Gason VHD Delta Wing D15 User manual

VHD Delta Wing

The VHD Delta Wing Series

INFORMATION & PARTS MANUAL

Includes Side Throw & Rear Throw Models.

Covering the

D15 & D20 Models

GPN: 229011 Revision D

11/2023

COPYRIGHT

Neither this manual or part thereof may be reproduced or published

without the permission of AF Gason Pty Ltd

3349

Contents

Ordering Parts 3

Standard Bolt Head Markings And Torque Specicaons 4

Machine Specicaons 5

Machine Informaon & Troubleshoong 6

Assembly Instrucons 7

Grease Point Locaons 8

Parts Diagrams 9

General Assembly 10-11

Pull 12-13

Decals 14-15

Single Blade Set-up 16

Dual Blade Add On (Opon) 17

Blade Installaon - Rear Throw 18

Blade Installaon - Mulch Throw 19

Axle 20

Wing PTO Shas 21

Input PTO Sha (05/2021 - Current) 22

Input PTO Sha (Pre- 05/2021) 23

Transfer PTO Sha (D15) 24

Transfer PTO Sha (D20) 25

Gearbox - Cuerhead 26

Gearbox - Power Divider 27

Driveline - Rear Throw 28-29

Driveline - Mulch Throw 30-31

Driveline Guards 32

Guards - Rear Throw 33

Guards - Mulch Throw 34-35

Hydraulics - Wing Li 36

Hydraulics - Height Control 37

Oversize Sign & Tail Lights Kit (Opon) 38

The following informaon must be supplied to

your local dealer to facilitate fast and accurate

processing of a replacement parts order:-

• Gason Part Number (GPN) and

descripon (as given in this manual)

• Quanty Required

• Machine Model & Serial Number

For your convenience record the following

informaon below.

Dealer Name:

Dealer Address:

Dealer Phone Number:

Machine Model No:

Date of Purchase:

Serial Number:

Subject to any applicable Federal, State or Terri-

tory laws or ordinances, which may apply from

me to me, AF Gason Pty Ltd reserves the right

to make changes in design and specicaons

without noce or obligaon and to change or

disconnue models at any me without incurring

any liability to any Purchaser thereof.

Le and right hand: All references in this manual

are determined by facing the direcon of travel.

For warranty provisions please consult your In-

stallaon and Warranty Registraon document.

While every eort has been made to ensure the

accuracy of the informaon in this manual,

AF Gason Pty Ltd reserves the right to delete,

change or add informaon without noce.

Serial No. Tag At Right Front Of Machine

SERIAL No.

Ordering Parts

3

SERIAL No.

Serial No. Tag At Front Of Machine

3

As part of our service to the end consumer

Gason make every eort to ensure all bolts and

nuts are torqued using specic procedures during

the assembly process.

Throughout this parts manual the following sym-

bols may be seen which indicate important set-

ngs criccal to the connued safe operaon of

your mower/slasher.

Standard Bolt Head Markings And Torque Specicaons

4

: Always Replace after disassembly

: Critical Torque Setting (N m)

Where a Torque is not specied on a nut or bolt it

should be assumed that it is torqued according to

the following tables.

NOTE

The above gures are based on zinc plated, lightly oiled hardware.

Recommended assembly torques for alternave nish or applicaon, may be obtained by mulplying the torque gures in

the table by:

0.78 – for degreased zinc plated bolts.

1.10 – for black oxide nished bolts. 4

Machine Specicaons

55

OVERALL TRANSPORT WIDTH

OVERALL TRANSPORT HEIGHT

Dimensions*Machine Size

15 (4.6m) 20 (6m)

Minimum PTO HP190HP 120HP

Overall Length2(m) 4.8 6.32

Overall Transport Width (m) 2.5 2.5

Overall Transport Height (m) 2.49 3.09

Overall Weight (kg) 3740 4400

Cut Height (mm) 18-410 18-410

Drawbar Weight (tonne) 2.5 3.0

Blade Tip Speed (/min) 16745 21948

Jack 3 Tonne

Deck Material 6mm Deck, Fully Welded with 8mm side plates

Gearbox 210 HP power matched driveline

PTO Shas Comer T80 Series to boxes, Wide Angle VP9 input

Clutch Over run devise on input & 4 plate slip clutches on each V80 Sha

Skids 8mm Height Adjustable sides with 100 x 12mm spring steel base.

