GBP Microclean User manual

MANUAL

Cleaners for factory tools and small parts

Microclean

Maxiclean

Masterclean

MANUAL

-Vaskemaskiner for maskin- og motordeler

Microclean

Maxiclean

Masterclean

MANUAL

-Vaskemaskiner for maskin- og motordeler

Microclean

Maxiclean

Masterclean

1

MASTERCLEAN

FUNCTION 12

INSTALLATION 12

Assembly instructions 12

CLEANING INSTRUCTIONS 13

MAINTENANCE 14

How to change liquid 14

How to change pump gasket 14

How to change pump 14

How to change power cord 14

SPARE PARTS 14

ACCESSORIES 15

TECHNICAL SPECIFICATION 15

INTRODUCTION 3

SAFETY 4

MICROCLEAN

FUNCTION 5

INSTALLATION 5

Assembly instructions 5

CLEANING INSTRUCTIONS 6

MAINTENANCE 6

How to change liquid 6

How to change pump gasket 7

How to change pump 7

How to change power cord

SPARE PARTS 7

ACCESSORIES 7

TECHNICAL SPECIFICATION 7

MAXICLEAN

FUNCTION 8

INSTALLATION 8

Assembly instructions 8

CLEANING INSTRUCTIONS 9

MAINTENANCE 10

How to change liquid 10

How to change pump gasket 10

How to change pump 11

How to change power cord 11

SPARE PARTS 11

ACCESSORIES 11

TECHNICAL SPECIFICATION 11

2

MASTERCLEAN

FUNCTION 12

INSTALLATION 12

Assembly instructions 12

CLEANING INSTRUCTIONS 13

MAINTENANCE 14

How to change liquid 14

How to change pump gasket 14

How to change pump 14

How to change power cord 14

SPARE PARTS 14

ACCESSORIES 15

TECHNICAL SPECIFICATION 15

3

INTRODUCTION

In order to maintain maximum safety, be sure to read the section ”SAFETY”

carefully before any maintenance is carried out on the cleaner.

This instruction manual is valid for the cleaners: MICROCLEAN, MAXICLEAN

AND MASTERCLEAN manufactured by GBP Ergonomics AB (GBP). It is

recommended by GBP to study the instruction manual carefully and –most

important of all- make sure that the manual is available for those who install,

maintain and use the cleaner.

GBP does not take responsibility for personal injury or damage on the cleaner, if

instructions are not followed.

Make sure to read the instruction manual before unpacking, installing or using

this cleaner. Observe all safety issues. Serious personal injury or damage to the

cleaner may occur if you choose to neglect this information

Furthermore it is important that you:

•Keep this information and other applicable documents during the lifetime of

the cleaner.

•Hand over the instructions to a possible new user.

•Insert possible changes and additional instructions in the manual, supplied

from GBP

This manual is valid for:

Serial No.

CE-certification

Our washers are CE certified, see fig 1 below. If the cleaner is modified or fitted

with other products, the CE certification is no longer valid.

fig 1

3

4

SAFETY

The warning labels in this manual stand for the following:

Negligence in the following instruction in this manual might be life threatening.

Negligence in the following instruction in this manual might lead to personal

injury.

Negligence in the following instruction in this manual might lead to damage to the

cleaner.

Work on electrical equipment shall only be performed by skilled personnel.

The definition of skilled personnel is:

•Personnel with the technical knowledge or enough experience to avoid the

risks involved in working with electricity.

How to act in case of an accident.

•If an accident has occurred, act promptly, send for medical help immediately.

•If the victim is breathing but unconscious, place him in semi-prone position

(stretched out on the side with mouth and respiratory passages free).

•If the victim is not breathing, start mouth to mouth resuscitation.

•In case of heart failure, give heart massage if you are trained in heart

massage.

4

5

MICROCLEAN (Part. No. 36-180-2101)

FUNCTION

MICROCLEAN can easily be fitted to the wall or placed on a workbench.

It is designed for manual cleaning using a spray gun.

The liquid is recycled automatically and cleaned using sedimentation.

Ventilation hose is available as an accessory.

MICROCLEAN has:

•A well designed ventilation system that is effective for manual cleaning.

