9

www.greenerblast.com

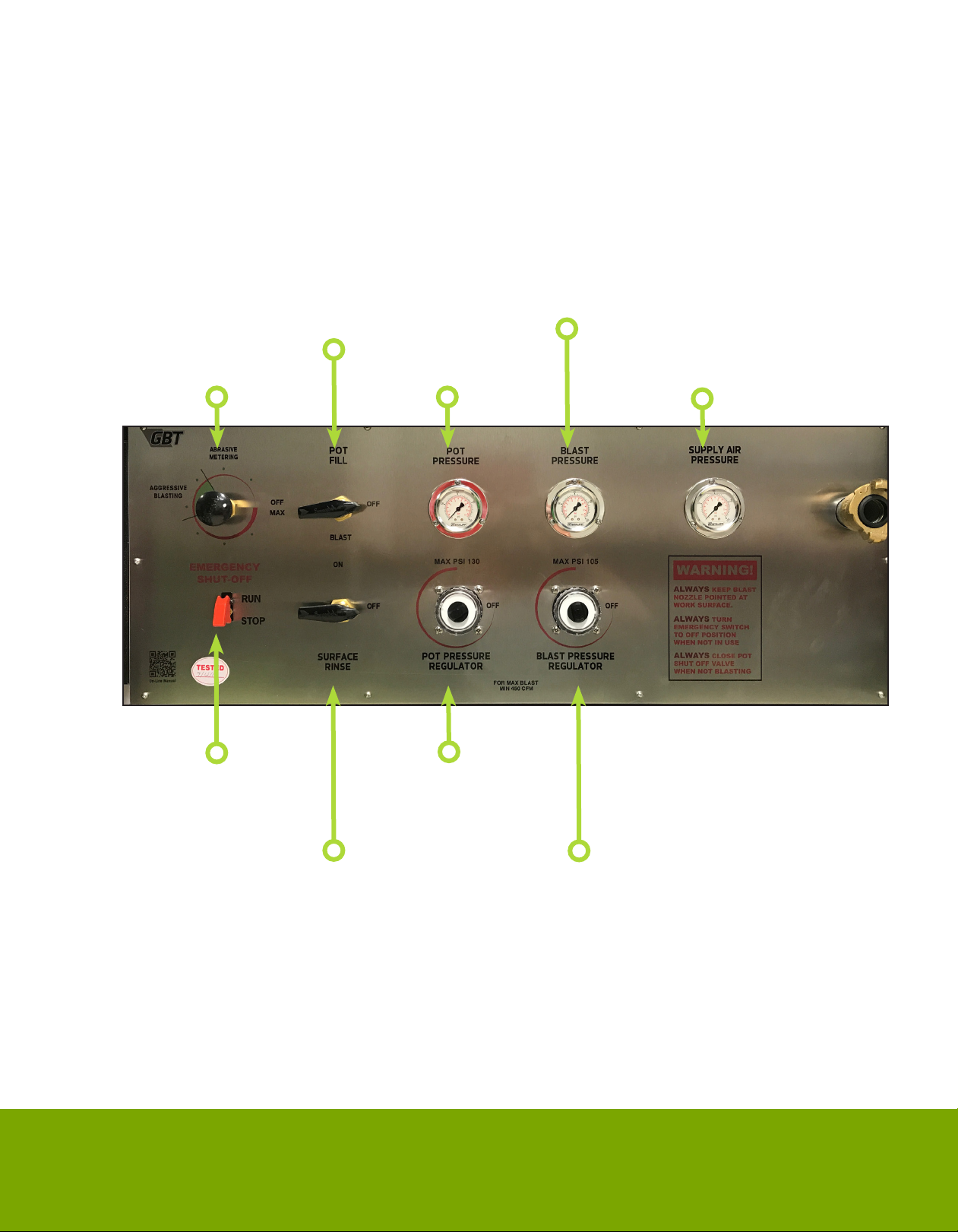

Setting Pot Pressure

Pot pressure must be set 25-30 psi higher (Max Pressure:140 PSI) than target blast pressure in

neutral position (Differential can vary based on the abrasive being used).

Example: Target blast pressure = 80 psi, pot pressure should be set approximately 110psi.

1. When the vessel is purged and pressurized, slowly increase pot pressure (clockwise) until desired

pressure is achieved, while you are not blasting.The selector switch is still in “pot fill” during this

step.

Helpful Hint: Inside the control panel an in-line relief valve has been installed. If during this step the

maximum pressure (150PSI) is exceeded this valve will let go (making a loud humming sound). In

this case the pot pressure must be turned down until the humming stops. At this point pot pressure

can now be dialed back up.

If while setting the pot pressure, you happen to exceed the desired setting, simply back off on the

regulator slightly and crack the Air Purge Valve for a second to relieve the excess pressure and

repeat the step (Air Purge Valve is located on the Blast Pot).

Setting Blast Pressure

1. Selector switch is still in “pot fill” for this step. Have the operator activate the dead man control

and dial the blast pressure in to the target setting. Remember, this is 25-30 psi lower than where

you set the pot pressure to in the previous step. While blasting, blast and pot pressures should be

about equal.

Offshore Model (serial number GBTI-OS) and units with serial number G20074 and above:

Blast pressure can be adjusted in neutral state (Deadman control not activated).

Important Note (Compressors <375cfm): Compressed air volume is critical for the operation of this

machine. With compressors of 375cfm and less, this machine will max out compressors supply. If

so, while setting the blast pressure, watch the inlet supply pressure. If that begins to rapidly drop, you

have exceeded the capability of your compressed air supply. What does this mean? You will need

to get a larger compressor, pick a lower blast pressure, or reduce the blast nozzle size to reduce the

amount of compressed air being consumed (see attached nozzle/air consumption guide).

Pressures cannot be adjusted while machine is active. If you choose to reduce the target blast

pressure, you must start over and reset the pot pressure procedure. Trying to increase or decrease

the pot pressure settings while you are running the machine will result in inefficient, or no media

delivery. Initial blast/pot pressure setup prior to blasting is critical to the operation of the system.