Gason 7370 Series User manual

09/08

T a

COPYRIGHT

Neither this manual or part thereof may be reproduced or published without the prior permission of AF Gason Pty Ltd

5 and 7 Tonne Series

Trailed Fertiliser and Lime Spreader

OPERATORS MANUAL

Low Ratio Series II Gearbox (215080)

GPN 217022 REVISION C 05/17

09/08

Page Intentionally Blank

Contents

09/08

Warranty Form

Introduction……………………………………………

1

Safety………………………………………………….

2

Specifications…………………………………………

4

Conversions…………………………………………..

5

Bolt Specifications……………………………………

6

Ordering Parts………………………………………..

7

Spare Parts Record………………………………….

8

Assembly Instructions……………………………….

9

Operation……………………………………………..

10

Adjustments Required…………………………..

10

Setting Spinner Speed………………………….

11

Engaging Jockey Wheel………………………..

11

Spreading (bout) Width…………………………

12

Determining Bulk Density………………………

12

Changing Gearbox Ratio……………………….

13

Rear door Operation…………………………….

14

Setting Application Rate……………………………..

15

By Rate Chart……………………………………

15

By Calibration Process………………………….

16

Application Rate Record Sheet……………………..

19

General Maintenance………………………………..

20

Trouble Shooting Section…………………………...

22

Spare Parts…………………………………………...

23

Optional Parts…………………………………………...

41

Application Rate Charts……………………………..

47

09/08

Page Intentionally Blank

INTRODUCTION

Page 1

09/08

AF Gason Pty Ltd is an Australian owned

family business operating from within rural

Victoria. The Gason company has been

servicing the needs of rural Australians for more

than 60 years.We operate through a local dealer

support network that spans the country. Gason

would like to thank you for purchasing your

Australian madefertiliser spreader, and trust that

you will have many years of trouble free service.

The Fertiliser Spreader has beendesigned

to be functional, practical and reliable.

The Gason 7300 Spreader is available in

either a 5 or 7 tonne capacity. While ideal for

large volumes of waste, wet or dry, the Gason

spreader will spread most materials. The feed

chain offers a positive method for metering light

rates of urea for top dressing crops through to

high rates of lime and gypsum. The spreader can

also handle chicken litter and general manures.

A fully enclosed three speed gearbox and

adjustable rear door is fitted to allow quick

change over to various products and rates. With

under slung spinners and a wide door opening,

material can be fed unobstructed into the high-

powered spinners. The spinners are mounted

directly to the hydraulic motors, reducing

maintenance.

High floatation tyres offer excellent

performance for these lightweight spreaders and

are built to handle high tonnage application

causing very little compaction damage to the

ground.

This manual endeavours to provide the owner

with a complete understanding of the spreader’s

operation and the processes requiredto obtainthe

highest level of performance possible. It is

suggested that the owner/operator read this

manual and any other literature that has been

supplied with your machine to ensure a safe and

trouble free operation.

References to the left and right hand sides of the

Spreader are from the rear of the machine looking

forward.

Fig. 1 7370 Series Fertiliser Spreader.

While every effort has been made to ensure the accuracy of the

information in this manual, AF Gason Pty Ltd reserves the right

to delete, change or add information without notice.

SAFETY

Page 2

09/08

The fertiliser spreader has been designed

with safety in mind. However, the equipment is

only as safe as the person operating it.

Do not operate the spreader until you

have read and understood this manual. If you

feel you need help or advice on the operation of

the Seeder, contact your local authorized

Gason Dealer.

To ensure trouble free and safe operation

of your spreader, it is important to carry out a

daily safety check to reduce the possibility of a

costly breakdown.

Items to Check Daily During

Operation

1. Check all wheel nuts are tight during the first

couple of days of use or after transportation

(refer page 6).

2. Check tyre pressures and tyre conditions in

general.

3. Ensure the safety guard around the spinners

is in place and is not damaged.

4. Check all hydraulic breakaway connections

are firmly engaged.

5. Check all hydraulic hoses and fittings for

leaks.

6. Check main spreader feed chain and drive

sprockets for wear or damage.

7. Check feed chain turns freely before

operating each day or after transporting

when loaded.

8. Check drawbar pin for wear.

9. Check main drive shear pins between the

gearbox and drive shaft are operational.

10. Check spinners for damage and wear before

operating and that they are clear of product if

starting near livestock or people.

General Safety Conditions

DO NOT ride on the machine when

operating.

DO NOT touch or attempt to adjust any

moving parts.

