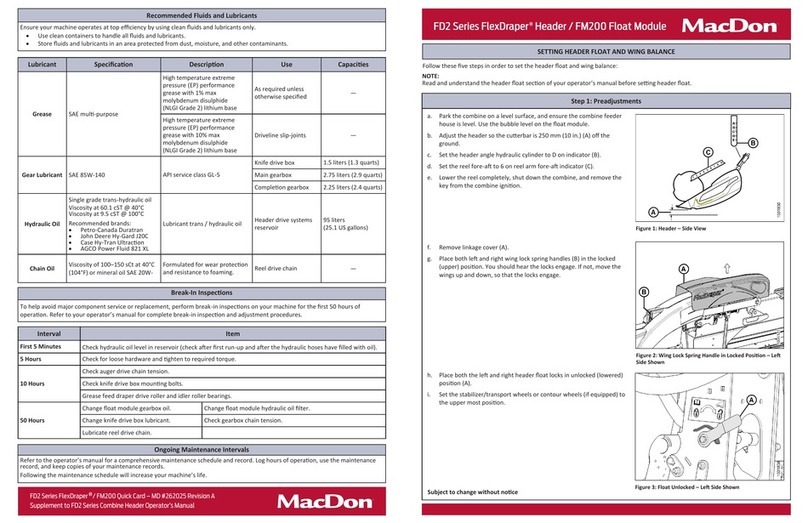

Gason NT8000 Programming manual

COPYRIGHT

Neither this manual or part thereof may be reproduced or published

without the prior permission of AF Gason Pty Ltd

Operators & Parts

Manual

SCARITILL, HYDRATILL

GPN 235554 REV* - 08/07/19

OH&S Compliance Certification

Company Name A.F. GASON PTY LTD

A hazard identification, risk assessment and risk control procedure has been carried out on a representative example of the under men-

tioned product(s) in accordance with the Occupational Health and Safety requirements of all states and territories of Australia and where

found necessary the appropriate risk control measures have been incorporated in the product specifications.

The operator’s manual contains the necessary health and safety information and safety warnings are applied to the product where neces-

sary.

Product Description NT8000 –8m Narrow Transport Width Planter

Models No. or No.’s SNT8000-XX-XXX, HNT8000-XX-XXX

Signed on behalf of the above named company

Name (printed) Tom Mccluskey

Position Design Engineer

Date 03/04/2019

Details of the Unit Assessed for the Purpose of Compliance

Model No. SNT8000-32-250

Serial No. 235555-00001

Date of Inspection 18/01/2019

Location of Inspection ARARAT, VICTORIA

Contents

Safety .........................................................................................................................................5

NT8000 Specifications................................................................................................................8

Transport Dimensions................................................................................................................9

Unloading From Transport.......................................................................................................10

Assembly..................................................................................................................................10

Operating the NT8000 .............................................................................................................12

Connection/Disconnection ..................................................................................................13

Tractor Requirements..........................................................................................................13

ScariTILL Operation..............................................................................................................13

HydraTILL Operation............................................................................................................13

Road Transportation............................................................................................................14

Depth Control Circuit ...........................................................................................................14

Wing Fold Circuit..................................................................................................................15

HydraTILL Circuit..................................................................................................................15

Pre - operation Checklist......................................................................................................16

Maintenance............................................................................................................................17

10 Hours or Daily..................................................................................................................17

100 Hours or Weekly ...........................................................................................................17

500 Hours or Seasonally ......................................................................................................17

Cleaning and Storage ...........................................................................................................17

Tyre Care..............................................................................................................................18

Bush Replacement ...............................................................................................................18

Wheel Bearing Maintenance ...............................................................................................18

Hard Facing Keech Adaptor .................................................................................................19

Replacement of Keech Adaptor...........................................................................................19

ScariTILL Tine Assembly .......................................................................................................20

Nordon Cylinders .................................................................................................................21

Owner Acknowledgement .......................................................................................................25

Spare Parts...............................................................................................................................27

SNT8000 & HNT8000 Models ..............................................................................................27

ScariTILL (Spring) Tine Assembly..........................................................................................28

HydraTILL (Hydraulic) Tine Assembly...................................................................................30

Shank Options......................................................................................................................32

NT8000 Assembly.................................................................................................................34

Centre Frame Assembly.......................................................................................................36

Left Wing Assembly..............................................................................................................38

Right Wing Assembly ...........................................................................................................40

Depth Indicator Kit...............................................................................................................42

Decals...................................................................................................................................43

Optional Seeder Mount Kit –1200 Series IM2 Seeder........................................................44

Optional Rear Tow Hitch Kit - 1700 Series Seeder...............................................................44

Optional Rear Tow Hitch Kit - Controlled Traffic Castor......................................................45

Optional Rear Tow Hitch Kit - Controlled Traffic Steerable.................................................46

Stub Axle Assembly..............................................................................................................47

Hydraulic System –Wing Fold .............................................................................................48

Hydraulic System –Depth Control.......................................................................................50

Optional Hydraulic Hitch Leveller ........................................................................................52

Hydraulic Hose Clamp Assembly..........................................................................................53

HydraTILL Plumb Kit –250mm Spacing ...............................................................................54

Layout - 178mm Spacing –45 Tines ....................................................................................56

Layout - 250mm Spacing –32 Tines (Optional Presswheels Shown) ..................................57

Layout - 308mm Spacing –26 Tines (Optional Presswheels Shown) ..................................58

Introduction

1

AF Gason Pty Ltd (Gason) is an Australian

owned family business operating from within

rural Victoria. The Gason Company has been

servicing the needs of rural Australians for

over 70 years. We operate through a local

dealer support network that spans the coun-

try. Gason would like to thank you for pur-

chasing your Australian made tillage imple-

ment, and trust that you will have many years

of trouble free service.

