GCE proFIT User manual

STRaIGHT LInE PoRTaBLE CUTTInG MaCHInE GB

TRaGBaRE BREnnSCHnEIDMaSCHInE

FüR GERaDES BREnnSCHnEIDEn DE

Přenosný řezací stroj Pro Přímé řezání kyslíkem

machine d’oxycouPage droite Portable CZ

MaCCHIna Da TaGLIo PoRTaTILE PER TaGLIo DIRETTo aD

oSSIGEno FR

máquina Portátil de corte transversal con oxígeno máquina cortadora

Portátil Para corte recto a oxigénio IT

Portabel skärmaskin för rätlinjig skärning med oxy-fuel

Переносной режущий агрегат для Прямой резки кислородом

Przenośny Półautomat do Prostoliniowego cięcia tlenem

hordozható lángvágógéP oxigénnel történő közvetlen vágásra

INSTRUCTION FOR USE

BEdIENUNgSaNlEITUNg

Návod k použití

MOdE d’EMplOI

ES

PT

SE

RU

PL

HU

MaNUalE d´USO

INSTRUCCIONES dE USO

INSTRUçõES dE USO

BRUkSaNvISNINg

ИнструкцИя по эксплуатацИИ iNstrukcja obsługi HaSzNálaTI úTMUTaTó

Page 1/156

4/222

GB

1. DESCRIPTIon

gCE proFIT®is portable oxy-fuel cutting machine

that cuts unalloyed steel by material combustion

with using of oxygen –fuel gas preheating flame.

This machine can also be used for linear and

circular cutting or for cutting curved (patterned)

profiles (figures) by moving manually or by

installing additional parts. there is an option to use

second cutting torch if necessary.

gCE proFIT®can be used for straight cutting,

curved cutting or bevel cutting with one or two

cutting torches at maximum. Maximal material

thickness to be cut is 150 mm with one cutting

torch and 100 mm with two cutting torches.

Complete machine consists of more parts to be

ordered separately, please see instructions and

recommendation below.

