GasTech GTA-4100R User manual

t +61 8 6108 0000 e info@gastech.com w gastech.com

GTA-4100R

Dual Processor Controller Card

OPERATOR’S MANUAL

GTA-4100R

Dual Processor, Dual Channel Controller Card

Part Number 73-4100R

Manual Re ision 6.41 (updated 5 December 2012)

Table of Contents

1

Introduction ................................................................................................................................................... 6

1.1

Features ................................................................................................................................................ 6

1.2

Front Panel Layout ................................................................................................................................ 7

2

Installation ..................................................................................................................................................... 8

2.1

Mounting ............................................................................................................................................... 9

2.1.1

Micro Rack

TM

..................................................................................................................................... 9

2.1.2

Standard 19” Rack............................................................................................................................. 9

2.2

Wiring .................................................................................................................................................. 10

2.2.1

Common Module ............................................................................................................................ 11

3

Configuration ............................................................................................................................................... 14

3.1

Isolate Mode ....................................................................................................................................... 14

3.2

Configuration & Programming ............................................................................................................ 15

3.2.1

Board Layout ................................................................................................................................... 16

3.2.2

Extender Card ............................................................................................................................... 167

3.2.3

Output Power Supply ...................................................................................................................... 17

3.2.4

Sensor Voltages .............................................................................................................................. 18

3.2.5

Relay Configuration ........................................................................................................................ 20

3.2.6

Switch Bank 1 .................................................................................................................................. 21

3.2.7

Switch Bank 2 .................................................................................................................................. 22

3.2.8

Setting the Range ............................................................................................................................ 23

3.2.9

Setting the Units of Measurement ................................................................................................. 25

3.2.10

Setting Alarms ................................................................................................................................. 26

3.2.11

Gain and Offset Settings ................................................................................................................. 27

3.3

Settings Summary Table ...................................................................................................................... 28

3.4

Configuration Examples ...................................................................................................................... 30

3.4.1

Catalytic Sensor .............................................................................................................................. 30

3.4.2

Two-wire 4-20mA Loop Powered Sensor & Transmitter ................................................................ 30

3.4.3

Three-wire 4-20mA Sensor & Transmitter (500mA Max) ............................................................... 31

3.4.4

Three-wire 4-20mA Sensor & Transmitter (500mA Min) ............................................................... 31

3.4.5

Digital Contact Open & Closed (Callpoints) .................................................................................... 32

3.4.6

Smoke & Heat Detectors ................................................................................................................ 32

3.4.7

Externally Powered Acti ate De ices.............................................................................................. 33

3.5

Calibration ........................................................................................................................................... 34

4

General Use.................................................................................................................................................. 35

4.1

Checks ................................................................................................................................................. 35

4.2

Alarms ................................................................................................................................................. 36

Page ii © 2008 GasTech Australia Pty Ltd

4.2.1

Low AL1 Alarm ................................................................................................................................ 36

4.2.2

High AL2 Alarm ............................................................................................................................... 37

4.2.3

Ack/Rest Button .............................................................................................................................. 37

4.2.4

Fault Alarm...................................................................................................................................... 37

4.3

Normal Operation ............................................................................................................................... 38

4.4

Maintenance ....................................................................................................................................... 38

APPENDIX I.

Troubleshooting ......................................................................................................................... 39

APPENDIX II.

Spare Parts List ........................................................................................................................... 40

4.5

Power Supplies .................................................................................................................................... 40

APPENDIX III.

Specifications .............................................................................................................................. 41

Page 2 © 2008 GasTech Australia Pty Ltd

PROPRIETARY STATEMENT

GasTech Australia owns proprietary rights in the information disclosed within. By recei ing this document, the

recipient agrees that neither this document nor the information disclosed within nor any part shall be

reproduced or transferred to other documents or used or disclosed to others for manufacturing or for any

other purpose except as specifically authorised in writing by GasTech Australia.

