Meva STB Series Owner's manual

Technical Instruction Manual

Support Frame STB

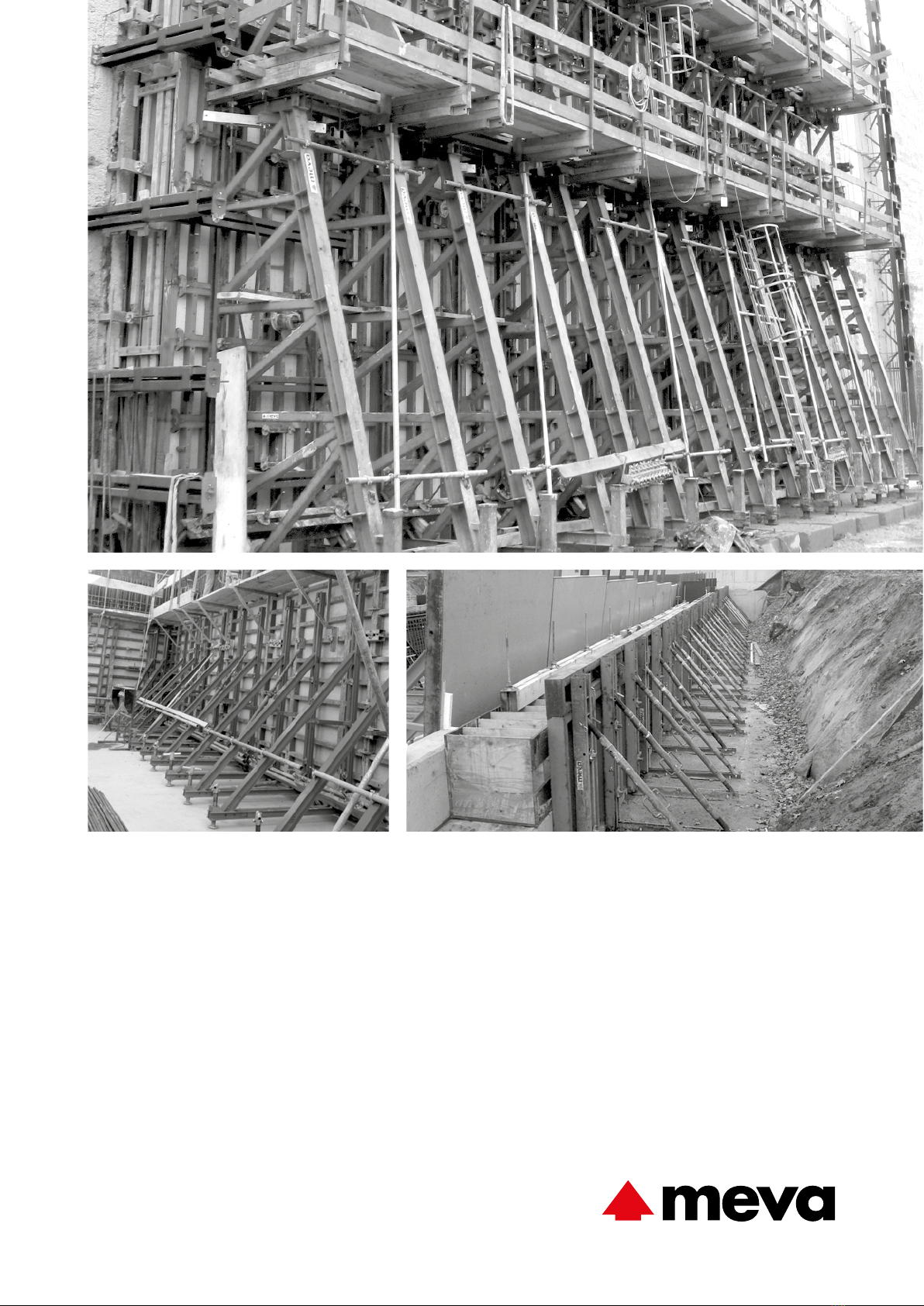

The support frame is mainly used for pouring against existing struc-

tures (walls, rock, soil, sheet piling, foundations, etc.) if only one side

of the formwork can be erected. For practical reasons it is generally

not possible to tie through the formwork. Hence, the total fresh-con-

crete pressure has to be transferred via the formwork into the support

frame and then on into the foundation. The MEVA support frame

consists of a welded and painted steel construction.

See the separate STB load charts for details about the loads that occur

in standard applications.

Permissible anchor loads according to DIN 18216

Anchor system Permissible loading

DW 15 90 kN per tie rod

DW 20 160 kN per tie rod

DW 26.5 250 kN per tie rod

When using the support frames, special attention must be paid to the

following:

ÆThe foundations and floor slabs, etc. must be able to withstand

the tensile and compressive forces that occur. A structural verification

may be required.

ÆThe "opposite side" of the single-sided formwork, i.e. the exist-

ing structure, must also be able to resist the fresh-concrete pressure.

ÆThe DW tie rods must not be welded, heated or deformed.

ÆFor more complex or special cases not dealt with in this manual

please contact the MEVA experts for advice.

ÆDeviations from the versions described in this manual always

require a separate structural verification.

Attention

Check on-site to make sure that the tensile forces Z and the compres-

sive forces V that occur can be safely transferred into the foundation

or floor slab. In particular, the concrete strength and the degree of

reinforcement used need to be reviewed. If the support frames are

used on top of slabs – for example in underground garages – support

the slab where the vertical forces V occur in order to transfer these

into the foundation.

Abbreviations, measurements, figures and tables, etc.

The abbreviation STB is used for the support frame. DIN means

Deutsche Industrie-Norm (German Industrial Standard). E DIN (E =

Entwurf / draft) means that the DIN is in draft status and not yet

approved. Any further abbreviations are explained where they are

used for the first time.

TÜV means Technischer Überwachungsverein. This is the independ-

ent German organisation that tests the safety of technical installa-

tions, machinery and motor vehicles. If a product passes the test, it

is permitted to carry the GS seal. GS stands for Geprüfte Sicherheit

(approved safety).

Measurements: This manual uses the metric system, i.e. m (for metre),

cm (for centimetre) and mm (for millimetre).

Non-defined dimensions are in cm.

The page numbers in this manual start with STB. The figures and

tables are numbered per page. Depending on its product abbrevia-

tion, a cross reference in the text refers to a page, table or figure in

this or in another manual. This is indicated by the product code with

which the cross-reference begins.

Product features

STB-2 Technical Instruction Manual / Status November 2019

STBSupport frame

Contents

This Technical Instruction Manual contains information, instructions

and tips that describe how to use the MEVA equipment on the

construction site in a proper, quick and economic way. Most exam-

ples shown are standard applications that will occur in practice most

often. For more complicated or special applications not covered in this

manual, please contact the MEVA experts for advice. They will help

you without delay.

When using our products, the federal, state and local occupational

health and safety regulations must be observed. Please observe the

assembly instructions that your local contractor or employer has cre-

ated for the site on which the MEVA equipment is used. Such instruc-

tions are intended to minimise site-specific risks and must contain the

following details:

ÆThe order in which all working steps including assembly, conver-

sion and disassembly must be carried out

ÆThe weight of the panels and other system parts

ÆThe type and number of ties and braces as well as the distance

between them

ÆThe location, number and dimensions of working scaffolds

including the working area and fall protection equipment required

ÆAttachment points for panel transport by crane. With regard to

panel transport, please observe this manual. Any deviation will require

structural verification.

Important: Generally, only well-maintained material may be used.

Damaged parts must be replaced. Use only original MEVA spare parts

for replacement.

