GB XD4A User manual

~

Q

~

~

~

I-'

~

ri

~

~

~

~

~

~

~

0

~

,Q.

,Q.

=

~

~

00

0

~

=

<

I

t

I

I

CAUTIONS

1.

This machine is not intended for use by the physicallyweak, intellectually obtuse,

mentally disabled

or

children , unless it

is

safely used under the help

or

instructions

of

those who are responsible for theirsafety .

{

2.

The

childrenshall

be

supervisedto ensure thatthey will notplaythe machine.

3.

Be

sure to remove the powerplug from the socket before cleaning

or

repairing the

machine.

4.

In

the event

that

the

power

cables are damaged

or

loose , please have them

replaced by the manufacture service station

or

qualified technician . The

connection is Y-type connection .

5. Remove thepowerplug aftet the shutdown

of

the machine.

6.

Use appropriate voltage and :frequency.

CONTENTS

Product Introduction-------------------------------------------------------------- 1

Safety Considerations ------------------------------------------------------------ 1

Main Structure--------------------------------------------------------------------- 1

Operating Procedures and Precautions----------------------------------------- 2

Care and Maintenance------------------------------------------------------------ 2

Main Troubles and How to Solve Them --------------------------------------- 3

Included Accessories ------------------------------------------------------------- 3

Techrlical Parameters ------------------------------------------------------------- 4

Explosion Views------------------------------------------------------------------- 5-9

Product Introduction

Welcome to buy and use XD4A Sweeper-Drier. This machine is featured in easy

operation, safe use and good cleaning effect, suitable for cleaning

of

the small-

and medium-sized grounds in office building, hotel, warehouse and square.

Safety Considerations

1.

This machine is not suitable for cleaning the carpet.

2.ln the event that the recharger

or

electric cable

is

damaged, please immediately

contact the manufacturer

or

its authorized service center.

3.Never mix different types

of

cleaning agents; otherwise toxic gas will be

generated.

4.Never use this machine in explosive environment.

5.Never use this machine for suction

of

inflammable liquids.

6.Never use the acid liquids that can damage this machine.

7.Make sure to shut down this machine and disconnect the battery before

maintenance.

8.Never clean this machine with high-pressure

jet

water or corrosive substances.

