GasTech GTA-VSD20i User manual

t +61 8 6108 0000 e info@gastech.com w gastech.com

GTA-VSD20i

Digital Ventilation Fan

Controller System

OPERATOR’S MANUAL

GTA-VSiTM

Digital Ventilation Fan Controller System

Part Number 73- 010

Manual Revision v1.0 (12 August 2014)

Table of Contents

1.

Introduction ................................................................................................................................................... 6

1.1

Features ................................................................................................................................................ 6

2.

Component Parts ........................................................................................................................................... 7

2.1

Main Controller Module ........................................................................................................................ 7

3.

Mounting .......................................................................................................................................................

3.1

Wiring Up The Modules ...................................................................................................................... 10

3.1.1

Power Connections - Main Control Unit, Extender Module and HMI ............................................ 10

3.1.2

Power Supply Considerations ......................................................................................................... 10

3.1.3

Connections From Gas Sensors and Connection to Fan System. .................................................... 11

3.1.4

Connections To Relay Switched Functions. .................................................................................... 12

4.

System Operation. ....................................................................................................................................... 13

4.1

System Commissioning ....................................................................................................................... 13

4.2

Running The System ............................................................................................................................ 13

4.2.1

Enabling a Channel (HMI required)................................................................................................. 13

4.2.2

Entering the Setup Password (HMI funcion)................................................................................... 13

4.2.3

Normal Input Signal Operation ....................................................................................................... 13

4.2.4

Fault Signal Indication ..................................................................................................................... 13

4.2.5

Fan Control / Alarm Relays ............................................................................................................. 14

4.2.6

Variable Speed Enable Signal .......................................................................................................... 14

4.2.7

Fan Control Voltage ........................................................................................................................ 14

5.

System Characteristics ................................................................................................................................. 15

© 2011 Gastech Australia Pty Ltd Page 2

PROPRIETARY STATEMENT

GasTech Australia owns proprietary rights in the information disclosed within. By receiving this document, the

recipient agrees that neither this document nor the information disclosed within nor any part shall be

reproduced or transferred to other documents or used or disclosed to others for manufacturing or for any

other purpose except as specifically authorised in writing by GasTech Australia.

COPYRIGHT STATEMENT

Information contained in this document is protected by copyright. No part of this document may be

photocopied, reproduced, or translated to another program or system without prior written authorisation

from GasTech Australia.

TRADEMARK STATEMENT

Protected through use and/or registration in the United States and many foreign countries are the trademarks

and service marks of GasTech Australia. The use of the ® symbol indicates registration in the United States

only and the “

TM

” is in Australia; registrations may not have been issued at present in other countries. All other

product names and logos are trademarks of their respective owners.

DISC AIMER

Under no circumstances will GasTech Australia be liable for any claims, losses, or damages resulting from or

arising out of the repair or modification of the equipment by a party other than GasTech Australia or its

authorised service representatives, or by operation or use of the equipment other than in accordance with the

printed instructions provided by GasTech Australia or if the equipment has been improperly maintained or

subject to neglect or accident. Any of the foregoing will void the warranty.

REVISIONS TO MANUA

All information contained in this manual is believed to be true and correct at the time of printing. However, as

part of its continuing efforts to improve its products and their documentation, GasTech Australia reserves the

right to make changes at any time without notice. Any revised copies of this manual can be obtained by

contacting GasTech Australia.

Page 3 © 2011 Gastech Australia Pty Ltd

SERVICE PO ICY

GasTech Australia maintains a service facility at the factory as well as authorised service facilities around the

world. Should your controller system require service, you may contact us toll free at 1 00 999 902 within

Australia only or 61- -610 -0000, or visit our website www.gastech.com.au for authorised service locations.

For non-warranty repairs, you will need to provide a purchase order number. If you need to set a limit to the

repairs costs, state a “Not to Exceed” figure. If you need a quotation before you can authorise repair costs, so

state, but understand this will incur additional costs and may delay processing of the repair.

GasTech Australia’s policy is to perform all needed repairs to restore the instrument to full operating

condition, including reactivation or replacement of all out-of-warranty electrochemical cells.

