Gate House TUT30 User manual

Two (2) 1/8" (3mm) pilot holes

Faceplate

WARNING

IF DRILLING IS REQUIRED, you should read and thoroughly understand steps 1 - 4 prior to

drilling.

Please drill holes from both sides to avoid splintering of the door face.

IF HOLES ARE ALREADY DRILLED IN YOUR DOOR, install latches and begin at step 5.

For questions, please call 1-877-4GATEHS, 8:30 a.m. - 5:30 p.m. EST,

Monday through Friday.

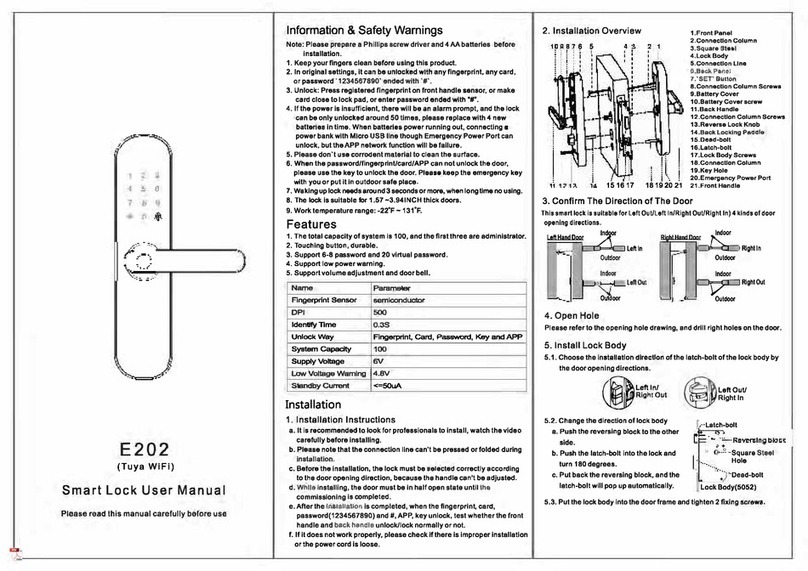

SAFETY INFORMATION

INSTALLATION AND CARE NOTATIONS:

1. The important safeguards and instructions appearing in this manual are not meant to

cover all possible conditions and situations that may occur. It must be understood that

common sense, caution and care are factors which cannot be built into any product.

These factors must be supplied by the person(s) caring for and operating the unit.

PREPARATION

Additional tools needed for NEW installation:

• Pencil • Hammer • 2-1/8 in.(54mm) Hole Boring bit • Chisel • Power drill

• Tape measure • 1 in.(25mm) & 1/8 in.(3mm) Drill bits • 2 in.(51mm) 6d common nail

