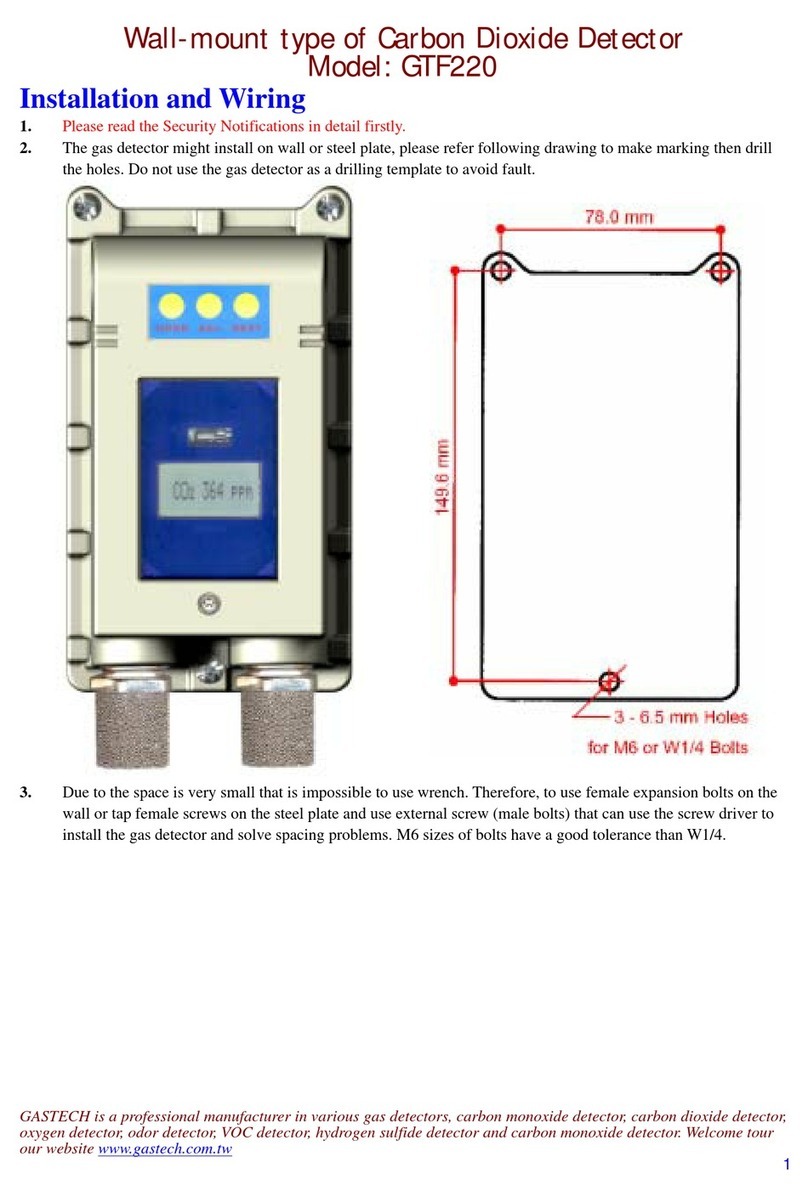

GasTech GTF220 manual

FIBARO

FIBARO CO Sensor FGCD-001 user manual

S&S Northern

S&S Northern Merlin Series Installation, operating and maintenance

Zehnder Rittling

Zehnder Rittling CO2 Sensor Manual for the user

Gas Clip Technologies

Gas Clip Technologies Multi Gas Clip user manual

YEEZOU

YEEZOU Y201 manual

Dräger

Dräger X-am 3500 Instructions for use