gCE proFIT® machine can also be used for plasma ®

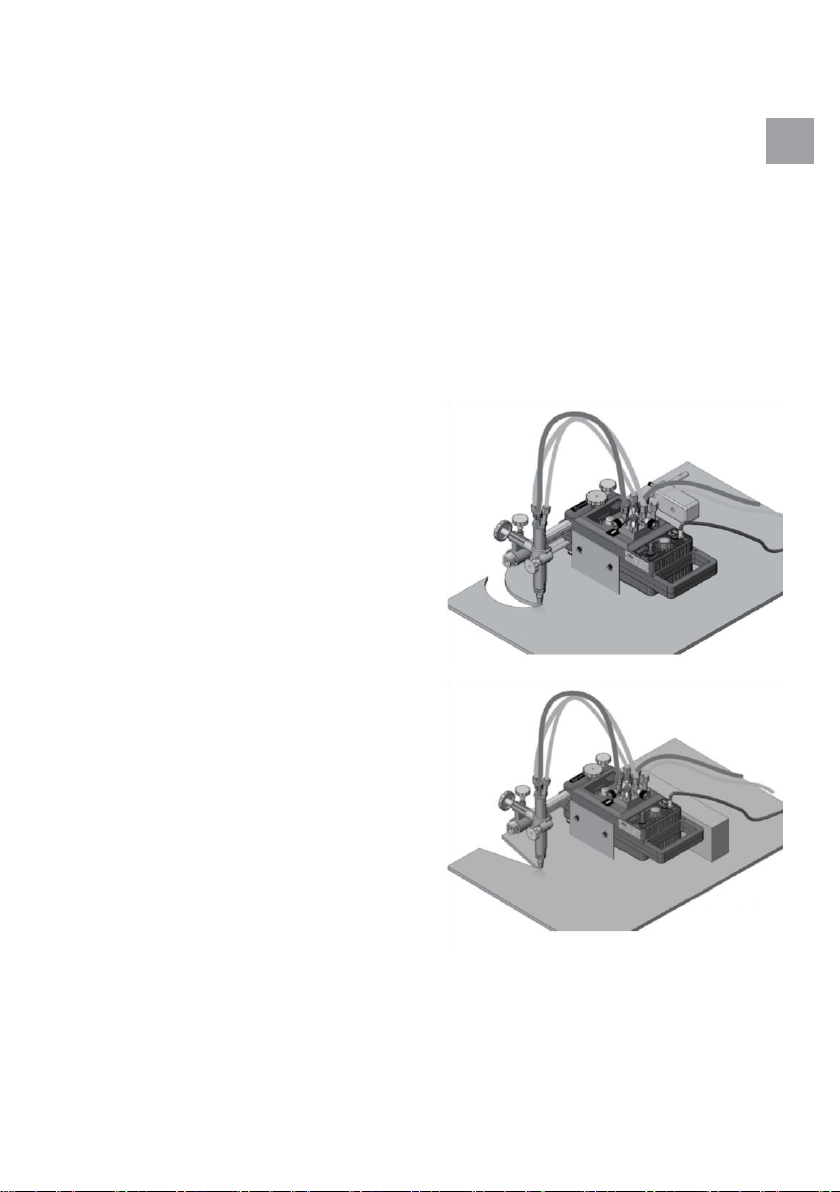

Fig.1 Machine GCE proFIT with Zn-coated guide rail

cutting, preheating and welding but with additional equipment (not supplied with the machine) and by

making necessary changes. these operating instructions explain safe and efficient operation of gcE

proFit® .

GCE proFIT®portable cutting machine should be used taking the

warnings specified in the instructions into consideration.

operators of the machine shall have learnt the content of this Instruction for Use and shall be

experienced with oxy-fuel equipment and trained according to request of iso, en or national

standards with respecting all requests of legal authorities.

2. FEaTURES

2.1 TECHnICaL DaTa

Cutting capacity

Cutting speed

up to 150mm with one torch, up to 100mm with two torches

75 - 700mm/min

Operation

forward and reverse with variable speed

Circle cutting diameter

80 –1340 mm (optional up to 2340mm)

Max. strip width

485mm (cutting with two torches parallel)

power supply

Engine supply

230v aC / 50Hz

24v dC

Oxygen inlet connection

g1/4“, up to 8bar, hose min. dN8

Fuel gas inlet connection

g3/8“LH, up to 1bar, hose min. dN8

5/222

GB

Machine dimensions

180x380x160 (WxlxH) without torch, hoses and torch bar

Weight

13kg with one torch, 16kg with two torches

2.2 basic machine Package includes:

•equipment for one torch-cutting application

•one nozzle-mix cutting torch (only for 548900060001)