DO NOT adjust hydraulic fittings while under

pressure.

DO NOT remove any safety guards while the

spreader is operating.

DO carry out the daily safety checks and operate

the spreader in a safety conscious manner.

Hydraulics

Before working on the hydraulic system

always check that the spinners are not

operating, and that there is no pressure in the

hydraulic system.

Never attempt to disconnect a breakaway

coupling if the spinners are operating. Turn the

tractor off if working on the spinners or gearbox

lift cylinder of the spreader.

Leaving the Spreader Unattended

Ensure that the drop leg on the jack is

correctly pinned into position and that the foot is

on firm ground.

Chock the spreaders wheels to prevent it

from rolling if on a slope.

When Working on the Spreader

Place suitable stands under the trailer if

removing a wheel or carrying out major work.

Wear safety glasses if standing close to the

machine with the spinners operating.

Safety

Page 3

02/13

Transporting

Never transport the spreader with the

jockey wheel in contact with the ground wheel.

Use the transport lock on the rear of the

spreader to lock the gearbox in the transport

position.

Fig. G1 Transport lock for gearbox.

Before towing on the road you should

consult with the appropriate state or local

authority for any specific regulations and

permits that may be required e.g. dimension,

weight, time of day and bridge restrictions, area

category etc.

Do Not transport the spreader on public

roads when loaded. Do Not exceed 25km/h

when towing the spreader when loaded on

private roads. Maximum speed for towing an

empty spreader is 40km/h.

Always shift into low gear when travelling down

steep slopes. Always be aware that the braking

distance of the towing vehicle will be increased

when the Spreader is attached.

DO NOT TOW:

Without the gearbox transport lock engaged.

At speed over rough ground.

With any person or persons riding on the

machine.

At night unless lights are fitted and a permit

has been issued if required.

In a dangerous manner that may threaten the

safety of any person.

With the bin loaded on public roads.

Reverse the spreader with the gearbox jockey

wheel in contact with the tyre. Damage will

occur to the feed chain.

Fig. G2 7370 Spreader.

SPECIFICATIONS

Page 4

07/13

Dimensions

7350

7370

Overall width

2500

2500mm

Bin width

2355

2355mm

Overall height

2330

2330mm

Side of bin height

2185

2185mm

Overall length

4900

5500mm

Bin length

2400

3000mm

Wheel centres

2000

2000mm

Step height

565

565mm

Ground Clearance (rear)

460

460mm

Spinner height to ground

690

690mm

*Heights measured with 500mm under front hitch & no

hungry boards or tarp kit.

Spreader Weight

Unloaded

1530

1700kg

Max. Loaded Weight

(gross) @ 25 km/h

7130

8900kg

Bin Capacity

By volume:

Bin shape

4720

5900 Lt

By weight:

Urea (estimated)

3540

4425kg

Super (estimated)

5664

7080kg

(urea @ 750kg/1000 litres

(single super @ 1200kg/1000 litres)

Wheels

Size:

Rear tyres

18.4-26

18.4-26

Type:

Rear Tyres

R1 Gripster

Tyre

Recommended Pressure

kPa

psi

18.4-26 (12pr) Gripster

220

32

Hydraulics

Spinner Motor type . fixed displacement

........................ Gerotor Type

Connections............½” pressure inlet/main

return

Hydraulic capacity...56 I/min. @ 950rpm

(spinner)

Spinner Speed control….

........................pressure compensated

flow control valve.

Maximum motor

Pressure (cont.)......124 Bar (1800 psi)

Pressure (intermit.). 165 Bar (2400 psi)

Maximum return

line oil temp ............90° C max.

Hydraulic fluid.........Mobil fluid 424 or

equivalent High quality

High VI multigrade

transmission and

hydrostatic tractor oil.

Drive System

Gearbox......................3 speed

Type ..........................Chain & Sprocket

Sprockets....................Steel

Lubrication..................Mobil HP grease

............................(general purpose)

CONVERSION FORMULAE

Page 5

09/08

Useful Conversions –Formulae

LENGTH:

1 km = 0.621371 mile

1 mile = 1.609344 km

1 m = 3.280840 ft.

1 ft = 0.304800 m

1 mm = 0.039390 inch

1 inch = 25.400 mm

SPEED:

1km/h = 0.625 mph

AREA:

1 ha = 10,000 m2= 2.471054 acres

1 acre = 10 sq. chain = 4840 sq. yd. =

0.404685ha= 4840 sq.

yd. = 0.404685 ha

1 km2= 0.386102 sq. mile

1 sq. mile = 2.589988 km2

VOLUME:

1 m3 = 35.31476 cu. Ft.