COPYRIGHT STATEMENT

Information contained in this document is protected by copyright. No part of this document may be

photocopied, reproduced, or translated to another program or system without prior written authorisation

from GasTech Australia.

TRADEMARK STATEMENT

Protected through use and/or registration in the United States and many foreign countries are the trademarks

and ser ice marks of GasTech Australia. The use of the ® symbol indicates registration in the United States

only and the “

TM

” is in Australia; registrations may not ha e been issued at present in other countries. All other

product names and logos are trademarks of their respecti e owners.

DISCLAIMER

Under no circumstances will GasTech Australia be liable for any claims, losses, or damages resulting from or

arising out of the repair or modification of the equipment by a party other than GasTech Australia or its

authorised ser ice representati es, or by operation or use of the equipment other than in accordance with the

printed instructions pro ided by GasTech Australia or if the equipment has been improperly maintained or

subject to neglect or accident. Any of the foregoing will oid the warranty.

REVISIONS TO MANUAL

All information contained in this manual is belie ed to be true and correct at the time of printing. Howe er, as

part of its continuing efforts to impro e its products and their documentation, GasTech Australia reser es the

right to make changes at any time without notice. Any re ised copies of this manual can be obtained by

contacting GasTech Australia.

Page 3 © 2008 GasTech Australia Pty Ltd

SERVICE POLICY

GasTech Australia maintains an instrument ser ice facility at the factory as well as authorised ser ice facilities

around the world. Should your instrument require ser ice, you may contact us toll free at 1800 999 902 within

Australia only or 61-8-9242-1869, or isit our website www.gastech.com.au for authorised ser ice locations.

For non-warranty repairs, you will need to pro ide a purchase order number. If you need to set a limit to the

repairs costs, state a “Not to Exceed” figure. If you need a quotation before you can authorise repair costs, so

state, but understand this will incur additional costs and may delay processing of the repair.

If you wish to set a limit to the authorised repair cost, state a “not to exceed” figure. GasTech Australia’s policy

is to perform all needed repairs to restore the instrument to full operating condition, including reacti ation or

replacement of all out-of-warranty electrochemical cells.

You may send the unit, freight prepaid, to: GasTech Australia Pty Ltd, 106 Westpoint Centre, 396 Scarborough

Beach Road, Osborne Park 6017, Western Australia. Attn.: Ser ice Department. Enclose the copy of your

contact details. Pack the instrument and all its accessories (preferably in its original packing) and any special

instructions. Repairs are warranted for 90 days from the date of shipment. Sensors ha e indi idual warranties.

Always include your address, purchase order number, shipping and billing information, and a description of the

defect as you percei e it. If this is the first time you are dealing directly with the factory, you will be asked to

pro ide credit references, prepay, or authorise COD shipment.

NOTE: GasTech Australia assu es no liability for work perfor ed by unauthorised service facilities.

Page 4 © 2008 GasTech Australia Pty Ltd

WARRANTY STATEMENT

1. Consumers ha e the benefit of conditions and warranties implied by the Trade Practices Act 1974 (TPA)

and similar pro isions of State and Territory enactments and nothing in these conditions is intended to

exclude, restrict or modify any statutory obligation of GASTECH AUSTRALIA PTY LTD (Company) if that

cannot lawfully be effected.

2. This warranty relates only to Equipment manufactured and ser ices supplied by the Company, its related

corporations and subsidiaries. Equipment or any part thereof which is returned to the Company,

transportation prepaid, within 15 months from the date of dispatch from the Company’s premises or 12

months from the date of shipment to the ultimate user (whiche er occurs first) and is found by the

Company, after examination, to be defecti e in workmanship or materials, will be either repaired or

replaced as determined by the Company, free of charge. The terms of this paragraph apply unless stated

otherwise in this instruction manual.