•torch holder, torch bar, stainless steel heat shield

•internal gas hoses, gas manifold with shut-off valves

•circle cutting pole, circle centre-piece

•10m electric cable with plug

•nozzle mounting and cleaning accessories

•flame lighter

•guide rail is delivered separately from the machine

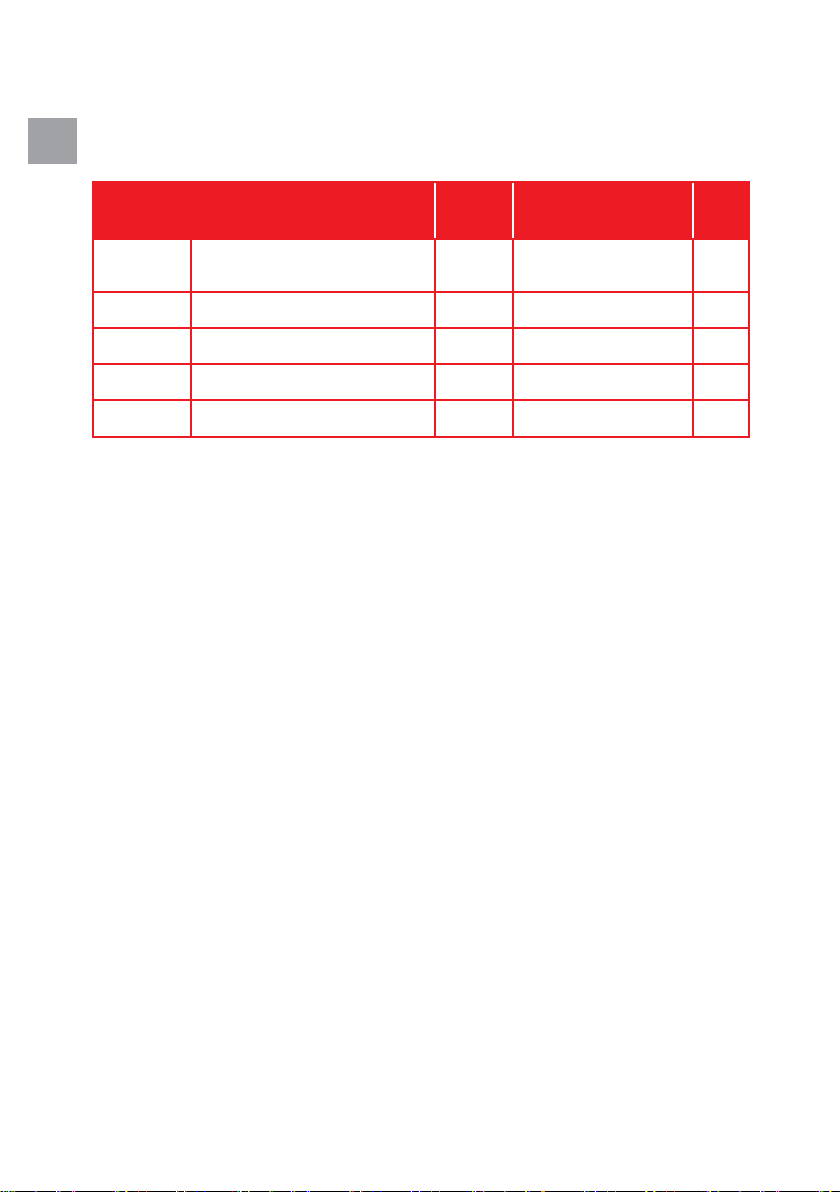

2.3 ITEMS To BE oRDERED

Cutting machines and guiding rail-tracks

art number

Description

548900060001

gCE proFIT®machine with one nozzle mix torch, without track

548900060000

gCE proFIT®machine without torch, without track

304605904

Extension kit for second cutting torch

14088703

guide rail track 2 m, extruded aluminium profile with connecting clip

60010

guide rail track 2 m, zn/coated steel

cutting torches to be ordered with machine 548900060000, see also Fig.2:

Fig.2 Cutting torches

6/222

GB

art number

Description

Gas

type

Recomended cutting

nozzles

Pos.

0766262

Nozzle mix cutting torch

apMYF

aNME, aMd Collex,

pNME, k50pUz

1

0766221

BIR Mini, injector cutting torch

a

aC, (aSd)

2

0766222

BIR Mini, injector cutting torch

pMYF

pUz, (pSd)

2

0766173

FIT Mini, injector cutting torch

a

Ma133

3

0766174

FIT Mini, injector cutting torch

pMYF

Mp133, (MY133)

3

7/222

GB

2.4 MaCHInE CUTTInG RanGE

adjustment

cutting torch vertical movement adjustment:

75mm. distance of cutting torch center from the

edge of body:

•from 40 mm to 170 mm, with one cutting torch

•from 40 mm to 345 mm, with extension kit for

two cutting torches

circle cutting pole adjustment:

•from 40 mm to 670 mm, with one cutting torch

•from 40 mm to 840 mm, with extension for two

cutting torches

distance between cutting torches in case of

extension is used:

•60 mm, with two cutting torches next to each

other at the same side

•485 mm, with two cutting torches opposite to

each other

circle cutting dimensions:

•Ø80 mm –Ø1340 mm, with one cutting torch

•Ø80 mm –Ø1680 mm, with extension for two cutting torches

by adding a circle pole extension piece and second circle pole:

•For one cutting torch: from 40 mm to1170 mm (Ø 80 –Ø 2340 mm)

•For two cutting torches: from 40 mm to 1340 mm (Ø 80 –Ø 2680 mm)