Rotor Bar 100 x 14mm spring steel

Blades 100 x 13mm swing back blades on hardened bushes.

Tyres Heavy duty otaon tyres 10/75-15.3 14 PLY

*all dimensions and masses are provided as a guide only if accurate dimensions are required it is recommended the specic machine be measured.

1 - Ensure Tractor Drawbar can supprot weight.

2 - Overall Length based on machine in transport posion. Machine length may vary when in operaon depending on cut height.

6

General

Gason Delta mowers are designed and built to with-

stand the toughest of condions from everyday

contractor demands to the seasonal roadside slash-

ing requirments, when cared for and maintained as

suggested in this and the general operators manu-

als.

Operang Speed

It is recommended that the Gason Delta mowers

be used at speeds of up to 8 - 15km/h Travelling at

speeds in excess of this may aect cut quality and

nish.

The speed will be dictated by the applicaon, ground

condions, tractor HP and cung height.

Gason recommend always commencing cung

at low operang speeds then steadily increasing

speed. The operator should always be observant of

the machine’s cung performance at all mes to

ensure a neat, even nish.

Cung Height

The Gason Delta Mower is designed to slash grasses

and general pasture and provide an even spread of

cut material. It is designed to cut at low heights. In

order to avoid premature wear or fague it is im-

peritave the machine be set-up correctly to avoid

ground contact when cung low.

Pull Angle

The Gason Delta Mower is designed to work through

a fore-a angle of ±15°from the horizontal. Working

the machine over ruts and bumps greater than this

may cause premature failure of the tow eye , pull or

PTO’s and may also damage blades and rotor bars.