9.In case that the machine is caught to fire, please ililJllediately use powder

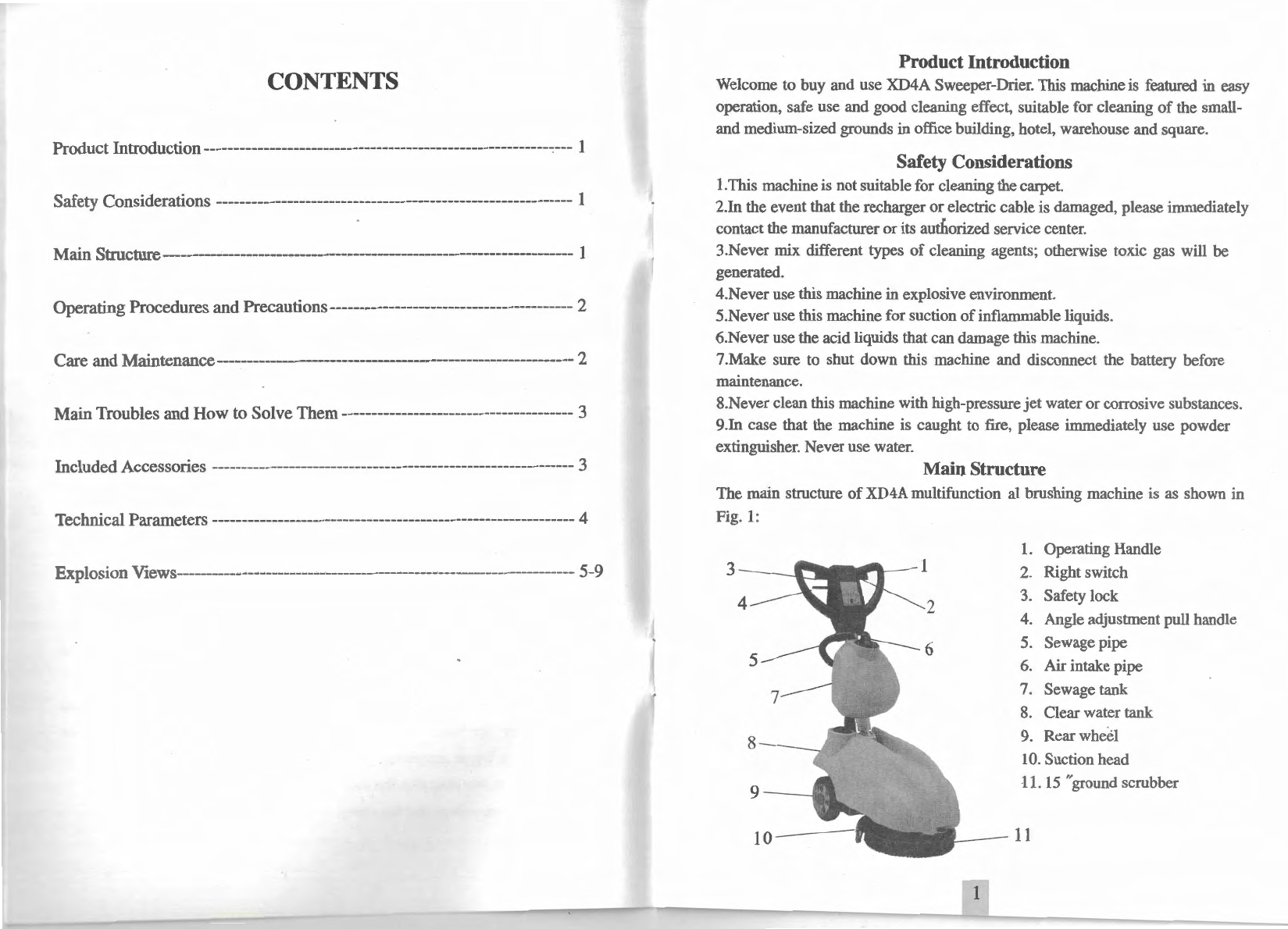

extinguisher. Never use water. Main Structure

The main structure

of

XD4A

multifunction

al

brushing machine is as shown in

Fig.

1:

l.

Operating Handle

3--.:::-m

2.

Right switch

4 3. Safety lock

4. Angle adjustment pull handle

5.

Sewage pipe

6. Air intake pipe

7. Sewage tank

8.

Clear water tank

9. Rear wheel

10.

Suction head

11.

