Gate Motors Blank Guide

13_2008

PRODOTTI

PRODUITS

PRODUCTS

ERZEUGNIS

PRODUCTOS

Manuale d’Installazione e d’Uso

Manuel d'Installation et Utilisation

Installation and use manual

Handbuch der Installation und des Gebrauchs

Manual de Uso e Instalación

AUTOMAZIONI PER CANCELLI A BATTENTE

AUTOMATISMES POUR PORTAILS A BATTANTS

AUTOMATION FOR SWING GATES

AUTOMATISIERUNG FÜR FLÜGELTORE

AUTOMATISMOS PARA BATIENTES

SCHEMA FUNZIONALE - SCHÉMA DE FONCTIONNEMENT

OPERATIONAL DIAGRAM - FUNKTIONSPLAIN - ESQUEMA FUNCIONAL

160

320

380

65

24V 230V OIL

24V dc

0,8 - 1

60 W

-------

230V ~ 50 Hz

1,2 - 1,7

300 W

10 µF

230V ~ 50 Hz

1,2 - 1,7

300 W

10 µF

200 N

66

1400 g/m

2,50 m 3,00 m 3,00 m

200 Kg 300 Kg 300 Kg

110° 110° 110°

15” 15” 15”

90% 50% 60%

300 N

66

1400 g/m

300 N

66

1400 g/m

-------- 150° 150°

-25° - +70°C -25° - +70°C -25° - +70°C

mt= Lunghezza anta

Longueur du portail

Leaf lenght

Torflügelbreite

Dimensiones hojas

Kg= Peso anta

Poids du portail

Leaf weight

Torflügelgewicht

Pesa de la hoja

Kg

mt

2,5 3,0 3,5

200

300

400

500

600

_

_

_

_

_

_

_

_

_

Il diagramma è valido con tutta elettronica PROTECO

Ce diagramme n’ast valable que pour une installation avec une électronique PROTECO

The diagram is efective with the whole of PROTECO electronics

Das diagramm ist gültig mit PROTECO elektronic

El diagrama es válido si se utiliza electrónica PROTECO

1 Motoriduttore-

2 Centraleelettronica-

3

4

5

6

7

Motoreducteur-Gearmotor-Antrieb- Motorreductor

Centraleélectronique-Electroniccontrolunit-Elektroschrank-Centraleléctronica

Fotocellule - Photocellules - Photocells - Fotozelle - Fotocélulas Rx

Tx

Antenna-Antenne-Aerial-Antenne-Antena

Ricevitoreradio-Récepteurradio-RadioReceiver-Funkempfänger-Receptorradio

Lampeggiatore-Clignotant-Warninglight-Blinkleuchte-LuzIntermitente

Selettoreachiave-Contacteuraclé-Keycontactor- SchlüsselschalterSelectordellave

--

A 3 x 1,5+T

B 2 x 1,75+T

F 2 x 0,75

C 2 x 0,75

2 x 0,75

_

C¹ 4 x 0,75

D

6

3

3

3

1

1

2

AA

F

D

C¹

C¹ C

C

7

3

5

4

Alimentazione - Alimentation - Power supply - Anschluss - Alimentaci n

Assorbimento - Consommation - Absorption - Stromaufnahme - Absorción de línea

Potenza - Puissance moteur - Motor power - Motorleistung - Potencia

Condensatore - Condensateur - Capacitor - Kondensator - Condensador

Protezione termica - Protection thermique - Thermic protection

Thermoschutz - Protecci n térmica

Spinta max - Poussée - Maximum thrust - Drehmoment - Empuje máx

Grado IP - Classe IP - IP level - Schutzart IP - Grado de protección IP

Giri motore - Vitesse moteur - Motordrehzahl - Rotación del motor

Temperatura di funzionamento - Température de service - Working temperature

Temperaturbereich - Temperatura de servicio

Lunghezza max anta - Vantail maximum - Leaf’s maximum length

Max. Flügelgellänge - Longitud máx. hoja

Peso max anta - Poids maximum du vantail - Leaf-s maximum weight

Max. Flügelgewicht - Peso máx. hoja

Angolo max di apertura - Angle max d’ouverture - Maximum opening

Max. Öffnungswinkel - Ángulo máx. de abertura

Tempo di apertura 90° - Temps d’ouverture 90°- 90° opening time

Öffnungszeit - Velocidad angular 90°

Ciclo di lavoro - Cycle de travail - Duty cycle - Benutzungshäufigkeit - Ciclo de trabajo