•The ventilating cover is easy to connect to existing ventilation system.

•A spray gun that is easy to grip and manoeuvre.

•The electrical system is totally insulated from the liquid.

•Closed off workspace preventing the liquid from leaking.

INSTALLATION

Assembly instructions

1. Mount the cleaner on a wall or place it on a workbench

(when placing it on a workbench, pull out the adjustable legs).

2. Make sure that the sedimentation plate is in place in the sedimentation tank.

3. Put the unloading plate, with the open slots to the left, on top of the

sedimentation tank.

4. Mount the connection to ventilation system on the right side of the cleaner

with the enclosed screws.

5. Fill the tank with 8 litres of liquid, low aromatic degreaser with flash-point

above 70° C. The liquid must not exceed the inner unloading plate.

6. Connect the cleaner to a 230V/50Hz earthed socket. The input plug should

be easy to reach, when the cleaner is in use.

•Do not mix the liquid with for example gasoline, thinner, acetone or similar.

•Do not place the cleaner in rooms where volatile solvents or inflammable

gases are stored or used. This may cause an explosion!

•Do not place the cleaner in wet or humid rooms. This may cause flashover!

5

6

CLEANING INSTRUCTIONS

1. Open the cover and put the parts, which need to be cleaned on the wash

board.

2. Turn the main switch to position 1.

3. Clean manually using the spray gun.

4. Turn the main switch to position 0.

1. Unloading plate

2. Wash board for manual cleaning

3. Sedimentation plate

4. Connection to ventilation system

5. Spray gun with hose

6. Net strainer

7. Main switch

8. Pump

9. Adjustable leg

10 Brush

MAINTENANCE

A bad cleaning result may be caused by:

•The cleaning fluid needs to be changed.

•Pump gasket needs to be replaced.

•Pump needs to be replaced.

A leakage is most likely caused by a damaged pump gasket.

How to change the cleaning fluid

1. Unplug the machine from the power supply.

2. Remove the drainage plug from underneath the machine making sure to

place a bucket or similar to collect the old fluid.

3. Pick up and clean the unloading plate, sedimentation plate and net strainer.

4. Put them back into place. Fill the tank with 8 litre fluid, low aromatic

degreaser with flash point above 70°C. The level of the fluid must not

exceed the inner unloading plate. When diluting degreaser make sure to

add the water before the degreaser.

•The liquids flash point

must exceed 70°C.

If not, it may cause a fire!

•

Do not place the cleaner in wet

or humid rooms.

This may cause flash over!

6

How to change the pump gasket

1. Unplug the machine from the power supply!

2. Empty the liquid, see: 'How to change the liquid'.

3. Unscrew the front plate and loosen the hose clip.

4. Loosen the two screws underneath the ground plate and lift up the pump.

5. Loosen the pump block and unscrew the pump wheel.

6. Change the gasket and put the pump together again.

7. Mount the pump, attach the hose and put the hose clip back on.

8. Refill the tank. See: 'How to change the fluid.

How to change of pump

1. Unplug the machine from the power supply!

2. Empty the liquid, see: 'How to change the fluid’.

3. Unscrew the front-plate and loosen the hose clip.

4. Loosen the two screws underneath the ground plate and lift up the pump.

5. Mount the new pump, attach the hose and put the hose clip back on.

6. Refill the tank. See: 'How to change the Fluid.

How to change the power cord

Work on electrical equipment must be performed by skilled personnel only.

Spare parts and accessories can be ordered from your supplier.

SPARE PARTS

38-100-0001 Brush

38-110-0001 Pump

38-102-0001 Pump gasket

38-103-0001 Net strainer

38-105-0001 Spray gun with hose

38-107-0001 Main switch

ACCESSORIES

36-190-0001 Ventilations hose

TECHNICAL SPECIFICATION

Spray gun with hose 1 st

Tank volume 8 litre

Pump capacity/min 28 litre

Max wash weight 20kg

Cleaning area WxDxH 515x170x335 mm

Cleaning table, WxD 515x340 mm

Outside dimensions, WxDxH 590x250x625 mm

Net strainer 1 st

Voltage supply 230V/50Hz 1fas.