ITEM #0226069/0226087/0226090/0226091/0141055/0141053

0225974/0225976/0239863/0239857

BED & BATH/HALL & CLOSET

MODEL #TUT30/TUTG0/TUX230/TUX2G0/TUX730/TUX7G0

LY9X203/LY9X20G/LY9X703/LY9X70G

INSTRUCTIONS FOR INSTALLATION OF LOCKSETS

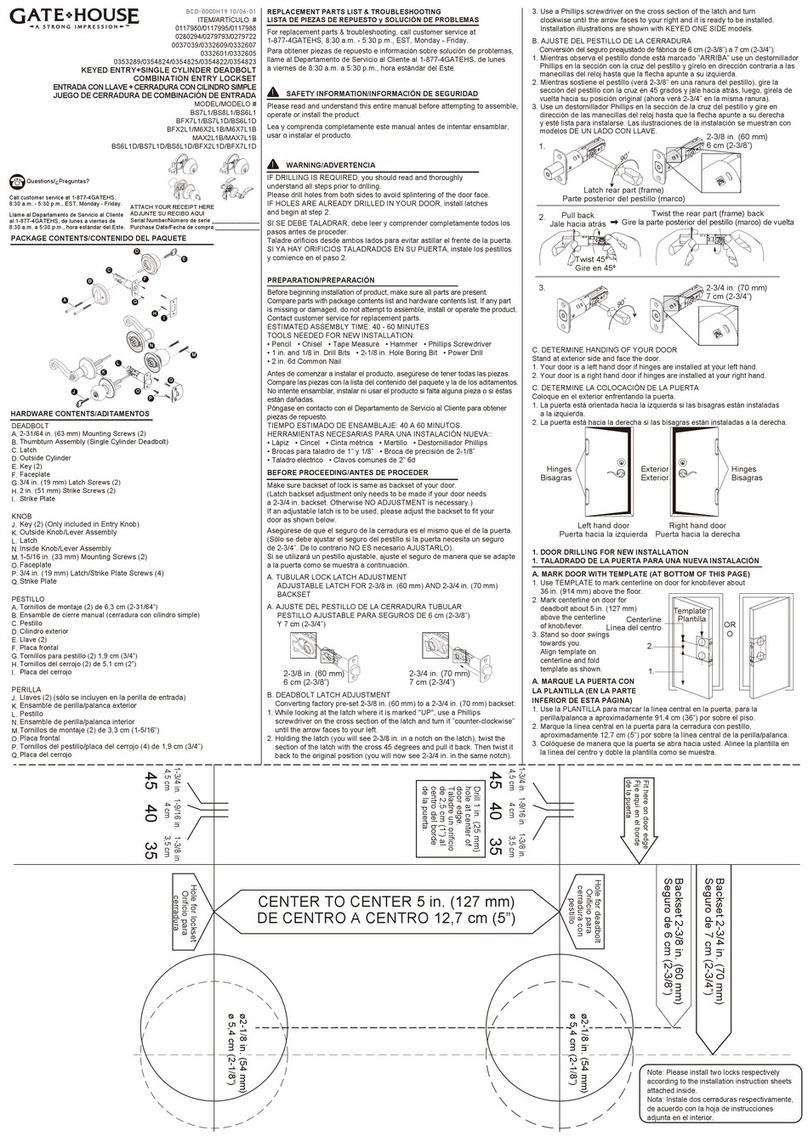

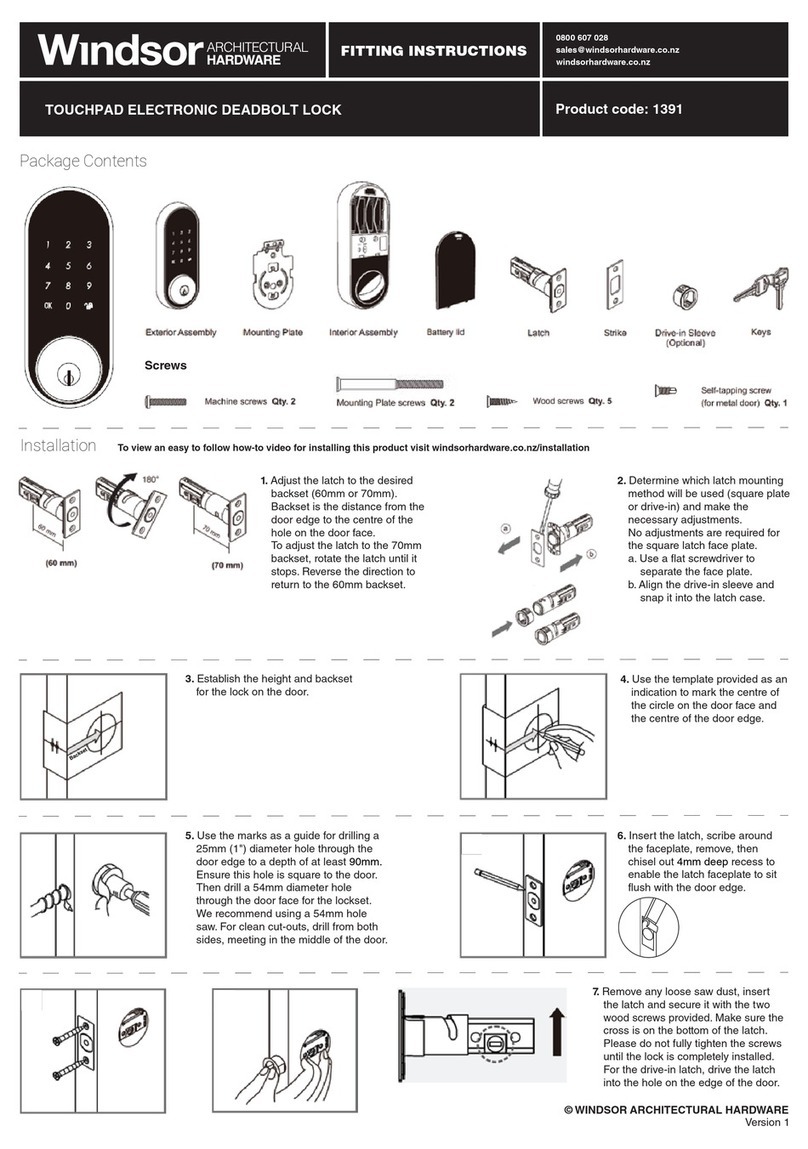

1. MARK DOOR

Use enclosed template to mark installation holes on both sides of the door as shown.

A. Heightline - 38 in. from floor (965mm).

B. Center of door thickness on heightline.

C. Knob hole center for backset - 2-3/8 in.(60mm) or 2-3/4 in.(70mm) as desired.

(Note 2-3/8 in.(60mm) is standard)

TO MARK OPPOSITE SIDE OF DOOR: fold template in opposite direction and place on other

edge of the door, matching up "mark (1B)" - center of door thickness as shown in

illustration.

(Back of template will be facing you.)

Mark knob hole center at point of template indentation (1C).

