Gaspar Xicoy LGC 13C User manual

-1-

Welcome!

Congratulations on the purchase of your new landing gear controller. Xicoy are

dedicated to the design and production of electronic controllers to the highest

standards of quality and reliability to bring you the customer the very latest next

generation designs.

Features

-Direct control of 3 motors in bidirectional and regulated mode up to 2,5 A.

-Control of electric brake, full proportional, lineal and adjustable pulsed mode.

-3 servo outputs for the control of the doors, endpoints programmable

-Steering servo processor. Programmable position of servo arm in retracted mode,

programmable center, sense of movement and gain on extended position.

-Single or dual channel mode.

-Programmable delay for extension and retraction of all gears independently.

-Easy programming trough a LCD display.

-Small size and lightweight.

Installation

Thanks the small size and lightweight of the unit, it can be placed in any place on the

model. We recommend a place where the wiring to the gears be the shorter as possible

to have a clean installation.

Electrical connections

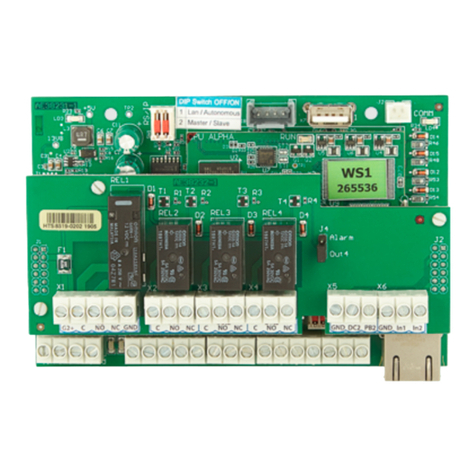

Picture 1

Motor connections

Connect the 3 motor leads to the sockets in the unit. Please note that are labeled “Nose

gear”, “Left Gear”, “Right Gear”. Assure you connect the correct gear lead to correct

output in order that later during programming, the delays are applied to correct retract.

-2-

The polarity of the connection lead is marked on the label of the unit. In the case of

using reversed gears, the connector should be connected backwards to reverse the

operation of the motors.

Brake connections

Connect the leads from

brakes on the sockets

labeled “Brake”. Polarity and

position are not important

on the brakes.

You can use good quality JR

extension leads for the

motors and brake leads if

necessary.

Battery connection

Battery should be connected on the yellow MPX connector. Double check the correct

polarity before connecting the battery on the unit, a reversed battery connection will

destroy the unit, often the damage is beyond repair.

Output for the door servos

Connect the 3 servos to the outputs on the unit. You can connect more than one servo

to each output using a “Y” lead.

Output to the steering servo

Connect the steering servo to “Steer Out” if used.

Radio inputs:

You can choose to use a single channel to control the gear and brake, or separated

channels. Gear input channel should be always connected for operation, brake channel

and steering input channel are optional.

Power supply considerations: PLEASE READ!

This controller can receive up to 3 different power sources. In order to prevent

malfunctions in your system you should know that:

The main battery should be between 6,6 to 9,9V. Recommended battery is a Lipo of

7,4V. Please double check the polarity before connecting it. The damage caused by

polarity reversal is not covered by warranty!!!