You may send the unit, freight prepaid, to: GasTech Australia Pty Ltd, 24 Baretta Rd, Wangara 6065, Western

Australia. Attn.: Service Department. Enclose the copy of your contact details. Pack the instrument and all its

accessories (preferably in its original packing) and any special instructions. Repairs are warranted for 90 days

from the date of shipment. Sensors have individual warranties.

Always include your address, purchase order number, shipping and billing information, and a description of the

defect as you perceive it. If this is the first time you are dealing directly with the factory, you will be asked to

provide credit references, prepay, or authorise COD shipment.

NOTE: GasTech Australia assumes no liability for work performed by unauthorised service facilities.

© 2011 Gastech Australia Pty Ltd Page 4

WARRANTY STATEMENT

1. Consumers have the benefit of conditions and warranties implied by the Trade Practices Act 1974 (TPA)

and similar provisions of State and Territory enactments and nothing in these conditions is intended to

exclude, restrict or modify any statutory obligation of GASTECH AUSTRALIA PTY LTD (Company) if that

cannot lawfully be effected.

2. This warranty relates only to Equipment manufactured and services supplied by the Company, its related

corporations and subsidiaries. Equipment or any part thereof which is returned to the Company,

transportation prepaid, within 27 months from the date of dispatch from the Company’s premises or 24

months from the date of shipment to the ultimate user (whichever occurs first) and is found by the

Company, after examination, to be defective in workmanship or materials, will be either repaired or

replaced as determined by the Company, free of charge. The terms of this paragraph apply unless stated

otherwise in this instruction manual.

3. This warranty does not apply to:

a) replacement or repairs which are required as a results of improper installation, misuse,

maladjustment modification or lack of routine maintenance by others;

b) items subject to deterioration or consumption in normal service, that is, those which must be

cleaned, repaired or replaced routinely such as (but not limited to) lamps, bulbs and fuses, pump

diaphragms and valves, absorbent cartridges, filter elements and batteries; or

c) goods, materials or parts supplied or manufactured by unrelated third parties and provided to

the Purchaser at the specific request of the Purchaser and such goods, materials or parts will be

repaired or replaced only to the extent of the original suppliers warranty.

4. Should the Company be liable for breach of a condition or warranty (other than the pursuant to section 69

of the TPA) implied by Division 2 of Part V of the Act (other than that implied by section 69 of the TPA) the

liability of the Company for such breach shall, subject to section 6 A(2) of the TPA, be limited to one of

the following as determined by the Company.

a) the replacement of the Equipment or the supply of equivalent Equipment-,

b) the payment of the cost of replacing the Equipment or of acquiring equivalent Equipment.

5. Subject to Clauses 2 and 4 and any legislation to the contrary:

a) representatives and agreements not expressly contained herein shall not be binding upon the

Company as conditions, warranties or representations; all such conditions, warranties, and

representations on the part of the Company, whether express or implied, statutory or otherwise,

whether collateral or antecedent or otherwise are hereby expressly negatived and excluded;

b) the Company shall be under no liability to the Purchaser for any loss (including but not limited to

loss of profits and consequential loss) or for damage to persons or property or for death or injury

caused by any act or omission (including negligent acts or omissions) of the Company or the

Company’s agents, wherever occurring, arising from the subject matter of this agreement;

c) the Purchaser shall indemnify the Company against any claims made against the Company by any

third party in respect of any such loss, damage, death or injury as is set out in sub-paragraph b)

hereof; the Purchaser further agrees to indemnify the Company against all losses and expenses

which the Company may suffer or incur due to the failure of the Purchaser fully to observe its

obligations under this contract; and

d) no warranty is given and no responsibility is accepted by the Company to ensure the Equipment

supplied complies with any statutory requirements relating to the marketing of goods.

Compliance with such legislation shall be the sole responsibility of the Purchaser.

e) the Company specifically denies any liability for the overall performance of any plant or the

results of any process with which the Equipment is integrated.

Page 5 © 2011 Gastech Australia Pty Ltd

MANUA CONVENTIONS

This product is designed to form part of a system to detect toxic gases and to give warning before they reach

harmful levels. In order to ensure that it will warn of dangerous concentrations, it is essential that the

instructions in this manual, particularly those concerning installation, operation, and maintenance, be read,

understood, and followed.

Notices are used in this operator’s manual to alert you to hazardous conditions to person or instrument and to

notify you of additional information. This operator’s manual uses the following notices.

