2

Safety precautions

Make sure to follow the precautions described below to avoid injury or unnecessary property loss to anybody.

The safety precautions are classied according to the degree of harm or damage caused by misuse.

Examples of symbols:

This symbol means

“reminding”.

This symbol means

“forbidden”.

This symbol means necessary

“instructions”.

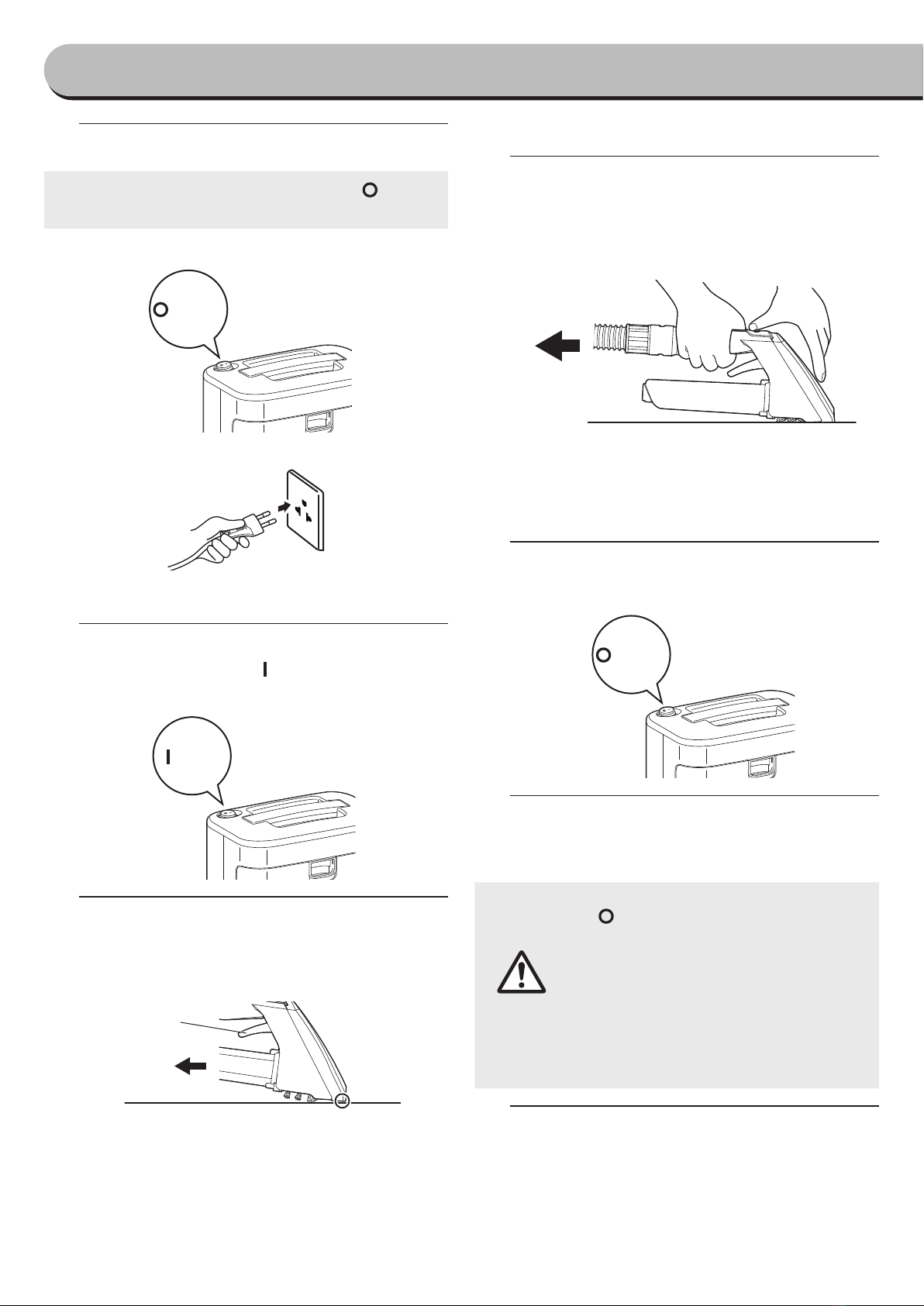

●In case of any abnormality or machine

failure, stop using the machine

immediately, turn o the power switch,

and unplug the power plug from the

power socket

Failure could cause smoke, fire, or electric

shocks

[Example of abnormalities]

• Abnormal sound or smell

➡Please stop using the product and contact the

store where the product was purchased from

or the Iris Call center

Warning The symbol means matters which may lead to death

or serious injury during faulty operation.