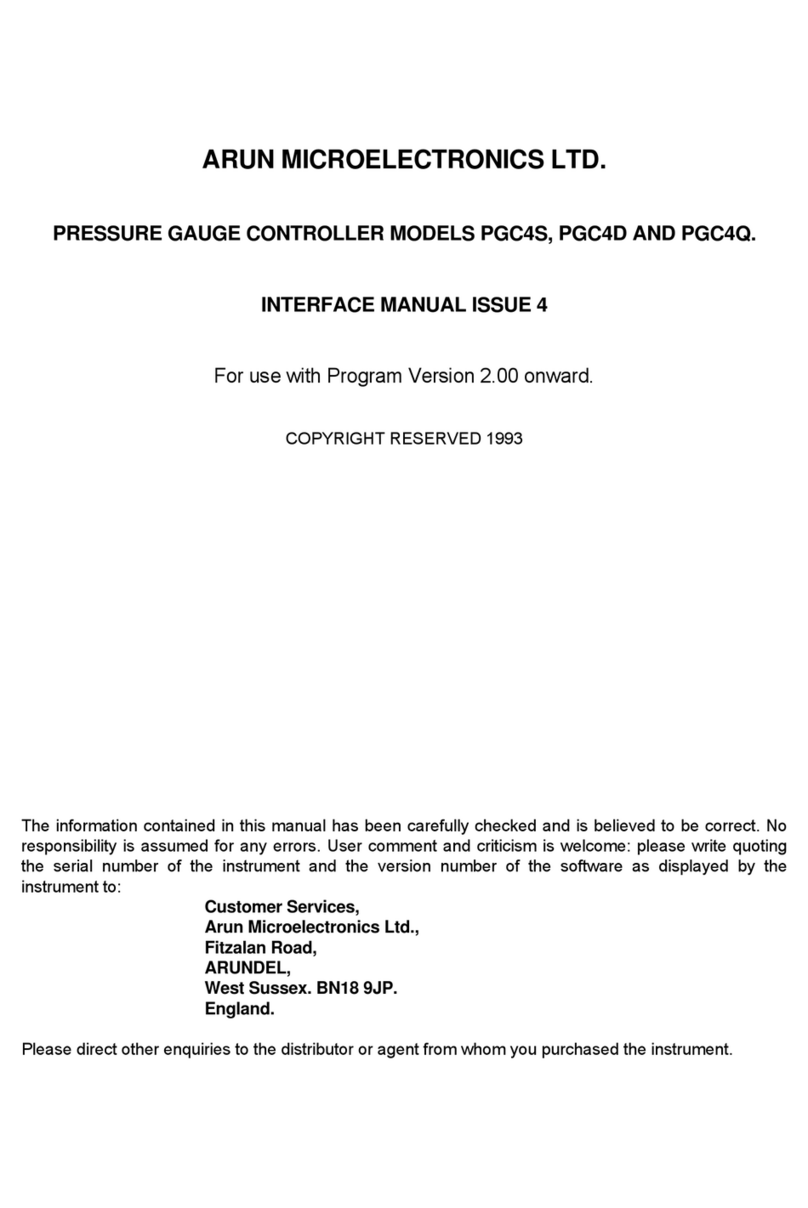

Picture 2

-3-

This battery powers the motors and the brakes. The controller have a internal switch

operated by the

Gear Input

power. It is not necessary to disconnect this battery between

uses, but it is recommended to disconnect it after the flying session. There is a minimal

power drawn from this battery when the unit is switched off that can drain a battery in a

2 month period.

In the case you use battery regulators

a) The steering servo is powered by same supply as on the steering input (

Steer In

). So,

for example, if the steering input comes from a battery regulator (powerBox, etc) at

6V and the

Gear In

channel comes directly from the receiver powered at 5V, the

steering servo will be powered at 6V.

b) The outputs to the servos for the doors are powered from the

Gear Input

socket. If

you connect directly the gear input to a low power source (for example, directly to

the receiver when the receiver is powered by a low power, 5V regulator) the current

draw by the servos of the doors could be excessive, causing the receiver to switch

off.

c) The power input pin of the

Gear

and

Brake

inputs are internally connected together.

This could cause a malfunction by connecting different voltages together. For

example, if you connect the

Gear Input

directly to the receiver that is powered at 5V

and the

brake input

to a battery regulator that supply 6V, then the 6V supply will

flow trough the unit to the receiver, being no longer powered at 5V by a

independent regulator. In this case, it is necessary to cut the central wire (red) on the

lead from

Gear In

to the receiver to prevent the voltage present at

Brake In

to reach

the receiver. The controller and the door servos will be powered by the power

arriving to the

brake input

.

All negative (ground) connections are connected together inside the unit. Always fully

disconnect the batteries (both poles) from the installation before charging, as current

can flow trough the unit from one battery to the other during charge, damaging the

installation.