Attention: Never wax or oil assembly locks!

Please note

Product overview.............................................................................. 4

Support frame STB 300/300 plus ...................................................... 6

Support frame STB 300 plus.............................................................. 7

Support frame STB 450................................................................... 11

Pre-assembly of support frame units ............................................... 12

Diagonal bracing ............................................................................ 13

Workplaces..................................................................................... 14

Workplaces – SecuritBasic............................................................... 15

Workplaces – Walkway bracket ...................................................... 16

Access ladder.................................................................................. 17

Anchoring details – General............................................................ 18

Anchoring – versions ...................................................................... 22

Anchoring details for STB 300......................................................... 23

Anchoring details for STB 300 plus ................................................. 24

Anchoring details for STB 450......................................................... 25

Anchoring – Installing anchor holders DW 15 – DW 26.5................ 26

Anchoring – Installing single/double anchors .................................. 28

Anchoring – installation of the anchor extension ............................ 30

Anchoring – Upstand bracket ......................................................... 31

Stop ends ....................................................................................... 32

Inside corner with cross brace STB and STB 300/300 plus ............... 34

Inside corner with cross brace STB and STB 450.............................. 37

Crane ganging................................................................................ 40

Moving STB units on a trolley.......................................................... 41

STB special connector ..................................................................... 43

Brace bracket SK 150...................................................................... 44

Brace bracket 80............................................................................. 46

Transport: stacking material............................................................ 47

Transport: loading trucks ................................................................ 48

Services .......................................................................................... 49

Poduct list....................................................................................... 51

Load charts..................................................................................... 85