Pump effect 85W

Weight 24kg

Fluid Low aromatic degreaser with

Flash point above 70°C

7

7

8

MAXICLEAN (Part. No. 36-181-2101)

FUNCTION

MAXICLEAN has two cleaning systems, which can be used separately or integrated.

The parts can be cleaned either in a closed area, where the liquid is automatically

sprayed on the part by three nozzles or placed on a wash board and cleaned manually

with a spray-gun.

The fluid is recycled automatically and cleaned using sedimentation. Ventilation hose

and castors are available as accessories.

MAXICLEAN has:

A well designed ventilation system. The ventilating cover is easy to connect to existing

ventilation system.

•A spray gun that is easy to grip and manoeuvre.

•The electrical system is totally insulated from the liquid.

•Closed off workspace preventing the liquid from leaking.

INSTALLATION

Assembly instructions

1. Lay the cleaner on its back. Mount the castors using the enclosed screws, two for

each castor.

2. Make sure that the sedimentation box is located on the left hand side of the liquid

tank.

3. Put the unloading plate, with the open slots to the left and the gripping edge

backwards.

4. Mount the protection hood using the enclosed screws.

5. Mount the connection of the ventilation system on to the protective hood using the

enclosed screws.

6. Fill the tank with 30 litres of fluid, low aromatic degreaser with flash point above

70°C. The liquid must not exceed the inner unloading plate.

7. Connect the cleaner to a 230V/50Hz earthed socket. The input plug should be easy

to reach, when the cleaner is in use.

•Do not mix the liquid with for example petrol, thinner, acetone or similar.

•Do not place the cleaner in rooms where volatile solvents or inflammable gases are

stored or used.

This may cause an explosion!

8

9

•Improper supplements such as thinner or trichloroethylene may cause damage to the

pump and hoses.

CLEANING INSTRUCTIONS

Automatic wash.

1. Open the cover of the protective hood and put the parts, which need to be cleaned,

on the unloading plate.

2. Close the cover and turn the main switch (10) to position 1 and open the faucet (8).

3. Let the cleaner run until the parts are dean.

4. Turn the main switch to position 0. Close the faucet and open the cover.

Manual clean.

1. In order to improve the cleaning result, close the faucet (8).

2. Put the parts that need to be cleaned on the wash board.

3. Turn the main switch to position 1.

4. Clean manually using the spray-gun.

5. Turn the main switch to position 0.

1. Unloading plate

2. Nozzle

3. Sedimentation plate

4. Protective hood

5. Wash board for manual cleaning

6. Connection to ventilation system

7. Service space

8. Faucet

9. Spray gun with hose

10. Mains switch

11. Net strainer

12. Pump

13. Legs

14. Cover.

15. Door

16. Brush

•The liquids flash point

must exceed 70°C.

If not, it may cause a fire!

•

Do not place the cleaner in wet

or humid rooms.

This may cause flash over!

9

10

MAINTENANCE

•A bad cleaning result may be caused by:

•The liquid needs to be replaced.

•The pump gasket needs to be replaced. .The pump needs to be replaced. The

nozzles need to be cleaned

•A leakage is most likely caused by a damaged pump gasket.

How to change the liquid

1. Unplug the machine from the power supply!

2. Remove the drainage plug located underneath the cleaner and collect the old liquid

in a bucket or similar.

3. Pick up and clean the unloading plate, sedimentation plate and the net strainer.

4. Put them back in the same place, fill the tank with 30 litres of liquid, low aromatic

degreaser with flash point above 70° C. The level of the liquid must not exceed the

inner unloading plate.

How to change the pump gasket

1. Unplug the machine from the power supply!

2. Empty the liquid, see: 'How to change the liquid' above.

3. Unscrew the front plate and loosen the hose clip.

4. Loosen the two screws underneath the ground plate and lift up the pump.

5. Loosen the pump-block and unscrew the pump wheel.

6. Change the gasket and put the pump together again.

7. Mount the pump, attach the hose and put the hose-clip back on.

8. Refill the tank see: 'How to change the liquid'.

How to change the pump

1. Unplug the machine from the power supply!

2. Empty the liquid, see: 'How to change the liquid' above.

3. Unscrew the front-plate and loosen the hose clip.

4. Loosen the two screws underneath the ground plate and lift up the pump.

5. Mount the new pump, attach the hose and put the hose-clip back on.

6. Refill the tank see: 'How to change the liquid'.

How to change the power cord

Work on electrical equipment must be performed by skilled personnel only.