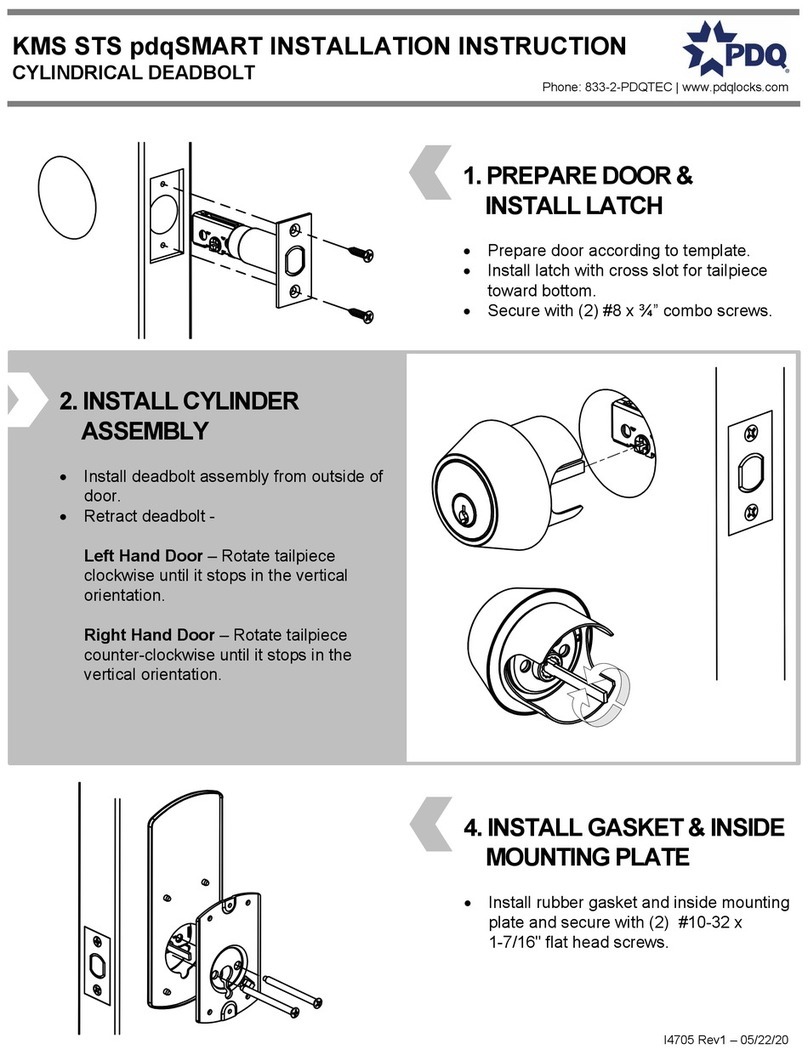

2. DRILL HOLES ( SEE ILLUSTRATIONS )

Drill 1/8 in.(3mm) pilot holes as marked in Step 1 at points (B) and (C).

A. Drill 2-1/8 in.(54mm) holes about 1/2 way through door, then finish drilling from other side,

to minimize splintering.

B. Before drilling latch holes, mark location for strike plate holes in door jamb by closing door

and inserting a 2 in.(51mm) common nail from inside 2-1/8 in.(54mm) hole in to pilot hole

so that nail makes an indentation in the jamb.

C. Open door and drill a 1 in.(25mm) latch hole in the door edge through to the 2-1/8 in.

(54mm) hole.

!

!

3. A. MORTISE FOR LATCH

Use faceplate as a pattern for mortise and pilot holes. Faceplate should fit flush.

B. lNSTALL LATCH

Install as shown. Ensure beveled edge faces door jamb.

4. PREPARE DOOR JAMB

Drill and Install strike plates

A. Mark outline for plastic dust box and then drill

33/64 in.(13mm) deep,

1-1/4 in. (32mm) height to allow for installation of plastic dust box,

61/64 in.(24mm) wide

Mark location of strike mortise using strike plate as a template by placing plate over

dust box and chisel outline. for strike plate with 1/8 in.(3mm) deep as marked on

door jamb

B. Insert dustbox into hole, and apply strikeplate.

Secure using 0.76 in.(19mm) wood screws into pilot holes as shown.