STB-3Technical Instruction Manual / Status November 2019

STBSupport frame

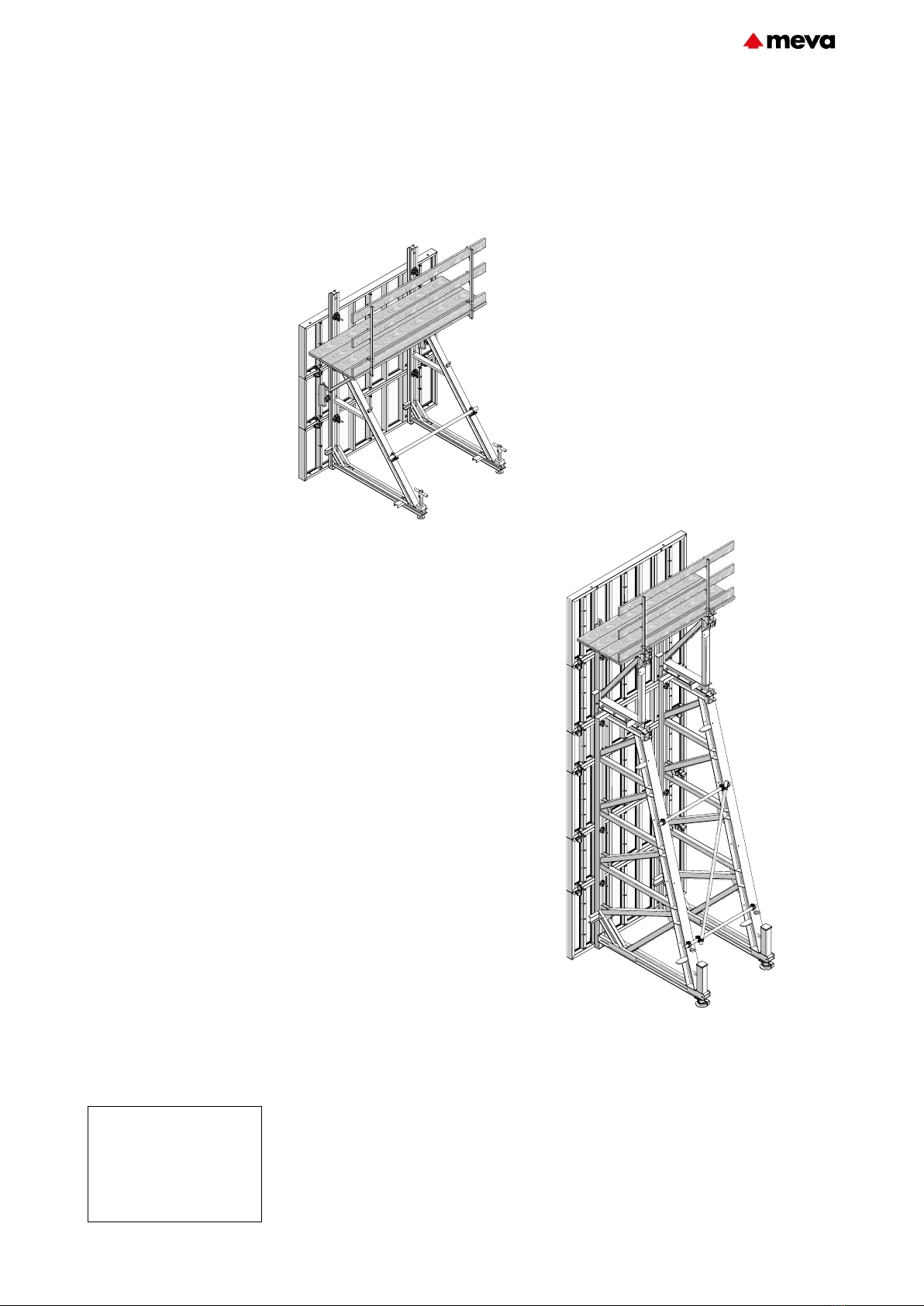

Product overview

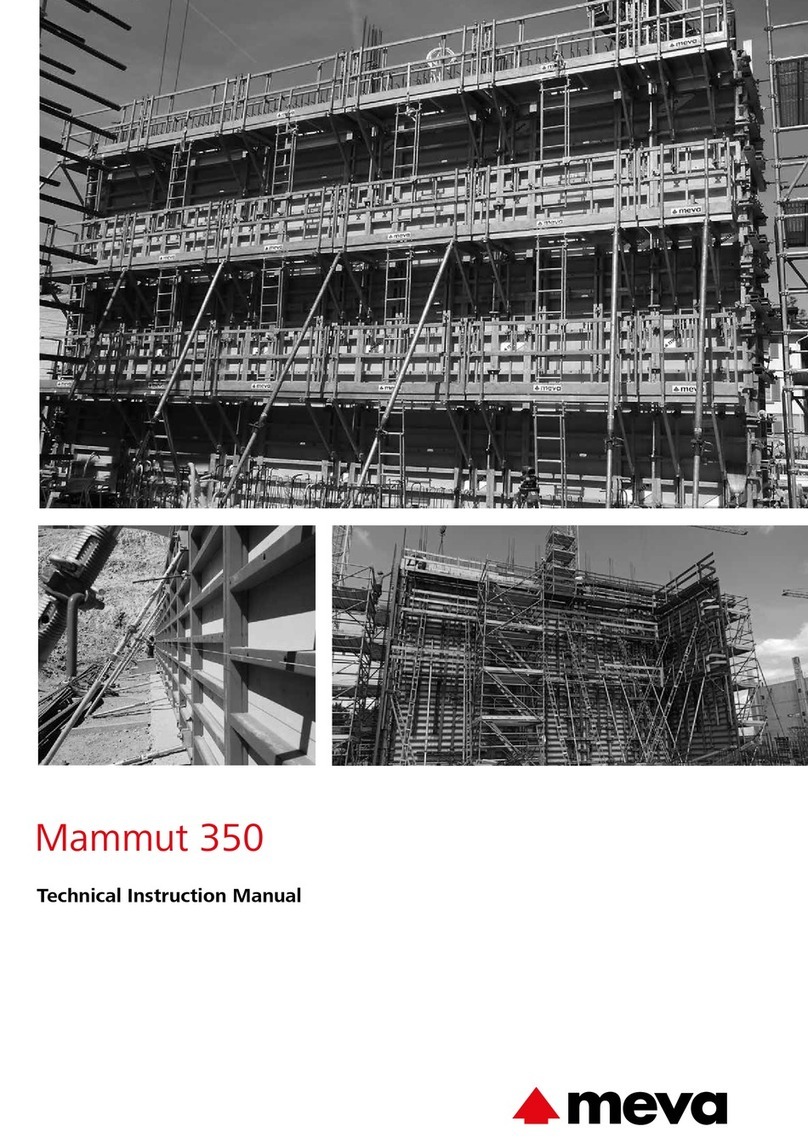

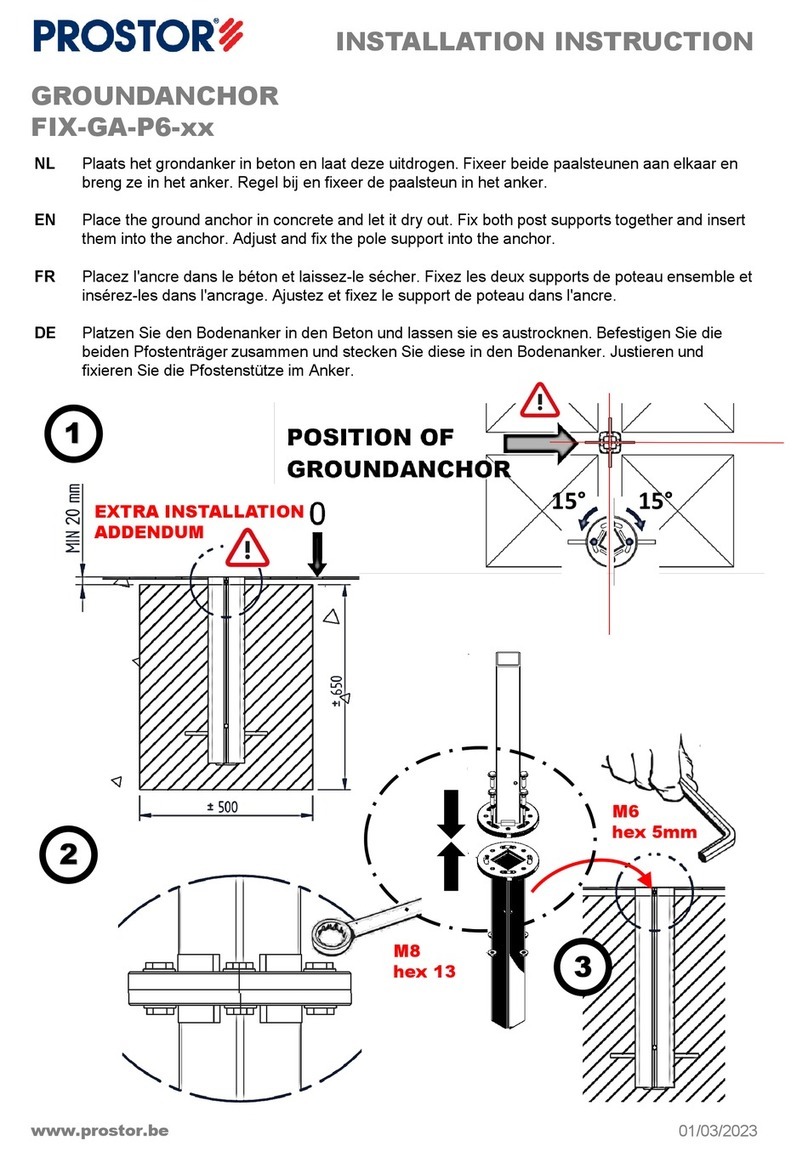

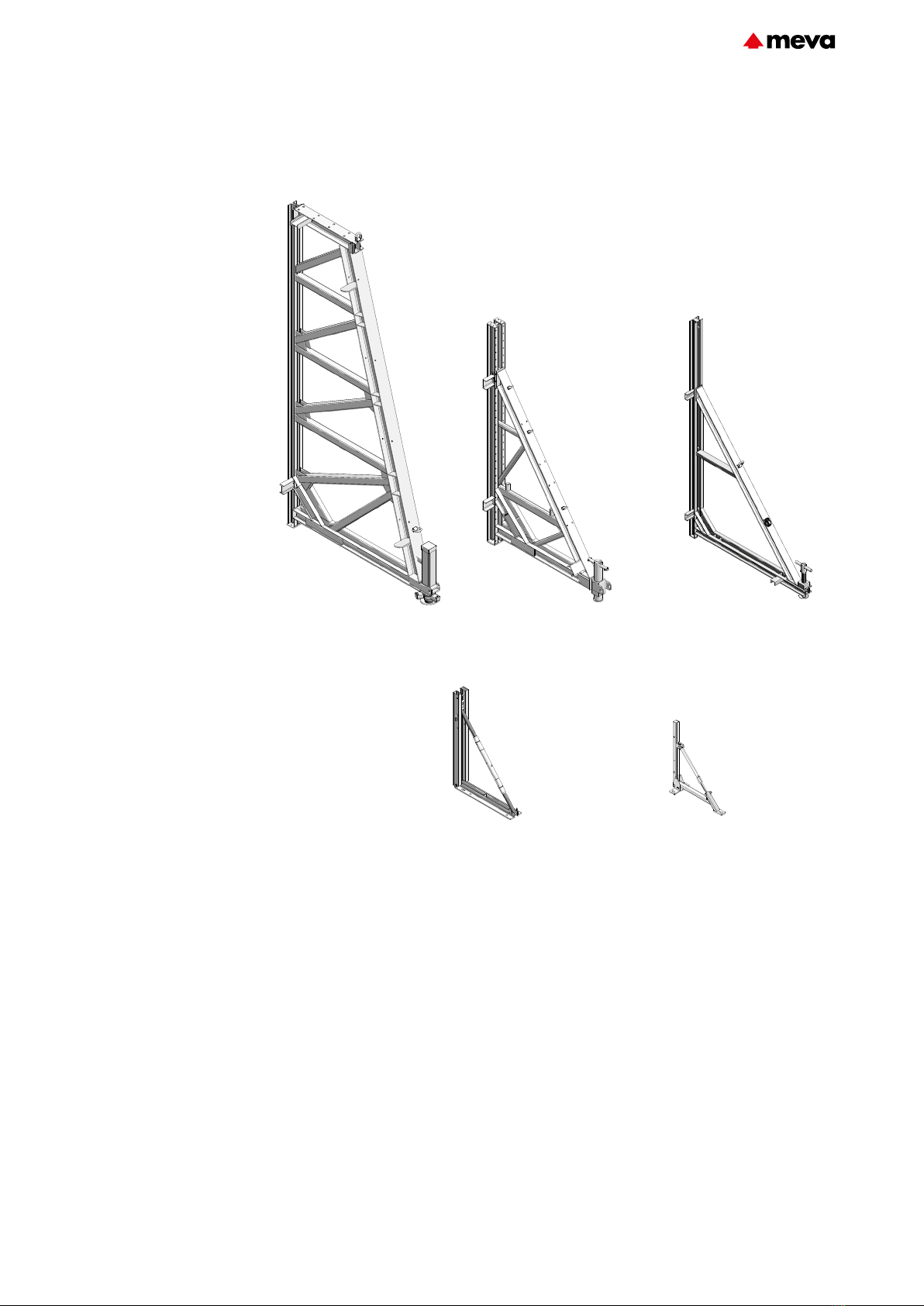

Fig. 4.1 Support frame STB 450 Fig. 4.2 Support frame STB 300 plus

Fig. 4.4 Brace bracket SK 150 Fig. 4.5 Brace bracket 80

Fig. 4.3 Support frame STB 300

Walls up to a pouring height of

13.50m can be formed from one

side using three support frame

versions.