15

"ground scrubber

11

1

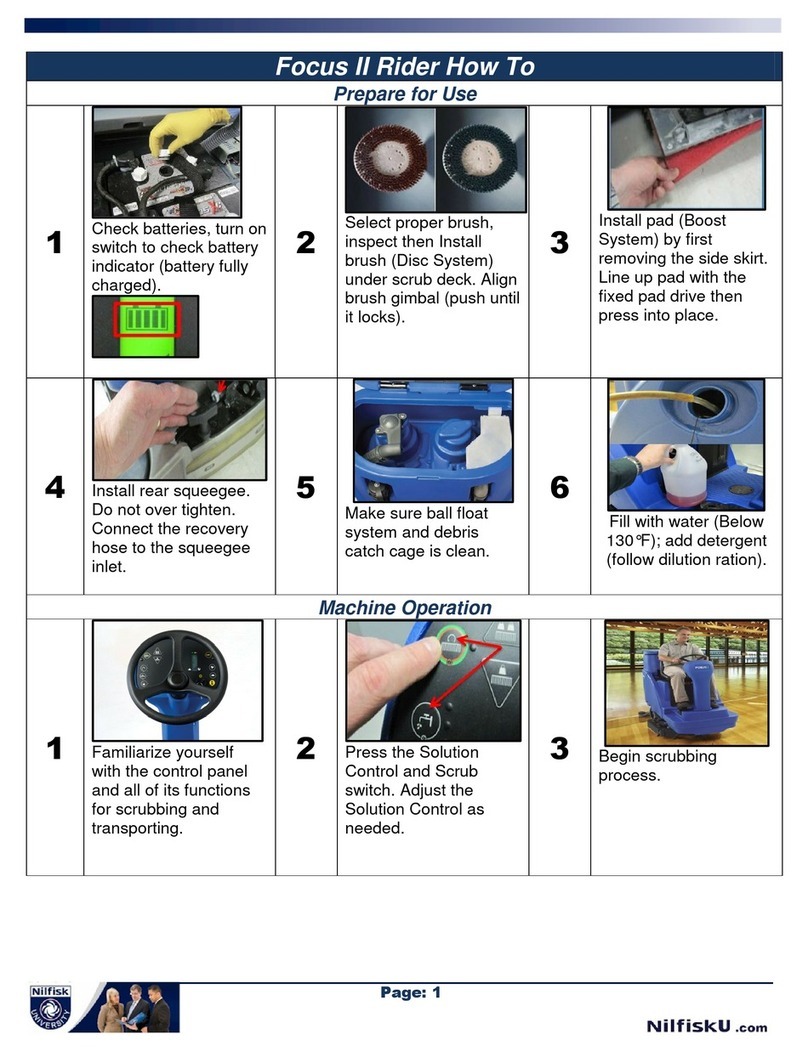

Operating Instructions

1.

Unpack the machine and take it out from the base plate.

Place the machine on ground and mount cleaning

scrubber.

2.

As

shown

in

Fig.

1,

adjust the angle adjustment pull

handle to 90 °- 120

°.

Then, remove the clear water tank.

Unlock the two clamps on the battery compartment

at

the

back

of

machine and connect the battery to a fixed socket.

3. Install the battery compartment cover and clear water

tank. Add

an

appropriate quantity

of

cleanser solution.

4.

Install the sewage

tank

to the hook on the aluminum

pipe ofoperating handle, and connect the suction pipe and

sewage pipe to the sewage tank.

5.

Put down the suction head UP/DOWN handle on the

back

of

machine (Fig. 3).

In

this case, the suction head

has been flatly placed on the ground. Pull the angle

adjustment handle to adjust operating handle to the height

desired

by

the operator. Then, release the handle.

6.

Put the main scrubber switch

(I),

pumping switch (2)

and solenoid valve switch (3) on the panel

of

operating

handle to "ON" position. Check

if

the signal lamp is

bright (green). Then, push the safety lock on operating

han

dle to center, and closethe hand-operated switch, so

that the machine will start to work.

Fig.2

Care and Maintenance

@ I.Main

scrubber

switch

2.Pumping switch

3.Solenoid valve

switch

To extend the service life

of

the machine and enable the machine to work under the best effect,

it is suggested to do the following after each use:

1.

Use

clear water to wash the suction head clean and wipe with dry cloth.

2. Remove the sewage tank and use clear water to wash it clean. At the

same

time, use water to

rinse the suction pipe clean.

3. This machine cannot be wash directly with water,

but

be wiped with semi-dry cloth, thus to

ensure that no water will enter into the machine. Otherwise, the electric parts

of

the machine

will be burnt.

4.When the machine is to be put long out

of

service,

the battery shall be reguJarly recharged;

01herwise the service life

of

the battery will be reduced.

2

Main Troubles and How to Solve Them

Trouble Cause

How

to Solve

The

power

socket is not properly Connect the power socket

No

power

supply connected properly

The

main scrubber switch is not Check and put

it

to

ON

put to

ON

position. position.

The

suction pipe is blocked Check and wash the suction

pipe

No

suction force

or

the

The

sewage tank cover is not Reinstall and seal the

suction force is low installed properly sewage tank

cover

properly

The

pipe connection is not tight

Check

and repair

The

suction carbon brush is worn Replace the carbon brush

The

hand-operated

power

switch Replace the

power

switch

The

scrubber motor is burnt Repair

or

replace the

motor

cannot rotate after it is

The

scrubber motor is burnt Repair

or

replace the circuit

energized

The

circuit board is failed board

The

carbon brush

of

motor is Replace the carbon brush

of

worn motor

The

carbon brush

of

motor

is

Replace the carbon

The

suction motor worn brush

cannot rotate after it

The

motor is short circuited Repair

or

replace

is

energized and burnt Repair

or

replace the

The

circuit board is failed circuit board

The

battery

is

short circuited Replace with a new

or

aged battery

The

battery cannot

be

The

recharging circuit is short Repair

or

replace

the

recharged circuited

or

burnt recharger

The

insert connecting the Check and repair

recharger is in poor contact

The

circuit board is failed Repair

or

replace

The

solenoid valve is short Replace

tl1e

solenoid

There

is no water out circuited valve

during working

The

drain pipe is blocked Check and clean the pipe

The

drain switch is not put to Check and put it to

ON

ON

position. position.

