gc MICROGUARD TEREX RCI 510/400 Manual

GREER COMPANY

Crane Systems

GREER COMPANY 1918 East Glenwood Place, Santa Ana, CA 92705 TEL: (714) 259-9702 FAX: (714) 259-7626

MicroGuard® RCI 510/400 CALIBRATION MANUAL PN W450189A 09/09/02

1 of 65

MICROGUARD

TEREX RCI 510/400 SYSTEM

TELESCOPIC BOOM CRANE

CALIBRATION PROCEDURE

ORs Full 9.7Klb Ctwt

ERECTED 60' TELEJIB 17 AUXHD ON

PICK FROM MAIN BOOM FRONT WINCH

TEST

MAX

SET

360

o

6

23,500

i2,300

44.8

62.7

26.4

o

Rated Capacity

Actual Load

Length

Main Boom

Angle

Main Boom

Load Radius

Parts

of

Line

Display Screen

GREER COMPANY

Crane Systems

GREER COMPANY 1918 East Glenwood Place, Santa Ana, CA 92705 TEL: (714) 259-9702 FAX: (714) 259-7626

MicroGuard® RCI 500 CALIBRATION PROCEDURE PN W450189A 09/09/02

2 of 65

MICROGUARDTEREX RCI 510/400 SYSTEM

TELESCOPIC BOOM CRANE

CONTENTS

PRE-CALIBRATION REQUIREMENTS ..................................................................................................... 4

OVERVIEW.............................................................................................................................................. 4-5

THE CAL SWITCH...................................................................................................................................... 5

ENTERING THE CALIBRATION MODE .................................................................................................... 6

ENTERING THE CALIBRATION SECURITY CODE ......................................................................... 6

USING THE DISPLAY KEYS IN COMMAND ROUTINES ......................................................................... 7

COMMAND 00 RUN ................................................................................................................................... 8

COMMAND 01 PERSONALITY................................................................................................................ 9

COMMAND 01/2 INITIALIZE .................................................................................................................... 10

COMMAND 01/0 SAVE............................................................................................................................. 11

COMMAND 02 TEST/FAULT ..............................................................................................................12-13

NUMBER ENTRY ..................................................................................................................................... 14

COMMAND 03 ZERO ............................................................................................................................... 15

ZERO PRESSURE TRANSDUCERS..........................................................................................16-17

ZERO EXTENSION SENSOR .....................................................................................................18-19

ZERO BOOM ANGLE SENSOR..................................................................................................20-21

COMMAND 04 SPAN ............................................................................................................................... 22

BOOM ANGLE SENSOR.............................................................................................................22-23

EXTENSION SENSOR ..................................................................................................................... 24

COMMAND 05 SWING............................................................................................................................. 25

SCALE .............................................................................................................................................. 26

ZERO ................................................................................................................................................ 27

DIRECTION ...................................................................................................................................... 28

CONFIGURATION SELECTION .........................................................................................................29-33

GREER COMPANY

Crane Systems

GREER COMPANY 1918 East Glenwood Place, Santa Ana, CA 92705 TEL: (714) 259-9702 FAX: (714) 259-7626

MicroGuard® RCI 510/400 CALIBRATION MANUAL PN W450189A 09/09/02

3 of 65

COMMAND 06 PRESSURE ................................................................................................................34-36

COMMAND 07 RADIUS/MOMENT – MAIN BOOM ............................................................................37-41

RADIUS MOMENT – MAIN BOOM + MANUAL .......................................................................... 42-45

COMMAND 08 BOOM DEFLECTION CORRECTION............................................................................. 46

COMMAND 09 ANNULAR GAIN .............................................................................................................. 47

COMMAND 12 WINCHES ........................................................................................................................ 48

COMMAND 13 ATTACHMENTS .............................................................................................................. 48

COMMAND 14 BOOM HEAD .............................................................................................................. 49-50

COMMAND 15 ALARM LIMITS ........................................................................................................... 51-53

COMMAND 16 ROPE DATA ............................................................................................................... 54-56

COMMAND 17 AMPLIFIER GAIN ............................................................................................................ 57

COMMAND 01 BACKUP .......................................................................................................................... 57

SWITCH OFF POWER TO THE SYSTEM............................................................................................... 58

COMMAND 01/4 RESTORE..................................................................................................................... 58

COMMAND 19 DIGITAL INPUTS............................................................................................................. 59

GLOSSARY ......................................................................................................................................... 60-64

GREER COMPANY

Crane Systems

GREER COMPANY 1918 East Glenwood Place, Santa Ana, CA 92705 TEL: (714) 259-9702 FAX: (714) 259-7626

MicroGuard® RCI 510/400 CALIBRATION MANUAL PN W450189A 09/09/02

4 of 65

MICROGUARDTEREX RCI 510/400 SYSTEM

TELESCOPIC BOOM CRANE

PRE-CALIBRATION REQUIREMENTS

Following satisfactory installation of the complete RCI 510/400 System:

♦ Ensure that the system is wired in accordance with the appropriate wiring diagram,

which is available upon request from Greer.

♦ Ensure that the crane is on firm and level ground, that the outrigger beams are fully

extended, and that the jacks are correctly extended to level the carrier.

♦ Ensure that throughout the procedure any structural or stability limits are not exceeded.

♦ Ensure that any attachments (aux. head, fly, jib, etc.) that can be optionally stowed or

erected on the boom during normal operation are removed prior to calibration of the

main boom.

♦ Ensure that the computer is fitted with the program and duty chips specified in the

installation manual.

Using the RCI 510/400 System display, proceed with the calibration commands, as directed in

this manual.

