Gast 87R-10BA User manual

®

Registered Trademark/™ Trademark of Gast Manufacturing Inc. ©Copyright 2023 Gast Manufacturing Inc. All Rights Reserved.

www.gastmfg.com

ISO 9001 CERTIFIED

A UNIT OF IDEX CORPORATION

Part No. 6190762 (Rev B)

User Manual

87R-10BA

Beverage System

6190762 (Rev B) Beverage System User Guide

© 2023, Gast Manufacturing

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

Table of Contents

Table of Symbols ......................................3

System Features ......................................4

Operating Manual .....................................5

Maintenance ..........................................9

Schematics ..........................................10

Parts and Accessories ................................12

Technical Data and Specifications .....................13

Troubleshooting ......................................15

Warranty.............................................17

WARNING

PLEASE READ THIS MANUAL COMPLETELY BEFORE INSTALLING AND USING

THIS PRODUCT. SAVE THIS MANUAL FOR FUTURE REFERENCE AND

KEEP IN THE VICINITY OF THE PRODUCT.

IMPORTANT SAFETY INSTRUCTIONS AND REGULATORY INFORMATION

Congratulations on the purchase of your new GAST Compressor System. This system uses an oil-free rocking piston

air compressor that produces high-purity compressed air for use in beverage syrup dispensing or other pneumatic

applications.

Beverage System User Guide 6190762 (Rev B)