Included Accessories

1.Machine, 1set

2.

Groundscrubber, 1

pc

3.

Sewage tank, 1 pc 4. Clear water tank, 1pc

5.

User Manual, 1 copy

3

Technical Parameters

Rated

power

I rated volatge

500W

I 12V

Working width

370mm

Width

of

suction head

440mm

Working efficiency 1350m2Jb

Scrubber diameter

370mm

Scrubber speed 165rpm/min

Scrubber motor 250V/W

Suction motor 250V/W

Clear water tank volume

UL

Sewage tank volume

llL

Battery 12V/85AH

Battery recharger 12V/20A

Battery compartment size

(L

x W x

H)

285Xl

75X235

mm

Length

of

machine after folding

970mm

Height

of

machine after folding

460mm

Net weight 67KG

Gross weight 79.5KG

Packaging size

(L

x W x

H)

l l IOX560X485rnm

l

4

Erating Handle Sub-assembly

1.

Front cover

of

handle

2.

PA5Xl0

3.

Flat washer

4.

NutMl2X3

5.

Round switch seat

6. Round switch

7. Self-lock nut M5

8. Angle adjustment handle

9.

BAH3.5XJ6

10. Cable clamp (fine)

11

. Handle spring

12.

Pin

13.

Circuit board

14.

Steel PA3Xl0

15

. Terminal strip

16.

Safety lock

17

. Left switch

18.

Back cover

of

handle

19.

BBH5Xl6

20. Right switch

21. TM6X25

22. Pull rod

of

handle

23. Spring

2Xl7X75Xl5N

24. Nut,

M5

25

. Washer

26. Needle tooth

27. Sewage tank support

28. Steel PM5X10

29. Steel CMSX45

30. Aluminum tube

of

handle

31. Self-lock steel nut M6

32. Suction head mechanism

33. Steel outer hexagonal

6Xl5

34. Steel outer hexagonal 5x20

35. Rubber casing

M8

36. Self-lock nut

M5

37. Steel outer hexagonal 8X25

38. Suction head mechanism

39. Steel set screw KM6Xl2

40. Clutch cable

41. Steel outer hexagonal 6X72

42. Steel outer hexagonal 8x20

43. Handle seat

44.Handle seat casing

45.Steel outer hexagonal

6Xl0

46.Slotted pin 4X20

47.Round tooth

48.Self-lock steel nut M6

<16

3

.........--4

-

~17

2~-~

',,,

~

--,\,

6 : 5

',,

-----

~

','

g 7

JO

'•,

_.../19

~

"

9

"-

---

'-..

----

-

"'

\ -

---------,

__

,

..

.

--

>

~20

-

~~12

11

.-

29

30

22

28

.\...-

-

t·

27 \ . 0 34

~35

-3

-

~-I

~~6

37

~~

--

---

'-=:::=

----:

~

38

23~

l:~-Jn

----32 / I 39

33

!.

_

25---.;-24

6---f

45

2 ' /

~----

-

----------

-

:

.

41--"~~

~ :

:,_

;

~:

;·

:

<_46,

'

'

42

~-

r .

43 44 -----

._--48

..

47

43 B

5

40

Water Tank I Support Sub-assembly

1.

Air

intake pipe

2. Sewage pipe

3. Sewage tank cover

4. Sewage tank seal ring

5.

Air

intake pipe connector

1-n

172

3

'.!

Q ;

' '

: :

6.

Air

intake pipe seal

ri

ng

7. Floating ball support

and

floating ball

4-+9

:

s

---1:l

i'

f

6~

'

1:

8. Sewage pipe

join

t

9. Sewage tank seal ring

10. Sewage tank

11. Clear water tank

cover

12. Clear water tank filter

13

.