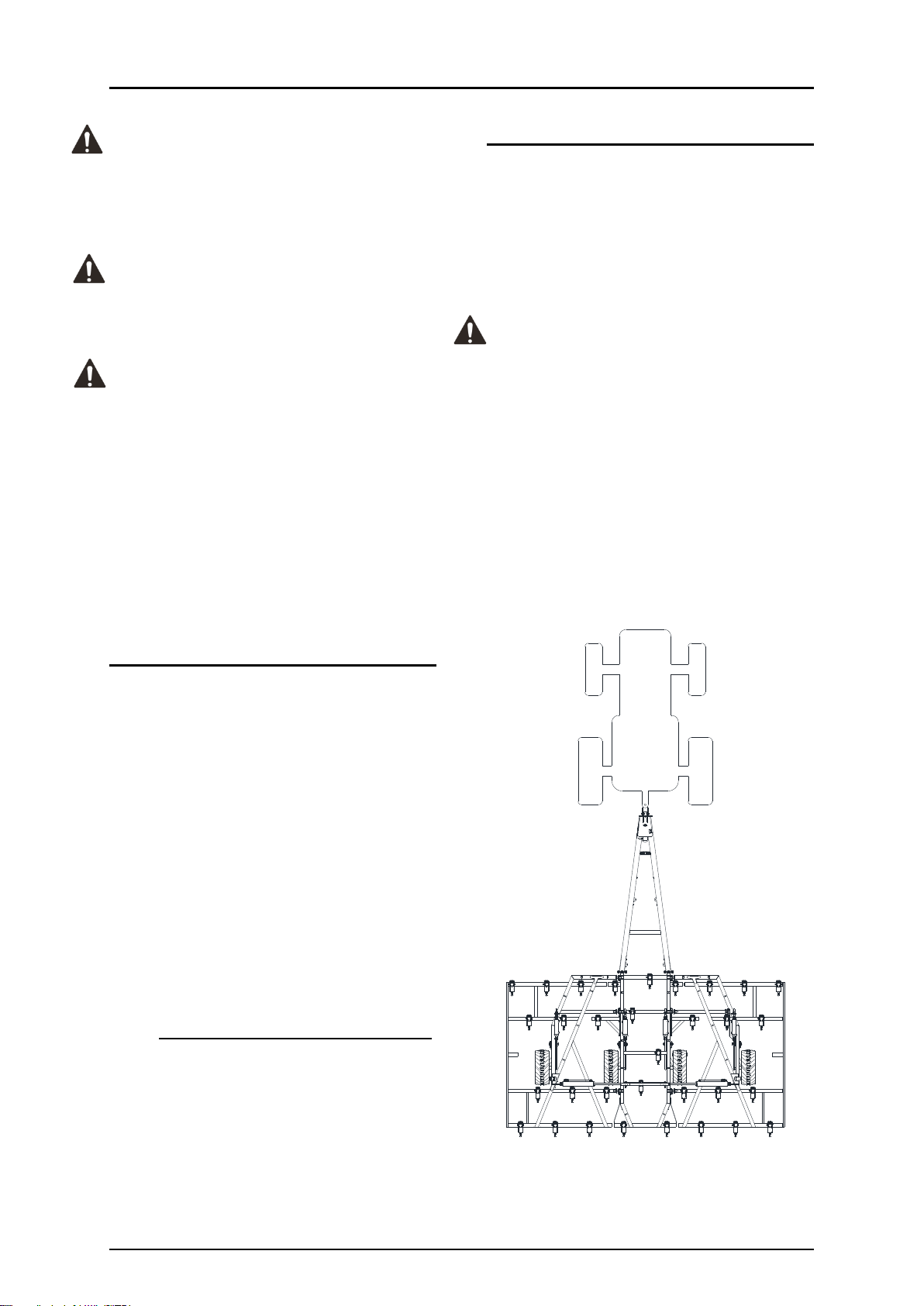

The NT8000 is an 8m wide planter that utilizes

five 100x100x9mm toolbars welded in a ro-

bust frame designed to fold up to 3.5m wide

for road transport. The NT8000 provides a

versatile platform that can be optioned with

the HydraTILL hydraulic tine assembly and the

ScariTILL spring tine assembly as well as the

Parallelogram and Toolbar Mounted Press

Wheel Assemblies. The NT8000 accommo-

dates 2m Controlled Traffic practices with its

2.0m wheel centers and 8.0m effective work-

ing width.

A) HydraTILL Tine with optional Parallelogram

Presswheel.

B) ScariTILL shown with optional Frame Mounted

Presswheel.

Gason ScariTILL and HydraTILL tines accept a

50mm x 25mm vertical shank with upper

holes enabling vertical adjustment. These tine

assemblies have been proven over many

years of use. Various points and sowing boots

are available.

Ideally coupled to a Gason Air Seeder as a

minimum till planter, the NT8000 can also be

used for conventional weed kill/soil prepara-

tion. With various tools and options the

NT8000 can be setup to perform a variety of

tasks depending on specific agronomic re-

quirements. These may include:

Conventional cropping: Multiple cultivations

before sowing for weed control and seed bed

preparation.

Direct drilling: One pass sowing system with

wide or full cut points for some soil disturb-

ance.

Minimum-till: Sowing systems aimed at mini-

mizing soil disturbance and retaining crop res-

idues.

2m Controlled Traffic: 4 wheels are mounted

inside the frame at 2.0m centres.

The NT8000 is equipped with 4 single 400/60-

R22.5 flotation tyres and wheel mounted in-

side the frame, which ensure easy turning and

contouring, and maintain tracking. The wheels

are positioned to obtain maximum clearance

for working tools and also cater for tight turn-

ing. The frame has been designed to maximize

stubble flow and provide uniform finishes

while accommodating multiple layouts.

A B

Introduction

2

Caution: This implement has been developed

for maximum residue/stubble flow. If work-

ing around hillsides, pairing of rows may oc-

cur.

Caution: Correct seed depth is critical to suc-

cess. Check seeding depth regularly during

sowing.

Caution: Fitment of additional attachments

such as anhydrous ammonia tanks and

prickle chains, which may place significant

loads on the frame, will void warranty on the

frame and any related components. Approved

attachments include, toolbar mounted press

wheels, parallelogram assemblies as well as

Gason’s range of mounted and trailed air

seeders. If unsure as to the warranty implica-

tions to any attachment or modification that

you wish to make to your NT8000, consult

your local authorized Gason Dealer.

To The Dealer

Assembly and proper installation of this prod-

uct is the responsibility of the Gason dealer.

The dealer and owner/operator must com-

plete & sign the Installation and Warranty

Registration Form included with this manual

before releasing the Implement to the new

owner.

Purchaser copy to be supplied to owner.

Dealer copy to be retained by dealer

Company copy to be returned to Gason.

In addition, the dealer must complete the

Dealer Pre-Delivery & In-field Commissioning

Check List included within this manual.

Gason strongly recommend a risk assessment

be carried out prior to the machine being op-

erated to ensure the operators fully under-

stand the dangers involved in the operation of

the Gason Tillage Implement.

About this Manual

This manual endeavors to provide the owner

with a complete understanding of the NT8000

implement’s safety, assembly, maintenance

and operation including the processes re-

quired to obtain the highest level of perfor-

mance possible.

Caution: It is of the utmost importance that

the owner/operator read this manual, and

any other literature that has been supplied

with the machine, to ensure a safe and trou-

ble free operation.

References to the left and right hand sides of

the Implement are from the rear of the ma-

chine looking forward in direction of travel as

shown.

LEFT RIGHT

Introduction

3

To The Owner

Caution: Read & understand this manual

before operating your Gason Implement.

The information presented will prepare you to

operate your machine in a more efficient and

safer manner.

This manual should ideally be kept in its pro-

tective satchel and stored with the machine.

Replacement manuals are available upon re-

quest from Gason or online at

www.gason.com.au. Replacement “holders”

are available through your nearest dealer.

The manual includes an Installation and War-

ranty Registration Form, of which, requires

the dealer & the owner/operator to sign. The

Purchaser copy of this form is to remain with

the owner/operator.

Caution: Ensure you carry out, and keep up

to date, a Risk Assessment. All operators

must read the manual carefully and become

acquainted with all the adjustments and oper-

ating procedures before attempting to oper-

ate.

The Implement you have purchased has been

carefully engineered and manufactured to

provide dependable and satisfactory use

when operated & maintained in line with this

manual. Like all mechanical products, it will

require routine cleaning, upkeep and mainte-

nance. Lubricate the implement as specified in

this manual. Observe all safety information in

this manual and obey all safety decals located

on the machine.

Please be aware that in an effort to bring you

the best products Gason are always imple-

menting continuous improvements that may

change the designs and specifications of the

implements. In doing this, Gason, together

with its dealers and distributors, are under no

obligation to implement such changes, free of

charge, on any previously delivered machines.