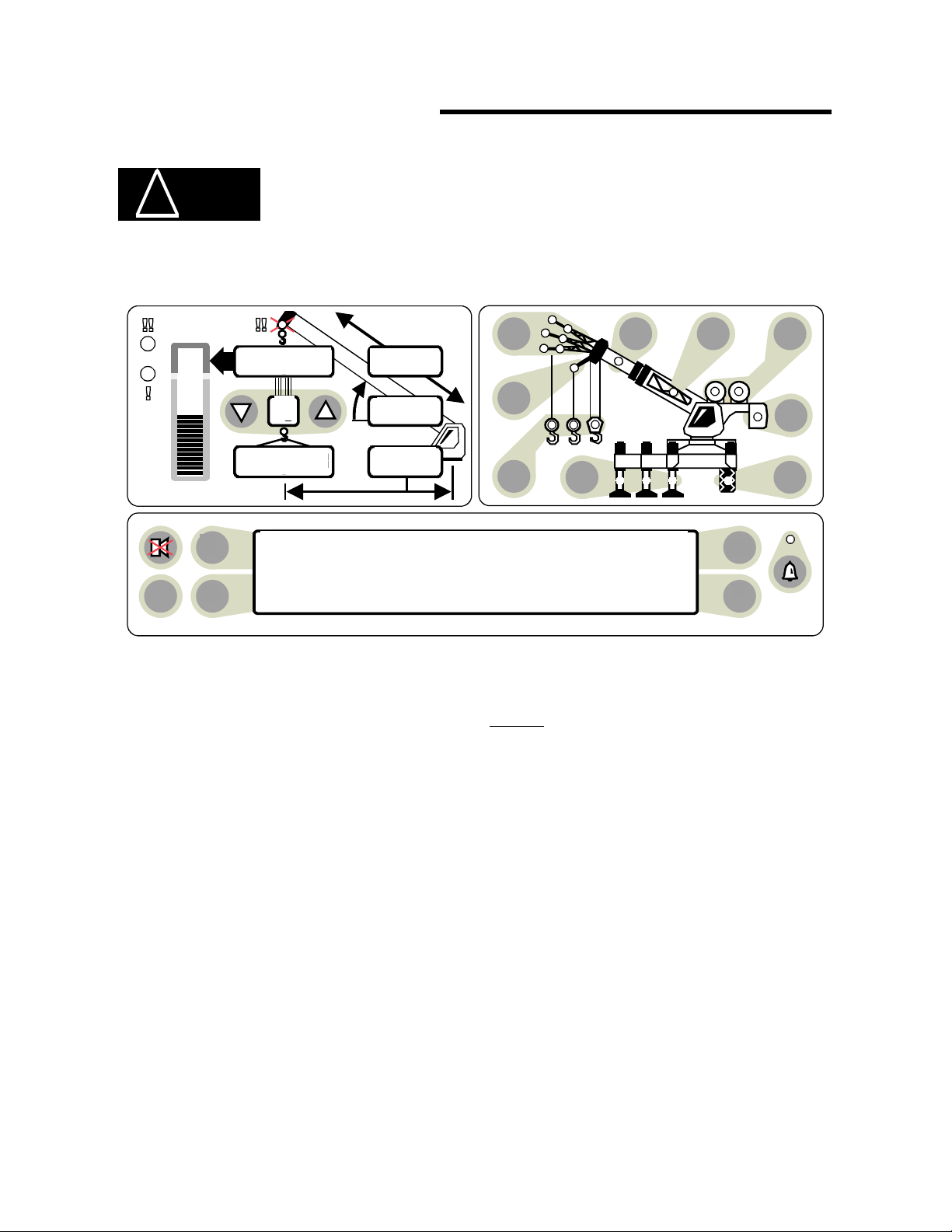

OVERVIEW

When accurately calibrated, this System provides the operator with a continuous display of the

following:

♦ Rated Load

♦ Actual Load

♦ Bar Graph showing Percentage of Rated Load

♦ Radius of the Load

♦ Boom Angle

♦ Main Boom Length

♦ Working Area

♦ Crane Configuration

The RCI 510/400 Display shown on the cover of this manual identifies where this data will

appear.

Messages on the display screen provide the operator with visual warnings of conditions that

occur during operation of the system.

THIS MANUAL PROVIDES STEP-BY-STEP DIRECTIONS FOR EACH COMMAND USED IN THE

CALIBRATION OF THE RCI 510/400 SYSTEMS.

GREER COMPANY

Crane Systems

GREER COMPANY 1918 East Glenwood Place, Santa Ana, CA 92705 TEL: (714) 259-9702 FAX: (714) 259-7626

MicroGuard® RCI 510/400 CALIBRATION MANUAL PN W450189A 09/09/02

5 of 65

OVERVIEW continued

WARNI NG

!

When the system is in the Calibration Mode,

the audible alarm and function kick-outs are

inhibited and there is no protection from two-

block or overload. All crane operations are at

the sole discretion of the operator.