1 cu. ft. = 0.028317 m3

1 L = 0.26418 US

gal.

1 US gal. = 3.78531 L

1 UK gal = 1.201 US

gal.

1 UK Bushel = 8.00 UK gal. = 1.2843 cu.

Ft. = 8.00 U.K. gal. = 1.2843 cu. ft.

= 1.2843 cu. ft.

1 L = 0.0274962 UK Bushels

1 UK Bushel = 36.369 L

1 L = 0.0283785 US Bushel

1 US Bushel = 35.2379 L

TORQUE:

1 Nm = 0.7375624 lbft.

1 lbft. = 1.3558175 Nm

FORCE:

1 lbf = 4.4482

N

1N = 0.22481 lbf

PRESSURE:

1 psi = 6.89476 kPa = 0.0689476 Bar

1 kPa = 0.145038 psi = 0.01 Bar

1 Bar = 14.5 psi

MASS:

1 kg = 2.204622 lb

1 lb = 0.453592 kg

1 kg = 1000

grams

POWER:

1 kW = 1.341

hp

1 hp = 745.7 W

DENSITY:

1 kg/m3 = 0.0624 lb/ft3

1 lb/ft3 = 16.0185 kg/m3

APPLICATION RATE:

1 kg/ha = 0.892 lb/acre

1 lb/acre = 1.121 kg/ha

HYDRAULIC HORSE POWER:

1 hp = FLOW (US GPM) x PRESSURE (psi)

1714

CONVERSION FORMULAE

Page 6

09/08

MASS FLOW RATE:

kg/min = Application Rate (kg/ha) x Area Rate (ha/hour)

60

lb/min = Application Rate (lb/acre) x Acre Rate (acre/hour)

60

BOLT SPECIFICATIONS

Page 7

06/07

STANDARD BOLT HEAD MARKINGS AND TORQUE SPECIFICATIONS:

CAUTION: Loose bolts can cause elongation of holes and part failures resulting in dangerous operating

conditions and equipment breakdown. Check all bolts and nuts periodically during equipment

operation and keep them tightened to the specified torque. If hardware replacement becomes

necessary, replace with equivalent metric grade number.

NOTE: The following torque figures are those recommended for zinc plated, lightly oiled bolts.

Recommended assembly torques may be obtained by multiplying the torque figures in the

table below by:

0.78 –for degreased zinc plated bolts

1.10 –for black oxide finished bolts

0.81 –for M20x2.5P Tine Toolbar Hardware

It is necessary that all bolts be tightened to the correct recommended assembly torque.

lbf.ft Nm lbf.ft Nm lbf.ft Nm

7/16 UNF 43 59 60 82 - -

7/16 UNC 39 53 54 74 - -

1/2 UNF 67 91 94 128 - -

1/2 UNC 59 81 83 113 - -

5/8 UNF 135 184 186 253 - -

5/8 UNC 117 159 165 224 - -

3/4 UNF 235 319 325 441 - -

3/4 UNC 210 285 290 394 - -

7/8 UNF 370 502 520 706 - -

7/8 UNC 335 455 470 638 - -

1UNF 550 746 775 1052 - -

1UNC 505 685 710 963 - -

M10 1.5 29 40 41 56 - -

M12 1.75 51 70 73 100 - -

M16 - - - - - 170 231

M16 2.0 126 171 180 245 - -

M18 - - - - - 243 330

M20 - - - - - 265 360

M20 2.5 247 335 351 477 - -

M22 - - - - - 340 462

M24 - - - - - 370 502

M24 3.0 425 577 608 825 - -

Recommended Assembly Torque

8.8

10.9

Wheel Stud

Metric Grade Number

S.A.E Grade Number

5

8

Size

Thread

Pitch

Wheel Stud

Head Markings

(Manufacturers marks

mayvary)

Head Markings

(Manufacturers marks

mayvary)

ORDERING PARTS

Page 8

06/07

When Ordering Parts:

The following information must be supplied to

facilitate fast and accurate processing of a

replacement parts order:-

•Gason part number and description (as

given in this manual)

•Quantity

•Machine model and serial number

•Method of despatch.

•Your Dealers name and address

For your convenience record the following

information below:

Name: ______________________________

____________________________________

Address: _____________________________

____________________________________

Telephone Number: ____________________

Machine Model No:_____________________

Date Machine Purchased:________________

Serial No.:____________________________

Subject to any applicable Federal, State or Territory laws or ordinances, which may apply from time to time, AF

Gason Pty Ltd reserves the right to make changes in design and specifications without notice or obligation and to

change or discontinue models at any time without incurring any liability to any Purchaser thereof.