6

Machine Applicaon & Capabilies

165°

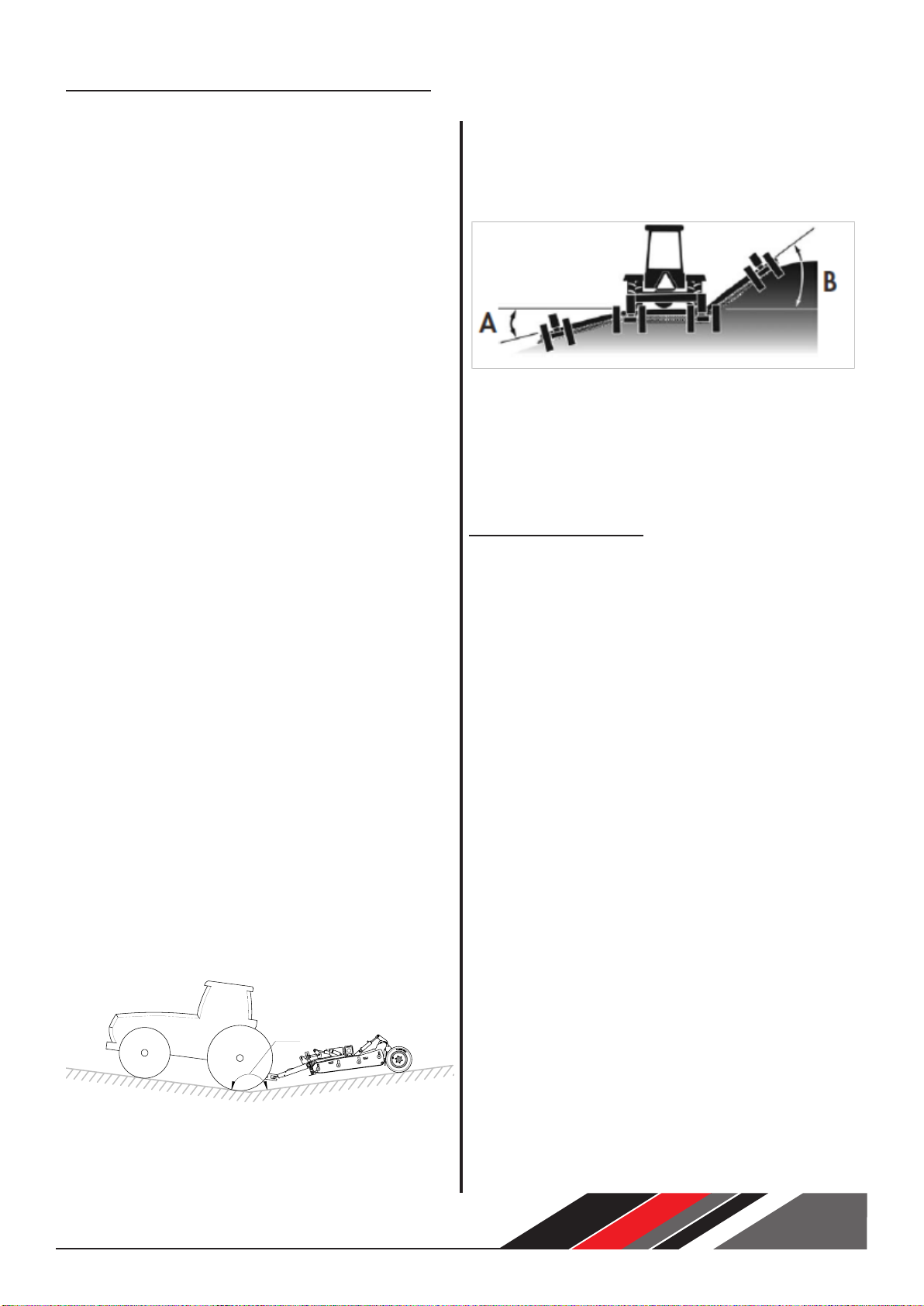

Wing Angle

The Delta Mower can operate in ground up to 45°

above and 20° below horizontal as represented in

the below image by leers A & B.

Gason recommend that at all mes the wheels re-

main in contact with the ground when in operaon.

Failure to do this may result in excess stress on cyl-

inders and may result in premature failure of the

machine.

Trouble Shoong

Why am I geng excessive skid wear?

In most cases excessive skid wear is a result of in-

correct machine set-up. Read the Tractor Connec-

on secon of the General Operators manual to aid

in nding the set-up error. As a guide, skid posion

should always be approximately 12mm from the

ground level when operang.

Why does my machine not follow the ground con-

tour?

The Delta Wing Mower uses an hyraulic oat sys-

tem. In order for this to work the tractor control

lever for the wing li circuit must be put into the

oat posion. Refer Tractor Operators manual for

more informaon on how to do this. Failure to do

this may result in premature wear of cylinder con-

necon points or in extreme cases cracking around

the hinges of the machine.

Why have my gearbox bolts come loose?

In most instances the bolts on the gearbox loosen

as a result of severe load being placed back into the

gearbox generally caused by connous scalping of

the ground.

Note: refer to torque specicaon page.

General

These assembly instrucons should be read in con-

juncon with the “General” Operators Manual sup-

plied. They are intended to provide model specic

details in addion to those in the General operators

Manual.

All Machine set-up should be conducted on at lev-

el ground to ensure even set-up across the machine.

Pull

The pull on the Gason Delta wing will generally be

shipped in a vercal posion and some assembly

will be required prior to conecng to the tractor.

The below image shows the posion the pull it likely

to be shipped in.

The Pull is a heavy components and will require the

use of a crane or forkli to be moved into posion.

Rotate pull to a horizontal posion and t hydraulic

cylinder and spring adjuster. Once complete t PTO

sha from idler sha to tee box. Prior to ng In-

put PTO read General Operators manual to ensure it

is cut to correct length to suit and is ghtened cor-

rectly.

Rear Crank

The rear crank on your Gason Delta Mower is likely

to be shipped in the posion shown above. Remove

all e downs and rotate crank again using a crane

or forkli to sit wheels on the ground, connect hy-

draulic cylinders to crank plate and posion wheels

to allow bolts to be put into crank plates to secure.