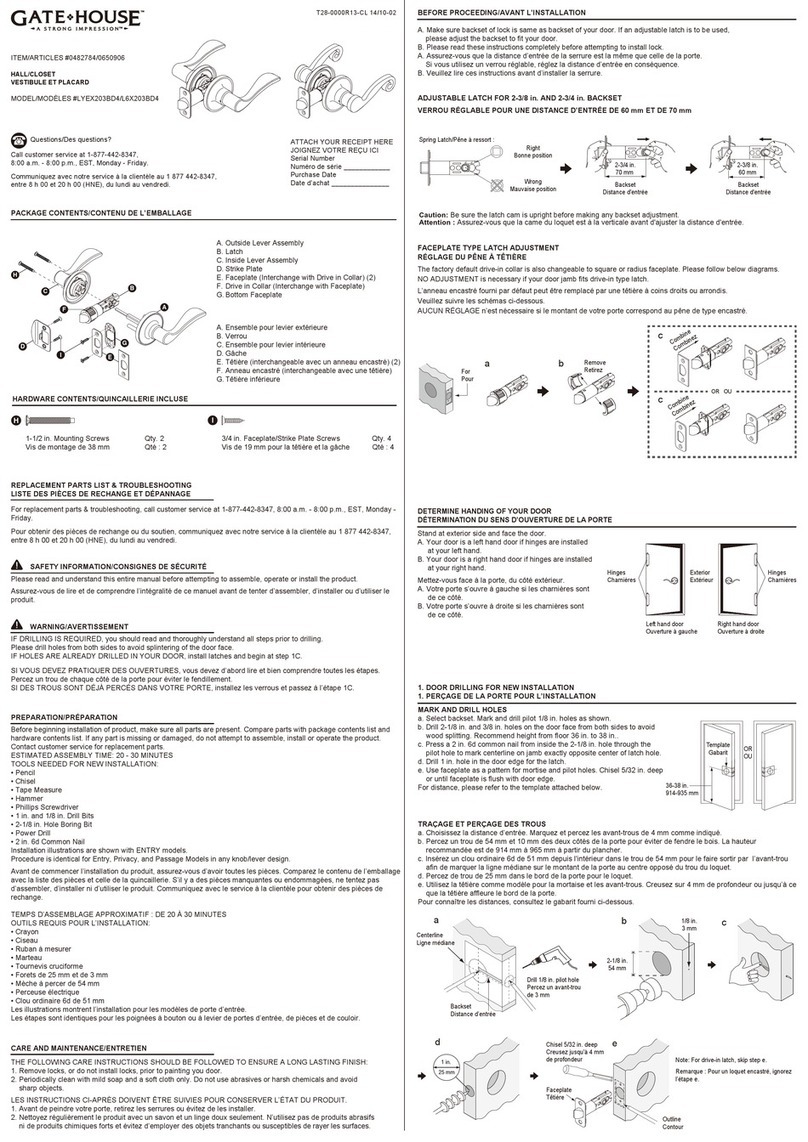

5. TUBULAR LOCK UNIVERSAL BACKSET LATCHBOLT

( This backset is set a 2-3/8 in.(60mm). It only needs to be adjusted if your door requires

a 2-3/4 in.(70mm) backset. )

IF BACKSET ADJUSTMENT IS NECESSARY:

A. Latch is preset at factory for 2-3/8 in.(60mm) backset.

Caution: Be sure the latch cam is upright before making any backset adjustment.

B. To convert latch to 2-3/4 in.(70mm) backset, pull the rear part until 2-3/4 in.(70mm) is

completely shown in indicator.

To correct cam expand to reset and compress back to 2-3/8 in.(60mm).

Note:

• Our latches come with interchageable faceplates, allowing conversion from a radius

shape toa square shape so it will fit most doors.

Look first at your door to determine which configuration will work best in your

application and make the suitable change according to the instructions below, if

needed.

• Converting from radius corner faceplate to square corner and vice versa:

Detach installed faceplate using a flat head screw driver.

Replace with new faceplate. Align holes in the faceplate and the base plate and snap

them together.

TCD-M0G0J12

09/12-02

A

B

C

38 in.(965mm) from finished floor

Template

Template

OR

2-1/8 in.

(54mm)

ABC

1 in.

(25mm)

}

(A1 )

B

A

}

0.76 in.(19mm)

(A1) Short wood screw

2-3/4 in.(70mm)

2-3/8 in.(60mm)

Yes No

Caution: Be sure the latch cam is upright before installing latch.

To correct, expand to 2-3/4 position to reset cam and compress back to 2-3/8 in.

Notch

Radius corner faceplate

Square corner faceplate

1-3/4 in.

(45mm)

1-3/8 in.

(35mm)

1-9/16 in.

(40mm)

Ø 2-1/8 in.(54mm)

Fold here. Place on

door edge.

Drill 1 in.(25mm)

hole at center of

door edge.

Backset 2-3/4 in.(70mm)

Backset 2-3/8 in.(60mm)

THE FOLLOWING CARE INSTRUCTIONS SHOULD BE

FOLLOWED TO INSURE A LONG LASTING FINISH:

1. Remove locks, or do not install locks, prior to painting you door.

2. Periodically clean with mild soap and a soft

cloth only.

Do not use abrasives or harsh chemicals, and

avoid sharp or scratching objects.

IF NEEDED, REVERSE LEVERS

Determine handing of your door

Stand on exterior side and face the door.