ÆSTB450 up to a height

of 5.20m, with height exten-

sions150 and, if required, addi-

tional accessories up to 13.50m

(Fig.4.1 and page STB-11).

ÆSTB300 plus up to a height

of 3.25m, with height exten-

sions up to a height of 4.50m

(Fig.4.2 and page STB-7.

ÆSTB300 up to a height of

3.30m (Fig.4.3 and page STB-

21.

Two support frame sizes enable

stop ends for floor slabs and

slab edges up to 1.50m to be

formed.

ÆBrace bracket150 up to a

height of 1.50m

(Fig.4.4 and page STB-44.

ÆBrace bracket80 up to a

height of 0.8m

(Fig.4.5 and page STB-46.

STB-4 Technical Instruction Manual / Status November 2019

STBSupport frame

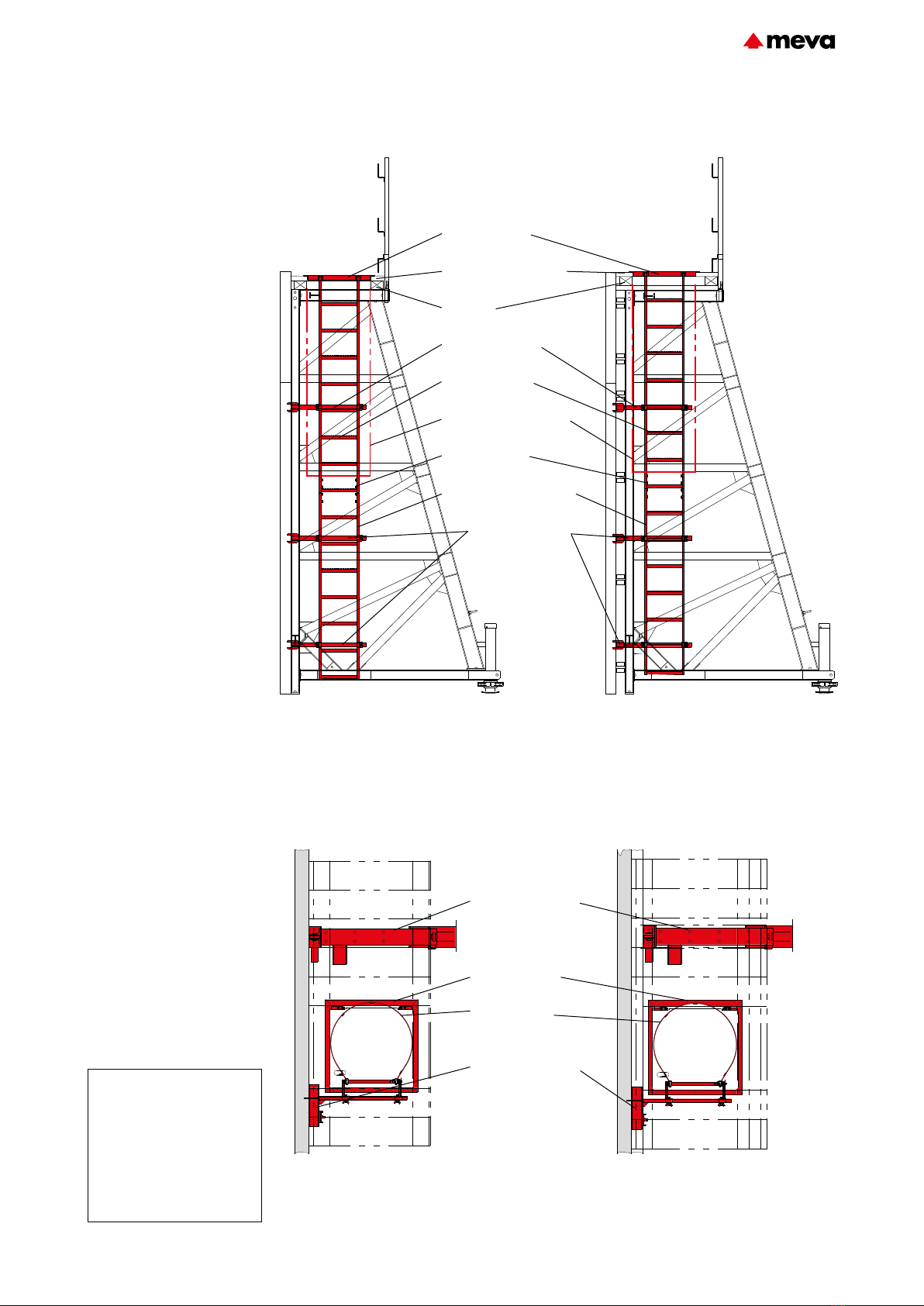

The STBsupport frames and the

brace brackets can be combined

with all MEVA wall formwork

systems as well as with special

designs.

From a structural and economic

point of view and depending

on the formwork system used,

it may be more advantageous

to use the support frame with

vertical (Fig.5.1) or horizontal

panels (Fig.5.2).

The support frame can be

attached to the MEVA wall form-

work panel from the frame side

with flange screw18 (Fig.5.3).

Alternatively, it can be attached

from the facing side using fixing

screw35 and articulated flange

nut15/120 or flange nut100

(Figures5.4 and 5.5).

Attention

ÆWhen using the STB unit

vertically, the spindle must be

set to the middle position before

mounting the STB on the form-

work. This ensures that it can

be perfectly adapted to suit the

supporting surface.

ÆRefer to the product list for

the spindle stroke.

ÆBefore pouring, ensure that

all STB spindles and additional

braces are secure and contact

the ground.

Product overview

Fig. 5.1 Support frame STB 300 with vertical panels Fig. 5.2 Support frame STB 450 with horizontal panels

Fig. 5.4 Detail – Fixing screw on the support frame side Fig. 5.5 Detail – Fixing screw on the facing side

Fig. 5.3 Detail – Flange screw 18, attachment on the support frame side

Spindle

STB-5Technical Instruction Manual / Status November 2019

STBSupport frame

Support frame STB 300/300 plus

Fig. 6.5 Support frame STB 300 with vertical panels

Fig. 6.1 Support frame STB 300 with horizontal panels

Fig. 6.2 StarTec horizontal, with fixing screw

Fig. 6.3 Mammut 350 horizontal, with fixing screw

Fig. 6.6 StarTec vertical, with flange screw

Fig. 6.7 Mammut vertical, with flange screw

Description Ref. No.

Support frame STB 300 ......... 29-402-62

Flange screw 18 .................... 29-401-10

Flange screw 28 .................... 29-401-12

Fixing screw

35/DW 15 ............................. 29-401-20

Articulated flange nut

15/120.................................. 29-900-10

Flange nut 100 ..................... 29-900-20

Crossbeam 300 ..................... 29-403-05

Pouring height

The STB300 (Figures6.1 and

6.5) is used up to a pouring

height of 3.30m.