77

Assembly Instrucons

8

Grease Point Locaons

COMMON GREASE POINTS

6

2

1

3

4

57

ITEM

DESCRIPTION

NO OF POINTS

GREASE

INTERVAL

(hrs)

D15 D20

1

REAR CRANK ARMS

888

2

HINGES

448

3

PULL BOSS

228

4

PULL SWIVEL EYE

118

5

PULL TRANSFER LINK

118

6

PTO'S

VARIES WITH SHAFTS

8

7

WHEEL BEARINGS

6 6 100

Parts Diagrams

9

3342

3

14

12

6

4

5

1

213

10

8

7

16

9

15

17

17

17

17

17

GENERAL ASSEMBLY

3343

11

ITEM PART No.

DESCRIPTION

QTY.

SIZE

17 8001380

NIPPLE GREASE 1/8" NPT

15

-

16 926318

M8 x 50 COACH BOLT

20

15 926309

M8 x 30 COACH BOLT

26

14 917413

SCREW SET M10x45 GR8.8

4

-

13 913713

BOLT M20x65 GR8.8 HEX Z/P

4

-

12 909005

WASHER SPRING M10 x 2.35 x 2.40 Z/P

4

-

11 907301

WASHER FLAT 5/16x1"x1.2 ZP

46

-

10 903931

NUT NYLOC M20 CL8 AS1285

4

-

9 903302

NUT NYLOC M8

46

-

8 224979

WHEEL ASSY 10/75-15.3

6

-

7 223965

RUBBER FLAP - DELTA 20

2

6 223946

RH WING WELDMENT - DELTA 20

1

5 223946

LH WING WELDMENT - DELTA 20

1

4 223946

CTR DECK WELDMENT - DELTA 20

1

3 223408

PIN-WING PIVOT

4

A

2 223405

SKID - ANTI DROP

2

1 205892

BUSH DU- Ø50 x 50mm LONG

8

-

10

General Assembly

11

Item GPN Descripon Qty.

15’ 20’

1 205892 Bush Du- Ø50 x 50mm 8 8

2223405 Skid - An Drop 2 2

3223408 Pin-Wing Pivot 4 4

4223390 D15 - Centre Deck Weldment 1 -

223946 D20 - Centre Deck Weldment - 1

5 223390 D15 - LH Wing Assembly 1 -

223946 D20 - LH Wing Assembly - 1

6223390 D15 - RH Wing Assembly 1 -

223946 D20 - RH Wing Assembly - 1

7223963 D15 - Flap - Wing Rubber 2 -

223965 D20 - Flap - Wing Rubber - 2

8224979 Wheel Assy 10/75-15.3 6 6

9 903302 Nut Nyloc M8 46 46

10 903931 Nut Nyloc M20 4 4

11 907301 Washer Flat 5/16”x1”x1.2 ZP 46 46

12 909005 Washer Spring M10 ZP 4 4

13 913713 Bolt M20 x 65 GR8.8 Hex ZP 4 4

14 917413 Screw Set M10 x 45 4 4

15 926309 M8 x 30 Coach Bolt 26 26

16 926318 M8 x 50 Coach Bolt 20 20

17 8001380 Nipple Grease 1/8” NPT 15 15

223676 Chain 8mm 11 Links - Mower Ref. Ref.

General Assembly (Connued)

2117 10

4

3

19

14 15 18 20 7

8

1514

13

1

2316

2

11 2212

6

16 24

3345

5

9

PULL

ITEM PART No.

DESCRIPTION

QTY.