NOTE: Notifies you of additional information.

CAUTION: Notifies you of potential damage to equipment.

WARNING: Notifies you of potential danger that can result in personal injury or death.

© 2011 Gastech Australia Pty Ltd Page 6

1. Introduction

The GTA-VSD20i

TM

is an AS166 .2 compliant ventilation fan controller system targeted at car park air quality

monitoring applications. The system is designed to provide ventilation fan control based on gas concentration

input signals from connected gas detectors. The inbuilt control software provides both on/off and variable

speed fan operation that complies with AS166 .2 and the operational recommendations published by fan

manufacturers.

The GTA-VSD20i consists of individual components that require connecting together to form the desired

system. The components are:- The main controller, optional extender Modules and an optional Graphical

Display.

The main control module is supplied factory pre-configured and will operate independently without the HMI

unit connected. The HMI is available as an option for systems where changes need to be made to the channel

operations of the system and / or visualisation of the gas concentration readings is required.

1.1 Features

•AS166 .2 compliant operation.

•Scalable from 4 to 20 inputs.

•Industry Standard 4 - 20mA inputs.

•Industry Standard 0 - 10V output.

•Variable Speed and on/off fan control.

•Low stress fan drive control.

•High gas overload signal output.

•System fault signal output.

•Gas alarm output signals.

•Touch screen user interface option.

Page 7 © 2011 Gastech Australia Pty Ltd

2. Component Parts

2.1 Main Controller Module

The main controller module contains the system program that accepts input signals from connected gas

detectors, processes the measurements and outputs the appropriate signal to the fan. The main module can

be used on its own to form a basic system with 4 input channels.

The Main module comprises:-

4 x 4 - 20mA inputs to connect to gas detectors.

1 x voltage output 0 - 10V to connect to fan driver systems.

5 x volt-free relay contacts to connect to fan driver, beacons, sounders etc.

1 x Digital communication port to connect to the optional graphical display module.

1 x Power input connector.

There are a number of additional features on the main controller but these are used for factory programming

and test and do not need to be included in user applications.

The 'Run' / 'Stop' switch must be in the 'Run' position for the controller code to function.

Signals X0 to X7 are not used in the GTA-VSD20i system. Connection to these terminals is not required.

4-20mA Inputs channels 1 - 3

4-20mA Input channel 4

0 - 10VDC Output control

voltage

Volt-Free Relay Contacts

Main Controller Module (Factory pre-configured)

Optional Extender Module shown fitted

Power-On indicator light

Program running status light

Communication activity to display

Volt-Free contacts status lights

Up to 4 Extender Modules can be added giving

a total of 20 input channels. Each additional

extender requires its own power connection to

be made per the connection diagrams shown

on the following pages.

© 2011 Gastech Australia Pty Ltd Page

3. Mounting

Install the Control Unit into an enclosure with sufficient space around it to allow heat dissipation, as shown

below.

DIN Rail Mounting: When mounting the control unit to 35mm DIN rail, be sure to use the retaining clip to stop

any side-to-side movement of the unit and reduce the chance of wires becoming loose. The retaining clip is at

the bottom of the housing. To secure the controller to DIN rail, pull down the clip, place it onto the rail and

gently push it up. To remove the unit, pull the retaining clip down with a flat screwdriver and gently remove it

from the DIN rail.

The optional HMI unit is designed for panel mounting. A mounting kit with gasket is provided to allow a proper seal

to be made around the mounting hole. Dimensions for the rectangular cut-out are given in the diagram below.

Page 9 © 2011 Gastech Australia Pty Ltd

Main Control Unit Front Panel

See following section and wiring diagrams for information on connecting to the controller terminals.

© 2011 Gastech Australia Pty Ltd Page 10

3.1 Wiring Up The Modules

The main control unit and (optionally) the HMI require to be wired together to form the complete ventilation

controller system. Wiring is required to provide power and signal inputs / outputs to and from the modules.

If the HMI option is included in the system configuration, the cable to connect the HMI to the main control unit

is supplied with the system components. The plugs for the for the power connections are also provided.

22-16AWG (1.5mm) single or multiple core wire is recommended for wiring the signal I/O terminals.