The STB300plus (Fig.6.9) is

used up to a pouring height of

3.25m and can be equipped

with height extensions for a

pouring height up to 4.50m.

Horizontal panels

The support frame is attached to

the multi-function profiles using

flange screws18. Alternatively,

it can be attached through the

tie holes of the formwork using

fixing screws35 and flange

nuts100 or articulated flange

nuts15/120 (Figures6.1 to 6.4).

Vertical panels

When using vertical StarTec

and Mammut/Mammut350

formwork (Figures6.5 to 6.7),

the crossbeam300 is used

(Fig.6.10). When used hori-

zontally between the formwork

panel and the support frame, the

crossbeam300 allows units to be

assembled.

The support frame is attached

to the multi-function profile of

the formwork panel using tie

rodsDW and flange nuts100 or

articulated flange nuts15/120

(Fig.6.5).

When MammutXT is used verti-

cally, an additional crossbeam is

not required (Fig.6.8).

Fig. 6.4 Mammut XT horizontal, with fixing screw

Fig. 6.8 Mammut XT vertical, with flange screw

Fig. 6.10 Crossbeam 300

ST 270 ST 270

ST 270

55 5555 55

160

M 350 M 350

M 350

55 55

55 55

140

Mammut XT Mammut XT

Mammut XT

55 55

55 55

140

ST 135

ST 135

135

ST 135

135 135

Formwork unit

ST 135 ST 135

M 350

125

Formwork unit

M 350 M 350 M 350

125 125 125

Mammut XT

62.5 125

Formwork unit

62.5 62.5 62.5

Mammut XT Mammut XT Mammut XT

15

25 25

15

60 60

180

125 125

300

Fig. 6.9 Support frame STB 300

plus with horizontal panels

STB-6 Technical Instruction Manual / Status November 2019

STBSupport frame

Support frame STB 300 plus

The STB300 plus (Fig.7.1) is

used up to a pouring height of

3.25m.

With a maximum of three

STBheight extensions50

(Fig.7.2), the STB300plus can

be used up to a pouring height

of 4.50m (see page STB-9).

The STBcompensation rail

(Fig.7.3) enables the support

frame unit to be dowelled to the

slab. It is attached to the support

frame or to the STBheight exten-

sion with the STBfixing screw

(Fig.7.4) (see page STB-10).

The STBpanel support (Fig.7.5)

ensures that the STB formwork

panel unit does not shift unin-

tentionally when being reposi-

tioned. Furthermore, additional

accessories such as a walkway

bracket can be attached to the

integrated multi-function nut

(see page STB-8).

When height-extending the

support frame using STBheight

extensions, additional braces are

attached to the STBbase exten-

sion57 (Fig.7.6).

The support frame300plus

enables additional scaffold tubes

to be installed at the positions

provided in order to provide

rigidity (Fig.7.1).

Fig. 7.1 Support frame STB 300 plus

Fig. 7.2

STB height extension 50

Fig. 7.3

STB compensation rail

Fig. 7.5 STB panel support Fig. 7.6 STB base extension 57

Description Ref. No.

Support frame STB 300 plus . . 29-402-60

STB height extension 50 ........ 29-402-63

STB compensation rail ........... 29-402-66

STB panel support ................. 29-402-68

STB base extension 57 .......... 29-402-69

STB fixing screw .................... 29-401-19

Fig. 7.4 STB fixing screw

1

4

2

3

Crane attachment points

and Support frame with formwork

and Support frame installed vertically

and Support frame installed horizontally

21

1 3

41

Positions for the

attachment of addi-

tional scaffold tubes to

provide rigidity

STB-7Technical Instruction Manual / Status November 2019

STBSupport frame

Support frame STB 300 plus

The STBpanel support (Fig.8.2)

prevents the STB formwork panel

unit shifting unintentionally

when being repositioned. Fur-

thermore, additional accessories

such as a walkway bracket can

be attached to the integrated

multi-function nut (Figures8.1,

8.3 and 8.4).

The panel support is attached to

the support frame300plus using

the integrated screws. The posi-

tion must be selected so that it is

located on the formwork panel

between two crossbeams or on

a cross stiffener (Figures8.3 and

8.4).

Fig. 8.1

Fig. 8.3

STB panel support

Walkway bracket

Description Ref. No.

Support frame STB 300 plus . . 29-402-60

STB panel support ................. 29-402-68

Fig. 8.2 STB panel support

Multi-function nut

Fig. 8.4

STB panel support

STB-8 Technical Instruction Manual / Status November 2019

STBSupport frame

Support frame STB 300 plus

Configuration Pouring height (m)

STB 300 plus 2.50 to 3.25

STB 300 plus + 1 height extension Up to 3.50

STB 300 plus + 1 height extension + 1 brace + 1 STB base extension 57 Up to 3.75

STB 300 plus + 2 height extensions + 2 braces + 2 STB base extensions 57 Up to 4.25

STB 300 plus + 3 height extensions + 3 braces + 3 STB base extensions 57 Up to 4.50

With a maximum of three

STBheight extensions50

(Fig.9.2), the STB300plus can

be used up to a pouring height

of 4.50m.

The STBheight extension50 is

attached to the support frame

or the STBheight extension50

located below using the inte-

grated screws (Fig.9.2).

The braces can be attached to

the STBheight extension50 and

to the STBbase extension57

(Figures9.1 and 9.2).

Refer to Table9.4. for the con-

figuration of the support frame

unit as a function of the pouring

height.

Refer to the STB load charts for

information on the forces that

occur and the type of bracing.

Table 9.4

Description Ref. No.

Support frame STB 300 plus . . 29-402-60

STB height extension 50 ........ 29-402-63

STB base extension 57 .......... 29-402-69

Zeichnung Nr. 3000_0107

Stand: 17.10.2018/bhe

Fig. 9.1

STB height extension 50

STB base extension 57

Support frame STB 300 plus

Bracing

Positions for the attachment of addi-

tional scaffold tubes to provide rigidity

Fig. 9.2 STB height extension 50 Fig. 9.3 STB base extension 57

Attachment point for

bracing

Attachment point for

bracing

STB-9Technical Instruction Manual / Status November 2019

STBSupport frame

Fig. 10.1

STB compensation rail (dowelled to the slab)

Timber

STB height extension 50

STB base extension 57

Support frame STB 300 plus

Bracing

Positions for the attachment of addi-

tional scaffold tubes to provide rigidity

Fig. 10.4 Detail view of STB fixing screw

Fig. 10.5 Detail view of STB fixing screw

STB fixing screw

Detail views in Fig-

ures10.4 and 10.5

Support frame STB 300 plus

The STBcompensation rail

(Fig.10.1) enables the support

frame unit to be dowelled to the

slab. A job-built square timber

bridges the gap to the formwork

panel.

The compensation rail is attached

to the support frame or the

STBheight extension using the

STBfixing screw (Figures10.2

and 10.3).

Description Ref. No.

Support frame STB 300 plus . . 29-402-60

STB compensation rail ........... 29-402-66

STB base extension 57 .......... 29-402-69

STB fixing screw .................... 29-401-19

Fig. 10.2 STB compensation rail

Fig. 10.3 STB fixing screw

STB-10 Technical Instruction Manual / Status November 2019

STBSupport frame

Support frame STB 450

Possible applications

The STB 450 is designed for

single-sided formwork up to

5.20m (Fig. 11.1). Using height

extensions 150 and other acces-

sories as required, the STB450

allows single-sided formwork to

be erected with the following

heights:

ÆUp to 6.70m – One height

extension (Fig. 11.2)

ÆUp to 8.20m – Two height

extensions, base extension,

Triplex SB braces

ÆUp to 9.40m – Three height

extensions, base extension,

Triplex SB braces (Fig.11.3)

ÆUp to 11.00 m – Four

height extensions, base exten-

sion, Triplex SB braces (Fig.11.4)

ÆUp to 12.50 m – Five height

extensions, base extension,

Triplex SB braces

ÆDepending on the

construction site and using a

corresponding number of height

extensions and Triplex SB braces,

support frame constructions for

formwork heights up to 13.50m

can also be built.