© 2023, Gast Manufacturing

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

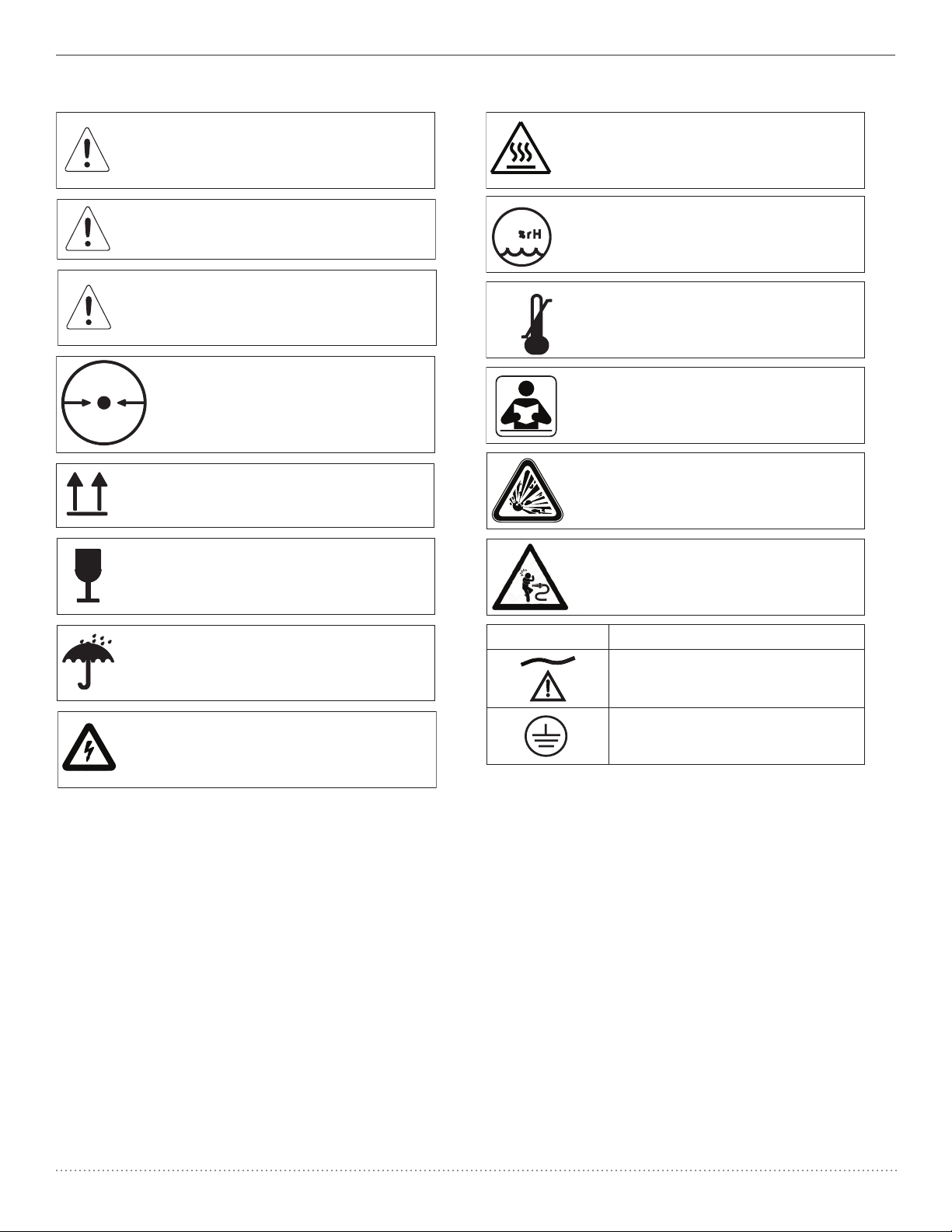

DANGER: Indicates an imminently hazardous

situation which will result in serious or fatal

injury if not avoided. This symbol is used only

in the most extreme conditions.

WARNING: Indicates a potentially hazardous

situation which could result in serious injury

if not avoided.

TABLE OF SYMBOLS

Electrical Shock Hazard.

Risk of electric shock present. Make sure power

is disconnected before attempting this procedure.

CAUTION: Indicates a potentially hazardous

situation which may result in minor or

moderate injury if not avoided. It may also be

used to alert against unsafe practices.

WARNING: To Avoid Serious Burns.

Do not touch surface during operation.

Indicates package should be handled with

these symbols pointing up.

FRAGILE: Handle package with care.

Indicates this package must be kept dry.

-29 °C

-20 °F

+50 °C

+122 °F

Indicates the acceptable shipping

temperature range.

95 Indicates the acceptable maximum

relative humidity for shipping.

372MM HG

.49 ATM

Indicates the acceptable lowest barometric

pressure conditions in which this unit

can be shipped.

Read operation and maintenance

manual before operating.

CAUTION: Risk of Bursting –

Do not adjust regulator to result in output

pressure greater than marked maximum

pressure of attachment.

WARNING: Risk of injury –

Do not direct air/nitrogen stream at body.

Symbol Description

A/C power

Ground

6190762 (Rev B) Beverage System User Guide

© 2023, Gast Manufacturing

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

System Features

REG & P. SWITCH ASM'S

DRYER/FILTER ASM'S

PUMP ASSEMBLY

TANK FEET

WALL MOUNT BRACKETS

TANK DRAIN

COOLING

COIL

K1054

FITTING KIT

3-PIECE

(PART 1/3)

K1054

FITTING KIT

COUPLING

(PART 3/3)

K1053

REGULATOR

ASSEMBLY KIT

K1052

PRESSURE SWITCH

ASSEMBLY KIT

DETAIL DRYER/FILTER ASM'S

SCALE 1 : 4

K1051

DRYER ASSEMBLY

K1051A

FILTER ASSEMBLY

DETAIL PUMP ASSEMBLY

SCALE 1 : 4

K1050

PUMP ASSEMBLY

NOTE: THERE IS ONLY ONE FITTING KIT, IT CONSISTS OF A

3-PIECE FITTING, A 2-PIECE FITTING AND A COUPLING.

THE 3-PIECE FITTING IS LOCATED BETWEEN THE PUMP

AND THE COOLING COIL. THE 2-PIECE FITTING IS LOCATED

BETWEEN THE PRESSURE SWITCH AND THE REGUATLOR.

THE COUPLING IS LOCATED ON THE TANK, UNDERSIDE OF

THE PUMP MOUNTING BRACKET.