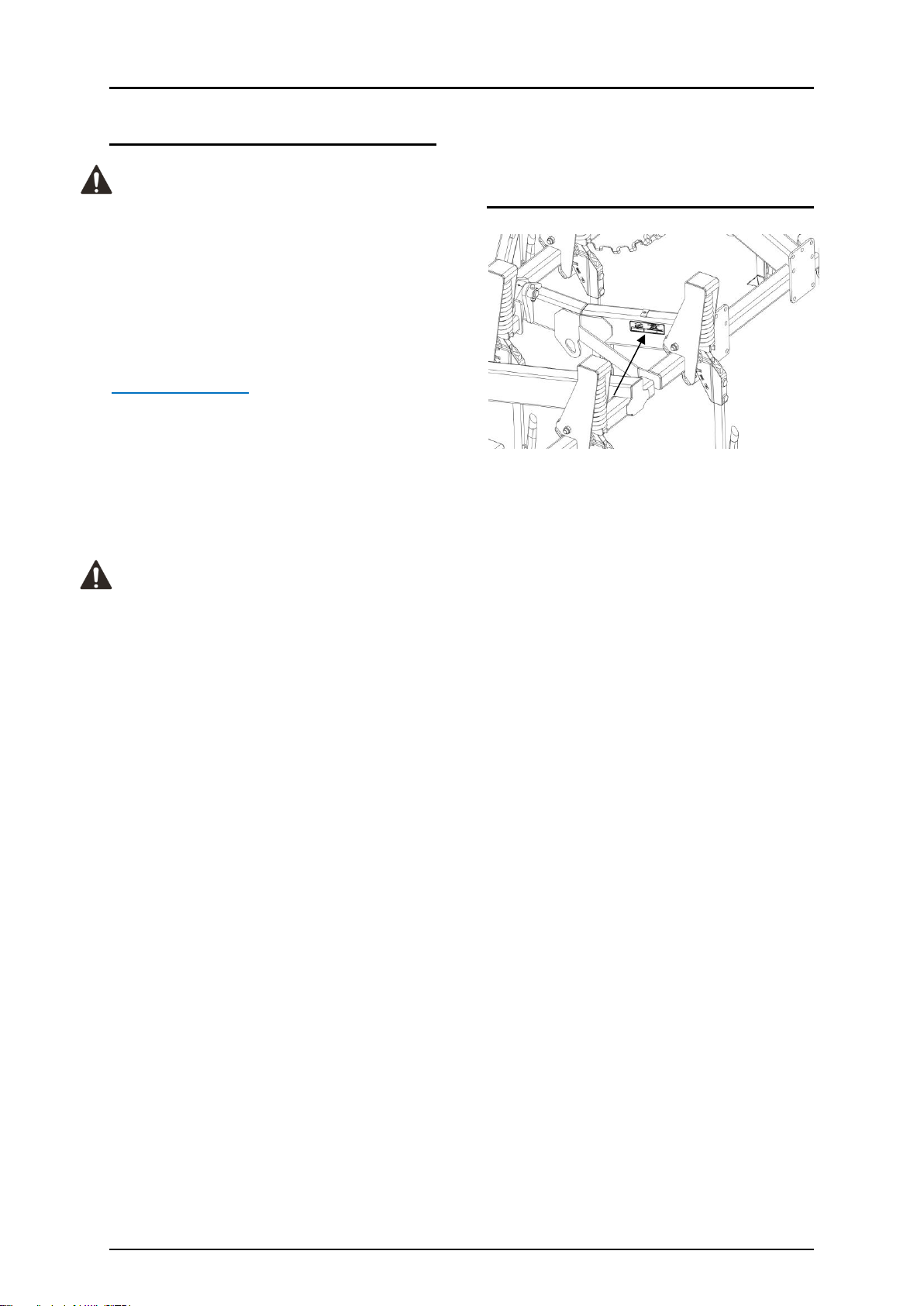

Machine Record

Serial No. Tag Located at left hand rear of cen-

tre frame.

Tine Spacing: __________________________

Number of Tines:_______________________

Serial Number: ________________________

Model: _______________________________

Date Purchased: ________________________

Owner Name: __________________________

Owners Address: _______________________

_____________________________________

_____________________________________

Options Fitted: ________________________

_____________________________________

_____________________________________

_____________________________________

_____________________________________

SERIAL No. TAG

Introduction

4

Dealer Pre-Delivery & In-Field Commissioning Check List

The following must be carried out upon machine delivery to customer

Tick to confirm action

√

Customer has ensured that Machine is correct for the required application.

Customer has checked tractor specification to ensure machine is suited to tractor.

Customer has checked all items are received as per order.

Machine Assembled Correctly as per Operators Manual instructions.

Check Wheel Nuts for correct torque (refer maintenance section)

Tyre Pressures are correct as recommend.

Grease all grease nipples; hinges and wheel assembly pivots.

Check for Hydraulic Oil leaks.

Air purged from Hydraulic Circuits and tractor’s hydraulic oil level is OK.

Ensure Depth Control cylinders are phasing correctly (synchronized).

Ensure Machine is level front to rear at working depth.

Ensure Machine is level across the width.

Ensure lock nuts on depth control adjustment are locked tight.

Check for correct tractor to tow bar connection.

Implement safety chain fitted to tractor.

Ensure all shanks and press wheels set at consistent settings across machine, (If prac-

tical set machine to operator’s initial operation settings).

Check Air Seeder Distribution for kinks and obstruction through all working ranges

(where applicable).

Check row spacing is correct. (At initial operation, drive in straight line, lightly scratch-

ing machine along flat ground. Measure distance between marks).

Owner has viewed the Operators Manual.

Owner instructed on correct maintenance and safe operation of machine.

Owner and operators instructed on phasing cylinders depth stop use and

Owner and operators instructed to fully extending wing fold cylinders when operating.

Owner has agreed to train all operators in the safe use of the machine.

Pre delivery and in field commissioning by:

NAME:

DATE:

SIGNED:

Safety

5

Safety

Gason rate operator Safety as one of the high-

est priorities when designing new features and

machines. Every effort is taken to consider the

end user and the safety risks they may face.

Accidents can Disable & Kill

Accidents are Costly

Accidents Can be Avoided

Safety Alert Symbol

The Safety Alter Symbol

means:

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

The Safety Alert Symbol identifies important

safety messages applied to the Implement in

this manual. When you see this symbol, be alert

to the possibility of injury or death. Follow the

instructions provided on the safety messages.

Throughout this Manual the Safety Alert Symbol

will be seen followed by one of the words.

Signal Words

DANGER: indicates an imminently hazardous sit-

uation that, if not avoided, WILL result in death

of serious injury if proper precautions are not

taken.

WARNING: Indicates a potentially hazardous sit-

uation that, if not avoided, COULD result in

death or serious injury if proper precautions are

not taken

CAUTION: Indicates a potentially hazardous situ-

ation that, if not avoided, MAY result in minor or

moderate injury if proper precautions are not

taken, or, serves as a reminder to follow appro-

priate safety practices.

Safety

6

General Safety

Whilst great care and every effort have been

made by Gason to provide a machine to the

highest possible safety standards, tillage imple-

ments by their nature are potentially danger-

ous.

Read and understand this manual and the man-

ual of the tractor towing the implement. Know

your machine and its limits and operate within

them. If in doubt, ASK!

Be Prepared

In the event of an emergency it is best to be

prepared. Gason recommend whilst operating

the Implement, a fire extinguisher and first aid

kit should be readily available in the event that

they might be required.

Safety Decals

All Gason Tillage Implements are provided with

a complete set of decals which include im-

portant safety information and are required to

ensure the machine complies with the relevant

work safe regulations. Every effort should be

made to ensure the decals are legible at all

times. Any decal which can be seen to be worn

or can no longer be read should be replaced.

For a detailed list of Decals and their positions

on the machines refer to the Parts section of

this manual.

Safety Rules

Danger: Do not operate the tractor or Im-

plement until you have fully read and com-

pletely understand this operator’s manual, your

tractors operator’s manual, and all safety mes-

sages found within these manuals, on the prod-

ucts, or other included material.

Warning: Ensure all operators are properly

instructed on the operation of the machine and

position of controls. Do not allow anyone to oper-

ate the machine without proper instruction.

Warning: Know your controls and how to

stop the machine quickly in an emergency.

Warning: Keep hands and body away

from pressurized lines. Wear safety glasses to

protect eyes. Hydraulic fluid (oil) under pressure

can easily penetrate the skin, ensure all opera-

tors and service personnel are aware that if hy-

draulic fluid (oil) penetrates the skin it will need

to be surgically removed. Failure to do so may

result in serious injury or death.