Attention

ÆBefore pouring, ensure that

all STB spindles and additional

braces are secure and contact

the ground.

Fig. 11.2 Up to a formwork height of 6.70m:

Four fixing screws are required for each STB

Fig. 11.1 Up to a formwork height of 5.20m:

Three fixing screws are required for each STB

Fig. 11.4 Up to a formwork height of 11.00m:

Seven fixing screws are required for each STB

Fig. 11.3 Up to a formwork height of 9.40m:

Six fixing screws are required for each STB

Description Ref. No.

Support frame STB 450 ......... 29-406-00

Height extension 150 ............ 29-406-10

Base extension ...................... 29-406-20

Fixing screw

35/DW 15 ............................. 29-401-20

Articulated flange nut

15/120.................................. 29-900-10

Flange nut 100 ..................... 29-900-20

Flange screw 18 .................... 29-401-10

STB-11Technical Instruction Manual / Status November 2019

STBSupport frame

Pre-assembly of support frame units

The surface on which the form-

work and the support frames are

pre-assembled should be clean,

even and capable of supporting

the total weight. The support

frames are attached to the rear

of the horizontal formwork

panels (Fig.12.1).

Assembly

ÆThe support frame is

attached to the formwork’s mul-

ti-function profiles using flange

screw18. Alternatively, it can

be attached using the tie holes

of the formwork with fixing

screws35 and articulated flange

nuts15/120 or flange nuts100.

The fixing screws must be in-

serted through the tie holes and

secured to prevent them falling

out, using the flange nut100 for

example, before the formwork

panel is placed on the ground.

ÆThe height extensions are

bolted to the support frame or

height extension below using

the eight (8) M20x50 screws and

M20 nuts supplied.

ÆThe pre-assembled units

should rest on square timbers

(face down) on the ground be-

fore they are flown into place.

Assembly of the Triplex SB

braces

Depending on the overall height,

it may be necessary to attach

TriplexSB braces to the height

extensions150 and the base

extensions. The fastening ele-

ments required are supplied with

the height and base extensions

(Figures 12.2 to 12.4).

Fig. 12.2

Fig. 12.1

Fig. 12.3 – Detail view of the upper

Triplex connection

Fig. 12.4 – Detail view of the lower

Triplex connection

Spindle

Attention

ÆWhen using the STB unit

vertically, the spindle must be

set to the middle position before

mounting the STB on the form-

work. This ensures that it can

be perfectly adapted to suit the

supporting surface.

ÆBefore pouring, ensure that

all STB spindles and additional

braces are secure and contact

the ground.

ÆRefer to the Triplex Tech-

nical Instruction Manual (www.

meva.net).

STB-12 Technical Instruction Manual / Status November 2019

STBSupport frame

Diagonal bracing

Scaffold tubes with Ø

48.3 x 4.05mm, bolt-on couplers

48/M14 and swivel-joint couplers

48/48 are needed to build the

diagonal bracing required.

A horizontal tube is required

for STB300 (Fig.13.1) and

STB300plus (Fig.13.2).

The STB 450 requires two hori-

zontal and one diagonal scaffold

tube (Fig. 13.3).

If height extensions are used,

additional horizontal scaffold

tubes must be installed from the

second height extension upwards

(Figures13.4 and 13.5).

Fig. 13.3 Fig. 13.4

Fig. 13.1

Fig. 13.2

Description Ref. No.

Scaffold tube 48/200 ............ 29-412-23

Scaffold tube 48/300 ............ 29-412-26

Scaffold tube 48/400 ............ 29-412-27

Swivel-joint coupler

48/48.................................... 29-412-52

Bolt-on coupler

48/M14 ................................ 40-080-70

Fig. 13.5

STB-13Technical Instruction Manual / Status November 2019

STBSupport frame

Workplaces

Above a height 2.00m the risk

of falling must be assessed.

SecuritBasic

The support frame STB450 can

be equipped with the safety

system SecuritBasic (Fig.14.1)

for safe and ecient work at

all heights. This prevents falling

accidents and at the same time

increases work eciency.

Conventional

If a scaffold is erected con-

ventionally (Fig.14.2) or with

walkway brackets (see page

STB-16), DINEN12811-1 and

DIN4420-1 must be observed.

Minimum cross section of

handrail and midrail: for a post

spacing up to 2.00m: 15x3cm

For a post spacing of up to

3.00m: 20 x 4cm.

We recommend the use of safety

meshes. They are quick and safe

method to provide fall protec-

tion.

Attention

ÆWhen using our products,

the federal, state and local

codes and regulations must be

observed.

Fig. 14.1

Fig. 14.2

STB-14 Technical Instruction Manual / Status November 2019

STBSupport frame

Workplaces – SecuritBasic

The support frame450 as well as

the height extension150 can be

equipped with the SecuritBasic

platform2470 with integrated

access ladder (Fig.15.1) on the

2.50m wide Mammut panel.

Refer to Tables15.2 to 15.4.

for the type and quantity of the

parts required for the complete

unit as depicted in Fig.15.1 or

for individual platforms.

Bill of material (complete unit as in Fig.15.1)

Posi-

tion

Quan-

tity

Ref. no. Description

1 2 29-406-00 Support frame STB 450

2 8 29-406-10 STB height extension 450

3 2 29-406-25 Horizontal girder STB

450 SB

4 1 29-406-66 Toe board STB 1290 SB

5 2 29-406-64 Toe board STB 480 SB

6 8 29-106-80 Guardrailing post 48/120

UK

7 19 29-412-50 Rigid coupler 48x48

8 8 29-601-78 Side railing hinged SB

tube coupler

9 6 29-406-27 Horizontal girder ST ex-

tension 150 SB

10 3 29-406-68 Toe board STB 2470 SB

11 2 29-406-62 Toe board holder STB SB

12 2 29-601-92 Support for guardrailing

post IC SB

13 2 29-406-29 Front railing post retract-

able STB 450

14 4 29-603-45 Telescopic ladder 1700-

3180 SB

15 8 29-406-87 STB special connector

16 4 29-600-15 Alu platform M 2470 SB

with hatch

17 10 29-603-55 Scaffold tube 48.3/2470

SB

18 1 29-603-80 Ladder fixture panel SB

Table 15.2

Fig. 15.1

1

5

6

7

9

10

6

4

2

5

11

12

13

14

15

3

2

1

6

7

7

9

9

9

10

10

16

16

16

16

17

8

8

8

8

18

Bill of material (individual platform on STB 450)

Posi-

tion

Quan-

tity

Ref. no. Description

3 2 29-406-25 Horizontal girder STB

450 SB

4 1 29-406-66 Toe board STB 1290 SB

5 2 29-406-64 Toe board STB 480 SB

6 2 29-106-80 Guardrailing post 48/120

UK

7 5 29-412-50 Rigid coupler 48x48

8 2 29-601-78 Side railing hinged SB

tube coupler

11 2 29-406-62 Toe board holder STB SB

14 1 29-603-45 Telescopic ladder 1700-

3180 SB

16 1 29-600-15 Alu platform M 2470 SB

with hatch

17 2 29-603-55 Scaffold tube 48.3/2470

SB

18 1 29-603-80 Ladder fixture panel SB

Bill of material

(individual platform on height extension 150)

