Y Series TechBook

11

Table of contents

Warnings ............................................................................................................................................................... 2

Introduction ......................................................................................................................................................... 3

Features ................................................................................................................................................................. 4

in.ye overview: ..................................................................................................................................................... 5

in.ye dimensions: ................................................................................................................................................ 5

in.yt overview: ...................................................................................................................................................... 6

in.yt dimensions: ................................................................................................................................................. 6

in.k200 dimensions: ........................................................................................................................................... 7

Y Series installation

in.k200 installation & connections

- Installing the in.k200 ............................................................................................................................. 9

- Connecting the main keypad to the spa pack ................................................................................... 9

Y Series connections

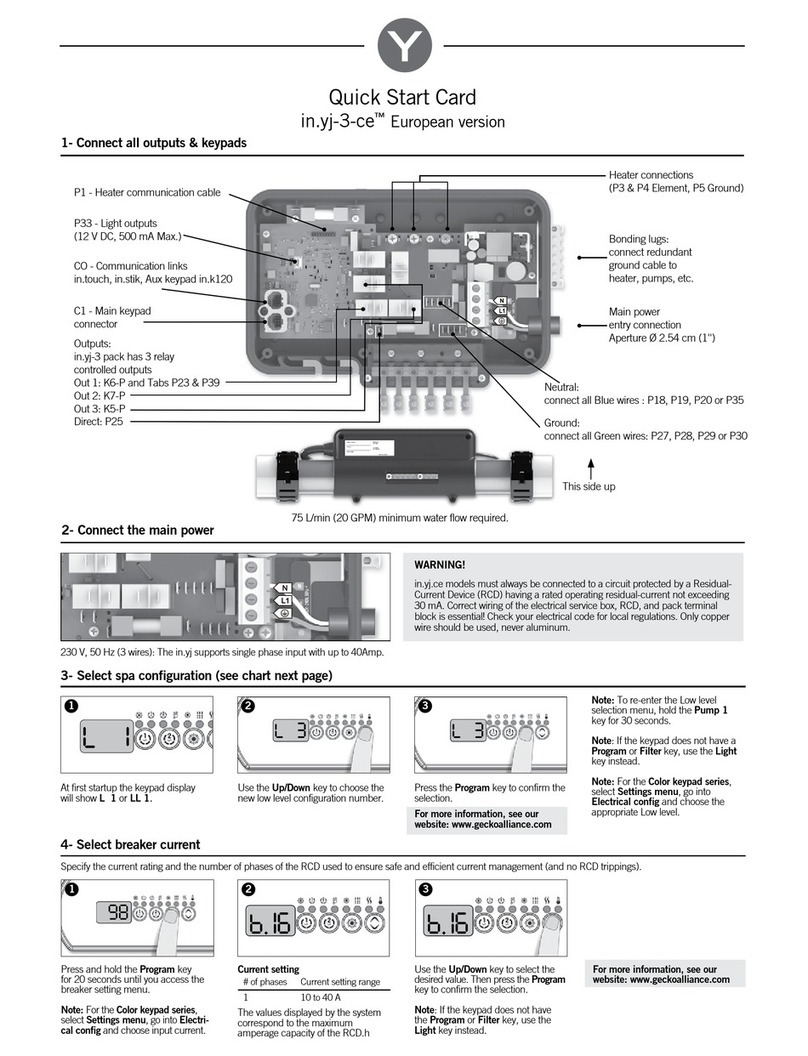

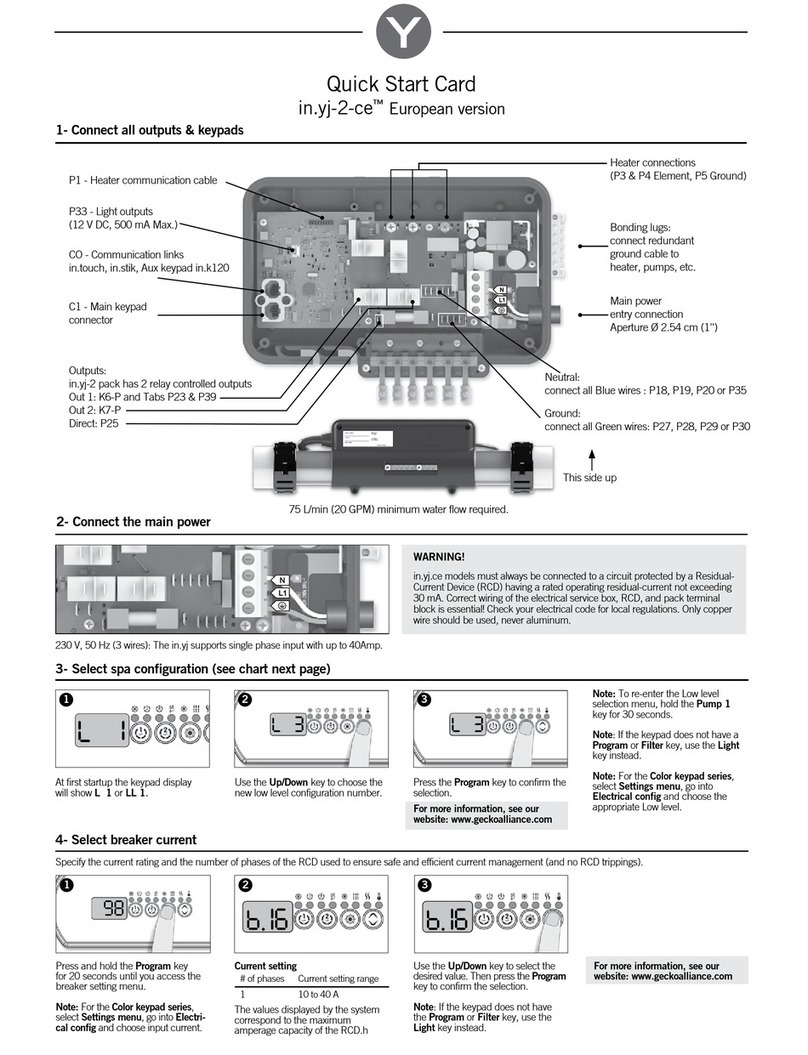

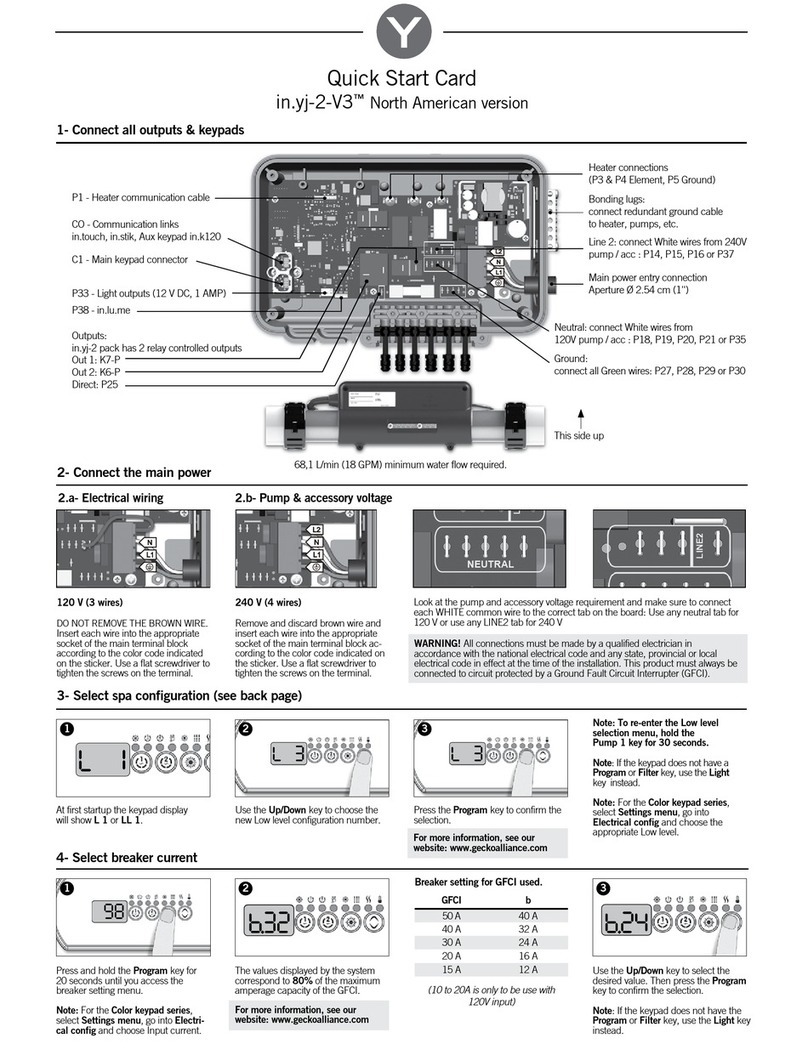

- Electrical wiring for North American model of the Y Series ........................................................... 10

- Electrical wiring for North American or CE model of the Y Series ................................................. 10

- Heater connections ............................................................................................................................ 12

Power-up & breaker setting .............................................................................................................................. 13

Programming the Y Series ................................................................................................................................ 14

Low-level configuration selection charts ......................................................................................................... 15

Y Series field programming options ................................................................................................................ 18

- High voltage accessory connections ................................................................................................ 21

In.k200 keypad overview

- Function description .......................................................................................................................... 26