Danger: Stand clear when folding or un-

folding wings.

Caution: Check that all hardware is tight

and properly installed. Refer Assembly Torque

table.

Caution: Ensure the implement is

properly attached, adjusted and in good work-

ing order before operating the machine.

Caution: Remove any debris that has ac-

cumulated on the implement or tractor.

Danger: DO NOT allow persons to ride on

machine during operation or transport.

Safety

7

Caution: For transportation on public

roads the operator must ensure that the tractor

and Implement complies with current state and

federal laws and must strictly adhere to all road

traffic regulations.

Warning: Use Extreme care and reduce

ground speed on slopes and rough terrain.

Warning: DO NOT transport implement in

excess of 20km/h.

Warning: DO NOT exceed 10° roll angle

with wings folded.

Caution: Always double check before re-

versing machine.

Danger: Never place any part of the body

underneath tines. Hydraulic systems can

“creep” (i.e. slowly lower). Any movement of

the control levers can cause the implement to

drop or move unexpectedly causing severe in-

jury or death.

Warning: DO NOT adjust Hydraulic fitting

while under pressure. Ensure pressure is re-

leased using tractor’s hydraulic system before

adjusting or disconnecting Implement.

Warning: Never remove hydraulic hoses or

ends with machine elevated. Relieve hydraulic

pressure before disconnecting hydraulic hoses

or ends.

Caution: Maintain sufficient hydraulic fluid

levels to ensure air is not introduced into the

system.

Caution: Keep all connectors clean for pos-

itive connections.

Caution: Ensure all fittings and hoses are

in good condition.

Disclaimer

Gason accepts no responsibility or liability for any losses, injuries or damages

that may result from failing to observe these safety rules and the safety decals

on the Implement.

Specifications

8

NT8000 Specifications

Machine Dimensions

Overall Length

9.80m

Overall Unfolded Width

8.10m

Frame Depth (front to rear)

4.20m

Overall Road Transport Width

3.495m

Overall Road Transport Height

4.55m

Road Clearance:

250mm (10”)

Max. Recommended Working Depth:

150mm (6”)

Overall Weight

8.0t **

**Approximate weight only, varies depending on configuration and attachments

Tine Spacing

Number of Tines

Effective Working Width

178mm (7”)

45

8.0m

250mm (10”)

32

8.0m

308mm (12”)

26

8.0m

No. of Toolbar Rows:

5

Toolbar Spacing:

1.0mtyp.

Toolbar Section:

100 x 100 x 9.0mm RHS Grade 450

Drawbar Section:

150 x 250 x 6.0mm RHS Grade 450

ScariTILL:

Breakout Force

180kg (400lbf)

245kg (540lbf)

Underframe Clearance

760mm to 660mm (30” to 26”) in 12.5 mm (½”) increments.

Tine Jump

350mm (13.8”)

HydraTILL:

Breakout Force Hydraulic

140kg to 310kg (310lbf to 680lbf)

Underframe Clearance

760mm to 660mm (30” to 26”) in 12.5 mm (½”) increments.

Tine Jump

350mm (13.8”)

Tyres:

400/60-22.5 18PLY Tubeless Floatation Tyre

Wheel Centre Width:

2.0m (2m controlled traffic)

Hydraulic Hoses (depth & wing fold)

½’’ I.D. SAE100R2 hose (non-skive)

Maximum Road Transport Speed:

20km/h

Specifications

9

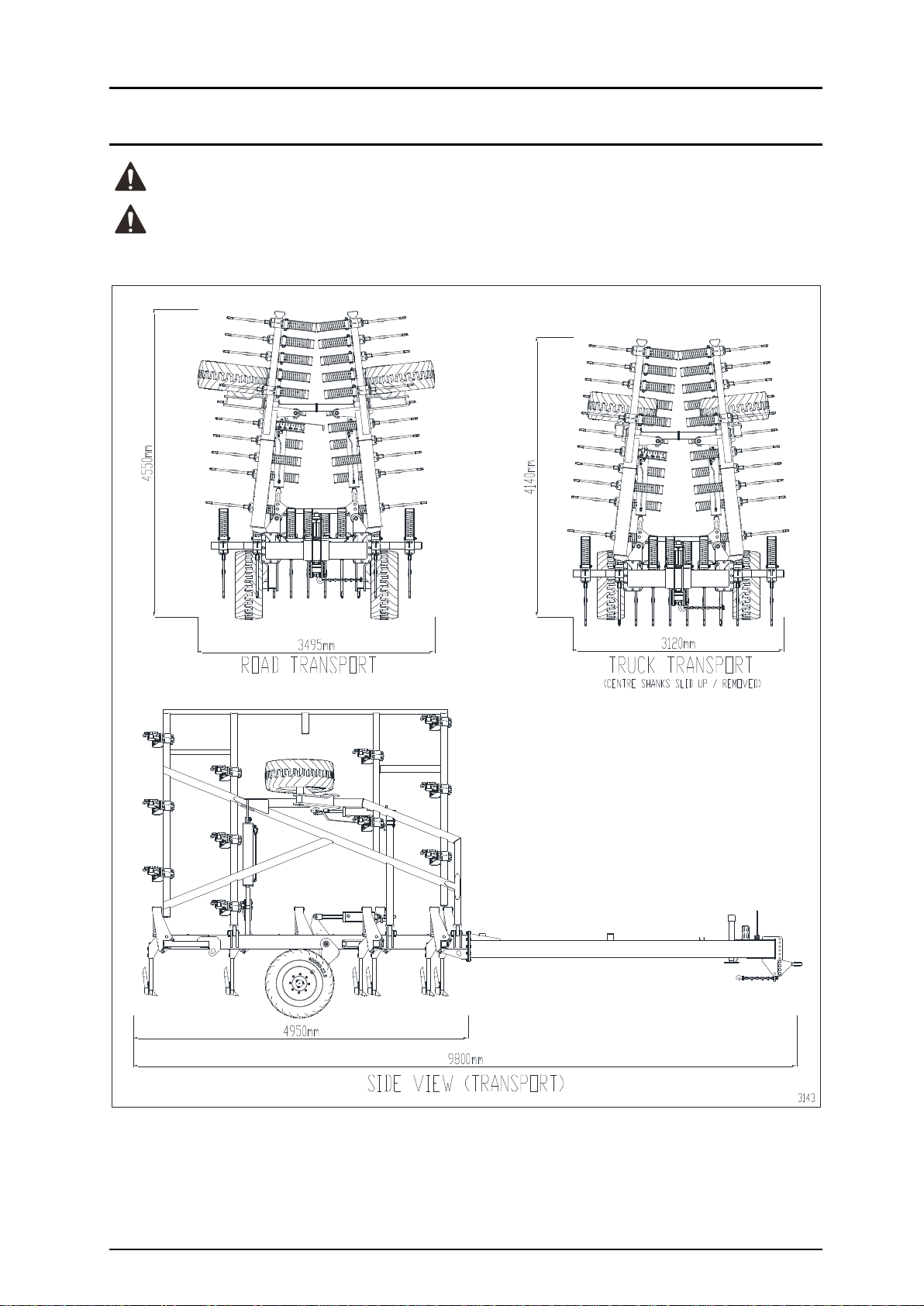

Transport Dimensions

Caution: Dimensions will vary depending on the machine configuration.

Warning: The machine can be configured such that the road transport width exceeds 3.5m.

Unloading and Assembly

10

Unloading From Transport

Because of the compact nature of the

NT8000, most machines will be delivered as-

sembled ready to be towed off the truck. If

not assembled or unable to be towed off

machines must be lifted by approved over-

head lifting gear and licensed operators.

Warning: Only qualified personnel are

to be involved with the lifting of machine.