Posi-

tion

Quan-

tity

Ref. no. Description

3 2 29-406-27 Horizontal girder ST ex-

tension 150 SB

6 2 29-106-80 Guardrailing post 48/120

UK

7 5 29-412-50 Rigid coupler 48x48

8 2 29-601-78 Side railing hinged SB

tube coupler

10 1 29-406-68 Toe board STB 2470 SB

14 1 29-603-45 Telescopic ladder 1700-

3180 SB

15 2 29-406-87 STB special connector

(also refer to the STB load

charts)

16 1 29-600-15 Alu platform M 2470 SB

with hatch

17 2 29-603-55 Scaffold tube 48.3/2470

SB

Additional parts on the uppermost height extension

12 2 29-601-92 Support for guardrailing

post IC SB

13 2 29-406-29 Front railing post retract-

able STB 450

17 2 29-603-55 Scaffold tube 48.3/2470

SB

Table 15.3

Table 15.4

STB-15Technical Instruction Manual / Status November 2019

STBSupport frame

Workplaces – Walkway bracket

Fig. 16.1 STB 300 with walkway bracket 90

Fig. 16.2 STB 450 with conventional scaffold on STB height extension

Attachment of boards to the walkway

bracket with screws (∅ 10mm and a mini-

mum length of 110mm)

Attachment of boards to the STB or height extensions with

screws (e.g. M20x75). The guardrailing posts are easily and

safely inserted into the guardrailing post supports of the

support frame or height extension.

Description Ref. No.

Walkway bracket 90 ............. 29-106-00

Guardrailing post 100 ........... 29-106-75

Guardrailing post 140 ........... 29-106-85

Guardrailing post 48/120 ...... 29-106-80

Side railing 90/100 ................ 29-108-20

Side railing 125/100 .............. 29-108-30

Hexagon-head bolt M20x75 . 63-119-91

Working platforms are built using

walkway brackets 90 (Fig.16.1)

together with guardrailing posts.

The procedure is as for two-sided

wall formwork. For details see

the Technical Instruction Manual

of the formwork you are using.

For safe access to the platform

we recommend using the MEVA

Stair Tower.

Permissible load:

1.5 kN/m², load class2 according

to DIN12811-1. Maximum influ-

ence width: walkway bracket90

= 1.80m

Planking classification S10.

Platform layout

The STB units can be set up flex-

ibly and combined with different

formwork systems and heights.

When planning, take the plat-

form layout and the fall height

into account.

STB 450

The planks and boards can be

attached to the support frame

or the height extension (Fig-

ures16.3 and 16.4). The guard-

railing posts are inserted directly

into the support for guardrailing

post of the STB 450 or the height

extension.

STB-16 Technical Instruction Manual / Status November 2019

STBSupport frame

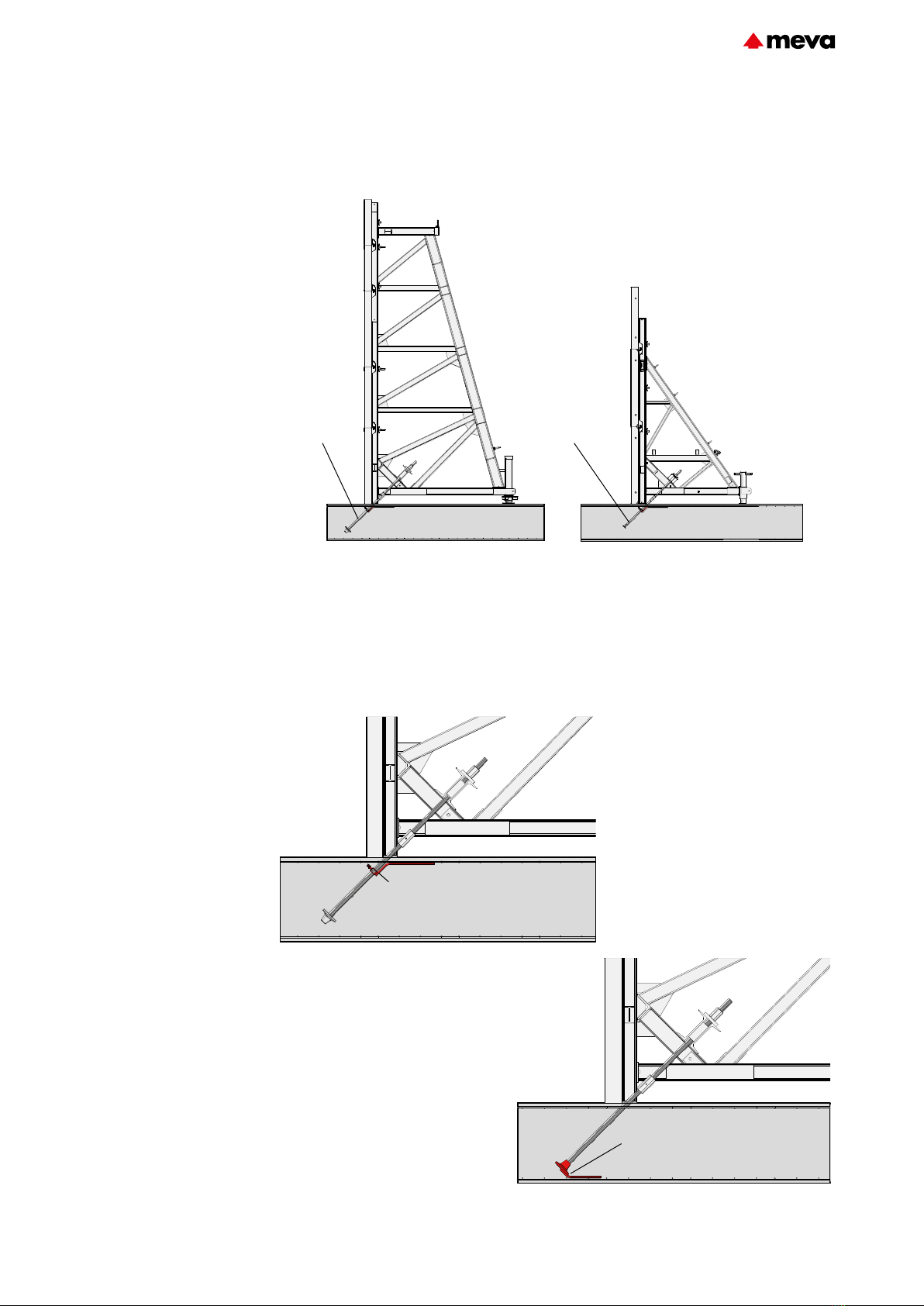

Fig. 17.1 STB 450 with ladder access; STB

attached directly to the formwork.

Fig. 17.2 STB 450 with ladder access; crossbeam or

alignment rail between STB and formwork.

Fig. 17.3 Ladder access with access hatch

without crossbeam

Fig. 17.4 Ladder access with access hatch and

crossbeam

Access hatch

Planking t = 50 mm

Timber

Ladder fixture 33/45

Ladder 243

Safety cage 210

Ladder connector

Extension ladder 210

An access ladder with safety

cage is required if the support

frame 450 is used. The distance

from the ground to the safety

cage must not exceed 3m. The

ladders are attached to the wall

formwork panels using the lad-

der fixture 33/45, regardless of

whether a crossbeam or align-

ment rails are used (Figures17.1

to 17.4). The ladder fixture is

bolted to the multi-function pro-

files of the wall formwork panels

using flange screws 18.