Clear

water tank

14. Iron box cover

15. Copper nut

of

iron box

16. Steel carriage 6x20

17. BatteryD

CI00-12V

85AH

18

. Recharger decoration

cover

19

. Recharger

20

. Battery iron compartment

21. Clamp

22. Steel carriage

LOX25

23. Rear wheel axle 200X50

24

. Rear wheel

25. R

ear

wheel axle sleeve 200X50

26. Bearing 6024

7~

/

F-

'

0 : 8

--

·

,'

_____

;---9

IO

Connection A

11

---q

13

14

Connection B

15~

17

:{]

~1

8

29. Steel outer hexagonal 8x20 e

a==~

30

. Wheel cover I 20

19

31. Steel carriage SX18

..,....,_-(j-n.

~

·

27. Steel spring washer

M8

28. Washer

8X25Xl.5

ur

-

-(j.

' · ·

21

32.

Ste~l

self-lock nut M8

-,

! · ·

--

--

.ft

~

33. Mam frame :

..

·• 26

34. Supporting plate

of

iron box 22 l

;

~

}

/~

~j

27

29

32--/-

31

::

23 I

\L\

ii

24 28 30

~

'

25 \

33

~

-:

..

:

:

'

'

'

34~

__

_!

6

Pumping System Assembly

4 0 -

----:

~

---

'

...

--""

...

, :

3

.,..

...

: I

1

~

~()

10

1

\ I I 1\

:~

\

13

•

••

~

8--;-~

-:

~

~

~

,~_-

:

:-

~

~

11-..........

_

~

18

//

E!J-'f!J-

··l/J

--A

:

-

;~.

_

;

' - -

°IJ'.

''

~

--

.

5 /

'.

i

14Y.r

15~16

6 7 : :

·-

- i

l.

2.

3.

4.

5.

6.

7.

8.

9.

Self-lock nut

M6

Fan supporting plate

Small motor ring

i

---

-+-

-;--

-

--

-----

)' : U

J:Lm-...11

19

~:

~

20 -

··

Suction motor 12V 250W

Terminal box 120x120x60 (upper

cover

)\·

-~

Circuit board

21~~

Terminal box 120x120x

60

(l

ower

cover

)

--

Self-lock steel nut

M6

22

~

Clear water tank supporting plate

~

10. Steel carriage 6x20

!?

----

~-.

.'

\ 1... -

.

.

.

'

.

'

'

11. Screw

M8

T----

- ·24

12

.

Clear

water tank fixing nut 25

13

. Steel outer hexagonal 10x20

14

. Star washer

15

. Steel outer hexagonal

6Xl5

16

. Steel outer hexagonal 8X25

17

. Steel outer hexagonal 6X88

18.

Main

frame

19

. Suction head assembly 28

20. Steel

se

lf-lock nut

M8

21.

Power

system assembly

22.

Belt

770JB channel

26n

'!

'r

27~

I I I I 1 1

'.

7

23.Steel

PM4Xl0

24.Steel spring washer

25.Scrubber cover

26.Scrubberclamp screw 154

27.Scrubber clamp 154

28.15 "ground scrubber

Explosion View

of

XD4A Power System Assembly

I.

Brush

motorSHWT70098 l

2V

250W

2.

Central

ax.is

of

pulley

3. Steel self-lock nut

M8

4. Washer 8X20X2

5. Fan supporting plate

6.

Movable

copper

washer

7.

Motor

fixing plate

8. Washer for central

ax.is

of

puHey

9. Spring (37 #)

JO

. Steel PM5XJO

11. Steel set screw

KM6Xl

2

12. Steel spring washer 6

13.

Steel outer hexagonal 6X

15

14.

Solenoid valve 12V

15. Iron piece

of

drain valve

16. Water

jacket

17. Self-lock steel nut M5

18. Steel outer hexagonal 8x20

19. Steel set screw KM8X20

20

. Pressure regulating iron

21. Washer

l2X23Xl.5

22. Bearing 6001

23.

Belt

wheel

ax.is

24

. Bearing

6204

25. Steel

nut

M8

28~~

26

. Steel spring washe

27.

Belt

bearing casing

28. Pulley

29

. Flat washer 15X28X2.4

30. Nut for central axis

of

puJJey

31.Flange

32.Flange

plug

33

.