3. This warranty does not apply to:

a) replacement or repairs which are required as a results of improper installation, misuse,

maladjustment modification or lack of routine maintenance by others;

b) items subject to deterioration or consumption in normal ser ice, that is, those which must be

cleaned, repaired or replaced routinely such as (but not limited to) lamps, bulbs and fuses, pump

diaphragms and al es, absorbent cartridges, filter elements and batteries; or

c) goods, materials or parts supplied or manufactured by unrelated third parties and pro ided to

the Purchaser at the specific request of the Purchaser and such goods, materials or parts will be

repaired or replaced only to the extent of the original suppliers warranty.

4. Should the Company be liable for breach of a condition or warranty (other than the pursuant to section 69

of the TPA) implied by Di ision 2 of Part V of the Act (other than that implied by section 69 of the TPA) the

liability of the Company for such breach shall, subject to section 68A(2) of the TPA, be limited to one of

the following as determined by the Company.

a) the replacement of the Equipment or the supply of equi alent Equipment-,

b) the payment of the cost of replacing the Equipment or of acquiring equi alent Equipment.

5. Subject to Clauses 2 and 4 and any legislation to the contrary:

a) representati es and agreements not expressly contained herein shall not be binding upon the

Company as conditions, warranties or representations; all such conditions, warranties, and

representations on the part of the Company, whether express or implied, statutory or otherwise,

whether collateral or antecedent or otherwise are hereby expressly negati ed and excluded;

b) the Company shall be under no liability to the Purchaser for any loss (including but not limited to

loss of profits and consequential loss) or for damage to persons or property or for death or injury

caused by any act or omission (including negligent acts or omissions) of the Company or the

Company’s agents, where er occurring, arising from the subject matter of this agreement;

c) the Purchaser shall indemnify the Company against any claims made against the Company by any

third party in respect of any such loss, damage, death or injury as is set out in sub-paragraph b)

hereof; the Purchaser further agrees to indemnify the Company against all losses and expenses

which the Company may suffer or incur due to the failure of the Purchaser fully to obser e its

obligations under this contract; and

d) no warranty is gi en and no responsibility is accepted by the Company to ensure the Equipment

supplied complies with any statutory requirements relating to the marketing of goods.

Compliance with such legislation shall be the sole responsibility of the Purchaser.

e) the Company specifically denies any liability for the o erall performance of any plant or the

results of any process with which the Equipment is integrated.

Page 5 © 2008 GasTech Australia Pty Ltd

MANUAL CONVENTIONS

This instrument is designed to detect one or more of the following: flammable apours, oxygen content and/or

toxic gas and to gi e warning before they reach harmful le els. In order to ensure that it will warn of

dangerous concentrations, it is essential that the instructions in this manual, particularly those concerning

start up, operation, calibration, and maintenance, be read, understood, and followed.

Notices are used in this operator’s manual to alert you to hazardous conditions to person or instrument and to

notify you of additional information. This operator’s manual uses the following notices.

NOTE: Notifies you of additional infor ation.

CAUTION: Notifies you of potential da age to equip ent.

WARNING: Notifies you of potential danger that can result in personal injury or death.

Page 6 © 2008 GasTech Australia Pty Ltd

1

Introduction

The GTA-4100 series is a family of fixed-instrument, continuous-monitoring systems. The GTA-4100R is a two-

channel dual processor, rack or panel-mounted control module that recei es signals from remote transmitters,

displays the reading, pro ides alarm, recorder, and relay outputs and pro ides power for remote transmitters,

including sample-draw transmitters.

1.1 Features

• Each channel accepts a standard 4 to 20mA analogue input signal from remote 2 or 3 wire transmitters.

• Supports 0-1V, 0-5V, 0-10V, and 0-24V as well as digital and resistance input types.

• Includes a 3 wire internal amplifier for catalytic sensors.

• Two processors per card pro iding independent channel isolation gi ing higher reliability

• Simultaneously displays the current reading for both channels.

• Pro ides a 4 to 20mA analogue recorder output for each channel.