Please contact to Xicoy Electronica for advice on particular installations.

SETUP

Once you have installed the controller in your model, you can adjust the radio, outputs,

delays and steering servo.

-4-

Setup can be done trough a data terminal or trough a pushbutton and LED light. Full

functions are only available if programmed trough the data terminal.

In both cases, first of all you should decide if you will use one or two channels for

control, and then setup your transmitter accordingly. Check with a servo first that the

transmitter is operating as it should and to identify the RX channels used.

Double channel operation. The

Gear In

input control the retract operation and the

Brake

input control the brake.

Single channel operation: The

Gear In

input control both the gear and the brake.

The operation similar to a turbine engine control where raising the trim enable the

engine to run and the stick throw regulate the engine power. In this case, first the

gear will be operated and then the brake. For example, you can setup a channel that

from –100% to –75% activate the gear and from –75% to +100% regulate the brake

power.

The following setup procedure assumes the use of a Xicoy data terminal, please jump to

the “Manual Setup” section for the pushbutton and Led setup procedure.

Setup using a data terminal

Connect the data terminal (Same model as used by Xicoy V10 ecus) on the socket at left

side of

Gear In

input.

You can navigate trough the different menus by the buttons on the left side of the box,

and values are changed using the + and –buttons on the right side.

First screen displayed show the status (gear up, gear down, etc), the battery voltage,

power of the brake, and, during motor operation, the amperage to each of the motors.

Second screen display the RC signals measured from the receiver. You can check that

the RX connection is working and the measured values change when the transmitter

controls are operated. Standard RC signal go from 1000 to 2000uS, 1000us typically is

displayed on RC transmitters as –100% 1500uS 0% and 2000uS as +100%. Due at display

space the numbers are divided by 10, so a measured signal of 1400uS is displayed as

“140”. You can check that, when operating the transmitter, the reading change

accordingly.

On third screen you can scroll trough the different programming sections. Select the

area you want to program by pressing the “+” button.