Washer

of

three-blade

impeller

34.Three

-b

lade

impeller

35.KCM8X50

• : 30

31

-'

I<

I I

32

i~

:

' '

' '

: I :

33

~~

+

3

4~

~

35-ti i

8

Suction HeadAssembly

1----w

5 •

(10

2~

~

----

69

v---

~--

JL::

7 ·--.,·

-~.

13

3

__...,

llY-W,

•'

c

4_____!

6/'

71

-:

/i

.14

r-10

_/r

~17

l.

Rotating shaft

of

suction head

2. Rotary support

3. Washer

6Xl2Xl

4. Steel set screw KM6X15

5. Landing

bar

6. Pressure spring

of

suction hea d

(l.6Xl

7 inner 3.5 torsion spring)

7. Torsion spring fixing shaft

8.

Washer

6X20Xl

9. Self-lock steel nut

M6

10.

Set

screw KM6X40

8 9

15 ..,,,., 18

2U

: .U

14

::

~

·

~

2 1

I l!i I

I : : '

22--+d=d

2

~

'

/

..

;:

~;

•

/

I :

, /'

:

~

--~---:--

·

<\,,-·

10

24

rp::;==7T

?O.::

~_i__N

~

:

,',4

/

,/'

•

,-'

------

,

Cl

25

F / 'j ,.-

~

11.

Landing block

12. Self-lock steel nut

MS

13.

Steel outer hexagonal 5x28

14. Self-Jock steel nut M6

15. Connection block

of

suction head

16.

Star head screw M6

17.