Cleaning nozzles

1. Unscrew the nozzles and clean them.

2. Return them.

Spare parts and accessories can be ordered from your supplier.

10

SPARE PARTS

38-100-0001 Brush

38-110-0001 Pump

38-102-0001 Gasket

38-103-0001 Net strainer

38-104-0001 Nozzle

38-105-0001 Spray gun with hose

38-107-0001 Main switch

ACCESSORIES

36-186-9001 Wash basket 420x270x190 mm

36-188-9001 Wash basket 250x120x90 mm

36-191-0001 Castor kit

36-193-0001 Ventilation hose

TECHNICAL SPECIFICATION

Number of nozzles 3

Spray gun with brush 1

Pump capacity/min 28 liter

Tank volume 30 liter

Max weight of parts to be cleaned 100 kg

Cleaning area, WxDxH 900x410x310 mm

Cleaning board, BxD 930x230 mm

Outside dimension, WxDxH (Without castors) 970x700x1130 mm

Wash boards height 830 mm

Net strainer 1

Voltage supply 230V/50Hz 1fas

Pump effect 85W

Weight 72 kg

Degreaser Low Aromatic degreaser with a,

Flash point over 70°C.

11

11

12

MASTERCLEAN (Part. no. 36-182-2101)

FUNCTION

MASTERCLEAN has two cleaning systems, which can used separately or integrated.

The parts can be cleaned either in a closed area, where the liquid is automatically

sprayed on the part by six nozzles or placed on a wash bench and cleaned manually

with a spray-gun.

The liquid is recycled automatically and cleaned using sedimentation. Ventilation hose

and castors are available as accessories.

MASTERCLEAN has:

•A well designed ventilation system. The cleaner is easy to connect to existing

ventilation system.

•A spray gun that is easy to grip and manoeuvre.

•The electrical system is totally insulated from the liquid.

•Closed off workspace preventing the liquid from leaking.

INSTALLATION

Assembly instructions

1. Make sure that the sedimentation box is located inside the liquid tank.

2. Put the unloading plate and the outflow plate on top of the sedimentation box.

3. Mount the connection of the ventilation system on to the protective hood using the

enclosed screws.

4. Fill the tank with 50 litres of liquid, low aromatic degreaser with flash point above

70°c.The liquid must not exceed the inner unloading plate.

5. Connect the cleaner to a 230V/50Hz earthen socket. The input plug should be easy

to reach, when the cleaner is in use.

•Do not mix the liquid with for example gasoline, thinner, acetone or the like.

•Do not place the cleaner in rooms where volatile solvents or inflammable gases are

stored or used. This may cause an explosion!

The flash point of the liquid must exceed 70°C.

If not, it may cause fire!

12

13

CLEANING INSTRUCTIONS

Automatic wash

1. Open the cover of the protective hood and place the parts on the unloading plate.

2. Close the cover.

3. If you wish to have the liquid sprayed only from above the part, turn the switch (6) to

position 1.

4. If you wish to have the liquid sprayed from both above and underneath the part, turn

the switch (6) to position 2.

5. Set the timer (7) for the desired cleaning time. 6. When the cleaning is finished open

the cover.