-5-

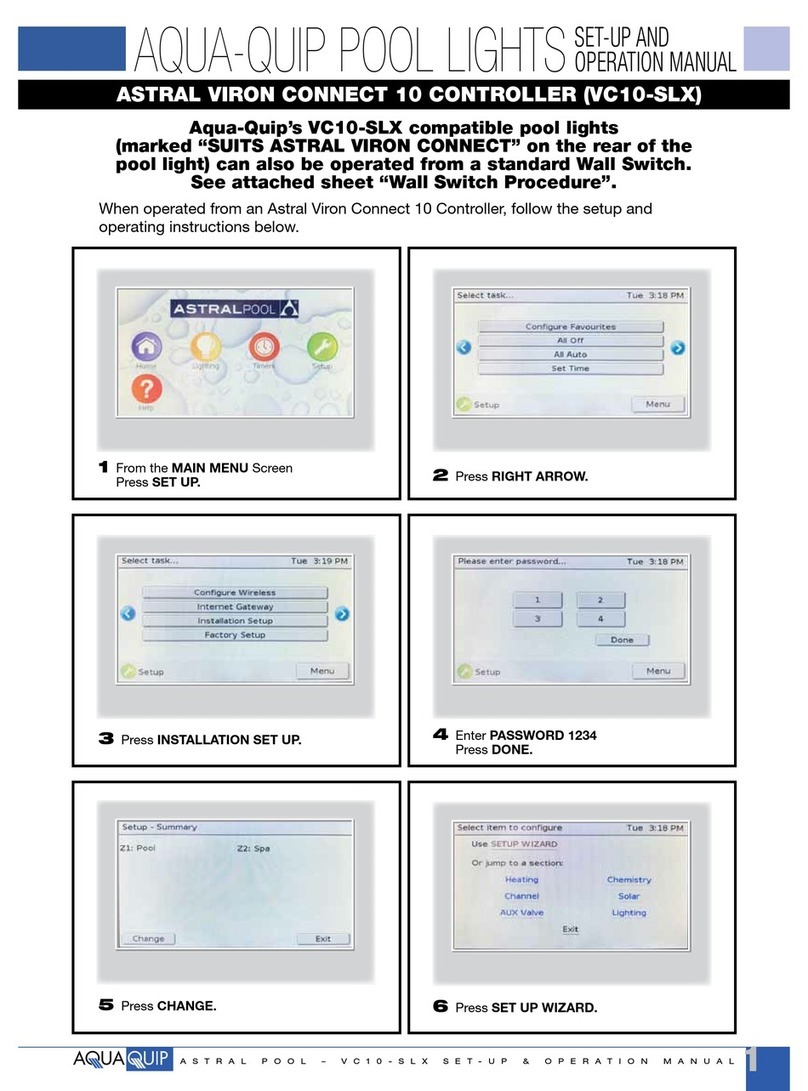

Radio Setup

On this section you can program the radio inputs to mach your transmitter and setup

the brake power.

First screen is the Gear Up position (Picture 3):

Set the transmitter switch or slider of the gear

channel in the position you wish that the gear be

in retracted position. Current reading is displayed

on the right side of the screen. Once the TX is set,

press the “+” button. The controller will store

the current signal received as “gear up” command.

Next screen is the Gear Down position:

Set the transmitter switch or slider of the gear channel in the position you wish that the

gear be in extended position. Once the TX set, press the “+” button. The controller will

store the current signal received as “gear down” command.

Next screen is the Brake OFF position:

Set the transmitter switch or slider of the brake channel (or on the gear channel if you

use the single channel option) in the position you

wish that the brake be unpowered. Press the “+”

button.

The controller will store the current

signal received as “Brake OFF”

command (Picture 4). Note that if in this step the controller does not detect a valid

signal in the brake input, then it will assume a single channel operation mode, To enable

double channel, this step should be repeated once the brake channel is connected to a

valid RC signal source.

Last radio screen is the Brake Maximum position.

Set the transmitter switch or slider of the brake channel (or on the gear channel if you

use the single channel option) in the position you wish that the brake be at maximum

power. Press the “+” button. The controller will store the current signal received as

“Brake 100%” command”.

This completes the radio setup for the gear and brake channels. But two more adjust

options are offered in this section:

Picture 3

Picture 4

-6-

1. Brake limiter: The limiter usually is set at 100% and the brake power is adjusted

trough the TX, but in the case that you need to limit the maxim brake power, you

can decrease this setting to reduce the power applied to brakes.

2. Brake pulse ratio: The power to the brakes could be pulsed in order to produce a

“ABS like” operation, brake power is pulsed at fast rate to avoid to create “flats” on

the tires on hard braking. It is possible to adjust the brake pulses in different values

to change the ratio between the “high power” and “low power” pulse depending on

wheel diameter and model weight.

Servo sequencer setup

The unit provides 3 independent outputs for to control the servo operated doors. All 3

outputs are adjusted by the same procedure, so the setup of only one output is

described

It is possible to define 3 different positions for each output:

Gear Up position: The position you wish that the servo be driven when the gear is

retracted. Typically is a closed door.

Gear Down position: The position you wish that the servo be driven when the gear is

extended. Depending on model type, could be a opened or closed door.

Motor ON position: The position of the doors when the retracts are moving, typically

open.

The setup of the position in each phase is easily done by the help of the steering input

channel. In the case you don’t use this channel on your installation you should

temporarily connect a RC signal from the rx or from a servo tester in order to operate

the servos manually to the desired position.

It is recommended to connect only the servo being adjusted to avoid the other servos to

move uncontrolled during the setup.

First screen is the “Servo 1 Gear Up

position”. (Picture 5)

When this screen is displayed, the

servo1 OUT

will deliver the same

signal as arriving to the Steering

input, so that you can move the servo

Picture 5

-7-

directly trough the rudder stick on your TX. Set the servo at the position you want that it

to be when the gear is retracted, and press the “+” button. The current position will be

stored in the permanent memory of the controller. In the case you don’t want to modify

this position to keep the old stored value, simply change of screen by the menu buttons,

the settings are only changed on the permanent memory when the “+” button is

pressed.