2.5 CUTTInG noZZLES

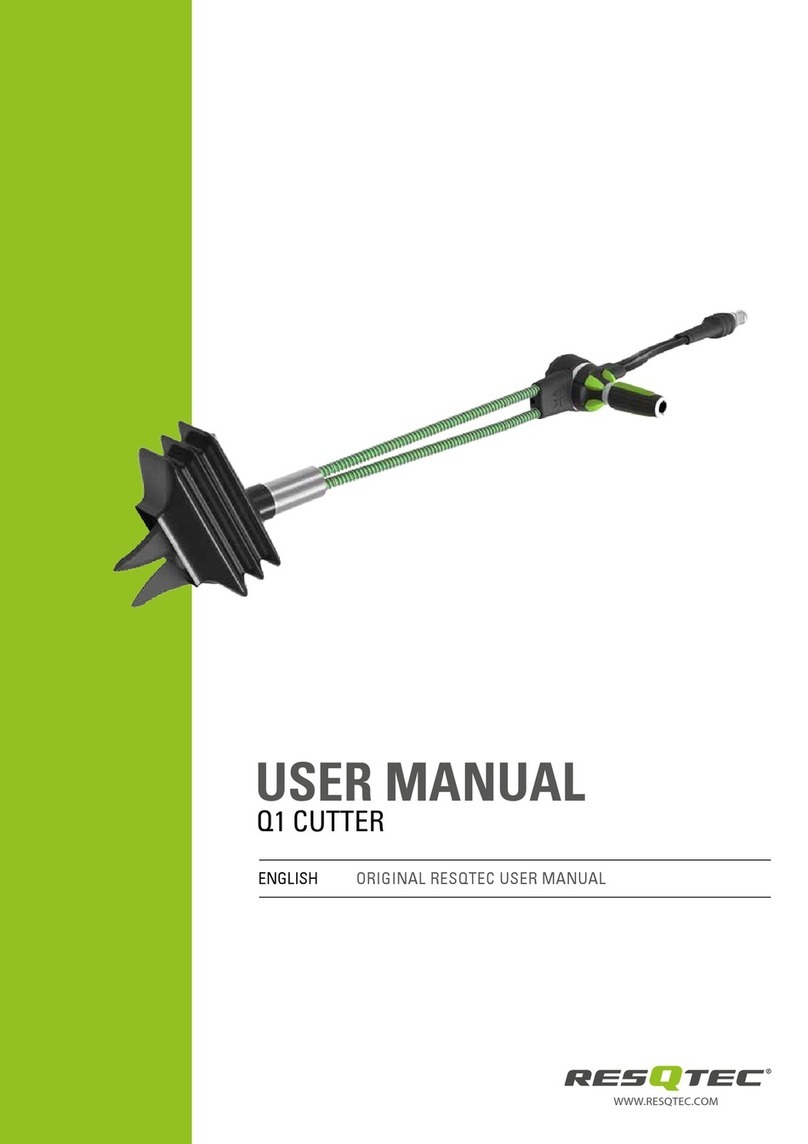

Fig.3: GCE proFIT

®

with one cutting torch

Fig.4: GCE proFIT

®

with two cutting torches

8/222

GB

14001010

14001011

14001012

14001013

14001014

14001015

14001020

14001021

14001350

14001351

14001352

14001353

14001354

14001355

14001147

14001148

3-10

10-25

25-40

40-60

60-100

100-200

3-100

100-300

3-10

10-25

25-40

40-60

60-10

100-200

3-10

100-300

600-730

410-620

340-410

310-340

250-320

210-270

** H. n.

** H. n.

550-600

400-560

350-400

310-340

260-310

180-260

** H. n.

** H. n.

2,0-3,0

4,5-5,0

4,0-5,0

4,0-5,0

5,0-6,0

6,5-7,5

2,0-3,0

4,5-5,0

4,0-5,0

4,5-5,5

5,0-6,0

5,5-6,5

2

2,5

2,5

2,5

3

3,5

2

2,5

2,5

2,5

2,5

3,0-5,0

0,5

0,5

0,5

0,5

0,5

0,5

0,2

0,2

0,2

0,2

0,2

0,3

1,3-1,7

2,3-2,8

2,3-2,8

4,1-5,1

8,1-9,5

12,0-13,0

1,3-1,7

2,8-3,4

2,8-3,4

4,6-5,6

8,1-9,5

12,6-14,4

0,4

0,5

0,5

0,5

0,5

0,6

1,3

1,5

1,5

1,5

1,5

1,7-2,5

0,3

0,35

0,35

0,35

0,4

0,5

0,33

0,38

0,3

0,38

0,38

0,50-0,7

a

a

a

a

a

a

a

a

B

B

B

B

B

B

B

B

* cutting and heating nozzles are delivered separately, cutting nozzles in the 5 pcs package.

** H. n. = Heating nozzle

Pic. A: Injector nozzles

AC*

Fuel gas: A

Use with torch: BIR Mini

A, 0766221

Pic B: Injector nozzles

PUZ*

Fuel gas: PM

Use with torch: BIR Mini

PMYF, 0766222

Pic. C: Injector nozzles

MA133

Fuel gas: A

Use with torch: FIT Mini A,

0766173

Pic. D: Injector nozzles

MP133

Fuel gas: PM

Use with torch: FIT Mini

PMYF, 0766174

Pic. E Mixing nozzles

A-MD Coolex

Fuel gas: A

Use with torch:

Nozzle mix,

60009

Pic. F: Mixing nozzles K50

PUZ and K70 PUZ

Fuel gas: PMYF

Use with torch: Nozzle

mix, 60009

Pic. G: Mixing nozzles

ANME

Fuel gas: A

Use with torch: Nozzle mix,

60009

Pic. H: Mixing nozzles

PNME

Fuel gas: PMYF

Use with torch: Nozzle

mix, 60009

9/222

GB

202150330

202150331

202150332

202150333

202150334

202150335

202150336

202150320

202150321

202150322

202150323

202150324

202150325

202150326

14001450

14001451

14001452

14001453

14001454

14001455

14001456

14001749

14001750

14001751

14001753

14001755

14001761

3-8

8-15

15-30

30-50

50-70

70-100

100-200

3-10

10-15

15-30

30-50

50-70

70-10

100-200

3-5

6-10

10-25

25-40

40-60

60-100

100-150

3-10

10-25

25-40

40-60

60-100

100-200

650-900

600-800

460-680

360-575

340-475

250-365

150-250

600-750

540-635

440-610

380-510

320-460

280-400

150-250

750-800

700-750

500-650

420-500

360-420

270-360

210-270

550-660

400-560

340-400

300-340

260-310

180-260

3-5 5-

6

6-7

6,5-7,5

7,5

7-8

5,5-7,5

4-5 5-

6

6-7

6,5-7,5

7-7,5

7-8

5,5-7,5

2-3

4-5

6,5-7,5

6,5-8

6,5-8,5

6,5-8

6,5-7

2-3

3-4,5

4-5

4,5-5,5

5-6

5,5-6,5

1,5

1,5

1,5

1,5

2,3

2,3

2,0-2,5

0,1-0,8

0,1-0,8

0,1-0,8

0,1-0,8

0,1-0,8

0,1-0,8

0,1-3,8

1

1

1

1

1,5

1,5

1,5

2,5

3

3

3

3

3,5-5,5

0,2-0,8

0,2-0,8

0,2-0,8

0,2-0,8

0,2-0,8

0,2-0,8

0,6

0,1-0,8

0,1-0,8

0,1-0,8

0,1-0,8

0,1-0,8

0,1-0,8

0,1-0,8

0,3

0,3

0,3

0,3

0,3

0,3

0,4

0,3

0,3

0,3

0,3

0,3

0,4

0,25-1,85

2,15-2,6

3,6-4,15

5,2-5,85

7,8-8

11,1-12,3

11,7-15,7

2

2,32-2,6

3,6-4

4,85-5,7

7,4-7,75

11,1-12,3

11,7-15,7

0,4-0,55

1,2-1,4

3,2-3,7

4,6-5,5

5,6-7,1

9,1-11

12,2-12,9

1,3-1,7

1,7-2,6

2,8-3,4

4,6-5,6

8,1-9,5

12,6-14,4

0,55

0,55

0,55

0,55

0,715

0,715

0,75-0,85

2

2

1,6-1,75

2

2

2

2

1

1

1

1

1

1

1

1,4

1,6

1,6

1,6

1,6

1,8-2,6

0,5

0,5

0,5

0,5

0,65

0,65

0,58-0,77

0

0

0,40-0,44

0

1

1

1

0,5

0,5

0,5

0,5

0,7

0,7

0,7

0,36

0,41

0,41

0,41

0,41

0,49-0,7

C

C

C

C

C

C

C

d d

d d

d d

d

E

E

E

E

E

E

E

F

F

F

F

F

F

0768670

0768635

0768599

0768636

0768662

0769494

0769495

0769496

0769497

0769498