Prohibited

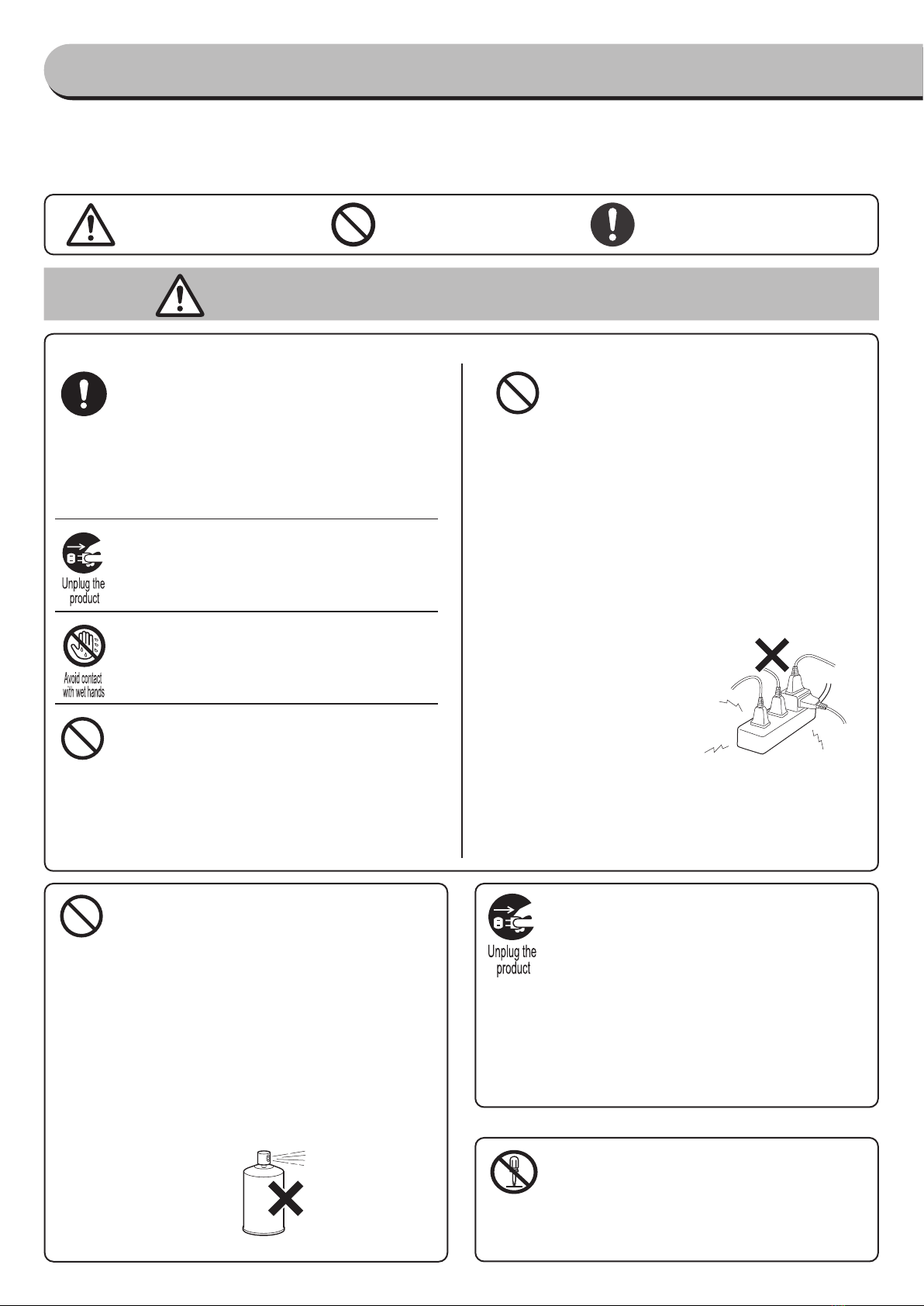

●Do not spray liquids onto this product,

such as insecticides, hair care products,

or lubricating oil, etc

●Do not use the machine to vacuum

flammable or combustible substances

(such as kerosene, gasoline, thinner,

copy machine toner, etc.)

●Do not use the machine to vacuum oil,

smoke or steam

●Do not use the machine to vacuum dry

dust

●Do not use the machine near combustible

substances, lit cigarettes or incense

sticks

Failure could cause a re.

●Do not disassemble, repair, or modify the

machine

Failure could cause a fire, electric shocks or

injury. For repair, please contact the store where

the product was purchased from or contact the

call center to arrange for repair.