Steel machine screw 6X40

18

. Steel outer hexagonal 6X35

19. Steel outer hexagonal

6Xl5

20. Joint

of

suction bead

/

/

//-~~-/

/

27~

~/

12

30_;:::®

-/

21. Weight bar

22. Rear pressure board

of

suction head

23. Rear pressure strip

of

suction head

24. Suction bead casting

25. Front rubber strip

of

suction bead

26. Front pressure board

of

suction head

27. Steel carriage 5x20

28. Steel carriage 5x30

29. Steel carriage 5x35

30. Small rubber roller

of

suction head

9

Table of contents

Other GB Scrubber manuals

Popular Scrubber manuals by other brands

Drieaz

Drieaz HVE-LL Large Loss Operation and service manual

Servpro

Servpro 879 Information & operation manual

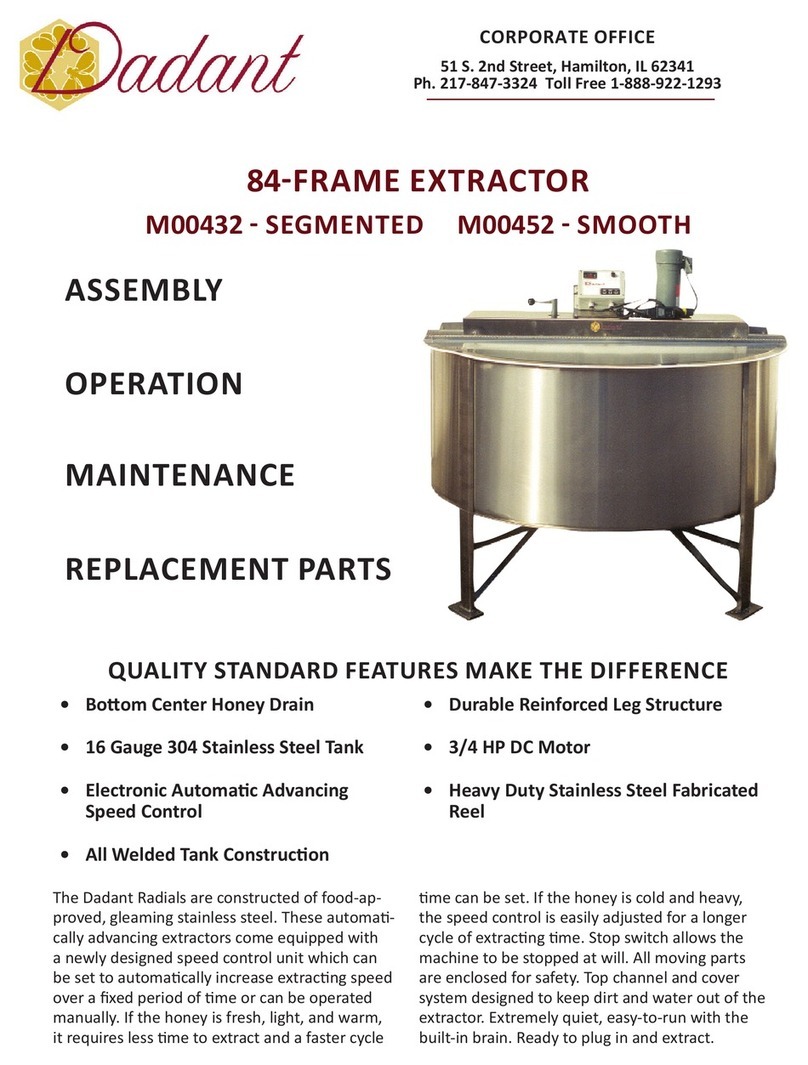

Dadant

Dadant M00432 Assembly, Operation, Maintenance, Replacement Parts

Crescent

Crescent SC800 User and maintenance guide

Hydro-Force

Hydro-Force Nautilus MX3-500HE operating manual

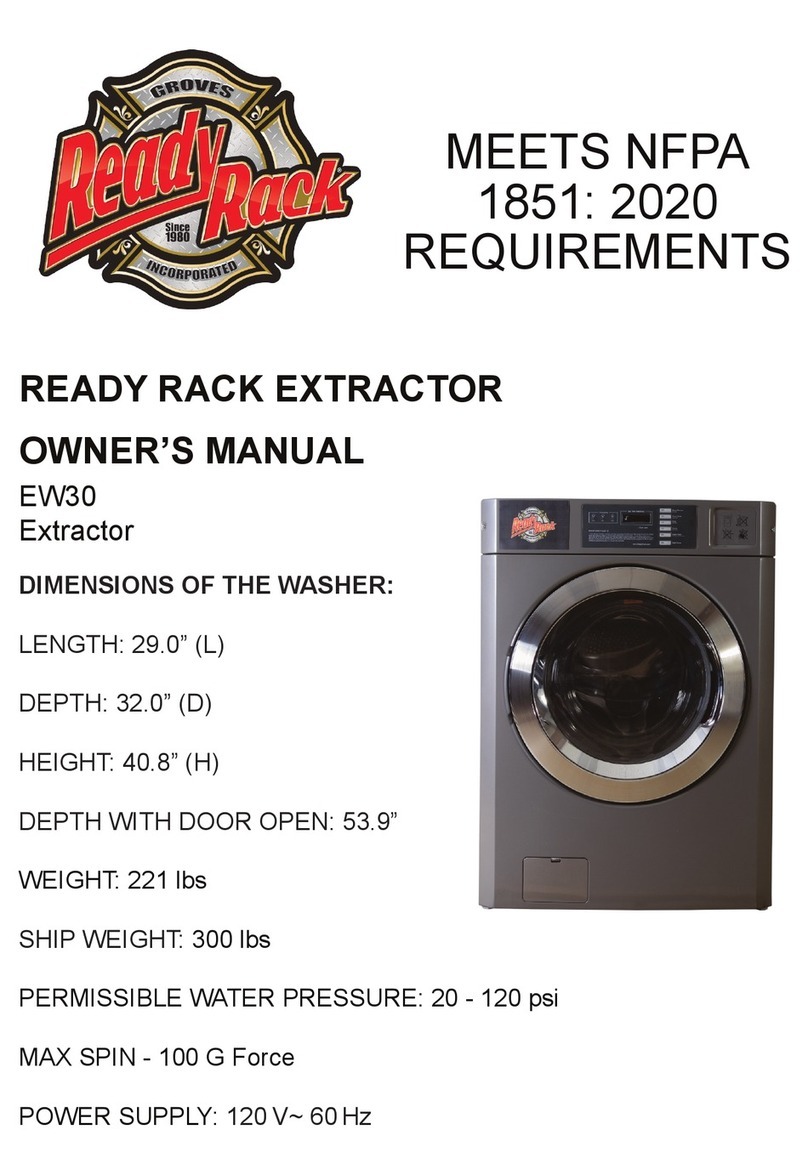

Ready Rack

Ready Rack EW30 owner's manual