3 - 6

5 - 12

10 - 75

70 - 100

90/-150

3-6

5-12

10-75

70-100

90-150

1/32

3/64

1/16

5/64

3/32

1/32

3/64

1/16

5/64

3/32

470/-560

390/-480

205/-400

150/-220

125/-160

430/-150

360/-440

205/-380

150/-220

125/-160

2,5-3,5

2,0-4,0

3,5-4,5

4,5-5,5

5,5/-6,0

2,5/-3,5

3,0/-4,0

3,5/-4,5

4,5/-5,5

5,5/-6,5

0,3

0,3

0,3

0,5

0,5

0,2

0,2

0,2

0,4

0,4

1,25-1,65

2,12-3,2

3,2-4,45

8,4-9,8

9,2/-14,6

1,8/-2,98 3,3/-

4,95

5,0/-4,95

9,4/-12,8

14,0/18,6

0,3

0,4

0,45

0,6

0,75

0,3

0,4

0,45

0,6

0,75

g g

g g

g

H

H

H

H

H

10/222

GB

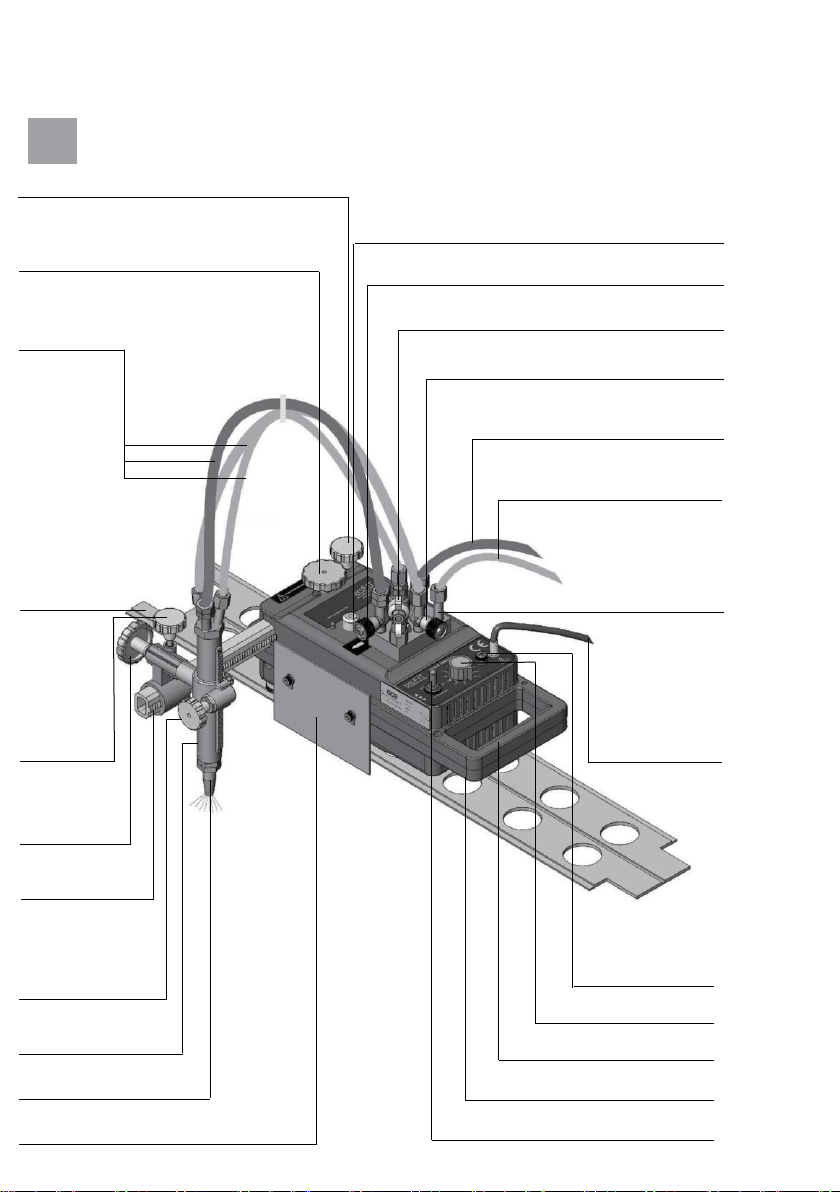

Fuel gas shut-off valve

Cutting oxygen shut-off valve

Heating oxygen shut-off valve

guiding

rail-track

Heat shield

Castor wheel for manual steering

Cutting nozzle

Cutting torch

with rack

Torch height

adjustment

hand-wheel

Forward-backward movement control

Machine body

Fuse (3a)

power cable

with plug (10m)

distance

adjustment bar

Cutting angle

hand-wheel

Torch

holder fixing

hand-wheel

Speed control

Internal gas

hoses

distance adjustment bar set up

handwheel

oxygen inlet connection: g1/4

Fuel gas inlet connection:

g3/8 lH

gas manifold

distance adjustment bar fixing hand-wheel

11/222

GB

Clutch lever

Fig.5: Machine description

3. MaCHInE InSTaLLaTIon

Machine is delivered partly dismounted with cutting torch and arm parts separated. take all parts out of the

pack. install them in sequence as below to operate it.

3.1. Power suPPly

check power supply before connecting the machine to the network (see above the point 2.1. technical data).

only undamaged plug and cable can be connected to the power network. only the way of connection

conforming to national standards shall be used.

description of the colours of the power cable single wires:

•brown: phase

•blue: Neutral

•green / Yellow: Earth

3.2. oxygen and fuel gas suPPly

3.2.1. inlet fuel gas hose should be with 8mm internal diameter at least (depends on the hose length). only

hoses according to iso3821 / EN559 shall be used. Machine hose in let connection is g3/8”LH with fitting

acc. to EN560. For fuel gas pressure and flow-rate follow please cutting nozzles chart with all details above.