Bystanders must remain clear at all times.

Danger: Ensure that all lifting equip-

ment is in good condition and has the ca-

pacity to lift the load. Do not lift unless the

weight is known or a reasonable assumption

of weight is determined.

Note: Gason dispatch department measure

and record the load & other lift information

on a Crane Lift form*. A copy of this form is

given to the truck driver for use at the un-

loading end.

If lifting points are around the RHS frame

use soft slings. Avoid excessive paint dam-

age, if chains must be used, ensure paint-

work is protected.

Assembly

If the NT8000 is transported partially disas-

sembled, items that may require assembly

are as follows:

Fitment of wheels and tensioning to cor-

rect torque. Wheels may have been re-

moved depending on transport height

required.

Fitment of pull.

Fitment of tines / press wheels to the

marked position.

Shank Fitment.

Reconnection of hydraulic hoses, secur-

ing hoses in clamps and priming hydrau-

lic circuits.

Fitment of implement depth indicator.

Ground tool Fitment.

Touchup of paint work if required.

Wheel Fitment - If wheels have been re-

moved for transport, loosely mount wheels

on hubs. Be Gentle. Avoid damage to

threads. Tighten all nuts firmly then proceed

to torque each wheel nut to 350N.m. Alter-

nating sides across stud pattern when tight-

ening up nuts.

Fitting Pull –the pull may be removed for

transport. Using a crane, position & fit the

drawbar to the front of the centre frame us-

ing the bolts provided i.e. M20 Grade 8.8

bolts and Class 8 Nyloc nuts. Torque bolts to

335 N.m. Lower the jack to support the

front of the drawbar and fit safety tow

chain.

Tine Fitment - Tine location decals (arrows)

should be fitted to the toolbar to indicate

the tine locations for tines/row units not fit-

ted or not fitted in the correct location.

Upon fitment, ensure the correct hardware

is used i.e. M20 Grade 8.8 bolts and Class 8

Nyloc nuts. Secure the four fasteners in

stages to pull up the tine evenly and

squarely onto the toolbar.

Caution: Assembly torque settings

are critical to ensure tine assemblies remain

secure to the toolbar at all times. Torque to

335 N.m. Confirm this setting with a good

quality torque wrench.

Shank Fitment - Fully raise implement, fit

the tine shanks to the upper tine assem-

blies. Ensure positioning pins are in the

same hole in both the shank and the pivot

bracket to the tine tower. Ensure the rear

M20 set screws are tightened up hard

against the shank and the locking nut is then

tightened.

Unloading and Assembly

11

Hydraulic Circuit - In setting up the hydrau-

lic circuit cylinders should be correctly lo-

cated and aligned. Hoses must be con-

nected to complete the correct circuit as per

schematics provided in the parts section of

this manual. Cleanliness of the system must

be maintained. When securing the hydraulic

hoses to the frames ensure that sufficient

slack is provided in areas where a pivot joins

members or the connection is to a moving

component.

Depth Control - The depth control circuit

consists of master/slave phasing cylinders in

series. Generally the depth control system

will be factory primed.

Wing Fold - A hydraulic circuit is employed

to fold the wings from the working position

for transport or storage. The wing fold cir-

cuit consists of a two double acting cylinders

connected in parallel. Generally the wing

fold system will be factory primed.

HydraTILL Circuit –If configured as a Hy-

draTILL an extra circuit is added including an

accumulator for tine breakout. Generally

the HydraTILL system will be factory primed.

Caution: Maintain a close watch on

tractor oil level and top-up with new clean

oil as required. Observe closely as too low

an oil level may introduce more air into the

system.

Warning: The presence of air in the

hydraulic circuits will cause the implement

to operate erratically and is potentially very

dangerous when folding wings or transport-

ing the implement.

Ground Tool Fitment - There are a selection

of aftermarket ground engaging tools availa-

ble to suit the range of shanks. Selection of

the most appropriate ground tool will de-

pend on your agricultural practices, ground

conditions and sowing boot design.