The terminal screws should be tightened to no more than 1.90 kg-cm (1.65 in-lbs) based on the use of 60/75ºC

copper conductor. 22-16AWG < 1.5mm.

DO NOT place more than a single circuit connection in each I/O connection point.

The diagrams below indicate which connection should be made to assemble the components into a basic

control system. Other connection schemes are possible based on the requirements of the application. The

diagrams below serve as a guide for such systems. Connectors on the modules are marked to indicate function

and pin function.

3.1.1 Power Connections - Main Control Unit, Extender Module and HMI

3.1.2 Power Supply Considerations

The power input to the main control modules and HMI is DC. When configuring a system using the modules,

please note the following points:

•Power is connected to the two terminals, 24VDC and 0V, and the range of power is 20.4 ~ 2 . VDC.

•If the DC supply voltage is less than 20.4VDC, the modules will stop running, all outputs will go “Off”

and the ERROR indicator will flash continuously.

•Power brownouts of less than 10 ms will not affect the operation of the modules.

•The main control unit plus a single extender and the HMI require a power supply of 20W or greater.

The supply will also need to be able to support the required number of connected gas sensors. For a

fully loaded system of 20 sensors, this would need to be around 35W.

Suitable power supplies are:-

49-DVPPS01 (1 amp) for systems with up to sensors.

49-DVPPS02 (2 amps) for systems with greater than sensors.

Extenders and

HMI are optional

items.

Page 11 © 2011 Gastech Australia Pty Ltd

3.1.3 Connections rom Gas Sensors and Connection to an System.

For sensor connection details, please refer to the individual sensor user manuals.

© 2011 Gastech Australia Pty Ltd Page 12

3.1.4 Connections To Relay Switched unctions.

Relay Contacts are rated at 1.5A each

(resistive). Maximum voltage on each

contact is 30VDC or 250VAC. The relay

common terminal is rated 5A maximum.

If the relays are being used to switch

inductive loads such as contactors, motors

or lamps directly, the contacts are rated

20WDC/100WAC maximum. If in doubt,

please contact GasTech Australia.

Page 13 © 2011 Gastech Australia Pty Ltd

4. System Operation.

4.1 System Commissioning

Once a system has been wired up and all sensors connected, power should be checked on the connector plugs

before plugging them into the main module, extender module and HMI. If all power is present and correct,

then turn off the power supplies and connect the power plugs into each module.

Conduct a final check of all sensor wiring and signal connection to and from any other components in the

system (such as fan controller, sirens, beacons etc.).

If connection are all correct, then power can be applied to the system.

At power up, the modules establish communications and initialise to the working state. If a HMI unit has been

included in the system, failure to connect or initialise correctly will be signaled by the HMI issuing warning

beeps.

A normally running system will measure signals form connected sensors into enabled channels. The 0 - 10VDC

control voltage signal will set to a value based on the sensor that is detecting the highest concentration of

carbon monoxide. In an application with a normal ventilated condition, the output will be 0V. The variable

speed enable signal will also be inactive.

During the first system power-up, it is possible that the sensors will produce a signal that is above the pre-set

fan switch points. This is due to the initial warm-up characteristics of the carbon monoxide sensors. The

GasTech 'C-Guard' has a 60 second warm-up timer that holds the output signal at 4mA to allow the sensor to

stabilise. If sensors have been stored for a long time or stored in extremes of temperature, the settling time of

the sensors may be longer than the 60 seconds, resulting in a period where the signals into the controller are

seen as measured gas concentrations. The result of this is hat connected fan systems will activate until the

sensors stabilise to their normal base-line condition. If this is likely to cause a problem with the application,

please ensure that the enable and control signals are disconnected from the main control unit before

powering up for the first time.

4.2 Running The System

Once running, the system is automatic in operation. Each sensor is measured and the control unit processes

the signals and outputs the required signals based on the measured carbon monoxide concentration. If a HMI

has been included in the system, the 20 available channels can be viewed by using the 'NEXT' and 'PREVIOUS'

buttons.

4.2.1 Enabling a Channel (HMI required)

By default each channel is set to the off state. To enable a channel, press the on/off button that sits over each

channel icon.

4.2.2 Entering the Setup Password (HMI function)

A password is required to make the change. The default password is set at '1234567 ' The password is

entered on the keypad that appears on the HMI screen when an attempt is made to switch a channel on or off.