ó

ó

Revolutions speed -

CARATTERISTICHE TECNICHE - CARACTERISTIQUES TECHNIQUES

TECHNICAL FEATURES - TECHNISCHE ANGABEN - CARACTERISTICAS TECNICAS

65 65

01 n°1 Motoriduttore - Gear-motor - Motoréducteur - Getriebemotor - Motorreductor

02 n°1 Cassetta di protezione - Protection box

n°1 Coperchio - Cover

n°1 Leva di sblocco - Release lever

n°1 Leva di trasmissione - Trasmission lever

n°1 Condensatore -

n°1

n°4

n°2 Rondelle 3x30 - Washer 3x30

Viti a brugola TCEI 6X12 zinc. -Screw TCEI 6X12

10 n° Sfera inox Ø25 / Inox ball Ø25

11 n° Viti 6x16 per fissaggio coperchio - Screw 6x16

n°1 Manuale d’installazione ed uso - Installation and use manual

Manuel d’installation et utilisation - Handbuch der Installation und des

Gebrauchs - Manual de Uso e Instalacion.

03

04

05

06 Condensateur - Capacitor - Motorkondensator Condensador

07 Chiave di sblocco - Realise key - Clé de deveuillage

Freisetzung des Schüssel - Llave de desbloqueo

08 Dadi M12 per fissagio motore - M12 nuts - Ecrous M12 - Verzinkte

Schraubenmutter M12 - Tuercas M12

09

Fig. B

110°

Fig. A

90°

COMPOSIZIONE - COMPOSITION - COMPOSITION - KOMPOSITION - COMPOSICION

Fig. C

Centrale

ea

Cntr le

21

Fig. D

Scavo di fondazione

Fig. N

Fig. I

Chiave di sblocco

Clé de deveuillage

Realise key

Freisetzung des Schüssel

Llave de desbloueo

Fig. M Posizione dei motori nelle cassette

Positionament des moteurs dans les caisson

Insert the motor in the box - Getriebemotors

Positionamento de los motores las casas

DxSx

Fig. H

L3

L2

L1

F2

Fig. G

L1

Fig. F

Dado M 12

F2F1

Fig. E

Fig. L

P2 P1

C

01

02 03

04

05

07 10

11

06 09

08

INTERNO -

- -

INTÉRIEUR

INSIDE INTERIOR INNENSEITE

ESTERNO - -

EXTÉRIEUR - OUTSIDE

EXTERIOR AUßENSEITE

SAFETY CRITERIA

1 Attention: before beginning anykind of procedure of installation is LOCKED ACTUATOR

absolutelynecessarytoreadallthismanuall. Thegearmotormaywithtrasmissionanddriveleverbeeitherlocked.

2Test/Control that the perfornces of the actuator auswer to your The electric lock must be installed on the wing that opens first and must be

installationneeds. connectedwiththeterminalboardofthecontrolunit.

3Besidescontrolthat: Positionoftheelectriclock:(Fig.C).

•Thegarehingesareingoodconditionsandperfectlyfattened. Position1: Lockbetweenthewings.

•Thegatehasmechanicallstopsintheopeningandtheclosing. (inthiscaseisnecessarytousetheboltRT15onthesecondwing)

Position2: Lockinthefloor.

INSTALLATION ADVICE (inthiscasetheutilisationoftheboltisnotessential)

Connections: Inanyothercase,wesuggestthelockedactuator.