A. Your door is a left hand door if hinges are installed on the left side.

B. Your door is a right hand door if hinges are installed on the right side.

FOLLOW THE PROCEDURE BELOW FOR CHANGING LEVER HANDING:

The leverset is preset as a right hand lever. If your door is a right hand door, you can install it now. If your door is left hand door, you

can change the lever handing by following the procedure below:

1. Use allen wrench to loosen set screw attached to the lever.

2. Remove lever and install the lever of opposite handing.

3. Make sure to align set screw hole with the correspondng hole on the spindle.

4. Insert set screw and tighten with allen wrench to secure the assembly.

* Make sure that the handle portion of the lever extends toward the hinges of the door.

LIFETIME WARRANTY

The Manufacturer extends a Full Lifetime Mechanical and Finish Warranty to the original “User” of this Product against defects in materials

and workmanship as long as the User occupies the residential premises upon which the Product was originally installed.

Upon return of a defective Product to the Manufacturer, the Manufacturer shall either replace, repair or refund the purchase price in

exchange for the Product.

This warranty does not cover abused or misused Products or those Products used in commercial applications.

No other warranties, express or implied are made with respect to the Product including but not limited to any implied warranty of

merchantability or fitness for a particular purpose.

The Manufacturer DOES NOT authorize any person to create for it any obligation or liability in connection with the Product.

The Manufacturer maximum liability hereunder limited to the purchase price of the Product, in no event shall the company be liable for

any consequential, indirect, incidental or special damages of any nature arising from the sale or use of this Product, whether in contract,

tort, strict liability or otherwise.

( For warranty service, please call 1-877-4GATEHS, 8:30 a.m. - 5:30 p.m. EST, Monday through Friday )

Note: Should the Product be considered a consumer product it may be covered by the Magnusson Moss Federal Warranty Act, please be

advised that: (1) Some states do not allow limitations or incidental consequential damages on how long an implied warranty lasts so that

the above limitations may not bully apply: and (2) This warranty gives specific legal rights and a User may have other rights which may

vary from state to state.

REPLACEMENT PARTS LIST & TROUBLESHOOTING

For replacement parts & troubleshooting, please call service department at

1-877-4GATEHS, 8:30 a.m. - 5:30 p.m. EST, Monday through Friday.

Part Part #

Screw pack SCR-L784

Tubular Latch KLB710-AQA3PCD

INSTALLATION OF COMPLETE LEVER OR KNOB ASSEMBLY:

A. Install exterior lever or knob assembly, inserting square spindle with posts through latch.

B. Install the interior rose plate with the threaded hole of the connecting piece facing down. Push the rose plate against door face and

apply two mounting screws to tighten firmly.

C. Apply interior rose to cover the rose plate.

D. Apply interior knob or lever to engage with square spindle, pushing against interior rose and apply set screw to tighten to complete

assembly.

REMARKS :

A-1. Privacy lock ( Bed & Bath ) fits on doors requiring locking from inside such as bedroom and bathroom.

Press button ( push rod ) on the inside of the lock will lock the door. Locking will be automatically relieved by turning

inside knob or lever.

A-2. When the locking mechanism is engaged, you will need to insert a small pin or a pointed tool into the small hole

on the lower outside rose, and push it in to unlock the door.

B. Passage lock ( Hall & Closet ) fits on doors which do not require locking. Turning knob or lever on either side will

open the door.

1.4 in.(35.5mm)

0.2 in.(5mm)

0.76 in.(19mm)

Inside Outside

Square spindle

Connecting piece

Tubular latch

Rosette

Short wood screw

Set screws

Knob/lever reinforcement plate

Allen wrench

Interior knob/lever

Mounting screws

Using allen wrench to firmly tighten set screws.

Inside Outside

Outside

Locking relief tool

Outside emergency

unlocking access hole

A-2

Inside

Turning inside knob or

lever to relieve locking

Locking button

( push rod )

A-1

Locking Unlocking

A.

Hinges

Left hand door Right hand door

HingesExterior

B.

Outside Inside

Exterior lever and interior lever can be switched.

Spindle

Outside Inside

Printed in Taiwan

This manual suits for next models

19

Other Gate House Lock manuals