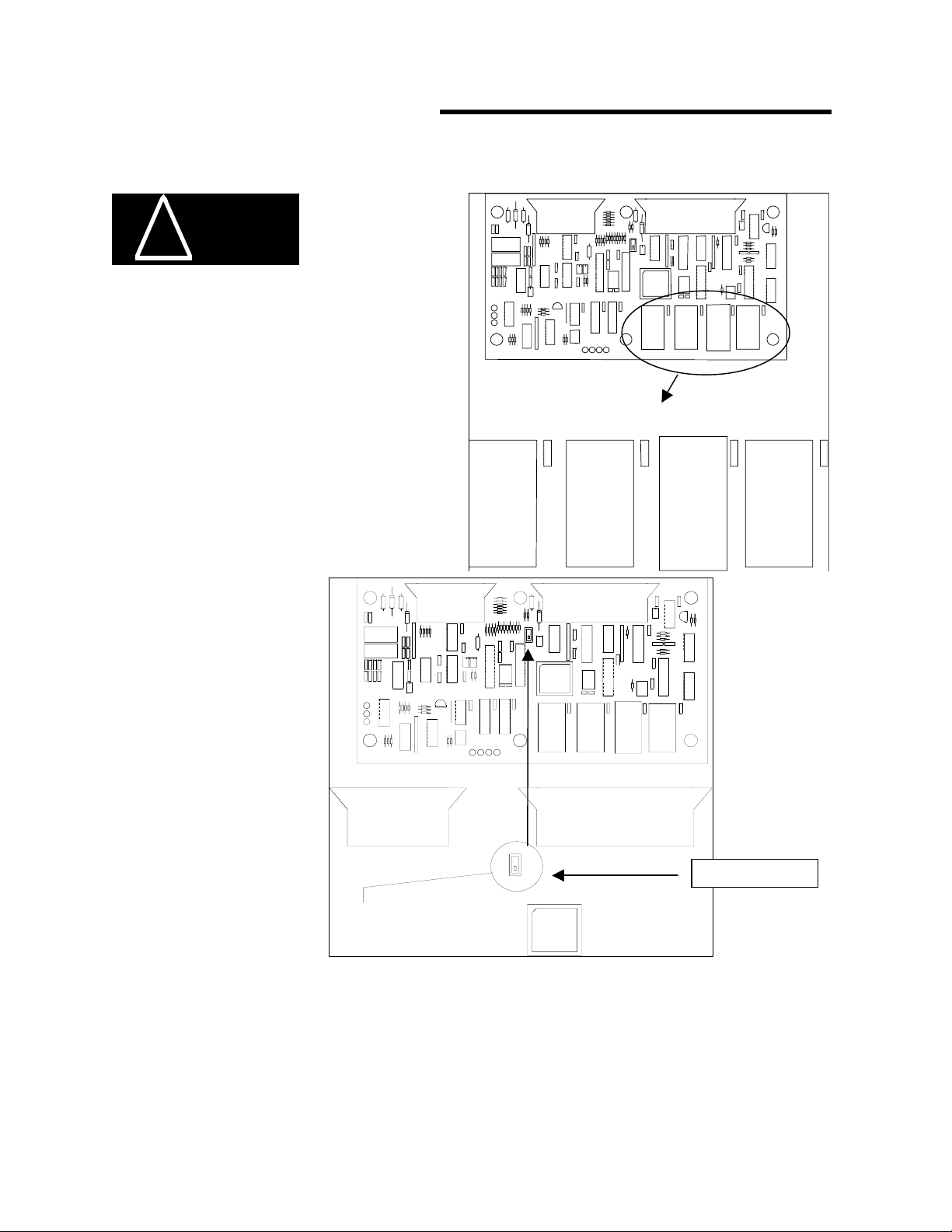

THE CAL SWITCH

CAL SWITCH

PROGRAM

CHIP

DUTY

CHIP

PERSONALITY

CHIP

IC2 IC3 IC7

CAL POSITION

The CAL switch in the

computer must be set to the

“CAL” POSITION when

performing

calibration procedures.

To access the CAL switch,

REMOVE the cover from

the computer assembly.

Locate the switch near the

center of the computer

board just between and

below the ribbon cable

connectors.

IMPORTANT: IF THE CALIBRATION SWITCH IS NOT ON (PULLED DOWN OR FORWARD) THE

DISPLAY SHOULD READ: ‘CAL DISABLED’ AND THE ROUTINES CANNOT BE ACCESSED.

GREER COMPANY

Crane Systems

GREER COMPANY 1918 East Glenwood Place, Santa Ana, CA 92705 TEL: (714) 259-9702 FAX: (714) 259-7626