SIZE

24 917419

SCREW SET M10x16 GR8.8

2

-

23 917413

SCREW SET M10x45 GR8.8

1

-

22 917309 SCREW SET M8x 25x1.25P 3

-

21 916604

SCREW SET 1/2 UNC X 1 IN

4

-

20 912920

BOLT 1" x 6.5" UNC

1

-

19 912913

BOLT 1" x 9" UNC

2

-

18 912908

BOLT 1" x 6" UNC

1

-

17 908604

WASHER SPRING 1/2 x 5/32 x 5/32 ZP

4

-

16 907503

WASHER FLAT M12x24x1.6 ZP

3

-

15 906902

WASHER FLAT 1" x 2-1/8"x7G Z/P

4

-

14 903911

NUT NYLOC 1" UNC

4

-

13 903406

NUT NYLOC M10 CL8 AS1285

1

-

12 902302

NUT WHIZ FLANGE M8 x1.25P HEX ZP

3

-

11 224257

DOCUMENT HOLDER-BLACK

1

A

10 223952

BRACKET - GUARD MOUNT

1

A

9 223751

BOSS

1

A

8 223750

PIN DRAWBAR 1 1/4"DIA x 8-1/4"

1

7 223536

LINK ARM - SHORTENED

1

A

6 223530

CYLINDER MOD

1

A

5 223404

BRACKET - LINK

1

A

4 222671

HANDLE LOCKING

1

A

3 222669

WELDED 3T JACK ASSY

1

A

2 212530

BRACKET HYD.HOSE TIP

1

A

1 211089

HOSE STAND SPRING

1

A

12

Pull

13

Pull (Connued)

Item GPN Descripon Qty.

15’ 20’

1 211089 Hose Stand Spring 1 1

2 212530 Bracket Hyd. Hose Tip 1 1

3222669 Welded 3T Jack Assy 1 1

4 222671 Handle Locking 1 1

5223404 Bracket - Link 1 1

6223530 Cylinder Assy 3” x 8 1 1

7223536 Link Arm - Shortened 1 1

8 223750 Pin Drawbar 1 1/4” x 8-1/4” 1 1

9 223751 Boss 1 1

10 223632 Bracket - Guard Mount D15 1 -

223952 Bracket - Guard Mount D20 - 1

11 224257 Document Holder 1 1

12 902302 Nut Whiz Flange M8x1.26P Hex ZP 3 3

13 903406 Nut Nyloc M10 1 1

14 903911 Nut Nyloc 1” UNC Hex ZP 4 4

15 906902 Washer Flat 1” x 2-1/8” ZP 4 4

16 907503 Washer Flat M12x24x1.6ZP 3 3

17 908604 Washer Spring 1/2 x 5/32 x 5/32 ZP 4 4

18 912908 Bolt 1” X 6” UNC 1 1

19 912913 Bolt 1” x 9” UNC 2 2

20 912920 Bolt 1” X 6.5” UNC 1 1

21 916604 Screw Set 1/2” UNC x 1” 4 4

22 917309 Screw Set M8x25x1.25P 3 3

23 917413 Screw Set M10x45 GR8.8 1 1

24 917419 Screw Set M10x16 GR8.8 2 2

Decals

14

10

1 14

15

22

15

A

B

2

51513

3344

DETAIL A

21

24

3

23

8

18

7

124

16

9

19

20

16 20

17

6

DETAIL B

SCALE 1 : 16

20

16

11

DECALS

ITEM PART No.

DESCRIPTION

QTY.

SIZE

24 8001418

TAG SERIAL NO

1

A

23 8001251

SCREW DRIVE 1/2"x 6g-U ZP

4

-

22 804465

DECAL GASON-AN AUSTRALIAN

2

A

21 228234

DECAL-MOWER DANGER NOTICE

1

A

20 227410

DECAL - GEARBOX OIL

4

A

19 226754

DECAL - PTO SHAFT LENGTH

1

A

18 224328

DECAL-MOWER CAUTION STOP

1

A

17 224327

DECAL-MOWER PTO ROTATING

1

A

16 224323

DECAL-MOWER CAUTION GUARD

4

A

15 224322

DECAL-MOWER STAND CLEAR

5

A

14 224321

DECAL-MOWER WARNING DEBRI

2

A

13 224320

DECAL-MOWER WARNING BLADE

2

A

12 224318

DECAL-MOWER 1000RPM

1

A

11 224246

DECAL-MOWER DELTA 20 SM

2

A

10 224245

DECAL-MOWER DELTA 20 L

2

A

9 223523

DECAL TRANSPORT SPEED 20km/h

1

A

8 216072

DECAL-DO NOT RIDE

1

A

7 207998

DECAL TMA

1

-

6 207247

GASON LOGO DECAL

1

A

5 207246

DECAL GASON - A/S & MOWER

2

A

4 206995

DECAL - T/PORT WARNING

1

-

3 206955

DECAL WARNING -SAFETY

1

A

2 206694

TAPE WHITE REFLECTIVE - 60 x100mm

2

-

1 205830

TAPE RED REFLECTIVE - 60 x100mm

2

-

Item GPN Descripon QTY

15’ 20’