• Warns of hazardous conditions with audible and isual indications at two alarm set points for each channel.

• Fault circuit pro ides isual, audible, and relay indication to warn of failure or other malfunction.

• Pro ides a low and a high alarm relay for each channel.

• Set up for one or two zones as standard.

• Slide-in module compatible with a standard 3U rack assembly.

• Occupies one 8E width (Standard 19” rack)

Page 7 © 2008 GasTech Australia Pty Ltd

1.2 Front Panel Layout

The diagram below shows the layout of the front panel. Each GTA-4100R card is di ided into two identical

channels - top and bottom. Each side of the card is completely isolated from the other and operates

completely independently. The only shared component is the LCD and the card will continue to work correctly

e en if the LCD fails. This is a non critical de ice and is written to by both processors but has no affect on either

channel.

Top Channel

Botto Channel

Zero pot

Acknowledge &

Reset Button

Span pot

Isolate Switch

Units of

Measurement

High Alarm

indication

Low Alarm

indication

Status

I

ndication

Backlit LCD

L

i e

R

eadings

Zero pot

Acknowledge &

Reset Button

Span pot

Isolate Switch

Units of

Measurement

High Alarm

Low Alarm

indication

Status

I

ndication

Backlit LCD

Li e Readings

Page 8 © 2008 GasTech Australia Pty Ltd

2

Installation

WARNING: Perfor all installation procedures in a fresh air environ ent (known to be free of

co bustible and toxic gas and having nor al oxygen content). The GTA-4100R is not in operation as a

syste , until the start up procedure is co plete.

NOTE: The packing slip indicates the serial nu ber of your GTA-4100R. The serial nu ber is also on a

label on the side of the GTA-4100R. Please record the serial nu ber on the front of this anual.

This section will outline and explain in detail the arious stages of commissioning a new system including:

• Mounting

• Wiring

Page 9 © 2008 GasTech Australia Pty Ltd

2.1 Mounting

The installation area should be in a safe place, preferably near an entrance door where the fire department or

other emergency response team can see the indication if an alarm has caused the building to be e acuated.

The GTA-4100R controller is suitable for mounting in a rack assembly using card-guides to support the main

circuit board and the two capti e screws at the front of the controller to secure it in place.

The GTA-4100R cards can be mounted in two different configurations:

1. Micro Rack

TM

2. A standard 19” rack case

2.1.1 Micro Rack

TM

The wall mountable Micro Rack

TM

shown below, can house up to four GTA-4100R cards.

2.1.2 Standard 19 Rack

A standard 19” wide rack case ersion can house up to ten GTA-4100R cards. It requires a standard rack frame

with 3 units of space free in order to be mounted.

Page 10 © 2008 GasTech Australia Pty Ltd

2.2 Wiring

Both the Micro Rack

TM

and the standard 19” rack case ersions contain a back plane. The back plane is the PCB

at the back of each enclosure that the GTA-4100R cards plug into. It is also where all wiring terminates ia

terminal blocks.

The Micro Rack

TM

ersion gets terminated from the front as the system is wall mounted - the termination

blocks are on the same side as the cards plug in.

The 19” rack ersion is terminated from the back and the 4100R cards are plugged into the front.

The diagram below shows the location of the terminal blocks and remote or indi idual channel relays on the

back plane.

Sensor wiring

Sensor wiring

Alarm relays

wiring

Alarm relays

wiring

4

-

20mA wiring

4

-

20mA wiring

24

VDC Power

Sensor wiring

Sensor wiring

Alarm relays

wiring

Alarm relays

wiring

4-20mA wiring

4

-

20mA wiring

Micro Rack

TM

19” Rack Mount

24

VDC Power

Page 11 © 2008 GasTech Australia Pty Ltd

There are fi e types of terminal block connectors on each back plane.