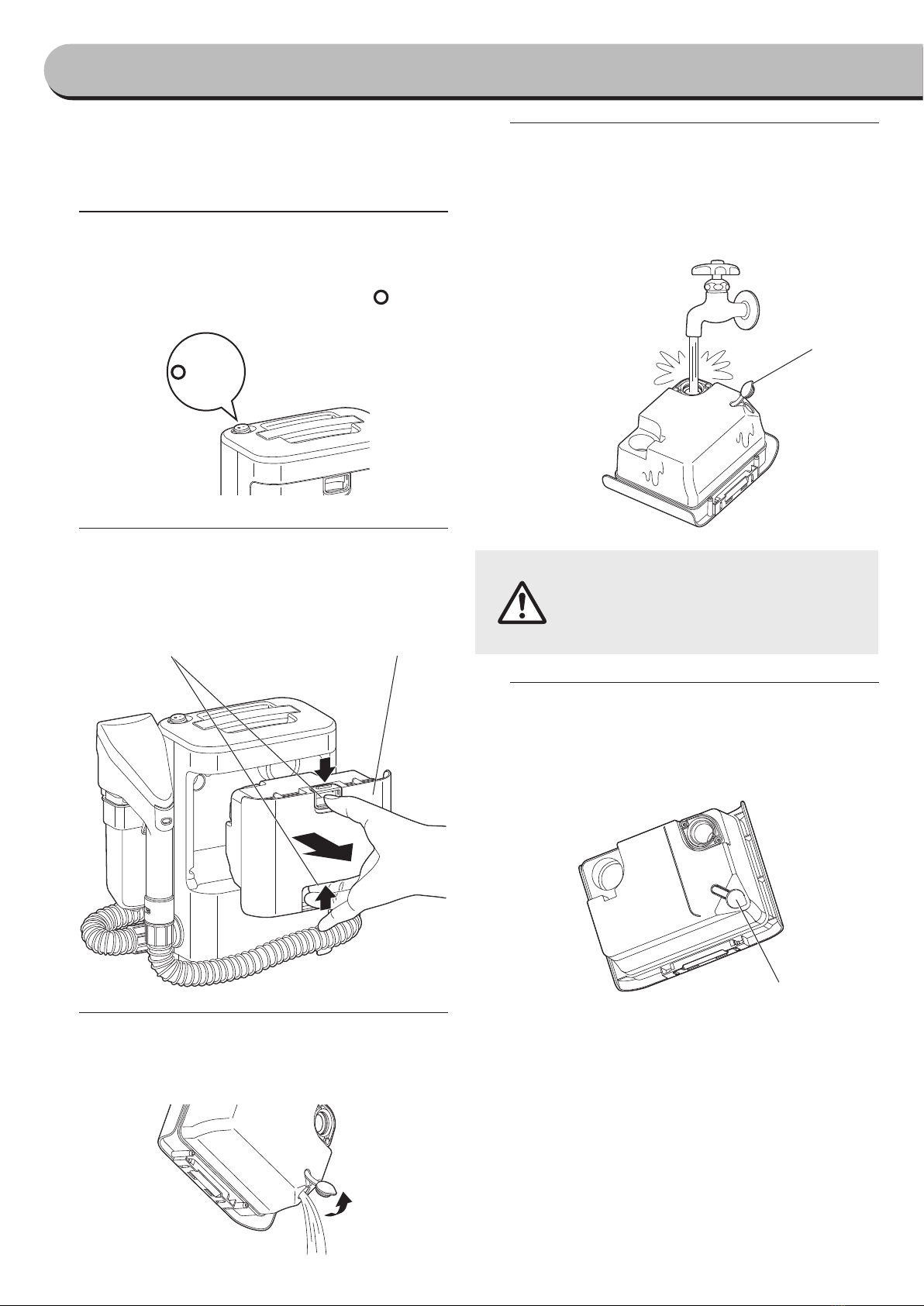

Correctly use the power plug and power cord

Be sure to

●Please periodically clean the dust from

the power plug

The accumulation of dust could cause fire or

electric shocks due to insulation faults.

●Insert the power plug into the socket

thoroughly

Otherwise it could cause re or electric shocks

due to short circuits.

●Be sure to unplug the power plug from

the socket before repairing, checking or

moving

Failure could cause electric shocks or injury.

●Do not plug or unplug the power plug

with wet hands

Failure could cause electric shocks, burn, or

injury.

Prohibited

●Do not let infants lick the plug

Doing so could cause an injury or electric

shocks.

●Do not power on the product when the

power cords are bundled

Doing so could cause empyrosis or re due to

overheating. Be sure to extend the power cord

for use.

●Do not damage the power cord

●Do not pull the power cord while moving

and storing

Do not damage or press the power cord,

forcibly bend or stretch the power cord, twist,

place heavy objects on or modify the power

cord.

Doing so could cause fire or electric shocks

due to the damaged power cord.

●Do not use a damaged power cord or

power plug, or a loose socket

Doing so could cause a re or electric shocks

due to a short-circuit. If the power cord is

damaged, please contact the call center to

arrange for repair.

●Do not use an

incorrectly rated

electrical outlet

socket or

extension cord

Failure could cause

a re.

●Do not use an AC power source other

than 220V~

Doing so could cause a re or electric shocks.

Prohibited