Left and right hand: All references in this manual are determined by facing the direction of travel.

For warranty provisions please consult your Installation and Warranty Registration document.

ORDERING PARTS

Page 9

06/07

PART No.

DESCRIPTION

QTY.

COST

DATE

ASSEMBLY

Page 10

06/07

Introduction

The fertiliser spreader has been

assembled as far as practicable at the factory to

minimize the amount of work required in the

field. The unit has been inspected and tested

before it leaves the factory and requires only a

few basic checks before it is commissioned.

Lifting the Spreader

The Spreader has been supplied with 4

lifting points located at each corner at the top of

the bin. Use appropriate lifting chains or

shackles and slings. Ensure that the spreader is

empty before attempting to lift the spreader.

Spreader weight unloaded

7350 model 1530kg approx.

7370 model 1700kg approx.

Fig. G3 Tarp kit fitted to a 7350 model.

Final Pre-Delivery Check List

After the Spreader has been assembled

and the distribution system fitted to the

implement a final check should be carried out

before delivery.

Trailer General

1. All wheel nuts tight.

2. Safety hitch chain has been fitted.

3. Check tyre pressures.

4. Bins clean on inside, no loose items.

5. Spinner tacho is working.

Hydraulic Connections

The hydraulic system has been tested

prior to dispatch from the factory.

Standard 1/2'” breakaway connectors

have been fitted to the spreader hoses. When

connecting to the tractor, place the smaller

diameter hose inthe supply (pressure) remote

outlet on the tractor. The larger hose should

then be connected to the return flow remote.

OPERATION

Page 11

06/07

General Information

Before operating the spreader, check

that the machine is in good working order.

Tyres should be in good condition and

inflated to the correct pressure.

All feed chain bushes and bearings have

been greased.

Grease gearbox before using. Ensure

that the gear selector pin has been fully

pushed in before greasing the nipple at

the end of the pin.

Feed chain turns freely.

All 4 drive shaft shear pins are in place

and are the correct type.

Fig. G4 Drive shaft shear pins.

Adjustments Required for Different

Products

The spreader requires minimal

changes to spread a variety of products.

Feed Chain Cover Plate

Feed chain cover plates (qty 2), are

provided to protect the feed chain and

reduce chain loading when using free

flowing granulated fertiliser.

Fig. G5 Feed chain cover plates.

Centre Vee

The second item that may also need fitting or

removal is the centre vee at the rear of the

spreader that directs product towards the

centre of the spinners.

Fig. G6 Centre vee removed in discharge area.

Refer to Table G7 for suggested fitment

or removal of cover plates and centre vee.

Spinners

The standard spinners will do most work but

it may be necessary to use a low profile

H/Duty spinner when doing some types of

manures. If the manures are heavy and in

large clumps you may need to fit qty 2 x

H/Duty spinners (GPN 217162). Consult your

Gason dealer for more information.

Product Type

Example

Feed chain covers

Centre vee

Granulated

Urea, DAP,MAP, Super

In place

In place

Loose

Lime, Gypsum, Sand

Removed

Removed

Manures

Chicken litter, general manures

Removed

Removed

Table G7.

Operation

Page 12

06/07

Setting Spinner Speed

Spinner speed is one of the most

important factors in achieving an accurate

spread pattern. The spinner speed can be

adjusted from the cab on most modern

tractors if equipped with closed centre

hydraulics, or from the front of the spreader

by using the flow control valve on open

centre hydraulic equipped tractors.

Refer page 18 for a guideline of

suggested spinner speeds for various

products. Every product will spread

differently depending on its bulk density,

granule size, variation in size and shape.

An incorrectly set spinner speed can

influence the spread pattern. By adjusting

the spinner speed by as little as 50rpm up or

down, it is possible to improve or alter

spread pattern.

Fig. G8 Speed control from spreader. Normally

set to fully open position for closed centre

equipped tractors.

For this reason it is suggested that

a spread pattern test be carried out if

maximum accuracy is required.

As a guide, if the spinner speed is too

high there will be too much material directly

behind the spreader. If the spinner speed is

too slow there will be too little material

directly behind the spreader.

Maximum spinner speed for the 675mm

spinners is 1050rpm.

Fig. G9 Post June 2013 Tachometer at front of

spreader.