Manual cleaning

1. Put the parts, which need to be cleaned, on the wash table.

2. Turn the switch (5) to position 1.

3. Clean manually using the spray-gun.

4. Turn the switch to position o.

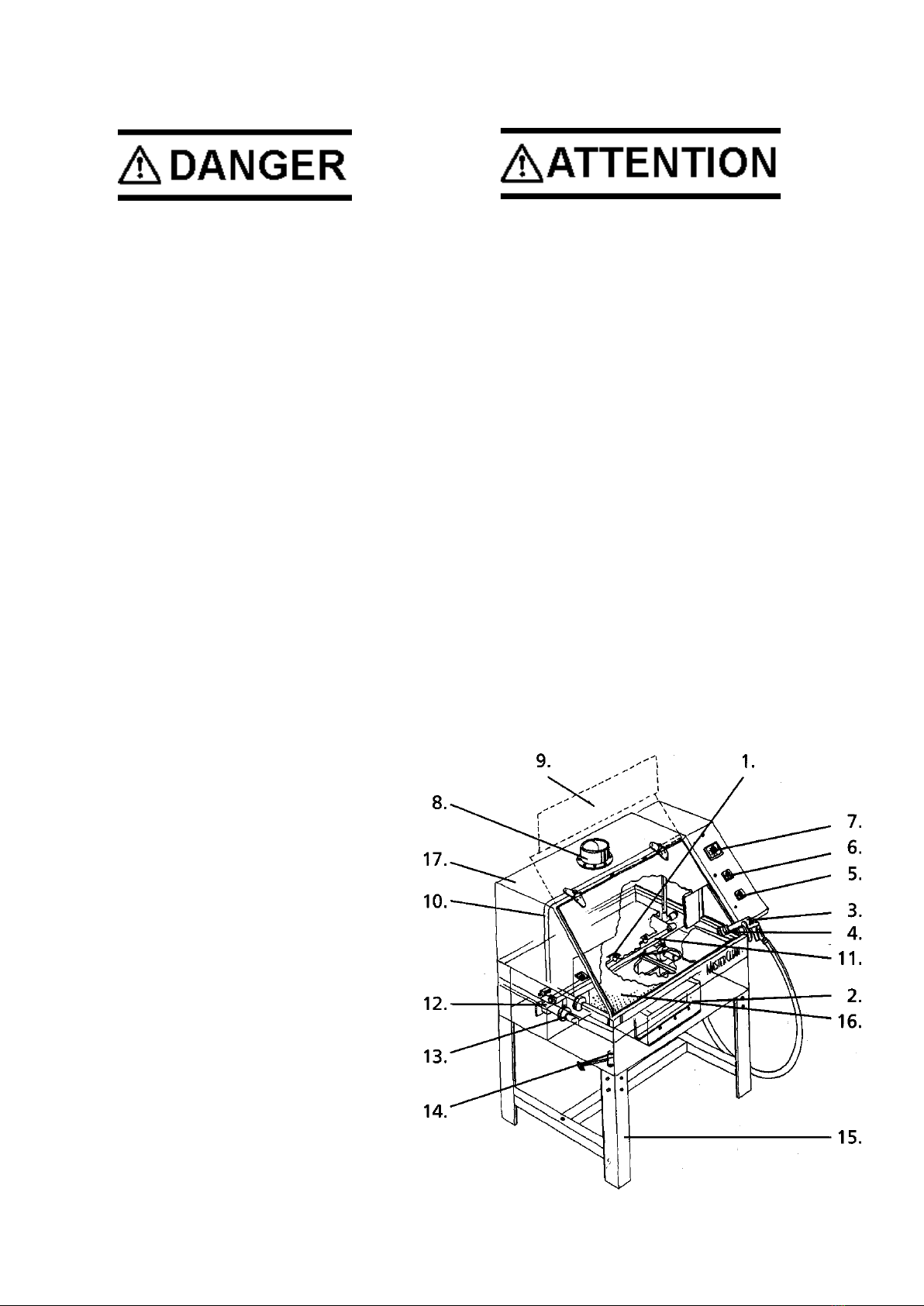

1. Nozzle

2. Sedimentation box

3. Spray gun with hose

4. Brush

5. Switch manual wash

6. Switch automatic clean

7. Timer

8. Connection for ventilation hose

9. Cover

10. Wash pipe, upper

11. Wash pipe, lower

12. Pump, 3

13. Net strainer 3

14. Valve

15. Leg

16. Wash board for hand wash

17. Protective hood

•Do not place the cleaner in

wet or humid rooms.

This may cause flash over.

•

Improper supplements such as

thinner or trichloroethylene may

cause damage to the pump and

hoses.

13

CLEANING INSTRUCTIONS

Automatic wash

1. Open the cover of the protective hood and place the parts on the unloading plate.

2. Close the cover.

3. If you wish to have the liquid sprayed only from above the part, turn the switch (6) to

position 1.