MicroGuard® RCI 510/400 CALIBRATION MANUAL PN W450189A 09/09/02

6 of 65

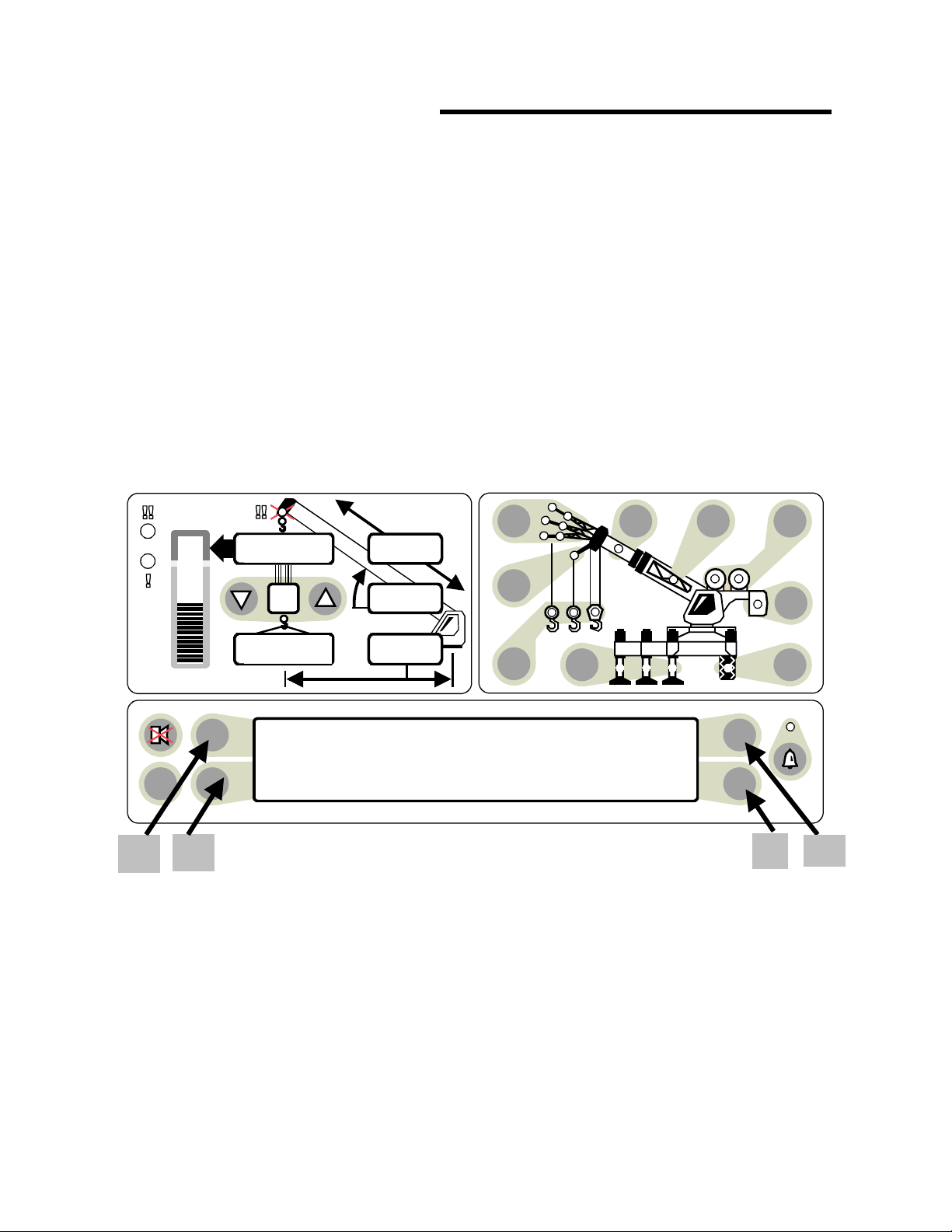

ENTERING THE CALIBRATION MODE

To perform any calibration routine, the System must operate in the “Calibration Mode.” To

access the Calibration Mode, press the Test and Set keys simultaneously for approximately

two seconds.

ENTERING THE CALIBRATION SECURITY CODE

Entry of the Calibration Security Code will be required often throughout these procedures.

Press keys 1 2 3 4 below in this sequence to enter the Calibration Security

Code. If the wrong sequence is used or if the entry is not completed within 5 seconds, the entry

will be aborted and must be entered again. This code will be used often throughout these

routines. It is helpful to memorize these key positions.

ORs Full 9.7Klb Ctwt

ERECTED 60' TELEJIB 17 AUXHD ON

PICK FROM MAIN BOOM FRONT WINCH

TEST

MAX

SET

360

o

6

23,500

i2,300

44.8

62.7

26.4

o

3 2 4

1 THE RCI 510/400 DISPLAY

GREER COMPANY

Crane Systems

GREER COMPANY 1918 East Glenwood Place, Santa Ana, CA 92705 TEL: (714) 259-9702 FAX: (714) 259-7626

MicroGuard® RCI 510/400 CALIBRATION MANUAL PN W450189A 09/09/02

7 of 65

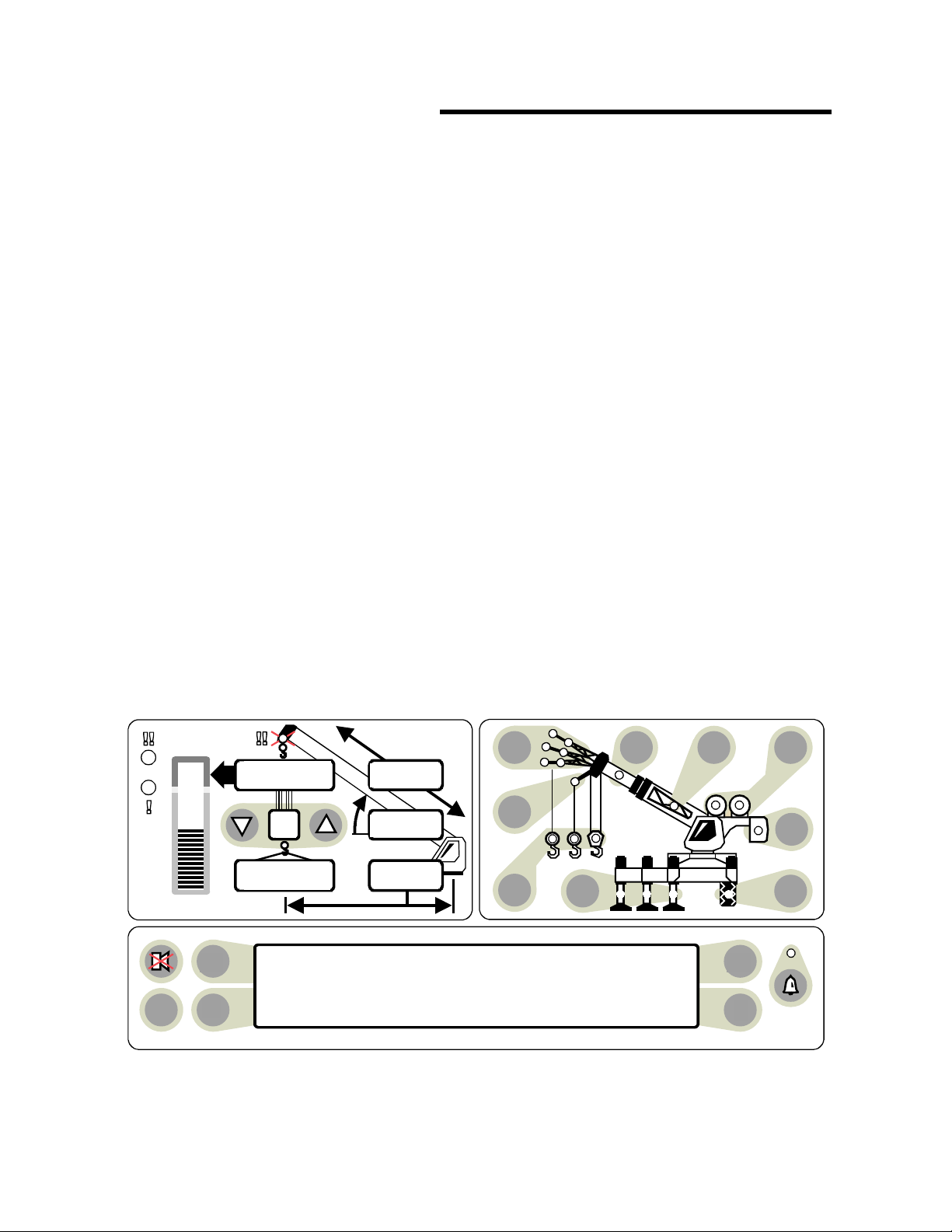

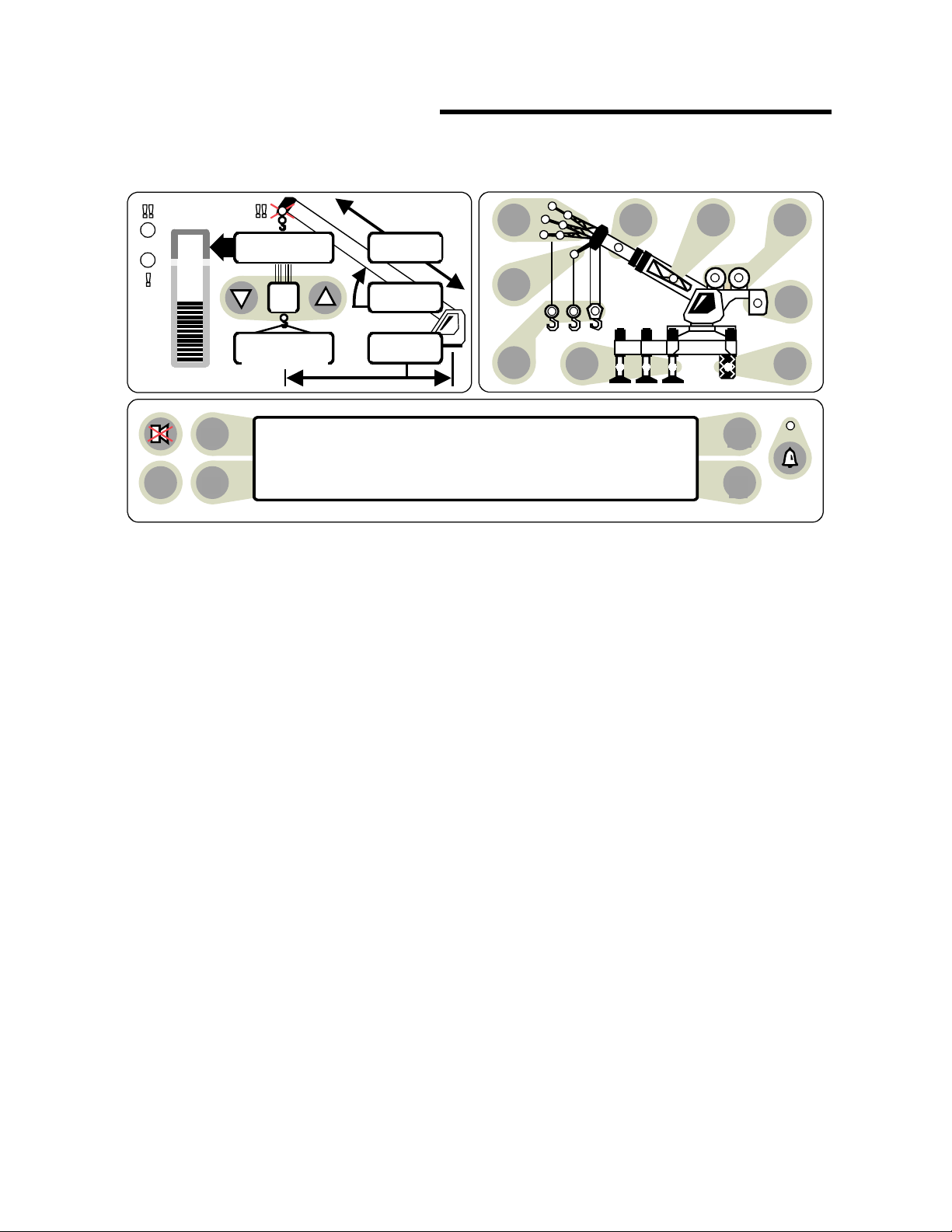

USING THE DISPLAY KEYS IN COMMAND ROUTINES

During the calibration routines, the A B C D display keys are used to enter data.

When entering the Calibration Security Code, use the 1234 format shown on page 6.

PRESS Ato scroll forward to a command or option, to enter a current selection into

the system, etc.

PRESS Bto scroll backward to an option or command, etc.

PRESS Cto start a command, to confirm an entry, to calibrate, or to respond to

screen questions, etc.

PRESS Dto exit a routine or abort a calibration.

Follow directions in each command carefully. To enter numbers other than the security code,

use the number entry procedure.

If the display reads: “system out of service,” simultaneously press the “Test“ and “Hold“keys

for a few seconds. The display will request entry of the calibration security code. Following

entry of the correct code, the user will be returned to the calibration mode.

When using the number entry routine, always press Cbefore exiting the routine to enter the

data into the system.

Display scrolling keys (Aand B) can be moved full circle allowing all options listed to be

viewed when moving in either direction.

The term “repeat last entry” is an option not a request. It allows the operator to repeat

entered information if a mistake is made.

ORs Full 9.7Klb Ctwt

ERECTED 60' TELEJIB 17 AUXHD ON

PICK FROM MAIN BOOM FRONT WINCH

TEST

MAX

SET

360

o

6

23,500

i2,300

44.8

62.7

26.4

oC

D

B

A

THE RCI 510/400 DISPLAY

GREER COMPANY

Crane Systems

GREER COMPANY 1918 East Glenwood Place, Santa Ana, CA 92705 TEL: (714) 259-9702 FAX: (714) 259-7626

MicroGuard® RCI 510/400 CALIBRATION MANUAL PN W450189A 09/09/02

8 of 65

COMMAND 00 RUN

After accessing the Calibration Mode and entering the Calibration Security

Code (see page 6),the system will be in the “Monitor Mode” at Command 00 Run.

Do not execute this Command when preparing to calibrate the system; to do so will

cause the system to carry out a “system test” followed by a return to the working screen.

Press “A” (menu up) or “B” (menu down) to view all commands. See the illustration on page 7.

Stop at Command 01 Personality.

GREER COMPANY

Crane Systems

GREER COMPANY 1918 East Glenwood Place, Santa Ana, CA 92705 TEL: (714) 259-9702 FAX: (714) 259-7626

MicroGuard® RCI 510/400 CALIBRATION MANUAL PN W450189A 09/09/02

9 of 65

WARNI NG

!

WARNI NG

!

COMMAND 01 PERSONALITY

Command 01 Personality is used to manipulate the crane calibration data.

The system stores two sets of data in EEPROM IC7.

“A“ Active Personality (IC7) –contains the data actually used by the main program.

“B“ Backup Personality (IC7) –contains a “protected” copy of the calibration data.

COMMAND 01 FUNCTION

♦DISPLAYS THE STATUS OF THE PERSONALITY SETS.

♦MOVES DATA BETWEEN THE TWO SETS.

♦DELETES DATA FROM THE ACTIVE PERSONALITY.

♦COPIES DATA TO A BACK-UP CHIP.

♦RETRIEVES DATA FROM A BACK-UP CHIP.

When the command is first selected (after copying data), both “A” and “B” sets are checked for

correct Check-Sum. This is indicated on the display screen by “Good” or “Bad.”

Set “A” is also checked against set “B.” Data that is identical is indicated by “Same” or if not the

same, by “Diff.”

Data can be moved using selected sub-commands and the calibration

security code. Data entered may also be aborted before completion of the

routine. Special care must be taken when working with the sub-commands

as some of the sub-commands can cause previously entered data to be

irretrievably lost.

SUB-COMMAND 01/0 SAVE SAVES “A” INTO “B” (“B“DATA IS LOST).

SUB-COMMAND 01/1 XCHG EXCHANGES “A” WITH “B” (DATA IS NOT LOST).

SUB-COMMAND 01/2 INIT INITIALIZES “A” PRIOR TO NEW CALIBRATION (“A“DATA IS

LOST).

SUB-COMMAND 01/3 BACK COPIES THE ACTIVE CALIBRATION TO A BACK-UP CHIP

(DATA IS NOT LOST).

SUB-COMMAND 01/4 RETR RETRIEVES THE CALIBRATION FROM A BACK-UP CHIP

(PREVIOUS “A“DATA IS LOST).

Power to the system should be switched off before inserting or removing

any integrated circuits. Failure to observe this precaution may cause

permanent damage to the system or its components and result in the loss of calibration data.

GREER COMPANY

Crane Systems

GREER COMPANY 1918 East Glenwood Place, Santa Ana, CA 92705 TEL: (714) 259-9702 FAX: (714) 259-7626

MicroGuard® RCI 510/400 CALIBRATION MANUAL PN W450189A 09/09/02

10 of 65

WARNI NG

!

COMMAND 01/2 INITIALIZE

Command 01/2 is used only when calibrating the System for the first

time. The use of this command causes all previously entered “A” side

calibration data to be erased. If the system has been previously calibrated

and data from a previous calibration is to be accessed or changed, proceed directly to the

command to be changed. Do not perform the initialization command below.

COMMAND 01/2 INITIALIZE ROUTINE

This Procedure Completely Erases All Previous Data From “A” Personality.

To cancel this routine, PRESS D, ABORT before completing Step 5.

1) PRESS A TO 01 PERSONALITY.

2) PRESS C TO START THE COMMAND.

3) PRESS A TO 2 INIT PERS A ONLY.

4) PRESS C TO START THE CALIBRATION.

5) PRESS C TO CALIBRATE OR PRESS D TO ABORT THE CALIBRATION.

6) PRESS 1234 (CALIBRATION SECURITY CODE)

AFTER THE MESSAGE, “CALIBRATING” ENDS, THE DISPLAY SHOULD READ:

“AGOOD BGOOD SAME“(See page 6).

7) PRESS D TO EXIT ROUTINE. THE SYSTEM WILL RETURN TO THE MONITOR MODE BUT

WILL REMAIN IN THE CALIBRATION ROUTINE.

2 Init Pers A Only

ORs Full 9.7Klb Ctwt

ERECTED 60' TELEJIB 17 AUXHD ON

PICK FROM MAIN BOOM FRONT WINCH

TEST

MAX

SET

360

o

6

23,500

i2,300

44.8

62.7

26.4

oC

D

B

A 01 Personality

GREER COMPANY

Crane Systems

GREER COMPANY 1918 East Glenwood Place, Santa Ana, CA 92705 TEL: (714) 259-9702 FAX: (714) 259-7626

MicroGuard® RCI 510/400 CALIBRATION MANUAL PN W450189A 09/09/02

11 of 65

COMMAND 01/0 SAVE

• If calibrating the entire system, execute Command 01/0 Save after completing

each calibration routine to ensure that a complete copy of the calibration data is entered in

the backup memory of the system.

• If modifying or correcting an existing calibration, do not save until satisfied with

the results of the calibration.

This Command can be used at any time to ensure that data entered up to the time that

this routine is completed will be saved in the system.

COMMAND 01/0 SAVE ROUTINE

(applicable to all calibration routines in this manual)

1) PRESS ATO 01 PERSONALITY.

2) PRESS CTO START THE COMMAND.

3) PRESS A TO 01/0 SAVE.

4) PRESS CTO START THE CALIBRATION.

5) PRESS CTO CALIBRATE OR PRESS D TO ABORT THE CALIBRATION.

6) PRESS 1234 (SECURITY CODE).

7) AFTER MESSAGE, “CALIBRATING” ENDS, PRESS D TO EXIT THE ROUTINE.

GREER COMPANY

Crane Systems

GREER COMPANY 1918 East Glenwood Place, Santa Ana, CA 92705 TEL: (714) 259-9702 FAX: (714) 259-7626

MicroGuard® RCI 510/400 CALIBRATION MANUAL PN W450189A 09/09/02

12 of 65

COMMAND 02 TEST/FAULT

Command 02 activates a System “Self-Test” to detect and display errors (faults) in the system.

1) PRESS ATO 02 TEST/FAULT.

2) PRESS C TO EXECUTE A SYSTEM SELF-TEST AND TO DISPLAY ERRORS.

3) PRESS D TO EXIT THE ROUTINE.

FAULTS

GROUP “A“ANALOG SENSORS

CODE

AAA

000 NO FAULTS

001 SENSOR 0 PISTON PRESSURE TRANSDUCER

002 SENSOR 1 ROD SIDE PRESSURE TRANSDUCER

004 SENSOR 2 EXTENSION SENSOR

008 SENSOR 3 BOOM ANGLE SENSOR

016 SENSOR 4 S’STRUCTURE ANGLE SENSOR

032 SENSOR 5 SWING POTENTIOMETER "A"

064 SENSOR 6 SWING POTENTIOMETER "B"

GROUP "B" INPUTS AND OUTPUTS

CODE

BB

00 NO FAULTS

01 FAULT 1 DIGITAL INPUT AND OUTPUT

02 FAULT 2 ANALOG INPUT AND OUTPUT

04 FAULT 4 DISPLAY UNIT

GREER COMPANY

Crane Systems

GREER COMPANY 1918 East Glenwood Place, Santa Ana, CA 92705 TEL: (714) 259-9702 FAX: (714) 259-7626

MicroGuard® RCI 510/400 CALIBRATION MANUAL PN W450189A 09/09/02

13 of 65

GROUP “C“MEMORY

CODE

CC

00 NO FAULTS

01 FAULT 1 EXECUTIVE ROM

02 FAULT 2 DUTY ROM

04 FAULT 4 SCRATCHPAD RAM

08 FAULT 8 PERSONALITY ROM

GROUP “D“GENERAL

CODE

DD

00 NO FAULTS

01 FAULT 1 NO DUTY FOUND

02 FAULT 2 CURRENT DUTY BAD

04 FAULT 4 ROPE OR RAM DIMENSION MISSING

08 FAULT 8 FLY NOT CALIBRATED

GREER COMPANY

Crane Systems

GREER COMPANY 1918 East Glenwood Place, Santa Ana, CA 92705 TEL: (714) 259-9702 FAX: (714) 259-7626

MicroGuard® RCI 510/400 CALIBRATION MANUAL PN W450189A 09/09/02

14 of 65

NUMBER ENTRY

The MicroguardRCI 500 does not have number entry keys. When numerical entry of data is

required, the display will change to allow the entry of numbers.

• A strip like the one below will appear with numerals from 0 to 9 followed by the three

symbols shown.

• The upper left corner identifies the Command (in this case, 06 Pressure). The upper

right displays each numeral as entered until the complete number to be calibrated

appears, including decimals and minus sign.

• The keys operate as in the calibration routines (A B C D).

1) When the number entry panal appears, the selectors < > will surround the zero < 0 >

numeral which will be flashing. Use “key B” or “key D” to select a numeral. If key B is

pressed, the cursor will jump to the opposite end of the display panel and the selectors

will surround the minus sign. With each press of key B the cursor will backtrack by one

digit toward the original site 0 (zero). When key D is used, the identical process occurs

in reverse.

2) When not at the starting point (“0“or “-“), pressing key B or key D will cause the

cursor to move one digit at a time toward its original site. Example:if the cursor were

flashing at numeral 5, pressing key B once would cause the cursor to move one digit

toward 0(zero).

3) WHEN ENTERING A MINUS SIGN FOR A NEGATIVE VALUE, ALWAYS DO SO

AFTER ALL NUMERALS HAVE BEEN SELECTED.

4) As each digit is selected, press key A to enter it into the system. The

numeral will then appear in the upper right bracket. Continue entering numerals and

decimal point, as appropriate, until the complete number appears in the upper right box.

A total of five digits may be entered in this way.

5) If an error is made when entering a numeral, immediately select the “less than” symbol

(<) and press key A. The number should be removed from the right upper selection

box. Numbers can be removed this way one digit at a time.

6) When all digits look correct, press key C to calibrate the complete number.

06 Pressure ( 1.0 )

Calibration Load

0 1 2 3 4 5 6 7 8 9 <<·> -

GREER COMPANY

Crane Systems

GREER COMPANY 1918 East Glenwood Place, Santa Ana, CA 92705 TEL: (714) 259-9702 FAX: (714) 259-7626

MicroGuard® RCI 510/400 CALIBRATION MANUAL PN W450189A 09/09/02

15 of 65

COMMAND 03 ZERO

Command 03 Zero permits calibration to zero for most analog sensors, including the four

system sensors shown below. Each sensor is allocated a number corresponding to the input

connection in the system.

♦PISTON SIDE PRESSURE TRANSDUCER INPUT TX. 0

♦ROD SIDE PRESSURE TRANSDUCER INPUT TX. 1

♦BOOM EXTENSION SENSOR ANALOG INPUT 2

♦BOOM ANGLE SENSOR ANALOG INPUT 3

DURING COMMAND 03 ZERO ROUTINES, THE BOOM MUST ALWAYS BE IN A

HORIZONTAL POSITION.

COMMAND 05 IS USED TO CALIBRATE THE SWING SENSOR.

Continue with the Command 03 Zero calibration routines on the following pages.

GREER COMPANY

Crane Systems

GREER COMPANY 1918 East Glenwood Place, Santa Ana, CA 92705 TEL: (714) 259-9702 FAX: (714) 259-7626

MicroGuard® RCI 510/400 CALIBRATION MANUAL PN W450189A 09/09/02

16 of 65

COMMAND 03 ZERO - PRESSURE TRANSDUCERS

♦Lower the boom until its lower end stops (boom hoist cylinder fully retracted). The boom

must be in a horizontal position when performing the zero routines.

♦Stop the hydraulic pump and reconnect electrical power to the system.

♦With the boom hoist cylinder fully retracted, depressurize the hydraulic tank and open the

hydraulic lines to the pressure transducers until no pressure remains in the boom hoist

cylinders.

♦With the pressure transducers open to atmosphere, calibrate the zero of the piston and rod

pressure transducers, as shown on the next page.

IMPORTANT: Ensure that the boom is in a horizontal position when performing

all zero routines.

GREER COMPANY

Crane Systems

GREER COMPANY 1918 East Glenwood Place, Santa Ana, CA 92705 TEL: (714) 259-9702 FAX: (714) 259-7626

MicroGuard® RCI 510/400 CALIBRATION MANUAL PN W450189A 09/09/02

17 of 65

COMMAND 03 ZERO - PRESSURE TRANSDUCERS continued

COMMAND 03 ZERO ROUTINE - PRESSURE TRANSDUCERS

IMPORTANT: ENSURE THAT THE BOOM IS IN A HORIZONTAL POSITION WHEN PERFORMING THIS

ROUTINE.

1) PRESS A TO 03 ZERO SENSOR.

2) PRESS C TO START THE COMMAND.

THE DISPLAY SHOULD READ: ZERO TX. 0 XXXX (ACTUAL input).

3) PRESS C TO START CALIBRATION OF TX. 0. SENSOR.

4) PRESS C TO CALIBRATE OR PRESS D TO ABORT THE CALIBRATION OF TX. 0.

AFTER THE MESSAGE, “CALIBRATING” ENDS,

THE DISPLAY SHOULD READ: ZERO TX. 0 XXXX (ZEROED input).

5) PRESS A TO ZERO TX. 1. 0.

6) PRESS C TO START CALIBRATION OF TX.1 SENSOR.

7) PRESS C TO CALIBRATE OR PRESS D TO ABORT THE CALIBRATION OF TX. 1.

AFTER THE MESSAGE, “CALIBRATING” ENDS,

THE DISPLAY SHOULD READ: ZERO TX.1 XXXX (ZEROED input).

8) PRESS D TO EXIT ROUTINE.

Reconnect all hydraulic lines and reinstall the tank pressure relief valve before resuming crane

operation.

ORs Full 9.7Klb Ctwt

ERECTED 60' TELEJIB 17 AUXHD ON

PICK FROM MAIN BOOM FRONT WINCH

TEST

MAX

SET

360

o

6

23,500

i2,300

44.8

62.7

26.4

oC

D

B

A 03 Zero Sensor

GREER COMPANY

Crane Systems

GREER COMPANY 1918 East Glenwood Place, Santa Ana, CA 92705 TEL: (714) 259-9702 FAX: (714) 259-7626

MicroGuard® RCI 510/400 CALIBRATION MANUAL PN W450189A 09/09/02

18 of 65

COMMAND 03 ZERO - EXTENSION SENSOR

The extension reel, fitted with 130 ft. of shielded 2-wire cable, cannot be shortened to

accommodate varying boom lengths.

IMPORTANT: Ensure that the boom is in a horizontal position when performing this routine.

COMMAND 03 ZERO PRETENSION ROUTINE – EXTENSION SENSOR

1) Fully retract all boom sections.

2) Remove the clamp on the reel cable and allow it to slowly rewind onto the reel until there is

no pretension.

3) Continue to rewind the reel until the distance between the attachment point and the end of

the cable is approximately 12 ft. Due to the clutch on the reel shaft, there will now be no

pre-tension.

4) Pull the cable toward the anchor point, continuing until the end of the cable is 3 ft. Beyond

the anchor point.

5) Secure the cable to the anchor point with at least 4 wraps, ensuring that there is sufficient

cable at the boom head to connect to the anti two-block switch, which is terminated in a

3-pin plug.

6) Manually turn the large gear on the potentiometer fully counterclockwise. Then, advance the

gear clockwise three clicks.

7) Calibrate the zero of the sensor, as shown on the next page.

GREER COMPANY

Crane Systems

GREER COMPANY 1918 East Glenwood Place, Santa Ana, CA 92705 TEL: (714) 259-9702 FAX: (714) 259-7626

MicroGuard® RCI 510/400 CALIBRATION MANUAL PN W450189A 09/09/02

19 of 65

COMMAND 03 ZERO - EXTENSION SENSOR CONTINUED

COMMAND 03 ZERO ROUTINE – EXTENSION SENSOR

IMPORTANT: Ensure that the boom is in a horizontal position when performing this routine.

1) PRESS ATO 03 ZERO SENSOR.

2) PRESS CTO START THE COMMAND.

3) PRESS ATO ZERO NO. 2 XXXX (ACTUAL INPUT).

4) PRESS CTO START CALIBRATION OF THE 03 ZERO SENSOR.

5) PRESS CTO CALIBRATE OR PRESS D TO ABORT THE CALIBRATION OF ZERO NO. 2.

AFTER THE MESSAGE, “CALIBRATING” ENDS,

THE DISPLAY SHOULD READ: ZERO NO. 2 XXXX (ZEROED INPUT).

6) PRESS DTO EXIT THE ROUTINE OR PRESS ATO CHANGE THE SENSOR.

ORs Full 9.7Klb Ctwt

ERECTED 60' TELEJIB 17 AUXHD ON

PICK FROM MAIN BOOM FRONT WINCH

TEST

MAX

SET

360

o

6

23,500

i2,300

44.8

62.7

26.4

oC

D

B

A 03 Zero Sensor

GREER COMPANY

Crane Systems

GREER COMPANY 1918 East Glenwood Place, Santa Ana, CA 92705 TEL: (714) 259-9702 FAX: (714) 259-7626

MicroGuard® RCI 510/400 CALIBRATION MANUAL PN W450189A 09/09/02

20 of 65

COMMAND 03 ZERO - BOOM ANGLE SENSOR

Use great care when calibrating the boom angle sensor. All subsequent calculations are

dependent on the accuracy of this calibration.

Use an inclinometer or measuring device with an accuracy of +/- 0.25 when calibrating the

boom angle sensor. Use of a less accurate device may result in calibration errors.

IMPORTANT: Ensure that the boom is in a horizontal position

when performing this routine.

♦Using an inclinometer, set the boom in a horizontal position.

♦The boom angle sensor is mounted inside the d3l0022 housing.

Mount the extension sensor perpendicular to the boom.

♦Calibrate the zero of the boom angle sensor (page 21).

Table of contents

Popular Construction Equipment manuals by other brands

Hagie

Hagie UpFront 120ft BOOMS Operator's manual

Manitowoc

Manitowoc National Crane NBT40-1 Series Service manual

Carlton

Carlton SP8018 owner's manual

Northern Industrial

Northern Industrial 144207 instruction manual

IMER

IMER MOVER 190D Operating, maintenance, spare parts manual

Parkside

Parkside PFMR 1400 A1 Original operating instructions