Engaging the Jockey Wheel

To operate the feed chain the jockey

wheel must be in contact with the ground

wheel. A hydraulic cylinder is used to raise

and lower the gearbox/jockey wheel. Before

operating the spreader in the field, check that

the transport lock has been pulled out and

rotated from the link arm.

Fig. G10 Transport lock for gearbox.

Once link is free to move, the gearbox /

jockey wheel can be lowered by engaging the

hydraulically driven spinners from the cab of

the tractor.

To disengage the feed chain lift the

gearbox / jockey wheel by reversing the flow

at the tractor’s controls. This will stop oil flow

to the spinners and raise the gearbox in one

operation.

Operation

Page 13

06/07

Use the transport lock if travelling

between paddocks or across roads.

Setting Application Rates

The application rate is controlled by:

1. The spread width of the product.

2. The bulk density of the product.

3. The gearbox ratio selected to run the

feed chain.

4. The rear door height setting.

Spreading Width

The maximum spread width, or bout

width for various products is determined by

a material’s bulk density, granule size and

granule shape. Some material will spread to

wide widths, such as granulated single

super, while lime and gypsum will only be

capable of spreading to a narrow width.

Refer to the table G26 on page 18 for

approximate spread widths for various

products.

Fig. G11 Bout width accuracy test.

To confirm the width for the actual

product being spread it will be necessary to

field-test the specific product and spreader

being used.

This process, if done correctly, involves

the collection of spread material in special

trays set out across the paddock at even

spacings.

The second and more simplistic method

to determine the approximate spread width is

to estimate the widthby eye. This can be done

by spreading a small amount of product at the

desired rate onto clear ground or onto alength

of shade cloth stretched out and pegged to the

ground that contrasts with the fertiliser. This

should demonstrate the approximate bout

width and the tapering off of product at the

extreme edges of the spread.

It may be necessary to drive over the

same path 2 or 3 times during the test if

spreading light rates of granular fertiliser.

The bout width is the distance that you

can drive apart on the paddock, maintaining

even coverage of product across the entire

paddock. The bout width will be less than the

overall spread width.

Determining Bulk Density

To determine the door and gearbox

setting it will help if you know the bulk density

of the particular product. This is done by using

the density meter that is supplied with the

spreader and by carrying out the following

steps.

Fig. G12 Density meter.

1. Fill the meter with product and level off.

2. Balance on ring and slide weight out until

level bubble is between the marks.

Operation

Page 14

06/07

3. Read density from the scale in tonnes per

cubic meter (top scale).