1. SENSOR INPUTS - First at the top right for top channel, or bottom right for bottom channel is the

sensor connector. This is a 2.5mm 3 way remo able connector which is fitted to all back planes. The

terminals are clearly marked on the PCB. Some examples for common sensors are shown later in this

manual or you can refer to the sensor manual for the correct connection details.

2. COMMON ALARM RELAYS - The second set of connectors are the indi idual alarm relay connectors,

this is to the right of the sensor connector a 3 tier non-remo able 1.5mm connector. The terminals

are for “N/C” Normally Closed, “C” Common, and N/O Normally open contacts. These are clearly

marked on the PCB. The bottom tier is for Fault, the middle tier is for “AL1” (alarm 1) and the top tier

is for “AL2” (alarm 2).

3. REMOTE 4-20 A OUTPUT - The third connector is a 1.5mm remo able connector at the top of the

relay connector. This is the 4-20mA output for each channel. The terminals are clearly marked on the

PCB “+ and –“

4. POWER – The power terminal block is a 2.5mm connector. On the standard 19” rack, the power

connector is a 3-way type at the top of the PCB between channel 17 and 19. There are two 5 Amp

fuses either side of the connector – one for the top channel and one for the bottom channel.

On the Micro Rack

TM

the power connector is a 2-way type located on the right side of the board, next

to the 5 Amp fuse. There is a green LED next to the power connector on each PCB which indicates that

the board is recei ing power. There is also a red LED next to each fuse. If a fuse is blown this red LED

will illuminate. The polarity for these power terminals are clearly marked on the PCB.

5. COMMON RELAYS – Each back plane contains common relays. These will be discussed in the next

section.

2.2.1 Common Module

The common modules purpose is to synchronize all the 4100R cards flashing LEDS as well as common up all the

alarm relays and runs a local buzzer. It also pro ides a global Ack/Reset button.

Common module Common module

Page 12 © 2008 GasTech Australia Pty Ltd

As you can see in the image abo e, both the Micro Rack

TM

and the standard 19” rack case ersions contain a

common module. In the Micro Rack

TM

the common module is built into the custom enclosure. In the standard

19” rack case ersion, the common module is a separate card half the width of the GTA-4100R cards.

In the standard 19” rack case ersion, the common module has two settings:

1. Co on Zoned - This is where jumper J1, J2, and J3 are in place. These will common all of the

channels and gi e the user two separate 10 amp relays for all the channels.

2. Double Zone - This where jumper J1, J2, and J3 are remo ed. This will zone the top channels together

and the bottom channels together gi ing one 10 amp relay for each zone.

NOTE: You can ix the zones – for exa ple you can co on zone the co on low alar s but double

zone the co on high alar s.

J1

J2

J3

19” Rack Mount Co on Module

Page 13 © 2008 GasTech Australia Pty Ltd

The terminals for these common relays are located on the right hand side of the circuit board next to channel

one and two. The terminals are 2.5mm top mounted plug in different colour to the channel inputs. The

terminals are clearly marked on the PCB.

With the Micro Rack

TM

ersion common module functions the same as the standard 19” rack case ersion

except that there is only one set of relays, so you cannot zone the top and bottom of the cards.

Zone 2 common fault

Zone 1 common fault

Zone 2 common Alarm 1

Zone 1 common Alarm 1

Zone 2 common Alarm 2

Zone 1 common Alarm 2

N/C

N/O

Com

Common Alarm 2

Common Alarm 1

Common fault

19” Rack Mount Co on Module Backplane

Micro Rack

TM

Co on Module

Page 14 © 2008 GasTech Australia Pty Ltd

3

Configuration

This section will outline and explain in detail the arious stages of configuring a system. This section should be

referenced when commissioning a new system but also as when changing transmitter or sensor types.

• Isolate Mode

• Configuration & Programming

• Configuration Examples

• Calibration

3.1 Isolate Mode

The Isolate feature is designed so the operator can do maintenance/calibration on that channel without

causing unwanted alarms.