Three ladder fixtures 33/45 are

required for formwork heights

between 350cm and 450cm.

For heights above 450cm please

contact MEVA.

Note

ÆAlternatively, a MEVA Stair

Tower can be employed to

access the working level.

ÆA MEVA Stair Tower is re-

quired above a height of 5.00m

if there are no intermediate

working levels.

Description Ref. No.

Ladder fixture 33/45 ............. 29-404-35

Ladder 243 ........................... 29-416-50

Extension ladder 210 ............ 29-414-60

Extension ladder 90 .............. 29-416-60

Extension ladder 60 .............. 29-416-62

Safety cage 210 .................... 29-414-85

Safety cage 85 ...................... 29-414-90

Safety cage 40 ...................... 29-416-90

Ladder connector .................. 29-414-70

Access hatch KLK .................. 29-416-05

Access hatch

Safety cage

Ladder fixture 33/45

Support frame 450

Access ladder

Ladder fixture 33/45

STB-17Technical Instruction Manual / Status November 2019

STBSupport frame

Anchoring details – General

Fig. 18.1 Support frame STB 450

Anchoring

Anchors for support

frame450 (Fig.18.1), support

frame300plus (Fig.18.2) and

support frame300 can be made

for different floor slab thick-

nesses using anchor loops or

DW tie rods, coupling nuts and

anchoring auxiliaries.

All parts are designed for the use

of DW15, DW20 and DW26.5

tie rods.

The anchoring auxiliaries can

be attached either to the upper

(Fig.18.3) or to the lower rebar

layer (Fig.18.4) depending on

the slab thickness or the number

and density of rebars. The angle

of installation of the tie rods is

automatically correct due to the

shape of the anchoring auxilia-

ries (45°).

Depending on the version it may

be possible to recover and reuse

the tie rods (see page STB-21).

Fig. 18.3

Fig. 18.4

Anchoring

Fig. 18.2 Support frame STB 300 plus

Anchoring auxiliary on the upper

rebar layer

Anchoring auxiliary on the lower

rebar layer

STB-18 Technical Instruction Manual / Status November 2019

STBSupport frame

Anchoring details – General

Decisive for the choice of tie

rod are the forces that occur at

the anchor point of the support

frame. Anchoring can be per-

formed as follows:

ÆWith tie rod DW15

(Fig.19.1) and M cross stiffener

44.

ÆWith tie rod DW20 or

DW26.5 and twin channel 80/22

or 245/22 (Fig. 19.5).

ÆWith anchor loop15

(Fig.19.2) or 20 and twin

channel (Figures19.3 and 19.4)

or with anchor loop 15 or 20

turned through 180° (Fig.19.4).

Contact the structural engineer if

additional rebars are required.

Maximum anchoring loads:

Tie rod DW

DW 15 = 90 kN per tie rod

DW 20 = 160 kN per tie rod

DW 26.5 = 250 kN per tie rod

Anchor loop

DW 15 = 180 kN

DW 20 = 320 kN

Fig. 19.3 Fig. 19.4

Fig. 19.5

Fig. 19.2 Anchor loop

Description Ref. No.

Tie rod DW 15/90 ................. 29-900-80

Tie rod DW 20/120 ............... 29-900-97

Tie rod DW 26.5/80 .............. 29-900-75

Anchor loop 15 ..................... 29-001-20

Anchor loop 20 ..................... 29-001-25

M cross stiffener 44 .............. 29-401-02

Twin channel 245/22............. 29-406-30

Twin channel 80/22............... 29-406-35

Twin channel 80/12............... 29-406-38

Fig. 19.1 Tie rod DW

Anchor loop

Twin channel 80/12

Anchor loop, rotated

through 180°

Twin channel 80/12

Tie rod DW

Twin channel 80/22 or 245/22

STB-19Technical Instruction Manual / Status November 2019

STBSupport frame

Anchoring details – General

Fig. 20.1 Anchor holder DW 15 – DW 26.5

Fig. 20.2 Single anchor DW

Description Ref. No.

Anchor holder

DW 15 – DW 26,5 ................ 29-925-80

Single anchor DW 15 ............ 29-925-40

Single anchor DW 20 ............ 29-925-45

Single anchor DW 26.5 ......... 29-925-50

Double anchor DW 15 .......... 29-925-60

Double anchor DW 20 .......... 29-925-65

Planing cap ........................... 29-917-75

Planing cap DW 26.5 ............ 29-917-85

Coupling nut 15 ................... 29-900-55

Coupling nut 20 ................... 29-900-50

Coupling nut 26.5 ................ 29-900-56

Fixed anchor DW 15 ............. 29-926-60

Fixed anchor DW 20 ............. 29-926-65

Fixed anchor DW 26.5 .......... 29-926-70

Fig. 20.4 Planing cap

Anchoring auxiliaries –

Individual parts

ÆAnchor holder

DW15–DW26.5 (Fig.20.1),

attachment to the upper rebar

layer. The use of the anchor

holderDW is recommended for

slab thicknesses greater than

approx.40 cm or for slabs with

a large number and density of

rebars.

It is bent to 45° and can be

used with DW 15, DW 20 and

DW 26.5 tie rods. If the anchor

holder DW with anchor sleeve is

used, it can be used with tie rods

DW15.

ÆSingle/double anchor DW,

attachment to the lower rebar

layer.

For slab thicknesses up to

approx. 40cm we recommend

the use of single anchors

(Fig.20.2) or double anchors

(Fig.20.3).

Maximum loading:

Single anchor DW

DW 15 = 90 kN per tie rod

DW 20 = 160 kN per tie rod

DW 26.5 = 250 kN per tie rod

Double anchor DW

DW 15 = 180 kN

DW 20 = 320 kN

The single/double anchor is bent

to 45°.

ÆThe planing cap (Fig.20.4)

with a 45° end face for use

with tie rods DW15 and DW20

(planing cap DW26.5 for tie

rodDW26.5) is made of rigid

foam and is inserted over the tie

rod or the anchor sleeve before

pouring, allowing a smooth,

level floor slab surface to be

achieved. Once the concrete has

been poured and the planing

cap removed, a coupling nut DW

can now be screwed onto the tie

rod and a second tie rod can be

installed to secure the support

frame.

ÆCoupling nut (Fig.20.5), to

enable the tie rods encased in

the floor slab to be extended.

The nut has a DW thread. Per-

missible load in KN and widths

across flats (WAF) in mm:

Ø 15: 90 kN, WAF 30

Ø 20: 160 kN, WAF 36

Ø 26.5: 250 kN, WAF 46

ÆFixed anchors DW15,

DW20 and DW26,5 (Fig.20.6),

to anchor the tie rods inserted

through the anchor holderDW.

Fig. 20.3 Double anchor DW

Fig. 20.5 Coupling nut Fig. 20.6 Fixed anchor DW

STB-20 Technical Instruction Manual / Status November 2019

STBSupport frame

This manual suits for next models

3

Table of contents

Other Meva Construction Equipment manuals

Popular Construction Equipment manuals by other brands

Auto Crane

Auto Crane 3203EH owner's manual

ECOVOLVE

ECOVOLVE ED1500 Operator's handbook

TUBESCA-COMABI

TUBESCA-COMABI NEOLIUM LINE 200 Assembly & operating manual

Farmi Forest

Farmi Forest FARMI 4571 OPERATION, MAINTENANCE AND SPARE PARTS MANUAL

Conquip

Conquip Base Box 2500 user guide

Terex

Terex HC60 Technical tips