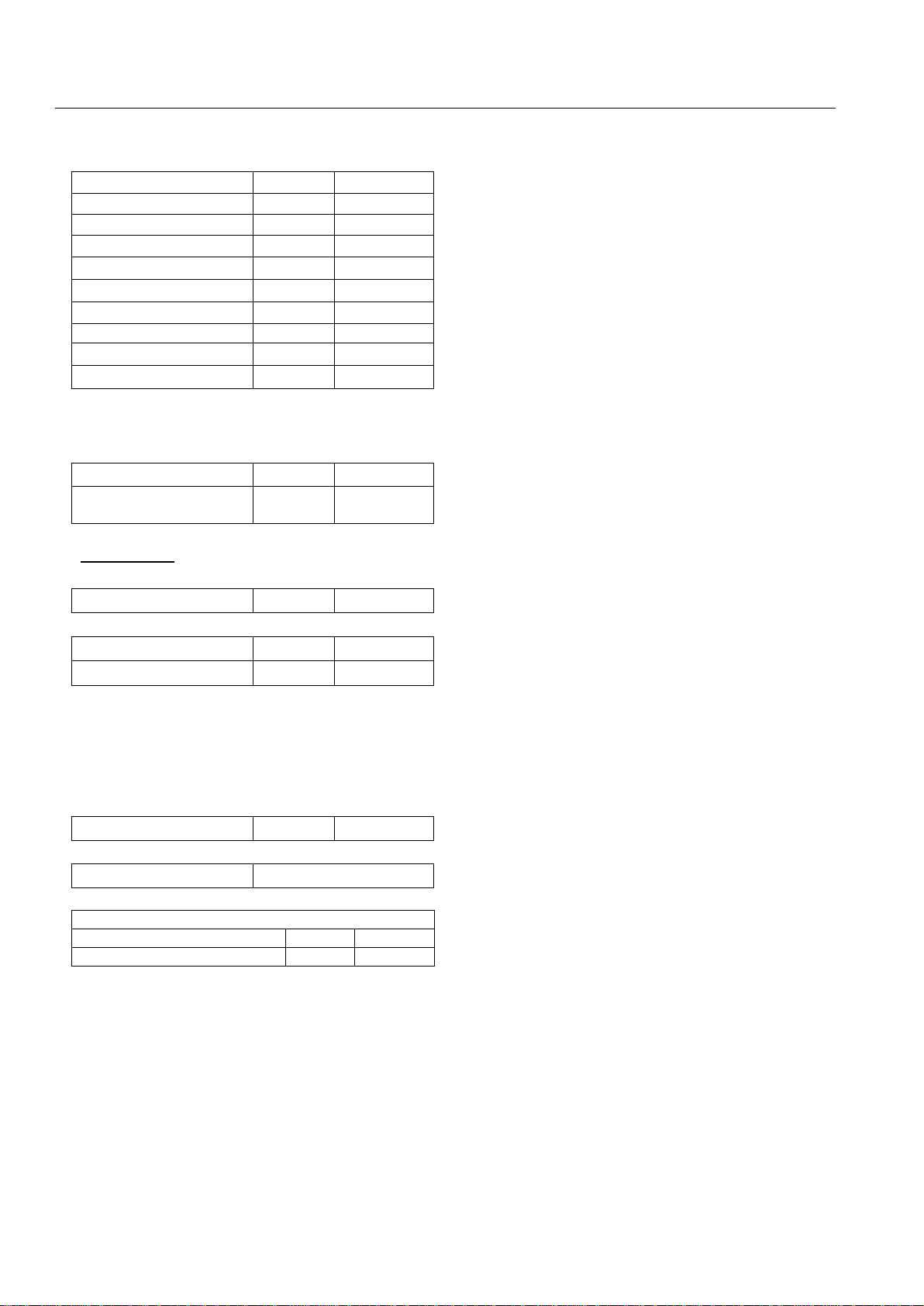

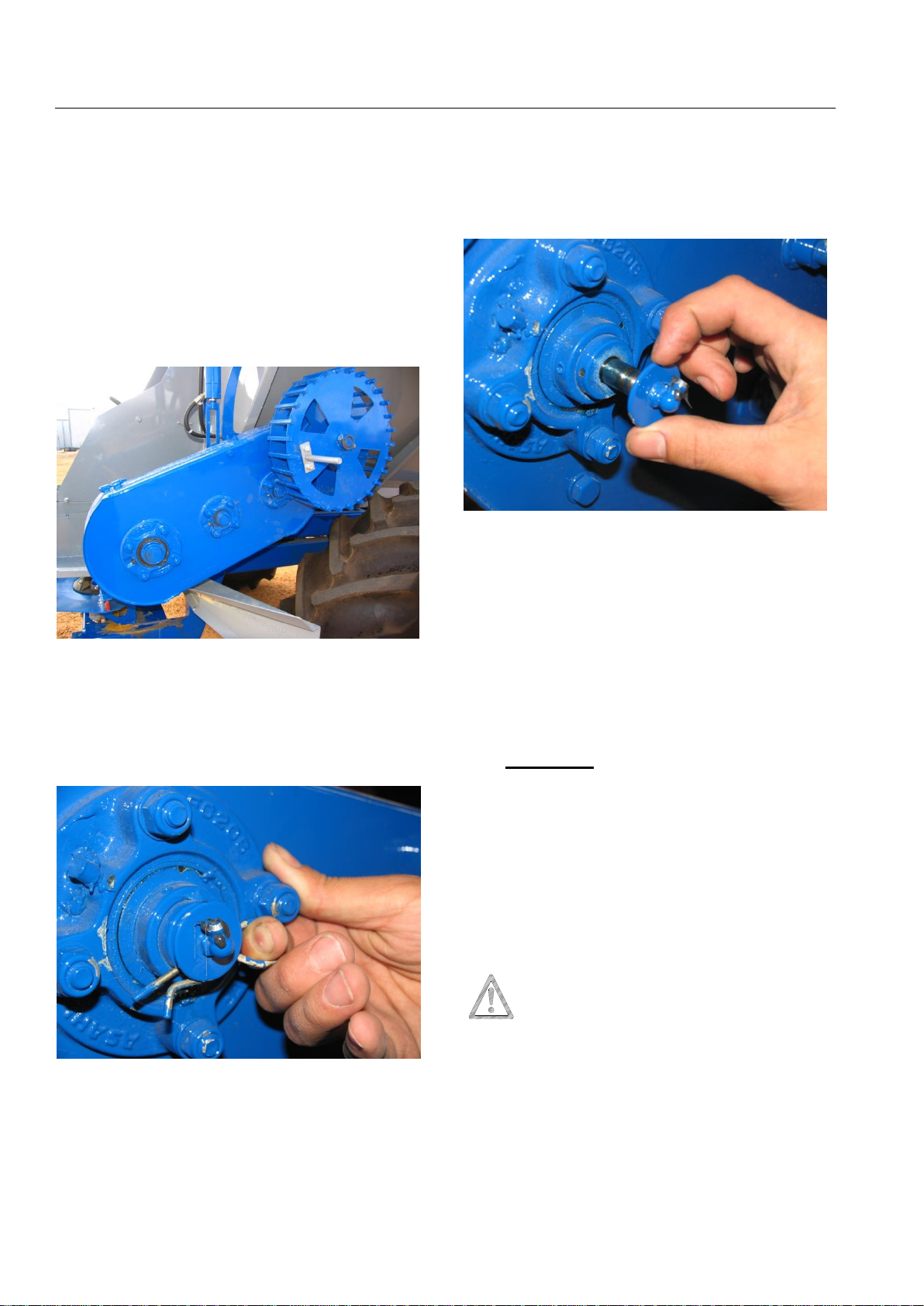

Changing Gearbox Ratio

The feed chain spreader is equipped

with a ground driven 3-speed gearbox. The

gearbox has been designed to offer a large

variation in feed chain speeds to cope with

the low and high application rates.

Fig. G13 Ground driven Gearbox.

To change between ratios you will

need to remove the clip from the inside face

of the top shaft (opposite the jockey wheel)

on the gearbox.

Fig. G14 Selector pin and clip.

Once removed, the selector pin can be

moved in to select low ratio, centralised to

select high ratio or fully withdrawn to drive

medium ratio. It will be necessary to either

rock the jockey wheel backwards and

forwards or to slowly turn the jockey wheel to

allow the internal drive key to slide from one

gear to the next.

Fig. G15 Selector pin central.

Once the correct ratio has been chosen

replace the retaining clip to lock the selector

pin into position.

Note: Always use the lowest gear

possible at the highest door setting to

minimise the loading on the gearbox.

Caution:

The rear door should never be

operated in the closed position with

fertiliser that can pack. On some fertilisers

it should not be operated with less than

40mm of gap as packing will occur and the

chain will jam.

IMPORTANT: Grease gearbox before

using. Ensure that the gear selector

pin has been fully pushed in before greasing

the nipple at the end of the pin.

Refer to the daily maintenance section on

page 20 for further information.

Operation

Page 15

06/07

Rear Door Adjustment

To set the rear door, remove the clip

from the adjusting handle and rotate to raise

or lower the door to the required position.

Fig. G16 Rear Door Adjustment.

A pointer, attached to the top of the

door, and calibration decal is used to show the

distance from the bottom of the floor to the

underside of the door. Replace the clip when

the door is set to the desired height.

Fig. G17 Rear Door Adjustment scale.

Fig. G18 Spreading urea.

APPLICATION RATE

Page 16

06/07

Setting Application Rate

Introduction

The application rate for the spreader

can be set as per the charts at the rear of the

manual or by calibrating the spreader.

The charts estimate the flow

characteristics of the product to determine

the door setting. Different products flow at

different rates. For instance, urea flows

faster than more irregular shaped products.

The chart can only estimate the actual door

setting required for the various application

rates.

If a high degree of accuracy is required,

particularly when spreading low rates, we

suggest a calibration test be performed. The

calibration process will allow the operator to

collect a sample of the actual product being

applied to determine the exact door setting

to achieve the desired application rate.

To collect a sample you will need to catch

the material as it falls off the feed chain. This

can be done by laying a small tarp or bag in

the rear discharge area of the spreader or by

purchasing a calibration kit (GPN 217025)

from your Gason Dealer. The kit includes 2

steel trays and a set of electronic scales to

allow you to collect a sample of product and

weigh it to determine your application rate.

Fig. G19 Optional Calibration kit

Application Rate by the Rate Chart

1. Determine the bulk density of the product.

2. Estimate the bout width that the spreader

will be driven.

3. Refer to the Rate Charts at the rear of the

manual to determine the rear door setting.

Note: Always use the lowest gear possible

at the highest door setting to minimise the

loading on the gearbox.