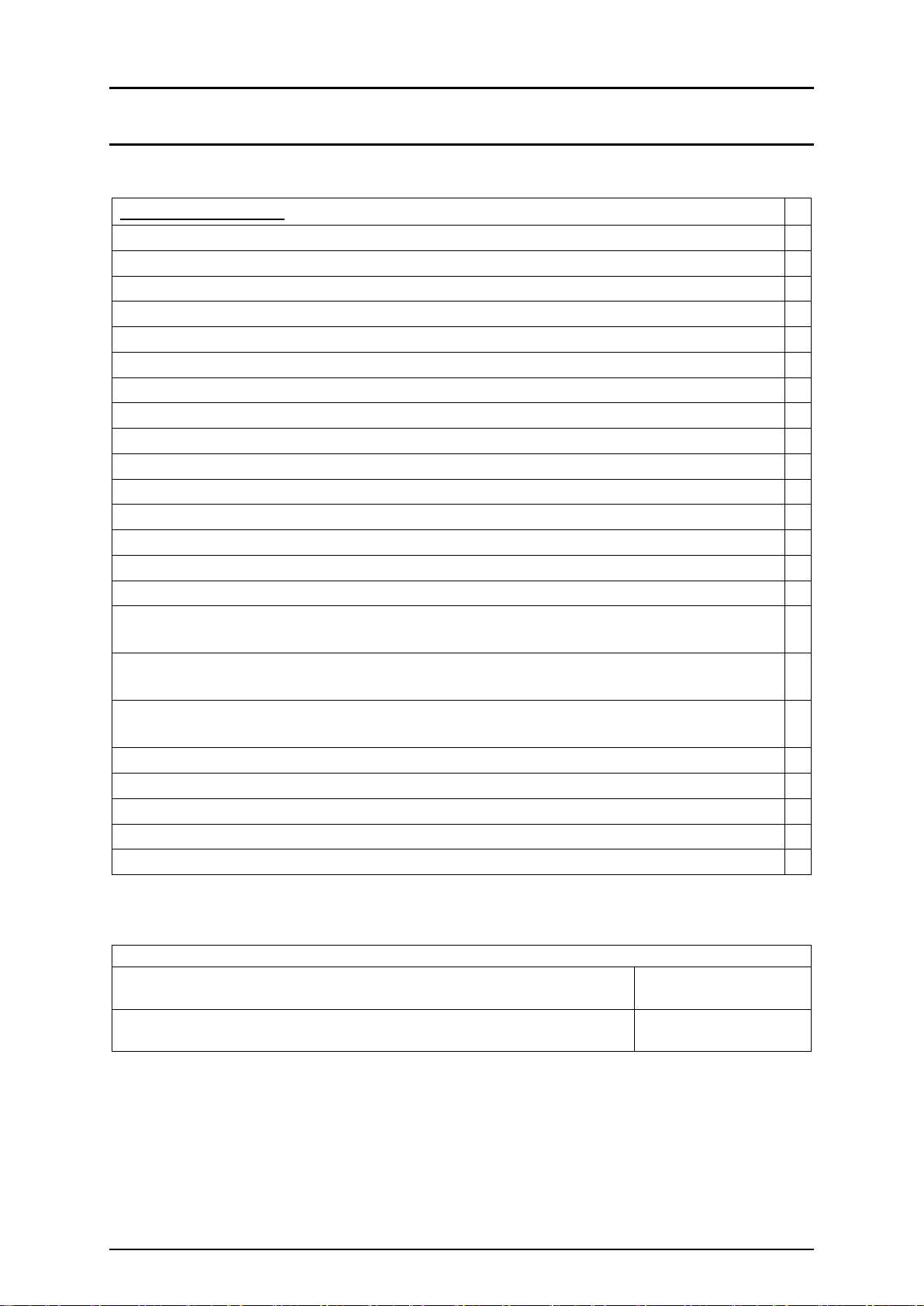

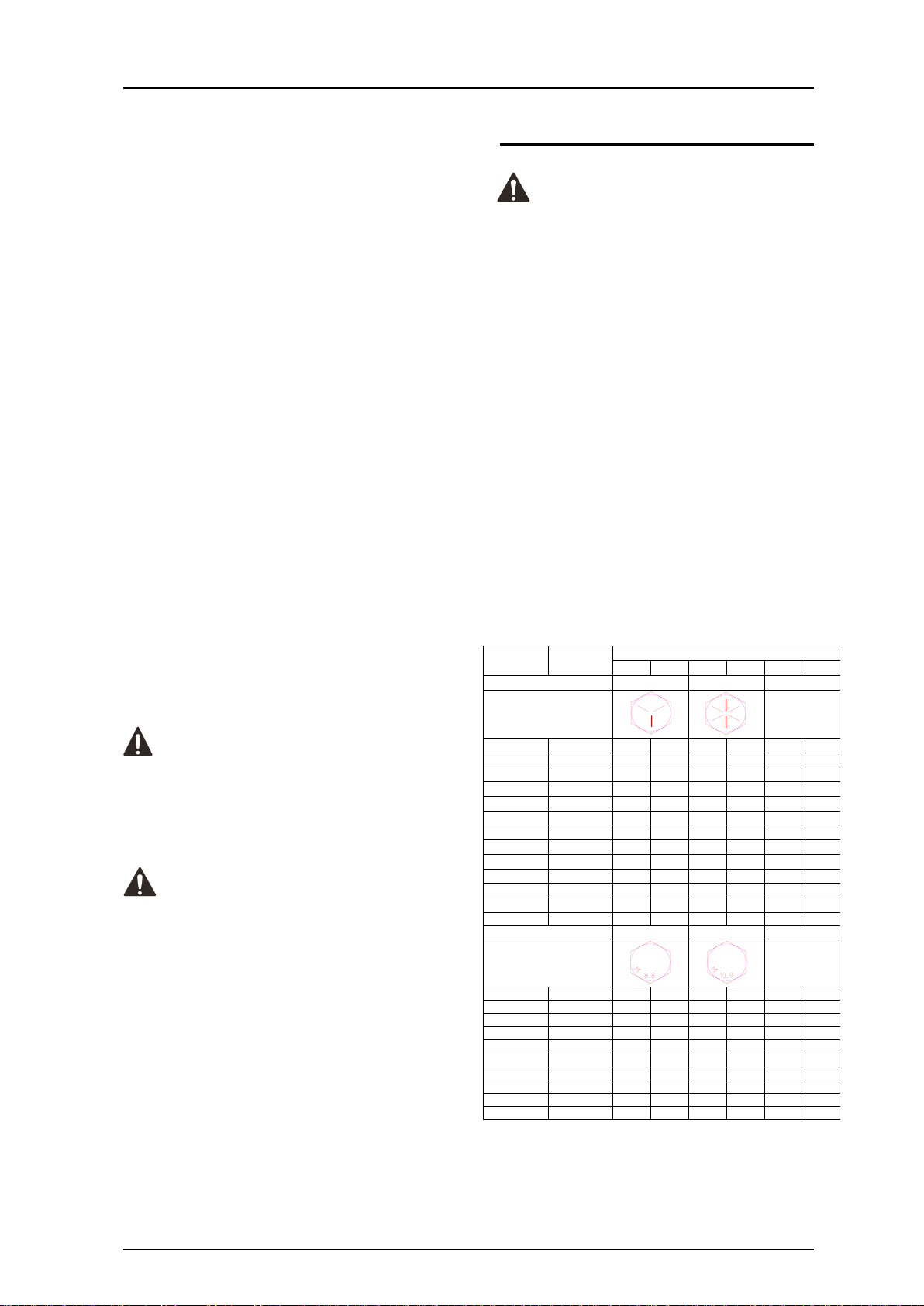

Torque Specifications

Caution: Torque values listed on the

following page should be used as a guide

only. If a different torque value or tighten-

ing procedure is specified for a specific ap-

plication, do not use these values.

Refer to the Parts section for proper grade

and length of bolts for replacement parts.

Do not replace Nyloc nuts with nuts and

spring washers. Replace all parts with origi-

nal specified parts only (note fastener

grades).

The following torque figures are those rec-

ommended for zinc plated, lightly oiled

bolts. Recommended assembly torques may

be obtained by multiplying the torque fig-

ures in the table below by:

0.78 –for degreased zinc plated bolts.

1.10 –for black oxide finished bolts.

lbf.ft Nm lbf.ft Nm lbf.ft Nm

7/16 UNF 43 59 60 82 - -

7/16 UNC 39 53 54 74 - -

1/2 UNF 67 91 94 128 - -

1/2 UNC 59 81 83 113 - -

5/8 UNF 135 184 186 253 - -

5/8 UNC 117 159 165 224 - -

3/4 UNF 235 319 325 441 - -

3/4 UNC 210 285 290 394 - -

7/8 UNF 370 502 520 706 - -

7/8 UNC 335 455 470 638 - -

1UNF 550 746 775 1052 - -

1UNC 505 685 710 963 - -

M10 1.5 29 40 41 56 - -

M12 1.75 51 70 73 100 - -

M16 - - - - - 170 231

M16 2.0 126 171 180 245 - -

M18 1.5 - - - - 254 345

M20 1.5 - - - - 376 510

M20 2.5 247 335 351 477 - -

M22 1.5 - - - - 475 645

M24 - - - - - 500 679

M24 3.0 425 577 608 825 - -

Head Markings

(Manufacturers marks

may vary)

Recommended Assembly Torque

8.8

10.9

Wheel Stud

Metric Grade Number

S.A.E Grade Number

5

8

Size

Thread

Pitch

Wheel Stud

Head Markings

(Manufacturers marks

may vary)

Operation

12

Operating the NT8000

The design of your NT8000 provides flexibility

in tine spacings and layouts, working depths,

ground engaging tools and provision for a

multitude of attachments, allowing its use for

more than just one application or practice. Re-

gardless of the practices being employed,

there are a number of general rules that

should be followed when working the NT8000

to ensure maximum working life.

1. Whenever starting or stopping, the tines

should always be out of the ground. When

commencing work, move off slowly and

lower the implement to the required

depth; then increase to the desired work-

ing speed (up to a maximum recom-

mended speed of 10 km/h).

2. Do not turn too sharply whilst tines are in

the ground as this will place excessive

loads on the tines, ground tools and

frame. Tines must be raised out of the

ground when turning at headlands or in

other tight situations.

3. Do not work with the wings folded,

whether partially or completely. Ensure

wing fold cylinders are always fully ex-

tended when operating to allow wings to

float up and down.

4. Become familiar and aware of the limita-

tion of the implement and work within

these limits. It is your responsibility to as-

sess your specific application and deter-

mine the risks involved and appropriate

action.

5. Upon selecting the desired working depth,

set the depth stop mechanism to control

the height as per depth control section of

this manual. Once set, work implement

for approximately 100m and check depth

consistency. Adjust as necessary.

6. Whilst working, regularly observe the en-

tire implement for any blockages of mud,

stubble or any other obstructions.

7. Avoid working on excessively steep slopes

or rocky terrain.

8. The tines are designed to trip when en-

countering an obstacle. The implement

should never be worked with the tine

shank constantly laying back from vertical

or jumping. This may cause premature,

abnormal wear of the tine assembly.

SUCH WEAR WILL NOT BE COVERED UN-

DER WARRANTY.

Working in this manner will also increase

the loads placed on the implement frame

and increase tractor fuel consumption. In

addition, the correct ground tool working

angle and consistent depth control will

not be maintained. If such a situation per-

sists, the load on the tine must be re-

duced by:

- decreasing ground speed.