1 205830 Tape Red Reecve 2 2

2206694 Tape White Reecve 2 2

3206955 Decal - Warning Safety 1 1

4 206995 Decal - T/Port Warning 1 1

5237734 Decal - Gason 2 2

6 207247 Decal - Gason Logo 1 1

7 207998 Decal - TMA 1 1

8216072 Decal - Do Not Ride 1 1

9 223523 Decal - Transport Speed 20km/h 1 1

10 224243 Decal - Delta 15 Large 2 -

224245 Decal - Delta 20 Large - 2

11 224244 Decal - Delta 15 Small 2 -

224246 Decal - Delta 20 Large - 2

12 224318 Decal - 1000 RPM 1 1

13 224320 Decal - Warning Blade 2 2

14 224321 Decal - Warning Debris 2 2

15 224322 Decal - Stand Clear 5 5

16 224323 Decal - Cauon Guard 4 4

17 224327 Decal - PTO Rotang 1 1

18 224328 Decal - Cauon Stop 1 1

19 226754 Decal - PTO Sha Length 1 1

20 227410 Decal - Oil Fill Level 4 4

21 228234 Decal - Danger Noce 1 1

22 237737 Decal - Gason An Australian 2 2

23 8001251 Screw Drive 1/2”x6gU ZP 4 4

24 8001418 Tag - Serial Number 1 1

15

Decals (Connued)

16

: Critical Torque Setting (Nm)

: Always Replace after disassembly

508Nm

5

7

8

3

9

2

6

4

1

1

1

345Nm

NOTE:

FOR CLOCKWISE SET-UP ITEM

9

BECOMES GPN:223542

ALL OTHER PARTS REMAIN THE SAME

Single Blade Set-up

Item GPN Descripon Qty.

15’ 20’

1 903803 Nut Nyloc 3/4" UNF Gr8 Ref. Ref.

2223545 Bush - Blade 3/4" ID x 13mm Ref. Ref.

3 912818 Bolt 3/4" UNF x 2-3/4" Gr8 Ref. Ref.

4912853 Bolt 3/4" x 9" UNF Gr8 Ref. Ref.

5 228729 Spacer - Rotor Bar Block 1 1

6 223564 Clamp - Rotor 1 1

7223544 Rotor Bar - 725mm 2 -

230585 Rotor Bar - 1200mm - 2

8 223722 Rotor Bar Spacer - 725mm 1 -

230586 Rotor Bar Spacer - 1200mm - 1

9223543 Blade - 450mm ACW (Shown) 2 2

223542 Blade - 450mm CW Ref. Ref.

B

A

C

B - 345 Nm

C - 508Nm

ALL BOLTS TO BE LIGHTLY OILED.

ENSURE BLADES ROTATE FREELY AFTER TORQUING BOLTS.

Blade Bolt Kit - GPN: 225718

Includes:

223545: Bush - Blade 3/4”ID x 13mm

903803: Nut Nyloc 3/4” UNF Gr 8

912818: Bolt 3/4 UNF x 2-3/4” HT

345Nm

A - 345Nm

508Nm

: Critical Torque Setting (Nm)

: Always Replace after Disassembly

ALL BOLTS TO BE LIGHTLY OILED

ENSURE BLADES ROTATE FREELY AFTER TORQUING BOLTS.

Blade Bolt Kit - GPN: 225720

Includes:

230591: Bush - Blade 3/4”ID x 9mm

903803: Nut Nyloc 3/4” UNF Gr 8

912825: Bolt 3/4 UNF x 4” HT

6

4

3

1

2

5

3362

ITEM PART No.