To turn that channel into Isolate modem flick the “Isolate” switch from right to left. The display will change to

an in erted mode as seen in the picture below. The isolate switch will isolate all alarms from that channel only

- not the complete card. The 4-20mA output will change to 2mA indicating the channel is in Isolate mode.

NOTE: The Isolate ode can be selected if a channel is giving spurious alar s and investigation is in the

process this will eli inate any alar s during the investigation period.

If a sensor takes longer than 30 seconds to stabilize or come on line the Isolate mode can be selected until the

sensor comes on line. The display will still show the sensor readings during this time.

NOTE: The GTA-4100R advanced software has a feature called zero suppression, which onitors the

sensor perfor ance and s all sensor drifts, which is a characteristic of all sensors. This drift is due to

sudden te perature, hu idity and pressure changes or aging sensors. Nor ally the advanced electronics

and software will re ove this insignificant drift and keep the detector reading zero or 20.9 (for an Oxygen

sensor). However in isolate ode the zero suppression feature is turned off, so during calibration the

channel can be exactly zeroed without the dead band asking.

Page 15 © 2008 GasTech Australia Pty Ltd

WARNING: Isolate ode of the GTA-4100R allows you to disable the alar LED’s, buzzer, and relays

during calibration procedures and response tests. When calibration ode is activated, the LED’s, buzzer, and

relays will not operate as described in this section. You ust de-isolate the channel to bring it back into

operation.

3.2 Configuration & Programming

NOTE: Each channel can be individually progra ed for any setting. A card does not have to be the

sa e i.e. Top channel ight be a co bustible sensor where the botto channel can be an Oxygen sensor.

Top channel in

Isolate mode.

(In erted display)

Top channel

Isolate switch

Bottom channel

in normal mode

Page 16 © 2008 GasTech Australia Pty Ltd

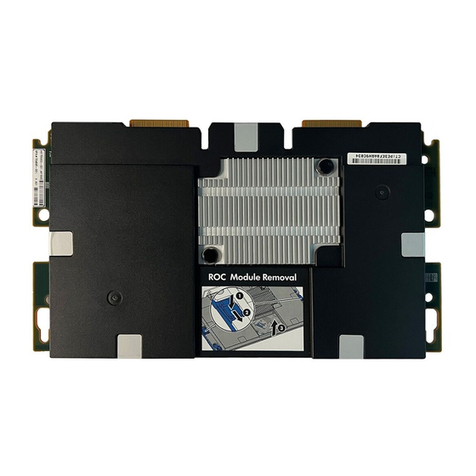

3.2.1 Board Layout

The diagram below shows the location of the arious jumpers, dip switches and trim-pots on the GTA-4100R

PCB.

CAUTION: Take note when adjusting switches, ju pers and potentio eters ensuring you are adjusting

the correct channel.

3.2.2 Extender Card

The GTA-4100R slides forward in its guides for access to the programming controls. An Extender Card (GasTech

P/N: 73-4103) allows you to power the card up from the 19” rack or the Micro Rack and adjust the settings or

conduct testing.

Top

Channel

Botto

Channel

Switch Panel 1

(8 switches)

Switch Panel 2

(8 switches)

High Alarm

Adjust (AL2)

Low Alarm

Adjust (AL1)

Head Volts

Positi e (TP7)

Head Volts

Adjust Pot (P16)

Output Power

Supply (J4)

Relay Energized/

De-Energized

Full Scale

Adjust Switch

Switch Panel 1

(8 switches)

Switch Panel 2

(8 switches)

High Alarm

Adjust (AL2)

Low Alarm

Adjust (AL1) Head Volts

Positi e (TP8)

Head Volts

Adjust Pot (P15)

Output Power

Supply (J3)

Relay Energized/

De-Energized

Full Scale

Adjust Switch

Head Volts

Ground (TP9)

Table of contents

Other GasTech Controllers manuals