4. If you wish to have the liquid sprayed from both above and underneath the part, turn

the switch (6) to position 2.

5. Set the timer (7) for the desired cleaning time. 6. When the cleaning is finished open

the cover.

Manual cleaning

1. Put the parts, which need to be cleaned, on the wash table.

2. Turn the switch (5) to position 1.

3. Clean manually using the spray-gun.

4. Turn the switch to position o.

1. Nozzle

2. Sedimentation box

3. Spray gun with hose

4. Brush

5. Switch manual wash

6. Switch automatic clean

7. Timer

8. Connection for ventilation hose

9. Cover

10. Wash pipe, upper

11. Wash pipe, lower

12. Pump, 3

13. Net strainer 3

14. Valve

15. Leg

16. Wash board for hand wash

17. Protective hood

•Do not place the cleaner in

wet or humid rooms.

This may cause flash over.

•

Improper supplements such as

thinner or trichloroethylene may

cause damage to the pump and

hoses.

13

Manual cleaning

1. Put the parts, which need to be cleaned, on the wash table.

2. Set the timer (7) for the desired time.

3. Turn the switch (5) to position 1.

4. Clean manually using the spray-gun.

5. Turn the switch to position 0.

14

MAINTENANCE

A bad cleaning result may be caused by:

•The liquid needs to be replaced.

•The pump gasket needs to be replaced.

•The pump needs to be replaced.

•The nozzles need to be cleaned

A leakage is most likely caused by a damaged pump gasket.

How to change the liquid

1. Unplug the machine from the power supply!

2. Open the valve, that is located underneath the cleaner and collect the old liquid.

3. Pick up and dean the unloading plate, the wash bench, the sedimentation plate and

the net strainer.

4. Put them back in the same place, fill the tank with 50 litres of liquid, low aromatic

degreaser with flash-point above 70° C.

The level of the liquid must not exceed the inner unloading plate.

How to change the pump gasket

1. Unplug the machine from the power supply!

2. Empty the liquid, see: 'How to change the liquid' above.

3. Unscrew the front-plate and loosen the hose clip.

4. Loosen the two screws underneath the ground plate and lift up the pump.

5. Loosen the pump-block and unscrew the pump wheel.

6. Change the gasket and put the pump together again.

7. Mount the pump, attach the hose and put the hose-clip back on. 8. Refill the tank

see: 'How to change the liquid'.

Change of pump

1. Unplug the machine from the power supply!

2. Empty the liquid, see: 'How to change the liquid' above. 3. Unscrew the front-plate

and loosen the hose clip.

4. Loosen the two screws underneath the ground plate and lift up the pump.

5. Mount the new pump, attach the hose and put the hose-clip back on.

6. Refill the tank see: 'How to change the liquid'.

How to change the power cord

Work on electrical equipment must be performed by skilled personnel only.

Cleaning nozzles

1. Unscrew the nozzles and dean them.

2. Return them.

Spare parts and accessories may be ordered from your supplier.

14

SPARE PARTS

38-100-0001 Brush

38-110-0001 Pump

38-102-0001 Pump gasket

38-103-0001 Net strainer

38-104-0001 Nozzle

38-106-0001 Spray gun with hose

38-107-0001 Switch manual wash

38-108-0001 Switch automatic wash

36-183-0001 Timer

ACCESSORIES

36-186-9001 Wash basket 420x270x190 mm

36-188-9001 Wash basket 250x120x90 mm

36-193-6001 Ventilation hose

TECHNICAL SPECIFICATION

No. of nozzles 6

Spray gun with brush 1

Pumps 3

Pump capacity/min 28 liter

Tank volume 50 liter

Max weight of parts to be cleaned 100 kg

Cleaning area, WxDxH 770x400x370 mm

Wash board, BxD 840x200 mm

Outside measurements, WxDxH 1010x710x1300 mm

Wash boards height 870mm

Net strainers 3

Voltage 230VI 50Hz 1fas.

Pump effect 255W

Weight 96 kg

Cleaning fluid Low aromatic degreaser with,

Flash point over 70°C.

15

15

This manual suits for next models

5

Table of contents