- Instructions .......................................................................................................................................... 26

- Typical settings .................................................................................................................................... 28

Y Series error codes

- Y Series error codes summary .......................................................................................................... 29

- Hr error message / flow chart & step-by-step ................................................................................ 30

- Prr error message / flow chart & step-by-step ................................................................................ 30

- HL error message / flow chart & step-by-step .................................................................................. 31

- FLO & UPL error message / flow chart & step-by-step ................................................................... 33

- OH error message / flow chart & step-by-step ............................................................................... 34

Troubleshooting

- Pump 1 doesn't work / flow chart & step-by-step ........................................................................... 35

- Pump 2 or blower doesn't work / flow chart & step-by-step ........................................................ 37

- Circulation pump doesn't work / flow chart & step-by-step ......................................................... 39

- Ozonator doesn't work / flow chart & step-by-step ...................................................................... 40

- Nothing seems to work / flow chart & step-by-step ....................................................................... 41

- Nothing seems to work / flow chart & step-by-step ....................................................................... 42

- Spa not heating / flow chart & step-by-step .................................................................................... 44

- Keypad doesn't seem to work step-by-step .................................................................................... 45

GFCI trips ............................................................................................................................................................ 45

Step-by-step field replacement procedure .................................................................................................. 46

How to replace the heater .............................................................................................................................. 49

How to replace main control board on in.ye ............................................................................................... 50

How to replace the main control board on in.yt ........................................................................................... 51

How to replace the upper extension board on the in.yt .............................................................................. 52

Specifications ..................................................................................................................................................... 53