Next screen is the “Servo 1 Gear Down

position”. Operate the servo trough

the TX to the position you want that it

to be when the gear is extended, and

press the “+” button.

The position could be the same as the

“gear up” position if you want a CLOSED-OPENED-CLOSED sequence.

Last screen is the “Servo 1 Motor On

position” (Picture 7). Again, operate

the servo trough the TX to the

position you want that it to be when

the gear is in movement, and press

the “+” button to store the setting.

Usually is the same position as the “gear down” position in the OPENED-CLOSED

sequence, but also it allow programming an over travel, the door opens more during

gear operation to give extra clearance to the wheel and legs, but return to “scale”

position when the gear is fully extended.

Servo 2 and Servo 3 are programmed same way.

Last screen is the “Servo switch off

time:” (Picture 8) To prevent the

possibility of a servo to be overloaded

and burned due at being jammed, a

protection function is added that allow

to release the servo force after some

seconds (programmable by this

parameter).

After the movement of retracts is finished, the servo signal is switched off, that cause the

servo to act as “unpowered”. The servo position is refreshed each 15 seconds to

compensate the small movement of the servo (if any) during these 15s to keep the door

Picture 6

Picture 7

Picture 8

-8-

in to commanded position, assuming that there is not a considerable force acting on the

servo during the switch off period. In the case you want that the servo be active all the

time, set this parameter to zero.

Correct operation of this feature implies a servo that become “soft” when no signal

received. All analog servos act like this, but some digital servos hold the position when

no signal is received. If you plan to use digital servos on the doors and to use the switch

off feature, check first if your servo is compatible, or use a analog servo. The Hitech and

Multiplex digital servos we have tested are not suitable, but JR 8511 is.

Motor delay

To replicate the operation of full size landing gears, it is possible to set a programmable

delay for each motor operation.

First screen on this section is the delay in seconds of the main, left gear when Gear Up is

selected. “Gear Up Delay Main Left”is displayed on the screen. Use the +/- buttons to

set the time you want the controller wait before the left main motor is operated since

the Gear Up command is selected.

Second screen is the delay time on the same gear (main left) motor operation when

“gear down” is selected.

Next screens adjust same delays for right mains and nose gear. Please note that you can

use this function to insert a delay from door operation to gear operation by

programming same delay on all 3 motors.

Steering servo processor

The steering servo is controlled trough the unit to assure that the nose wheel is centered

to a defined position during retraction and does not move while the gear is retracted.

Over this function, a signal processor is added that allow modifying the center, gain and

direction of operation of the steering when the gear is down. Thus, it is possible to take

the steering input signal from the same channel as the rudder, despite the different

centering, sense of movement and travel between these two servos, saving one RC

channel.

Setup

Connect the Steering input to the desired RX channel for the steering (or troughs a “Y”

lead on the rudder channel).

If you use same signal as the rudder, first setup the rudder centering and travel. Once

you are satisfied with the rudder operation, connect the steering servo and proceed to

adjustment.

-9-

First adjustment is the position of the steering servo at retracted position. Using the

rudder channel of your TX, set the servo to the position you want it when the gear is

being retracted and stored. Press the “+” button to store the setting in the permanent

memory.

Next adjustment is the centering of the servo in deployed position. Double check that

the rudder is centered, and then using the + and –buttons center the steering servo.

Finally, check the steering travel and sense. A range of adjustment from –200% to

+200% is provided. Positive numbers mean same direction as rudder, negative numbers

mean reverse operation. A 100% setting give same travel and direction as the rudder

servo, -100% give same travel but reverse operation, 200% travel mean double travel

than rudder, 50% give half movement. Once you set the travel and sense, it is possible

that the centering need a new adjust, just go back to previous adjustment by the menu

buttons.

Motor adjust

This last section of adjustment allows adapting the unit to different motors. These

adjustments are not available in some of the units that are setup by motor

manufacturer.

First adjustment is “Motor Cut

Amperage”(Picture 9). Maximum

value is 2,5A.