K1054

FITTING KIT

3-PIECE

(PART 2/3)

Beverage System User Guide 6190762 (Rev B)

© 2023, Gast Manufacturing

We reserve the right to make any alterations which may be due to any technical improvements

Printed in the USA

Information

Please note that you can find the pictures and figures we are

referring to throughout the manual

Important - read this first!

Please read the following information and operating instructions

included with this product before use. This information is for your

safety and it is important that you follow these instructions. It will

also help prevent damage to the product. Failure to operate the

unit in accordance with the instructions or using unauthorized

spare parts can cause damage to the unit and could cause

serious injury.

CAUTION: To reduce risk of electric shock

• Only authorized service agents should carry out service.

Removing parts or attempting repairs can create an electric

shock. Refer all servicing to qualified service agents.

• If this unit is supplied with a three-pin plug, connect with a

properly earthed outlet only.

WARNING: To reduce risk of electrocution

• Do not use this unit with electrical voltages other than

stated on the rating plate located on the back of the system.

• Store in a dry place.

• Keep surrounding floor area dry around system.

• Do not reach for this product if it has fallen into liquid.

Unplug immediately.

• This unit is not weatherproof. Never operate outdoors in the

rain or in a wet area.

DANGER: To reduce risk of explosion or fire

• This unit is not intended to be used as a sprayer.

• Do not use this product in or near explosive atmospheres or

where aerosol products are being used.

• Do not allow compressor to intake any other gases other

than atmospheric air.

• Do not pump combustible liquids or vapours with this

product; do not use it in or near areas with combustible or

explosive liquids or vapours.

• Do not use this unit near open flames.

CAUTION: To prevent injury

• Compressed air/nitrogen can be dangerous; do not direct

airflow at a persons head or body.

• Always keep the system out of reach of children.

• Never operate this product if it has a damaged power lead

or plug, if it has been dropped or damaged, or if it has

fallen into water. Return the product to a service center for

examination and repair.

• Keep the electrical cable away from hot surfaces.

• Ensure all openings are kept free of restriction and never

place the system on a soft surface where the openings may

be blocked. Keep all openings free from dust, dirt and other

particles.

• Never insert fingers or any other objects into fans.

• This unit is thermally protected and can automatically

restart when the unit cools and the overload resets.

• Wear safety glasses, when servicing this product.

• Use only in well ventilated areas.

• This product may only be connected to units or tools with a

max. pressure rating higher or equal to that of the system.

• The internal surface of the system can get hot. Do not touch

internal system surface during operation. Keep the system

cover in place during operation.

• The surface of the system can get hot. Do not touch system

surface during operation.

Operating manual Failure to observe the safety precautions could result in severe

bodily injury, including death in extreme cases.

IMPORTANT: General directions for use

• Protect the system against rain, moisture, frost and dust.

• The system is constructed and approved for a max.

pressure as stated under Technical Specifications.

• Do not operate system at ambient temperatures exceeding

40°C/104°F or falling below 4°C/39°F.

• If the supply power lead on the system is defective, an

authorized distributor or other qualified personnel must

carry out the repair.

Warranty

Good Bad

Min. 4 °C/39 °F Max. 40 °C/104 °F

Provided that the operational instructions, maintenance, and

service have been carried out, your system is guaranteed against

faulty material or workmanship for 2 years. Reference warranty

statement at back of manual.

Conditions for Sale and Delivery will generally apply. Gast

Manufacturing, Inc. A/S reserves the right to change technical

specifications/constructions.

Contents of box

Your system should be delivered in a clean and undamaged box.

If not, contact your equipment provider immediately. The box

should contain the following:

• system

• system operating manual

• quick start guide

Unpacking

DO

• Ensure incoming line voltage is above Vac ( Vac for

high volt models)

• Ensure room temperature is below °C (°F)

• Inspect product for damage

• Ensure bottom and sides of system are clear from

obstruction

DON’T

• Throw away packaging, manuals, or part packet

• Install in a dusty/dirty non-ventilated or enclosed area

without proper cooling

Table of contents