3.2.2. Inlet oxygen hose should be with 6mm internal diameter (depends on the hose length and cutting

thickness). only hoses according to iso3821 / EN559 shall be used. Machine hose inlet connection is g1/4”

with fitting acc. to EN560. For oxygen pressure and flow-rate follow please cutting nozzles chart with all

details above (always the higher value should be taken from both heating and cutting oxygen).

note: in order to prevent flashback (flame backfire) hazards, appropriate flashback arrestors should be

used specified in accessories below. note: only undamaged gas hoses with undamaged, clean and properly

fastened fittings shall be used. Tightness of the hoses shall be tested every three months at latest with using

of maximal working pneumatic pressure in water bath. it is recommended to exchange all gas hoses every

three years at latest.

3.3. InSTaLL CaBLE anD InTERnaL GaS HoSES

together e.g. with using of hose brace.

3.4. install cutting torch bar, cutting torch holder and CUTTInG ToRCH

as shown at the pic. 5 to 8 in accordance with requested cutting shape.

3.5. ConnECT InTERnaL HoSES To CUTTInG ToRCH anD GaS ManIFoLD.

as the hose connection of each gas hose is different, it’s not possible to mix them together.

3.6. insert the Power Plug of your machine

to a proper socket (use the type of connection according to national standard). connect inlet oxygen hose

and inlet fuel gas hose to proper supply system. noTE: install your machine to an earthed plug in order to

avoid electrical power hazards.

4. oPERaTIon

4.1. BEFoRE STaRT CUTTInG

4.1.1. the operator shall be aware of safety operation specified in this instruction for use before any handling

with gCE proFIT®. the operator shall be experienced with oxy-fuel equipment and trained according to

request of iso, EN or national standards with respecting all requests of legal authorities.

12/222

GB

4.1.2. only the cutting nozzle according to chart above shall be used. Nozzle-mix/injector type of the cutting

torch has to be respected as well as type of the fuel gas. use only undamaged nozzle with undamaged and

clean seat.

4.1.3. please check also cutting torch head seat before mounting the nozzle into the cutting torch head. only

cutting torch from the list above with undamaged and clean nozzle seat can be used. Nozzle-mix/ injector

type of the cutting torch has to be respected as well as type of the fuel gas.

4.1.4. noZZLE CHooSInG please follow the chart with cutting nozzles above. use proper nozzle size

according to metal plate thickness. gcE cutting nozzles are designed for cuts of quality level 1 according to

EN iso 9013. it is possible to reach

maximal cutting speed by set-up cutting

parameters according to chart above,

cutting of straight cuts, by using of clean

metal sheet surface, quality cutting

machine, undamaged cutting nozzle and

oxygen with purity 99,5% or better. gas

pressures are measured at the torch

inlet.

4.1.5.tightening torque of the nozzles:

Nozzle-mix cutting torch: 22-30 Nm cutting

torch Fit Mini: 22-30 Nm cutting torch bir

Mini: 12 Nm for inner cutting nozzle and

18Nm for outer heating nozzle.

noTE: all parts in contact with oxygen should

be free of oil and grease due to explosion

hazards! check whether all threaded joints

and sealing surfaces, e. g. cones and balls,

are clean and undamaged!

4.2. FLaME IGnITIon anD SET UP

4.2.1. check all gas connection tightness.

4.2.2.adjust inlet gas pressures according to

the values in the table of cutting nozzles

above, see point 2.5. (1 bar = 1,05 kpa

100kpa = 105 N/m2, 1 bar = 14,22 psi). the

operating pressures for the heating oxygen

and fuel gas should be adjusted with open

torch valves. Open the fuel gas valve and

heating oxygen valve. ignite the outgoing

mixture with proper lighter supplied with the machine. With correct pressure adjustment is produced

carburizing flame. a neutral heating flame is to be adjusted with the fuel gas valve to suit the cutting task.

the heating oxygen valve remains fully open. Use a proper lighter given along with the machine to ignite the

flame. do not use hot metal or matchstick.

4.2.3. Open shortly the cutting oxygen valve to see correct adjustment of neutral flame and close it

afterwards (see also Fig.6).

4.3.CUTTInG PRoCESS InITIaTIon

Bring the torch to the initial cutting position and start locally heating the workpiece to the ignition

temperature, approximately bright red / yellow colour. then open the cutting oxygen valve and switch on

the feed in the same moment.