- reducing working depth.

- replacing ground tools with design that

produces less draft.

- shortening the tine shank by sliding up

the casting.

- delay working until more suitable soil

conditions prevail.

9. Conduct (or have your dealer conduct)

pre-season checks on your implement as

per “Maintenance” section of this manual.

Replace pins and bushings immediately

where excessive wear is observed to pre-

vent damage to housings.

10. Inspect implement and ground tools for

damage daily. Grease and Maintain as per

the “Maintenance” section of this manual.

11. It is recommended that the machine is

stored undercover when not in use. The

lifespan of hydraulic hoses, paintwork and

distribution kit components is dramati-

cally reduced when left outside for ex-

tended periods of time.

Operation

13

Connection/Disconnection

Ensure the implement is always discon-

nected/connected on flat, level ground.

When connecting the NT8000;

Ensure a suitable drawbar pin is used with

a retaining clip fitted.

Ensure hydraulic couplings are clean and

not damaged.

Install a suitably rated implement safety

tow chain (supplied with machine), from

drawbar to a secure location on the trac-

tor.

Ensure hydraulic hoses and electrical

wires are sufficient in length and if neces-

sary, tied up to prevent catching/pinching

as the tractor and implement articulate.

Lift jack to its uppermost setting before

moving.

When disconnecting the NT8000 close both

safety lockout valves and float all hydraulic

circuits before unplugging from tractor.

Tractor Requirements

Ensure your tractor is compatible with the

NT8000 implement and seeder combination.

Check the following:

Does the tractor have sufficient power to

pull this combination in the field? Gener-

ally you will require between 5-9hp per

tine and 8hp per ton of seeder.

Does the tractor have sufficient weight to

tow the combination safely on public

roads?

Does the tractor of have sufficient hydrau-

lic capability? ScariTILL models require 2

sets of remotes, HydraTILL models require

3 sets of remotes. This is in addition to

seeder requirements.

Important: These are only rough guidelines;

hills and soil conditions can have a large im-

pact on tractor power requirements.

Note: The implement hitch has been designed

to suit a Category 4 drawbar or Category 3

drawbar (2-1.5” dia. pin). Tractors with Cate-

gory 1 or 2 drawbars should not be used.

ScariTILL Operation

The ScariTILL Tine utilizes a spring

as the break out mechanism. The

tine’s breakout is nominally 180kg

(400lb) or 245kg (540lb) depend-

ing on the model. The ScariTILL’s

tine shank height can be adjusted

vertically in 12.5mm (1/2”) incre-

ments.

Digging depth is adjusted using

the frame’s depth control system.

Important: M20 set screws secur-

ing the shank may need retightening upon ini-

tial bedding in.

Note: The tine breakout force increases as the

underframe clearance (UFC) is reduced.

HydraTILL Operation

The HydraTILL Tine utilizes a

hydraulic cylinder as the break

out mechanism. The tine’s

breakout can be varied from

nominally 140 to 310kg (300 to

680lb) depending on circuit

pressure, position of shank &

ground tool.

The HydraTILL’s tine shank ad-

justment is identical to the

ScariTILL.

Digging depth is adjusted using the frames

depth control system.

The tine break out can be adjusted on the go,

between the range 600 –1300 psi. Reduce the

tine breakout when the machine is working

passes through areas known to have rocks or

other submerged objects.

Note: The tine breakout force increases as the

under frame clearance (UFC) is reduced.

Operation

14

Road Transportation

The NT8000 was designed with ease of road

transport in mind. Before transporting, ensure

the following procedures are considered:

1. Tractor has sufficient weight to handle the

machine. Generally the tractor needs to

be 2/3 the weight of the Implement com-

bination. See Specifications for machine’s

overall weight approximation.

2. Tractor has sufficent braking capacity for

emergency stops. Maximum of 15m

stopping distance.

3. Fully fold and raise the NT8000, close

both transport lockout valves to prevent

accidental lowering or unfolding of the

implement.

4. Release hydraulic pressure from hydraulic

tines enabling them to freely move if they

hit an object.

5. Understand state and local authority reg-

ulations for transport of agricultural ma-

chines. Always abide by these regulations.

E.g. dimensions, weight, time of day, road

and bridge restrictions, piloting, beacons,

signs, flags, etc.

6. Centre frame wheels have the maximum

tyre presure to prevent excessive tyre side

wall heat and distortion and rapid tyre

wear.

7. The safety tow chain must be fitted

around a substantial part of the tractor

and hooked back onto itself. Ensure hook

safety catch is engaged. The chain must

be fitted to allow normal angular

movement of the coupling without

unnecessary slack. If towing a combina-

tion, ensure safety chain tow capacity is

adequate. An additional chain may be re-

quired.

8. Do not exeed the maximum transport

speed of 20km/h.

9. Do not exceed 10° roll angle with wings

folded.

10. After transporting for a few kilometres,

stop and check all wheel nuts. This should

be repeated if transporting extended

distances. In particular, wheel nuts can

work loose until bedded in. Refer “Torque

Specifications” section of this manual.

Danger: Beware of power lines and other

obstructions when transporting with wings

folded.

Warning: The machine can be configured

such that the road transport width exceeds

3.5m. It is the operator’s responsibility to un-

derstand and follow local laws and regula-

tions.

Depth Control Circuit

The NT8000’s depth control circuit consists of

4 phasing cylinders connected in series. These

rephasing cylinders have a system that allows

oil to pass the piston when it is fully extended

or retracted allowing them to synchronize or

rephase.

The NT8000 depth control circuit has a dual

pilot operated check valve fitted which allows

the hydraulic couplings to be disconnected

from the tractor whilst the circuit is under

pressure (i.e. implement lifted).

The working depth of the implement can be

limited with mechanical depth stops fitted to

the master cylinder. A pressure relief valve is

used to limit the maximum retract pressure

and prevent excessive load on the depth stop

plates.

Setting the implement’s working depth is

achieved by the following procedure:

1. Back off or remove the mechanical depth

stop plates on the master cylinder to al-

low the cylinders to fully retract.

2. Raise and lower the implement a couple

of times, allowing the cylinders to fully ex-

tend and rephase.

1392

Operation

15

3. Engage the implement to the required

working depth and operate for 50-100

metres.

4. Refit or adjust cylinder depth stop plates

until at rest on the cylinder end cap. En-

sure that both plates of the depth stop

are secured level. As a check, count the

number of teeth exposed on each depth

stop plate.

Priming the Depth Control Circuit –To re-

move air from the depth control system, re-

move all depth stop plates from cylinder clev-

ises. Actuate tractor hydraulics to fully retract

implement cylinders and hold for 1 minute.

Then, fully extend implement cylinders and

hold for another minute. All cylinders should

operate simultaneously and evenly. If not, re-

peat priming procedure again. Refit depth

stop plates once confident that the system is

fully primed.

Upon working machine, if cylinders become

unsynchronized, rephasing can be achieved by

simply extending the cylinders & holding.

To adjust the frame depth across the ma-

chine, retract depth control cylinders so that

the load is just off the wheels. Loosen the

locknuts on the cylinder mount eyebolts. By

reducing the measurement shown, the imple-

ment will lower.

The factory setting for

the depth control cylin-

der eyebolts should be as

shown. It should be noted

that this adjustment will

alter the overall transport

width of the implement.

Wing Fold Circuit

The NT8000’s wing fold hydraulic circuit con-

sists of two double acting cylinders connected

in parallel fitted with counterbalance valves to

prevent unfolding in case of hose failure. A

spool type flow divider is used to encourage

cylinders to operate simultaneously. Restric-

tors are used to limit the speed of operation,

tractor hydraulic flow should be set low to re-

duce unnecessary pressure in the system.