4.2.3 Normal Input Signal Operation

Once enabled, a channel expects to see an operational input current between 4mA and 20mA corresponding

to gas readings in the range 0 - 100ppm.

4.2.4 ault Signal Indication

If any active channel receives an input signal less than the lower fault limit of 3.0mA a warning is given on the

HMI and the system fault relay will be active. This will signal a sensor fault or sensor disconnection.

© 2011 Gastech Australia Pty Ltd Page 14

4.2.5 an Control / Alarm Relays

When a gas reading reaches or exceeds the pre-set alarm points, the programmed relay contacts will activate

(see specification table for operating points). The corresponding LED will illuminate on the main control unit

to show that the contact is active. If fitted, the HMI screen will also indicate that a signal is active.

The low and high speed fan control signals can be used to drive the fan system between two fixed speeds

depending on the gas concentration detected.

4.2.6 Variable Speed Enable Signal

The Variable Speed Enable can be used to switch the fan system on and off based on a cycle time compliant

with AS 166 .2. Additionally the timing of this signal is designed to present the least stress to the fan system

by limiting the number of on/off cycles to no more than 4 per hour.

This signal is used in conjunction with the 0 - 10VDC output drive signal to control the fan speed during its on

cycle.

4.2.7 an Control Voltage

The main control unit produces a control voltage signal that can be connected to fan controller units to allow

the fans to be driven at variable rates. The control voltage range is the industry standard 0 - 10VDC.

The 0 - 10VDC is scaled such that 0V represents ppm of detected carbon monoxide and 10V represents

30ppm of detected carbon monoxide. Between ppm and 30ppm, the voltage will be set proportionately.

This allows the fans to work only as hard as is required to move the level of detected carbon monoxide back to

the accepted limits according to AS166 .2. This variable drive in conjunction with the timed enable signal

provide the most efficient form of fan control and is recommended above the use of basic two level on/off

type systems. The control voltage is set based on the highest input signal fed from any of the enabled

channels. For a gas sensor this represents the unit that is sensing the highest concentration level.