• Seethe“OperationalDiagram” andrefertothecontrolcentralscheme. In this case remenber to remove the lock or at least block the lock in opening

• Theadjustmentmustbeeffectedwhenthedevicehasnopowersupply. positionandtakeawayalltheboltsoflock.

• Foreseea omnipolar breakingdevice near to the apparatus (the contact

mustmeasureatleast3mm). DETERMINATION OF FIXING MEASURES

Always protect the power supply using a 6Aautomatic switch, or a 16A Following the instructions, choose the exact position of the gear motor

single-phaseswitchfises. paying attention to the structure and the opening you want.

• Thepowersupplylinesthemotors,tothecontrolunit andtheconnection GATE FIXED IN THE MIDDLE OF THE PILLAR (FIG. A)

lines to the outfits must be sepated to avoid troubles which could In this case the maximal opening corner of the gate is 90°.

generateproblemsintheinstallationworking. GATE FIXED ON THE EDGE PILLAR (FIG. B)

• Any outfits (ofcontrol or safety) eventually connected to the control unit In this case the gate can open with a corner superior to 90°. (max 110°)

mustbetensionfree.

Spareparts: PROTECTION BOX (FIG. D)

• useesclusivelyoriginalspareparts. - Make, in the established position, a digging on the ground which can

Installation: cobtain the Protectionbox.

• In order to correctly use the product and to exclude the possibility of - PuttheProtection boxinto thedigging.

injury or damage, refer to the "Generals" page enclosure, which is an Make sure that the pin is aligned with the pivot of the leaf and that you

integratedpartofthismanual. have respected the distance of 65 mm between the centre of the pivot

• Theuseofthisequipmentmustbeinobservanceofthesafetystandards andthepiller.(Fig.E)

in force in the country where it is installed, as well as the standards - Make near the holes F1 of the Protection box a discharge for the water

governingproperinstallation. inordertoavoidapossiblebackwateraswellasanoxidationofthegear

Warranty: motor.(Fig.F)

• Thewarrantysupplied bythemanufacturerbecomesvoid intheeventof - Notioe that the electrical cables have to go through the hole F2 of the

interference, carelessness, improper use, lightening damage, power Protectionbox,asinthe“Functionalschemeforswinggate”.(Fig.N)

surgesorusebyunqualifiedpersonnel. - MakesurethattheProtectionbox isperfectlyhorizontalandburyitwith

• The warranty will also become void in the event of the following: concrete.

Failuretoobservetheinstructionsgiveninthemanualssuppliedwiththe

product. GEAR MOTOR

The application of any part in a manner differing from that provided for - Put the gear motor on the bottom of the Protection box and fasten it

current legislation or the use of spare parts which are unsuitable and/or firmlytothetapping-screwwiththerightnutsM12.(Fig.F)

notapprovedbymanifacturer. - Installthelever“L1”onthepinwhichcomesoutfromthebox.(Fig.G)

• The manufacturer cannot be held responsible for damages due to - Install the lever ”L2” lever of Transmission on the “L1” ( just installed).

improperorunreasonableuse. (Fig.H)

- Juin the lever “L2” to the lever “L3” (coming out from the gear motor) by

INSTALLATION INSTRUCTION SEQUENCE driving thepins into the right pivots and them with screws SPEI M6X18.

1Before the installation, anomalyse the risks referring to the chapter (Fig.H)

“Generalities” of this instructions manual, fill the technic table and - Closed the Protection box, with the cover and fasten it with the right

eliminatetherisksanoticed. screwM6x18TPSCEI.

Incaseofmorerisks,foreseethe installationwithsecuritysystem. - Aligne both the leaf of the gate and the lever “L1” which comes out from

2Estthesecuritylawsofthe“SecurityCriteria”. the Protectionbox. Fixthemallwithsoldering.

3Controlallthecomponents.

4Decidethepositionwhereyouwanttoinstallthegearmotor. MECHANICAL STOP

5After deciding the right position tou have to make a digging on the Now it is necessary to put the locks in order to make the openin and in the

Ground. closing of the swing.

6InstalltheProtectionbox inthe diggingon the Ground.

7Foreseeadischargeforthewater. GATE WITH EXTERNAL OPENING

8ConnecttheElectricalcablesasinthe“OperationalDiagram” If the gate has an external opening it is possible to put the motor in to the

9Putthe gear motor onthe botton ofthe Box and fastenit firmly inside the Protection box moving it of 180°.

protection.

10 Installtheleversforthegatemovement MOTOR RELEASE

11 ClosetheProtectionbox. - Turn off the electricity.

12 Aligneandfixtheleafofthegate. - Putthereleasekeyinthecorrectholeonthereleaseleverandturntheleft

13 Connectthecentralandalltheaccessoires clockwise,whereastherightleafintheotherdirection.

14 Programtheradioreceptor Inthiswayyouwillreleasethetransmission.(Fig.I)

15 Pèrogramworkingtimes Takeoutthekeyanddotheemergencymanouvre.

Incaseofbadworking,seethe“AnomaliesandCounsuls” - Nowitispossibletoopenandtoclosethegatehandly.

IF YOU DO NOT FINDANY SLUTION COLLTHE NEATESTASSISTENCE - In order to re-estabilish the transmission, you have to put the leaf in the

CENTRE. startingposition(theclutchisauomatic).

- Re-estabilishthepowersupply.

DEVICE 180° (A 008)

Thedevice hasbeenappliedtoparticularcases,toallowopeningsutil180°.

For a correct installation of the device 180°, fallow carefully these

instructions:

- FindoutthepinionP1onthegearmotor.(Fig.L)

- MounttheleverwithpinionP2onthepinwhichcomesoutfromthebox.

- putthetransmissionkey“C”onthespurwheel,stretchitandfastenit.

- Grease the chain. Close the box with the cover and fix it with suitable

screwsM6x18TPSCEI.

- AligneboththeleafofthegateandtheleverL1whichcomesoutfromthe

box.Fixthemallwithsoldering.

- Repeatthesameoperationwiththeotherleaf.

Other Gate Motors Garage Door Opener manuals

Popular Garage Door Opener manuals by other brands

SI

SI Veil Tracks installation instructions

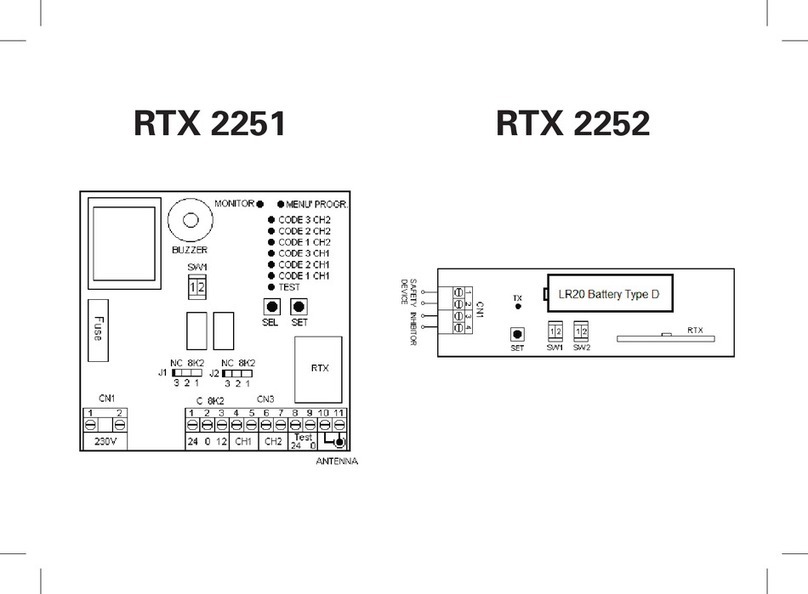

Seav

Seav RTX 2251 manual

BFT

BFT KR92522800003 Installation and user manual

Manaras

Manaras Opera MGT Installation and instruction manual

Chamberlain

Chamberlain 2280 owner's manual

CornellCookson

CornellCookson SDCL-5025 Installation instructions and operation manual

Roger

Roger AYRON Series INSTRUCTIONS AND RECOMMENDATIONS FOR THE INSTALLER

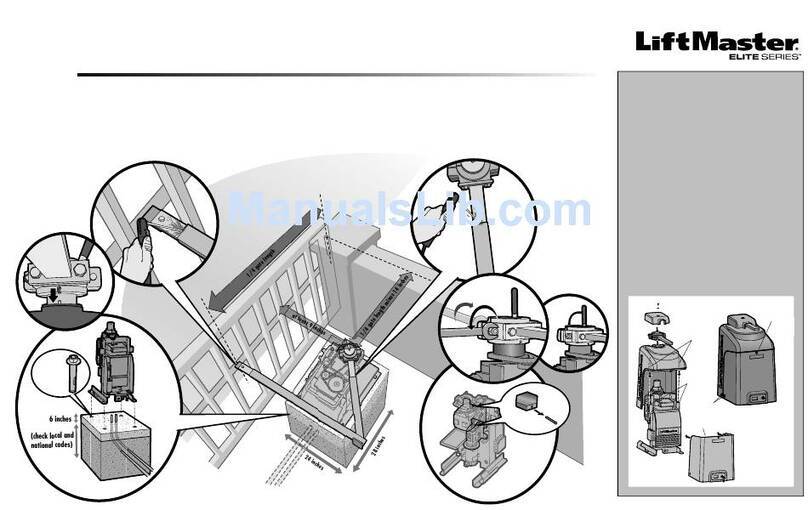

Merik

Merik LiftMaster PREMIUM Series user guide

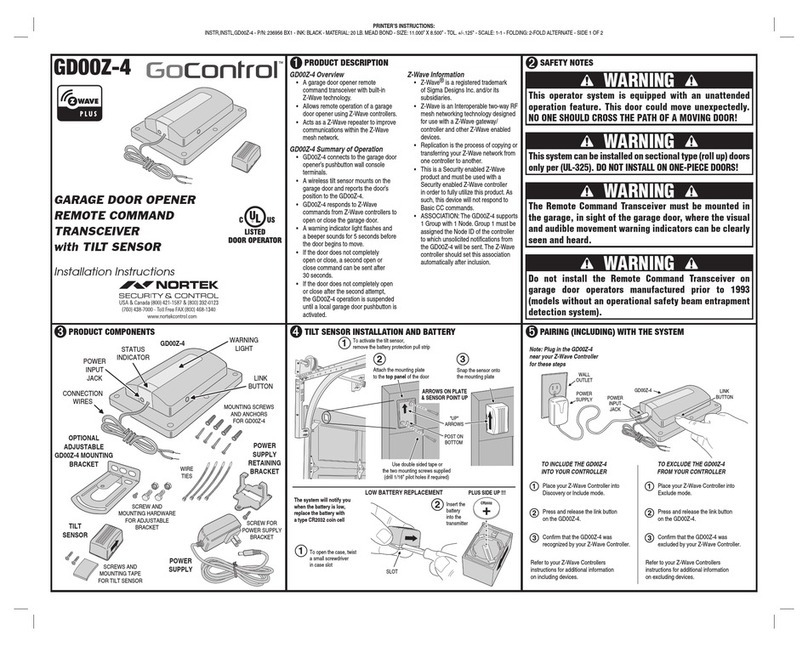

Nortek

Nortek GoControl GD00Z-4 Installation instructions manual

Chamberlain

Chamberlain LiftMaster CSW24V quick start guide

SEA

SEA Saturn 600 manual

Johnson Controls

Johnson Controls HomeLink OHHL3 user manual