This is the threshold amperage to detect that the motor have arrived at end of travel.

This is the most important parameter that should be set to the recommended value

from the motor manufacturer. It should not be changed unless you know exactly what

you are doing. A too high value could cause that the endpoint be undetected, burning

the motor, or that the gear train to be damaged by a excess of torque.

Next, it is the “Unload time”.

(Picture 10) When the gear

movement is finished, a short pulse

of reversed power is sent to the

motor to remove the tension stress

on the gears, bearings and

suspension.

Picture 9

Picture 10

-10-

Too low time will not unload the motor, causing high stress and wear; too long time can

move the slider out of “lock” position.

Last adjustable parameter is the “Maximum Motor time”. This is a security parameter

that will power down the motors after a certain operation time (programmable) to

prevent the case that the endpoint is undetected.

Last screen display a counter of operations to track the number of the cycles and

schedule maintenance.

Manual operation

Besides the operation in normal mode (controlled by the radio), there unit offers several

testing options to operate the gear in manual model.

Under “Manual mode” menus, you can deploy or retract the gear, with the possibility of

to stop and resume the movement in any point, plus operate each gear independently

up and down, with the possibility of to stop, reverse and resume the movement in any

point of the travel.

NOTE: When you leave the manual mode menus, the controller will return to a “RC

mode”, so the gear will move automatically to the currently command received from the

transmitter.

Switch On delay

There is some intelligence build in the controller to prevent unwanted gear operation

when switching on the receiver and power supply. At power up, the controller will wait

during 3 seconds, waiting for the receiver to boot and stabilize the outputs, ignoring any

glitches that it could generate during this time. After these 3 seconds, the controller will

begin to check the RC signal, but will wait to operate the gear until a change on RX

signal is received. Thus, if at “switch on” the gear is down, but the signal received from

the TX is “gear up”, the gear will keep down, it will be necessary to place the TX switch

to “gear down” and back to “gear up” to initiate the retraction.

Setup without the Data terminal

There is a LED indicator and a pushbutton to allow setup the unit without the data

terminal. In this case the options are considerably reduced from the full options

available using the data terminal.

Connect the RC channels you want to use (

Gear In

obligatory,

Brake In

and

Steering In

optional). Set the

Steering In

(Rudder channel) in the position you want that the

steering servo be placed during retraction and gear up position.

-11-

Leave the main battery disconnected to prevent accidental movement of motors.

Switch off the power. Press the button with the aid of a plastic rod (a pen, etc, but

nothing metallic that could damage the electronic board). While the button pressed,

switch on the power on the receiver.

When receiver powered, release the switch.

The blue LED will light intermittently, one short flash with a long pause between flashes.

Set your transmitter at the position you want the gear to be retracted.

Once the TX set, press the switch again. Hold it pressed until it lit continuously, this will

indicate that the command received from the TX as been stored as “Gear Up” command.

Release the button, the led will blink 2 short times followed by a long pause. Repeat the

procedure described above for to memorize the remaining radio commands:

1 blink Gear Up command

2 blinks Gear Down (extended) command

3 blinks Brake OFF. The unit will detect if signal present on Brake In, if not will

assume single channel mode.

4 blinks Brake maximum.

5 Blinks Steering servo retracted position.

NOTE: Executing this procedure will set all remaining adjustments to the factory

defaults, all delays, door servo positions, steering servo adjustments will be reset to

default. This procedure allow to use the controller in simple models without the need of

a data terminal.

Disposal

Electrical equipment marked with the cancelled waste bin symbol must not be

discarded in the standard household waste; instead it must be taken to a suitable

specialist disposal system.

In the countries of the EU (European Union) electrical equipment must not be discarded

via the normal domestic refuse system (WEEE - Waste of Electrical and Electronic

Equipment,directive 2002/96/EG). You can take unwanted equipment to your nearest

local authority waste collection point or recycling centre. There the equipment will be

disposed of correctly and at no cost to you.

By returning your unwanted equipment you can make an important contribution to the

protection of the environment.

Table of contents