Example (Note. Examples in this section are

for demonstration only. Actual values may

differ from the charts in rear of book)

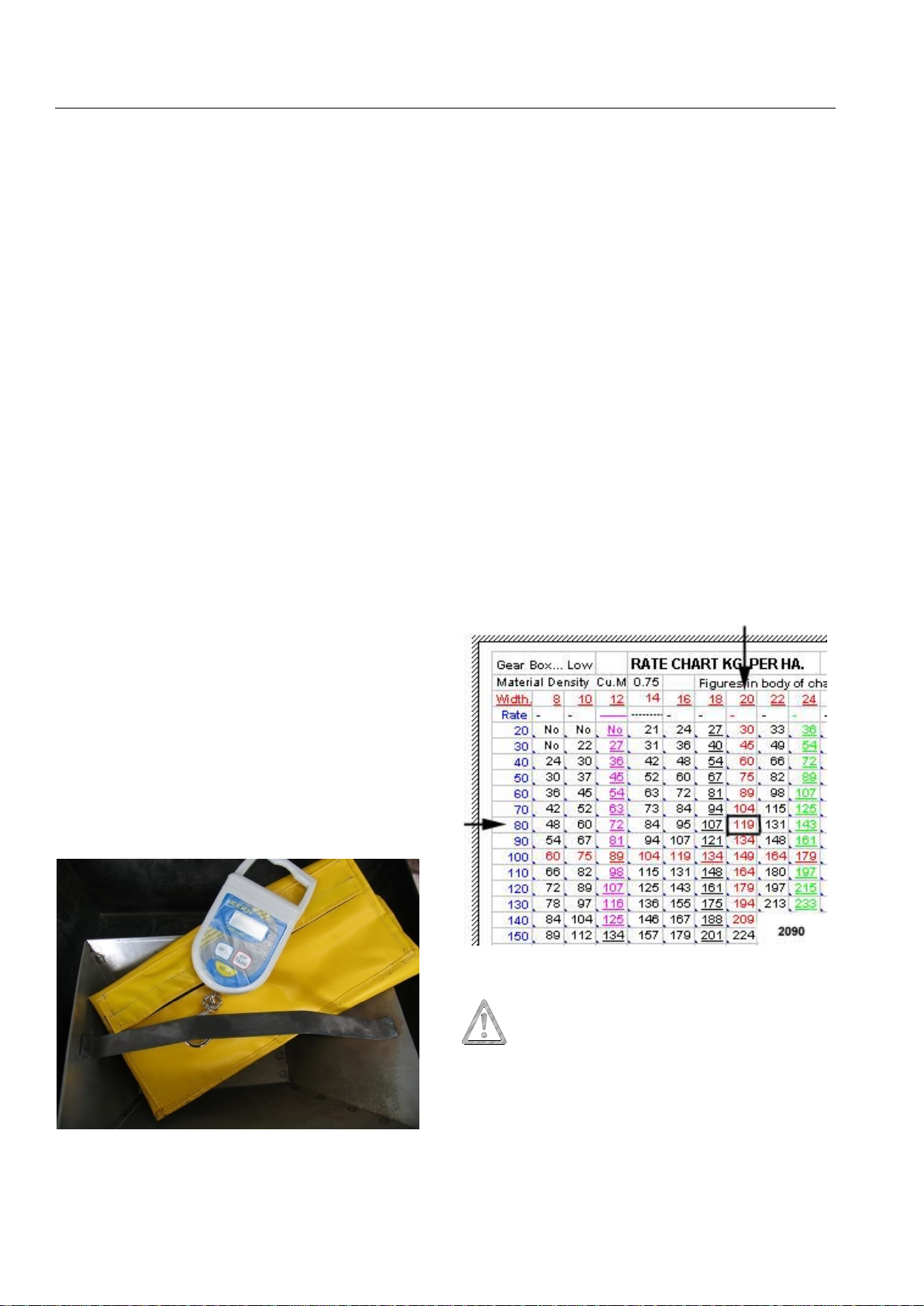

Shown in figure G20, urea that has a

bulk density of 0.75 tonnes per cubic metre is

to be spread to a 20 metre bout width at 80

kg/ha. By using the lowest gearbox ratio

possible, using the ‘Gear Box…Low’ chart,

and reading across the chart we can see that

the estimated rear door setting should be

119mm opening.

Fig. G20 Rate Chart example.

IMPORTANT: If the rate chart is the

only method to be used for setting the

rear door opening, a known weight of product

should be used in the spreader for the first

load to ensure the correct application rate is

being achieved.

This manual suits for next models

1

Table of contents

Other Gason Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions