Ssab HARDOX 400 User manual

Cutting of HARDOX wear plate

Oxygen fuel cutting of HARDOX wear plate

is as simple as cutting of regular Mild Steel.

When cutting of thicker HARDOX plates special

attention is needed. For thick and hard plates the

risk of developing cut edge cracks increases. By

following the recommendations and guidelines

given below cut edge cracking and component

softening can be prevented.

Cutting methods

HARDOX wear plate can very well be cut

using both cold and thermal cutting methods.

The cold methods are abrasive water jet cut-

ting, shearing, sawing or abrasive grinding,

while thermal methods are oxy-fuel, plasma

and laser cutting.

This leaflet contains general suggestions and calculation models. SSAB Oxelösund AB does hereby expressly exclude any liability whatsoever for

their suitability for individual applications. It is the responsibilty of the user of the manual to adapt the recommendations contained herein to the

requirements of individual applications.

1000

CO2Laser

Plasma

Oxy-fuel

1.5 kW

3.0 kW

4.0 kW

100 A

200 A

600 A

Thickness range for different cutting methods

Plate thickness [mm]

10 1001 1000

Abrasive

water jet

cutting

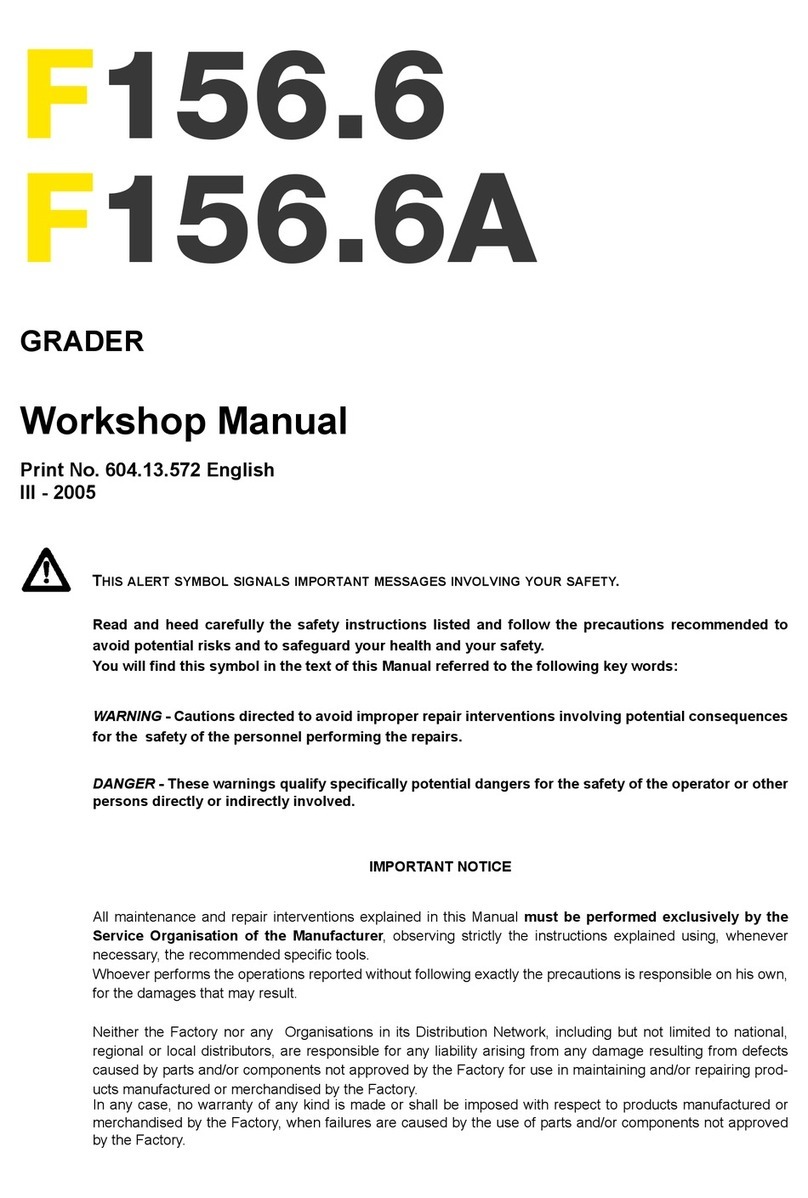

General features for different cutting methods

Cutting method Cutting speed Kerf HAZ Dim. tolerance

Abrasive water-jet cutting 8 –150 mm / min 1– 3 mm 0 mm ± 0,2 mm

Laser cutting 600

– 2200 mm / min < 1 mm 0,4 – 3 mm ± 0,2 mm

Plasma cutting 1200

– 6000 mm / min 2– 4 mm 2– 5 mm ± 1,0 mm

Gas cutting 150

– 700 mm / min 2– 5 mm 4 –10 mm ± 2,0 mm

Table 1

Diagram 1

Cut edge cracking

Cut edge cracking is a phenomenon that is closely related to hydrogen

cracking in welds and occurs when thermal cutting methods are used. If cut

edge cracks should occur, they will become visible between 48 hours

and up to several weeks after the cutting. So cut edge cracking can be re-

garded as delayed cracking. The risk of cut edge cracking increases with the

steel hardness and plate thickness.

Preheating

Preheating prior to cutting is the best way

of eliminating the risk of cut edge cracking.

Preheating is most commonly applied prior

to oxy-fuel cutting. As shown in Table 2, the

preheating temperature depends on the steel

grade and the plate thickness.

Preheating can be carried out by means

of burner lances, electric heating mats

or by heating in a furnace. The required

temperature should be measured on the

opposite side from that at which heating

takes place.

N.B. It is important to maintain a low

temperature gradient across the plate cross-

section in order to avoid local overheating at

the contact area of the heat source.

Low cutting speed

Another way of avoiding cut edge cracking is

to maintain a low cutting speed. This could

be an alternative if preheating cannot be

carried out. Cutting at low speed is less reli-

able than preheating for preventing cut edge

cracking. If preheating is not employed, the

maximum permissible cutting speed depends

on the steel grade and the plate thickness, as

shown in Table 3.

A combination of preheating and low cut-

ting speed is recommended for reducing fur-

ther the susceptibility to cut edge cracking.

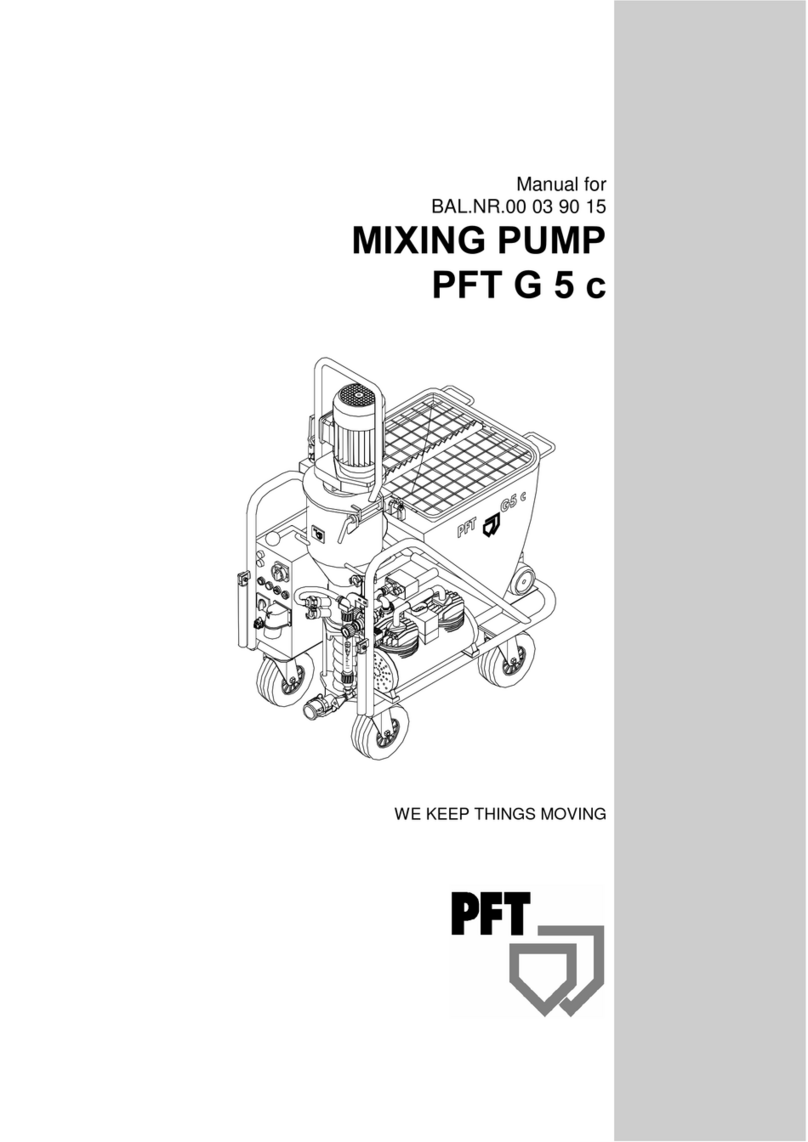

Table 2.

Preheating

of HARDOX

prior to oxy-

fuel cutting.

Table 3.

Maximum cutting peed, mm / minute, if no

preheating is employed in oxy-fuel cutting.

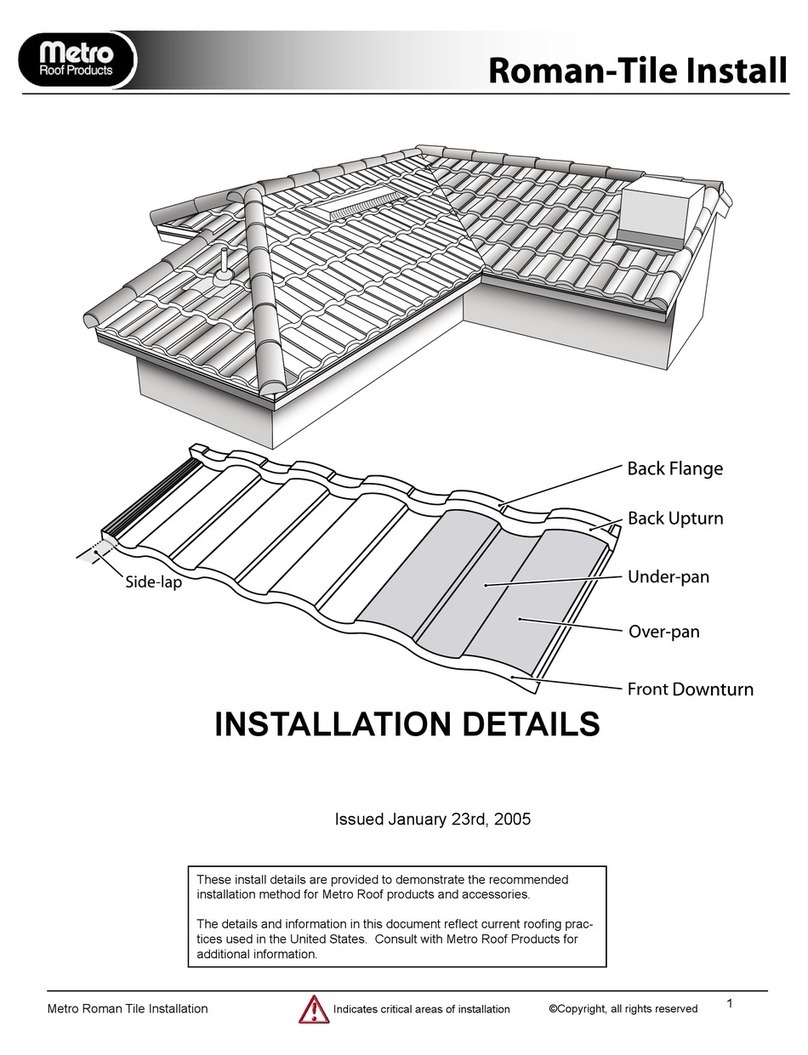

Preheating

using the Linde

blow pipe sys-

tem.

Grade Plate thickness Preheating temp.

HARDOX HiTuf ≥90 mm 100�C

HARDOX 400 45

– 59,9 mm

60 – 80 mm

> 80 mm

100�C

150�C

175�C

HARDOX 450 40

– 49,9 mm

50 – 69,9 mm

70 - 80 mm

100�C

150�C

175�C

HARDOX 500 30

– 49,9 mm

50 – 59,9 mm

60 – 80 mm

100�C

150�C

175�C

HARDOX 550 20

– 50 mm 150�C

HARDOX 600 12

– 29,9 mm

30 – 50 mm

150�C

175�C

Plate thickness HARDOX 400 HARDOX 450 HARDOX 500 HARDOX 550 HARDOX 600

≤12 mm no restrictions no restrictions no restrictions no restrictions no restrictions

≤15 mm no restrictions no restrictions no restrictions no restrictions 300

mm / min

≤20 mm no restrictions no restrictions no restrictions no restrictions 200

mm / min

≤25 mm no restrictions no restrictions 300 mm/min 270

mm / min

180

mm / min

≤30 mm no restrictions no restrictions 250

mm / min

230

mm / min

150

mm / min

≤35 mm no restrictions no restrictions 230

mm / min

190

mm / min

140

mm / min

≤40 mm no restrictions 230

mm / min

200

mm / min

160

mm / min

130

mm / min

≤45 mm 230

mm / min

200

mm / min

170

mm / min

140

mm / min

120

mm / min

≤50 mm 210

mm / min

180

mm / min

150

mm / min

130

mm / min

110

mm / min

≤60 mm 200

mm / min

170

mm / min

140

mm / min -

-

≤70 mm 190

mm / min

160

mm / min

135

mm / min

- -

≤80 mm 180

mm / min

150

mm / min

130

mm / min -

-

>80 mm

Preheating - - -

-

Slow cooling

Regardless of whether or not preheating of

the cut parts is employed, a slow cooling

rate will reduce the risk of cut edge crack-

ing. Slow cooling can be achieved if the parts

are stacked together while still warm from

the cutting process, and are covered with an

insulating blanket. Allow the parts to cool

slowly down to room temperature.

Post-heating

Heating of the parts immediately after

cutting is another method that can be used.

This will prolong the time at temperature

to allow the hydrogen to escape from

the plate and, to some extent, reduce the

residual stresses at the cut edge. The soaking

temperature should be the same as that given

in Table 2, and the soaking time should be at

least 5 minutes per mm of plate thickness.

Burner lances, electric heating mats or heat

treatment in a furnace can be used for post-

heating.

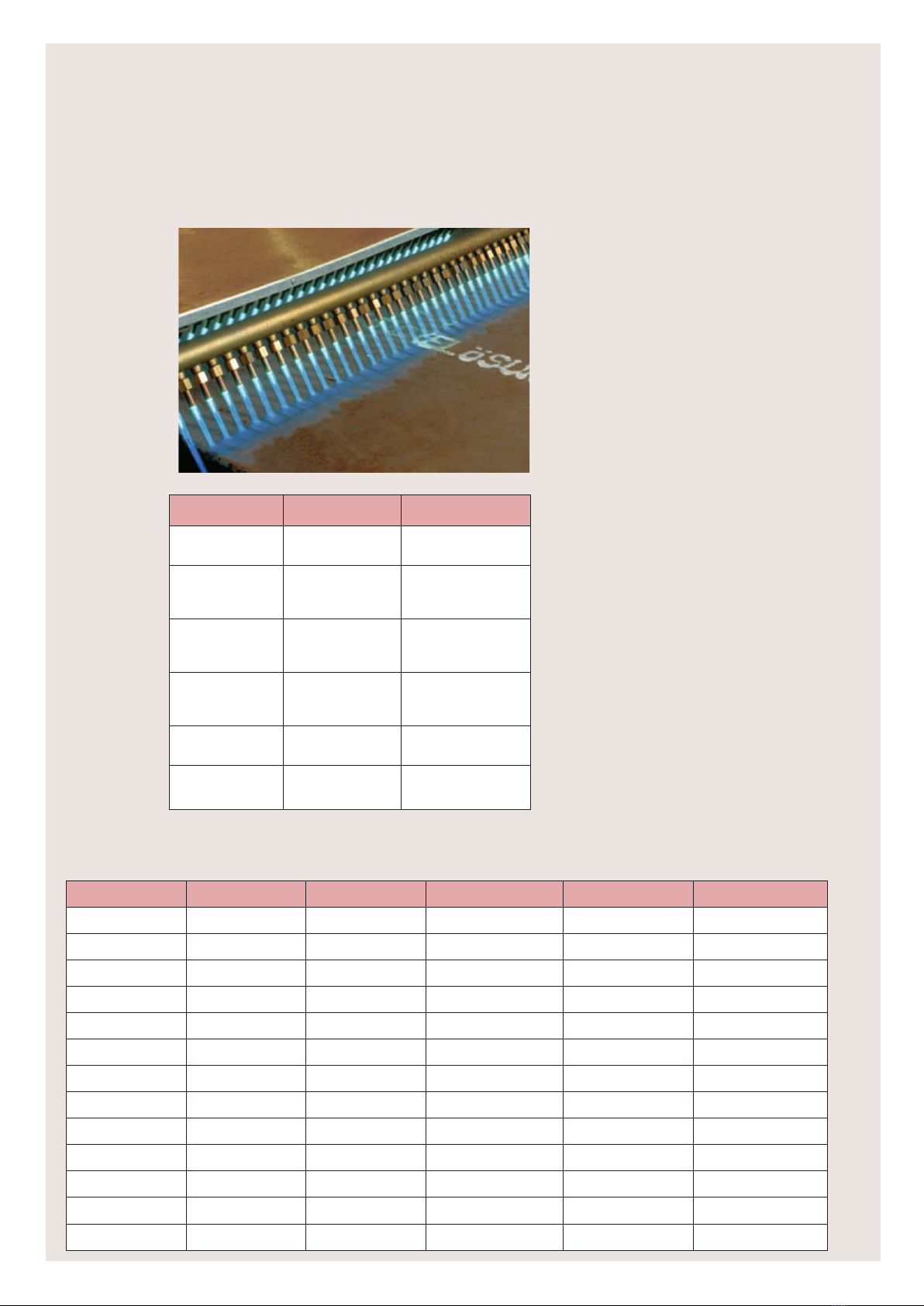

Diagram 2

Submerged cutting.

Reducing the risk of softening

The resistance of the steel to softening de-

pends on its chemistry, microstructure and the

way in which it has been processed.

The smaller the part that is thermally cut,

the greater the risk of the whole component

being softened. If the temperature of the steel

will be reduced, according to diagram 2.

Cutting method

When small parts are cut, the heat supplied

by the cutting torch and by preheating will be

accumulated in the workpiece. The smaller

the size of the cut part, the greater the risk of

softening. When oxy-fuel is used for cutting

30 mm or thicker plate, the rule of thumb is

that there is risk of loss of hardness of the

entire component if the distance between two

cuts is less than 200 mm.

The best way of eliminating the risk of

softening is to use cold cutting methods, such

as abrasive water jet cutting. If thermal cut-

ting must be performed, laser or plasma cut-

ting is preferable to oxy-fuel cutting.

This is because oxy-fuel cutting supplies

more heat and thus raises the temperature of

the workpiece.

Submerged cutting

An effective way of limiting and reducing

the extent of the soft zone is to water-cool

the plate and the cut surfaces during the cut-

ting operation. This can be done either by

submerging the plate in water or by spraying

water into the cut during cutting. Submerged

cutting can be done both in plasma cutting

and in oxy-fuel cutting.

Some advantages offered by

submerged cutting are listed below.

whole component

cutting

650

600

550

500

450

400

350

300

Surface hardness vs. tempering temperature

Tempering temperature, [�C ]

100 150 200 250 300 350 400 450

HARDOX 600

HARDOX 500

HARDOX 400

Hardness HBW

650

600

550

500

450

400

350

300

HARDOX wear plate only from SSAB Oxelösund.

HARDOX is a registered trademark of SSAB Oxelösund.

SSAB Oxelösund AB

SE-613 80 Oxelösund

Sweden

Phone +46 155 25 40 00

Fax +46 155 25 70 73

www.ssabox.com

www.hardox.com

The latest version of this document can be downloaded from www.ssabox.com/techsupport

TS-16-cutting-UK-v3-2007. Österbergs & Sörmlandstryck, Nyköping. Art. nr. 5284251

Avoiding both softening and cut

edge cracking when oxy-fuel

cutting small parts from thick

HARDOX plate

When small parts are cut by oxy-fuel from

thick HARDOX plate, there is risk of soften-

ing as well as cut edge cracking. This is best

avoided by submerged cutting at low cutting

speed in accordance with Table 3.

For thermal cutting of HARDOX 600, see

specialinformationsheet–TechSupport#23.

This manual suits for next models

4

Other Ssab Construction Equipment manuals

Popular Construction Equipment manuals by other brands

MULTIQUIP

MULTIQUIP Whiteman series Operation and parts manual

Lumag

Lumag EB400PRO Operator's manual

Stone

Stone CHAMPION 465PM Operator's manual

Conquip

Conquip Concrete Coneflow Kibble 500 user guide

Spanco

Spanco A Series Assembly and maintenance instruction

nokka

nokka 2051P Installation, operation and maintenance manual