Page 15 © 2011 Gastech Australia Pty Ltd

5. System Characteristics

Table of contents

Popular Control System manuals by other brands

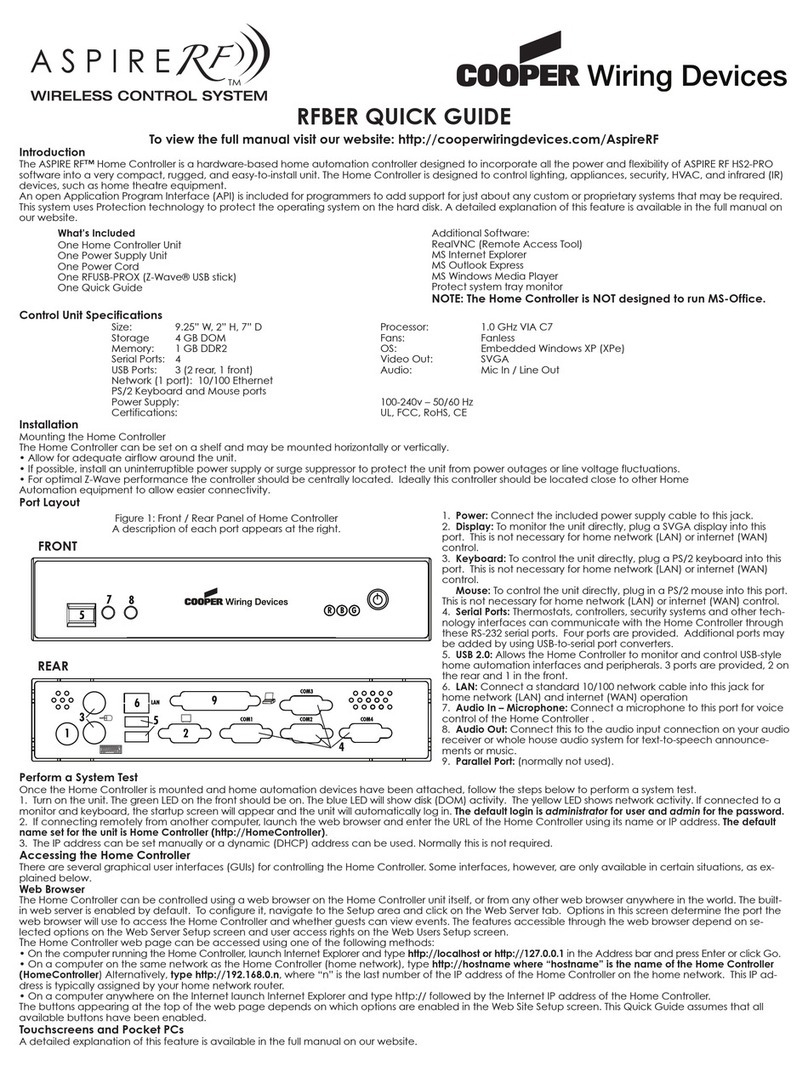

Cooper Wiring Devices

Cooper Wiring Devices Aspire RF quick guide

Trane

Trane Engineered Smoke Control System Application guide

FunkTronic

FunkTronic Major 4 manual

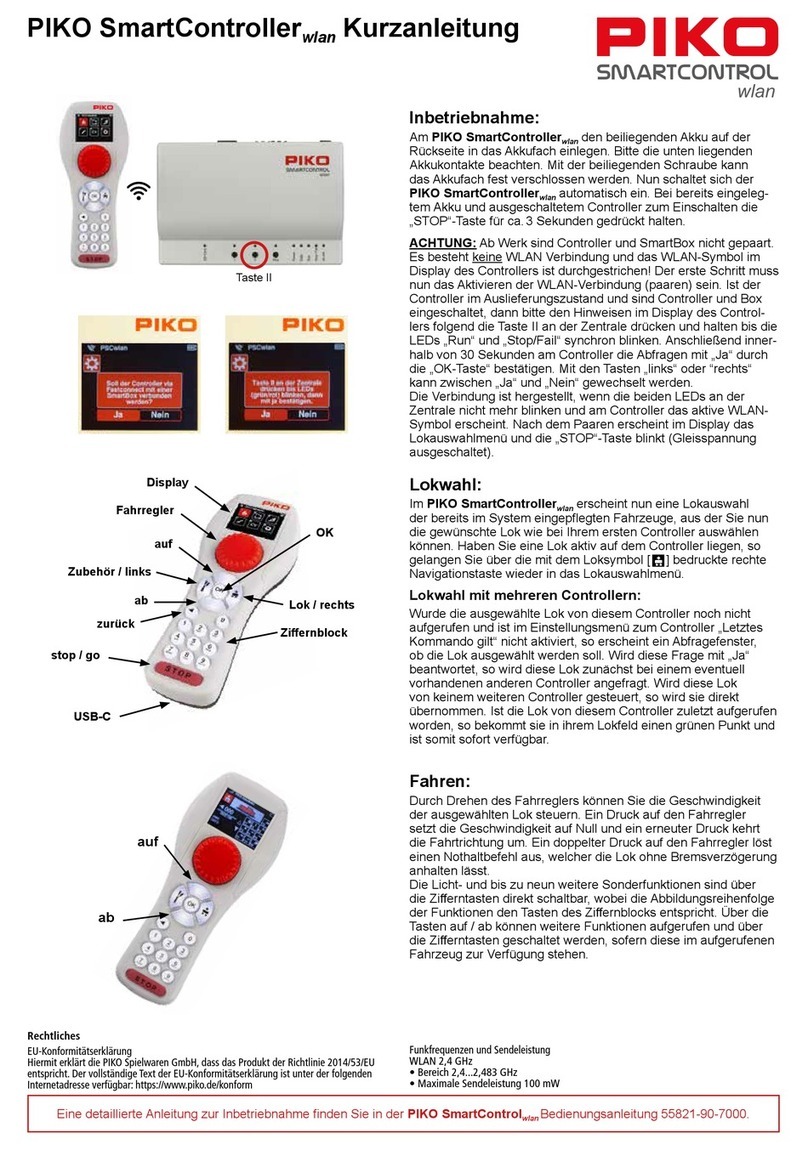

PIKO

PIKO SmartController wlan Quick manual

Controls

Controls MVP-A3305 product manual

Liberty Pumps

Liberty Pumps SX34-3-131 Installation Instructions and Operation/Troubleshooting Manual