Always ensure that the wing fold cylinders are

fully extended when working or transporting

with the wings unfolded.

Priming Wing Fold Cylinders –With only the

base end of the wing fold cylinders attached

use suitable blocks to support the rod end of

the barrel and ensure that the rods will have

freedom to fully extend without fouling. Actu-

ate tractor hydraulics to fully extend wing fold

cylinders. Maintain a close watch on tractor

oil level and top-up with new clean oil as re-

quired. Fully retract and extend until all cylin-

ders work simultaneously and evenly.

Once comfortable all air is purged from the

circuit, fully extend the cylinders and secure

to the centre frame. Ensure the bush is posi-

tioned inside each cylinder eye and can freely

rotate.

HydraTILL Circuit

The HydraTILL system utilizes a dedicated sin-

gle acting Hydraulic circuit with a pre-charged

accumulator as a means of allowing the tine

mechanism to break out. Breakout force can

be adjusted by increasing or decreasing circuit

pressure within specified range.

Note: Maximum recommended system pres-

sure is 10350KPa (1500psi) during operation.

The accumulator is pre-charged to 4000KPa

(580psi). A factory set relief valve should pre-

vent overcharging of HydraTILL circuit.

Warranty will be void if circuit pressure is set

in excess of the above figure, and/or accumu-

lator pre-charge pressure increased. Exceed-

ing these pressures will significantly reduce

the number of tines capable of jumping. In

conditions where a large number of tines at-

tempt to jump simultaneously, hydraulic lock-

up may occur. Consequently, damage to ei-

ther tine or implement may result.

Operation

16

Priming the HydraTILL Circuit:

Loosen the last hydraulic hose on the outside

ends of each chain of hoses. This will assist in

purging all air from the system. Loosen the JIC

fitting on the hose, hold the fitting on the cyl-

inder firm. Once the implement is ready to be

primed, lower so that the implement is resting

on the shanks/ground tool and creep forward,

lowering the implement further as you go.

Continue until tines are at full jump height

(tine cylinders fully retracted). Attach the tine

hydraulic circuit to a remote port on the trac-

tor. With the tractor in neutral and the hand-

brake disengaged, slowly begin to introduce

hydraulic oil to the system. As the tines begin

to return to working position they will pull the

tractor backwards. Someone must remain in

the tractor at all times. Continue until oil be-

gins to emerge from the loosened fittings. Nip

up fittings and continue to force oil into the

circuit until tines have returned to their work-

ing position i.e. the cylinders are extended. In-

crease hydraulic pressure until desired work-

ing pressure is reached.

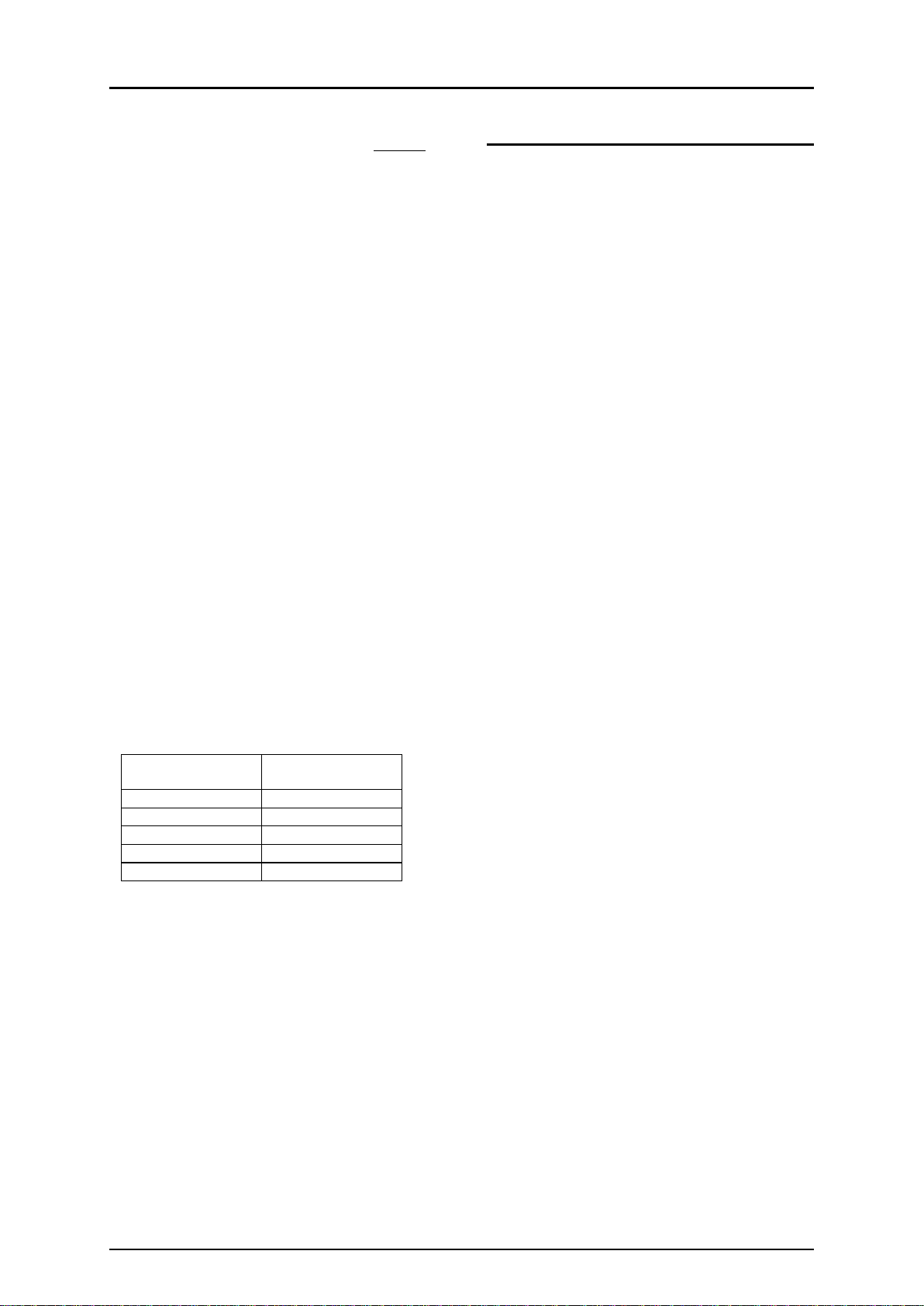

The following is a table shows theoretical val-

ues of desired breakout at 710mm underframe

clearance (UFC) and the corresponding hy-

draulic pressure.

Breakout [lbf] at

710mm UFC.

Hydraulic

Pressure [psi]

310 586

400 756

500 946

600 1135

680 1286

40 bar (580 psi) precharge

Note: As a rule of thumb, tine breakout force in

pounds is approximately equal to circuit pres-

sure (psi) divided by 2.

Note: As the under frame clearance increases,

so does the pressure necessary for maintaining

a given breakout.

Pre - operation Checklist

Read and understand the operator’s man-

ual and all safety decals.

Read and understand tractor operator’s

manual.

Inspect all tyres are in good working condi-

tion and correct pressure.

Inspect all points & hardware are in good

working condition.

Check that all hardware is in place and is

tight. Refer to “Torque Specifications” sec-

tion for assembly torques.

Check that the hydraulics are primed and

bled of all air.

Check that all hydraulic hoses arerouted to

accommodate working angles between

implement members joined by pivots,

checking for potential pinching, fouling or

rubbing of hoses.

Check that all accessories do not foul with

implement wheels or framework through

their working/transporting range.

Check all hydraulic connections for leaks.

Check safety tow chain is fitted to imple-

ment.

Table of contents

Other Gason Farm Equipment manuals