DESCRIPTION

QTY

SIZE

6 912825

BOLT 3/4" x 4" UNF

4

-

5 903803

NUT NYLOC 3/4" UNF GR.8

4

-

4 230591

BUSH - BLADE 3/4"ID x 13mm

2

A

3 227408

SPACER 120 - DUAL MULCH BLADE

2

A

2 227407

ROTOR BAR CLAMP EXT.-173

2

A

1 224936

450mm FLAT BLADE

2

A

17

Dual Blade Kit (Opon)

GPN: 226254

Item GPN Descripon Qty.

1224936 450mm Flat Blade 2

2227407 Rotor Bar Clamp Ext. -173mm 2

3* 227248 Spacer 100 - Dual Mulch Blade 2

227408 Spacer 120 (pre - 12/2020) 2

4230591 Bush - Blade 3/4" ID x 13mm 2

5 903803 Nut Nyloc 3/4" UNF Gr8 4

6912825 Bolt 3/4" x 4" UNF Gr8 4

* Note: When ordering item 3, measure rotor bar

bar width and select correct spacer to suit.

18

2

2

1

C W

A C

AC

3358

ITEM PART No.

DESCRIPTION

QTY.

SIZE

2 236627

BLADE KIT AC- 20ft DELTA

2

A

1 236626

BLADE KIT CW - 20ft DELTA

1

A

Blade Installaon - Rear Throw

Item GPN Descripon QTY

15’ 20’

1236624 Blade Kit - Clockwise 1 -

2236626 Blade Kit - Clockwise - 1

3236625 Blade Kit - An Clockwise 2 -

4 236627 Blade Kit - An Clockwise - 2

19

A C

C W

CW

1

12

3352

ITEM PART No.

DESCRIPTION

QTY.

SIZE

2 236627

BLADE KIT AC- 20ft DELTA

1

A

1 236626

BLADE KIT CW - 20ft DELTA

2

A

Blade Installaon - Mulch Throw

Item GPN Descripon QTY

15’ 20’

1236624 Blade Kit - Clockwise 2 -

2236626 Blade Kit - Clockwise - 2

3236625 Blade Kit - An Clockwise 1 -

4 236627 Blade Kit - An Clockwise - 1

: Always Replace after disassembly

: Critical Torque Setting (Nm)

345Nm

14

11

412

1

97

6

15

13

3

10

582

3205

ITEM

PART No.

DESCRIPTION

QTY

15 922316

SCREW CAP M8x25

3

14 221039

AXLE STUB MACHINED

1

13 220749

HUB MACHINED

1

12 220748

STUD WHEEL M18x1.5

6

11 220747

SEAL RING

1

10 220746

WEAR RING

1

9220745

NUT SLOTTED M33x2

1

8220742

PIN SPLIT 8x80

1

7220741

NIPPLE GREASE 6mm

1

6220740

DUST CAP

1

5220739

BEARING OUTER 55x120x31.5

1

4220737

TRIPLE LIP SEAL

1

3220413

BEARING INNER 80x140x35.25

1

2217232

WASHER M8 RIB LOCK

3

1204622

WHEEL NUT M18 x 1.5 HEX

6

Axle

GPN: 220724

20

Item GPN Descripon Qty

1204622 Wheel Nut M18 X 1.5 Hex 6

2 217232 Washer M8 Rib Lock 3

3 205298 Bearing Inner 55x100x22.75 1

4220737 Triple Lip Seal 1

5 205297 Bearing Outer 40x80x19.75 1

6 220740 Dust Cap 1

7220741 Nipple Grease 6mm 1

8220742 Pin Split 8 x 80 1

9220745 Nut Sloed M33x2 1

10 220746 Wear Ring 1

11 220747 Seal Ring 1

12 204621 Stud Wheel M18x1.5 6

13 220749 Hub Machined 1

14 221039 Axle Stub Machined 1

15 922316 Screw Cap M8 x 25mm 3

16 204678 Axle Assembly Ref

This manual suits for next models

1

Table of contents

Other Gason Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions