ALARM

RESET

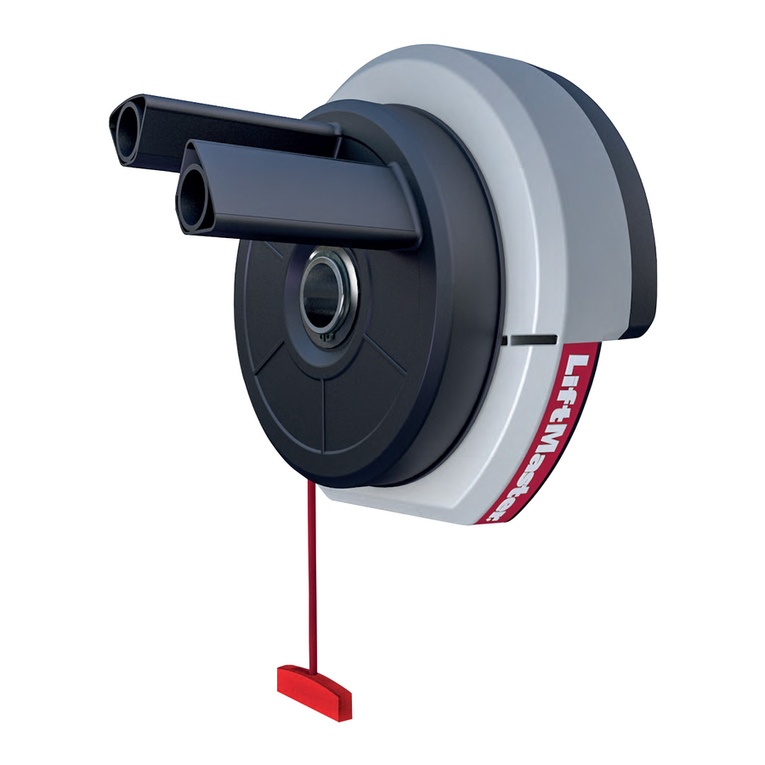

©2011 The Chamberlain Group, Inc.

01-35589 All Rights Reserved

WIRING

FINE TUNE THE FORCE

PROGRAMMING

INITIAL LIMITS AND FORCE ADJUSTMENT

OBSTRUCTION TEST

When limits are set properly the operator will automatically exit limit setting mode.

51Press and release the SET OPEN and SET CLOSE buttons simultaneously to enter limit setting mode.

2Press and hold one of the MOVE GATE buttons to move the gate to the

open or close limit.

3Press and release the SET CLOSE or SET OPEN button

depending on which limit is being set.

4Press and hold one of the MOVE GATE button to move the

gate to the other limit.

5Press and release the SET CLOSE or SET OPEN button depending on which

limit is being set.

61Open and close the gate with the test buttons.

2If the gate stops or reverses before reaching the fully open or

closed position, increase the force by turning the force control

slightly clockwise.

7

81Press and release the LEARN

button (operator will beep

and green XMITTER LED will

light).

2Press the remote control button for the

desired function. The

operator will automatically

exit learn mode (operator

will beep and green

XMITTER LED will go out)

if programming is

successful.

6Cycle the gate open and close. This automatically sets the force.

The FORCE DIAL on the control board is used for fine tuning the force. The force setting should be high enough that

the gate will not reverse by itself nor cause nuisance interruptions, but low enough to prevent serious injury to a

person. The force setting is the same for both the open and close gate directions.

3Perform the “Obstruction Test” after every force setting adjustment (see below).

1Open and close the gate with the test buttons, ensuring that the gate is stopping at the proper open and close limit

positions.

2Place a solid object between the open gate and a rigid structure. Ensure that the gate, the solid object, and the rigid

structure can withstand the forces generated during this obstruction test.

3Run the gate in the close direction. The gate should stop and reverse upon contact with the solid object. If the gate

does not reverse off the solid object, reduce the force setting by turning the force control slightly counter-clockwise.

The gate should have enough force to reach both the open and close limits, but MUST reverse after contact with a

solid object.

4Repeat the test for the open direction.

To protect against fire and electrocution:

• DISCONNECT power and battery BEFORE

installing or servicing operator.

For continued protection against fire:

• Replace ONLY with fuse of same type and

rating.

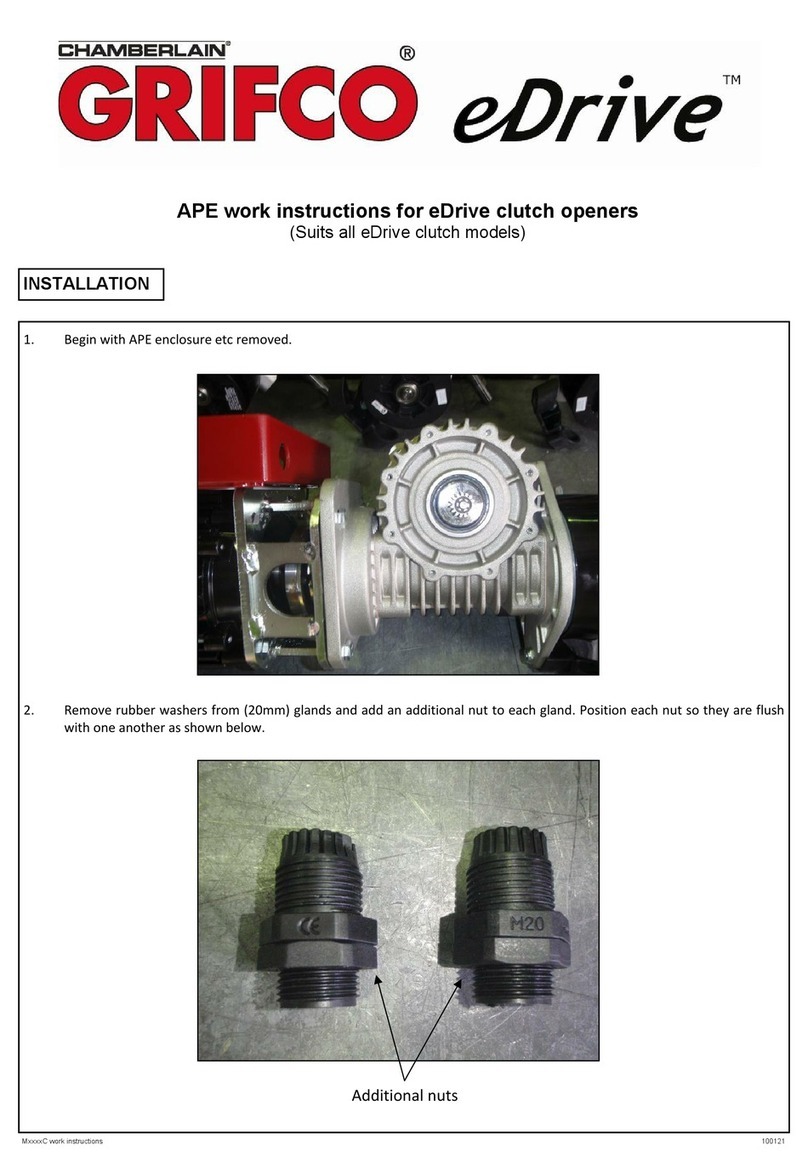

WIRE THE ENTRAPMENT PROTECTION DEVICES

Connect the entrapment protection device to the EYES EDGE terminal on the control

board.

• Close Photoelectric Sensor Entrapment Protection: Connect wires from the

photoelectric sensors to the Inputs on the CLOSE EYES/INTERRUPT terminal.

• Close Edge Entrapment Protection: Connect wires from the entrapment protection

device to the Inputs on the CLOSE EDGE terminal.

• Open Entrapment Protection: Connect wires from the entrapment protection device

to the Inputs on the OPEN EYES/EDGE terminal.

POWER WIRING

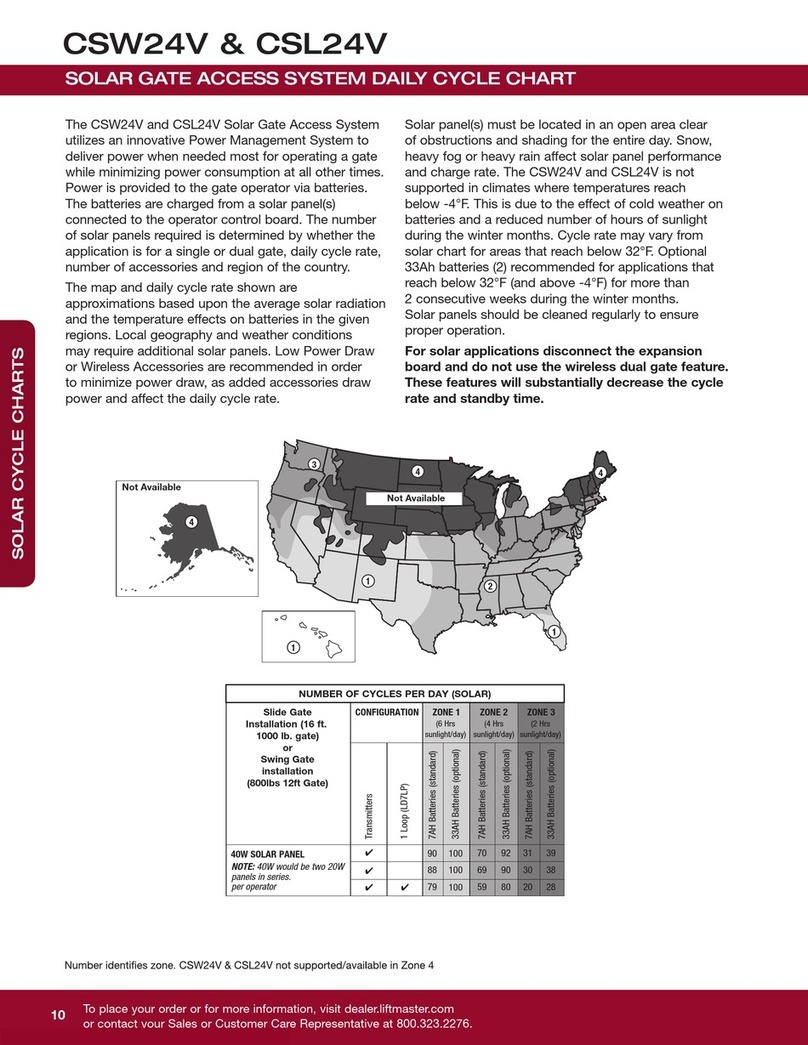

This operator can be wired for either 120 Vac or 240 Vac or a

solar panel (not provided). These instructions show a 120 Vac

application. For information regarding a 240 Vac or solar

application refer to the installation manual.

1

2EARTH GROUND ROD

1Install the earth ground rod within 3 feet

of the operator.

2Run wire from the earth ground rod to the

operator.

Check national and local

codes for proper depth

3

4CONNECT BATTERIES

Red Wire

Black Wire

Jumper

1Connect the battery wires to the

J15 plug on the control board.

2Turn ON AC power to the

operator.

3Turn ON the AC power switch on

the operator.

1Turn off the AC power from the main

power source circuit breaker.

2Run the AC power wires to the

operator.

3Connect the green wire to the earth

ground rod and AC ground using a

wire nut. NOTE: The earth ground

rod can be grounded to the chassis.

4Connect the white wire to NEUTRAL

using a wire nut.

5Connect the black wire to HOT using

a wire nut.

Junction Box

SET OPEN SET CLOSE

OFF

PRESS &

RELEASE

TO BEGIN

LIMIT

ALARM

RESET

MOVE

GATE

5

INPUT POWER

STATUS:

PRESS &

RELEASE

TO BEGIN

SETUP

LIMIT

ALARM

RESET

60

180 MIN MAX

BATT LOW

NETWORK

OPEN CLOSE STOP

XMITTER

NETWORK

AC Power Switch