4.4. THE CoRRECT CUTTInG SPEED

can be seen from the slag production, from the Fig.7: Zn coated track extension almost vertical spray of sparks

and from the cutting noise. the approximate values of the cutting speed can be taken from relevant cutting

nozzle table as above.

Fig.6: Flame adjustment

Carburazing fl

ame

during ignitin

g

Neutral flame

Neutral flame wit

h

cutting oxygen jet

approx. 1 mm

Workpiece

Straight

edge

13/222

GB

4.5. striPs cutting with guiding rail

4.5.1. place the rail on the part to be cut. if there is a need for a length more than 2m then connect the second

rail with the first as shown on Figure 7.

4.5.2. place gCE proFIT®on the rail. Make sure that front and rear wheels fit in the rail furrows.

rear wheel should fit,wthat it doesn’t move.

4.5.3. adjust the cutting speed in relation to particular nozzle and material thickness. adjust also movement

direction. turn clutch lever to the direction of arrow to stand-by position.

4.5.4. set the cutting torch on the metal sheet at the place of cut start. ignite and set pre- heating

flame as required according to instruction above. preheat the material on the ignition temperature.

4.5.5. Fully open cutting oxygen valve in the same time and start moving machine by switching of

movement control knob in requested direction as shown on the Figure 3 or 4.

4.5.6. after the cutting is over, stop the machine by bringing the movement control switch in central position,

shut all the gases of. gas valves shall be closed in following sequence: 1. cutting oxygen, 2. fuel gas,

3. heating oxygen.

4.6. striPs cutting with beam

(profile) guidance (see Figure 8)

4.6.1. use a metal profile which is 15 mm high at

least and fix it on the metal sheet according to

Figure 8.

4.6.2.Smooth edges of the metal beam should be

300 mm away from the edge to be cut.

4.6.3. Castor wheel should be slightly leant to the

template so that it moves to lean on the beam

when the machine moves backward.

4.6.4. continue according to points 4.5.3. –4.5.6.

4.7. CIRCLE anD RaDIUS CUTTInG

4.7.1. Install the components of circle pole and

centre piece as shown in Figure 9 for circular and

Fig.9: Circle cutting radius cutting. if circles with

small diameters are to be cut, then cutting torch

should be installed on the side of circle pole.

4.7.2. Make a punch sign on the center of the

circle to be cut which is 1.5 mm deep and 60

degree angle. disengage the revolving wheel and

place gCE proFIT®on the metal sheet.

4.7.3. It is recommended to drill 3 mm hole at the

place of cut start-end to ensure smooth cut

connection. it is possible to pierce also material

directly by oxygen which is usually recommended

for metal sheets with thickness below 80mm.

4.7.4. place the machine at the cut start point to

have cutting nozzle in exact position against the

drilled hole. start cutting according to points 4.5.3.

–4.5.6.

Fig.8: Cutting with beam guidance

14/222

GB

4.8. manually guided cutting

gCE proFIT®can be guided manually by the operator for free pattern cut over the outer line of the

pattern to be cut. castor wheel is to be adjusted

free for all directions and all of the three wheels

should be in contact with the panel. see also

Figure 10.

4.9. PREPaRInG oF THE METaL

sheet edges before welding

–bevel cutting with one torch (without weld root

face creation). prepare gCE proFIT® according to

point 4.5. above. Lose a bit the cutting angle

hand-wheel and turn the torch with the torch

holder to get requested angle. then tighten

properly again cutting angle hand-wheel. proceed

according to point 4.5. afterwards

4.10. cutting with two ToRCHES

In case the gCE proFIT®machine is equipped for

only one torch cutting operation, it is necessary to

mount Extension kit with second torch (part

number 304605904) first (see Fig. 11).

Please follow the steps:

1. dismount gas manifold for one torch from

the machine body and hoses from the

manifold.

2. Remove torch holder with torch from

distance adjustment bar and take the bar

from the machine.

3. Install second heat shield (6) at the

second side of the machine, opposite to

existing heat shield using distance

washer (7), imbus screw M6x20, washer

and spring washer (8, 9,10).

4. Mount gas manifold for two torches (1) on

the machine body.

5. put distance adjustment bar for two

torches into the machine.

6. Install both torch holders with cutting

torches at the distance adjustment bar.

7. Connect both torches and gas manifold Fig.11: Extension kit with second cutting torch with proper gas

hoses.

8. use proper cutting nozzles according to point 2.5 above. gcE proFit®machine with two

torches can be used for bevel cutting and for strip cutting as shown at the Figure 12.

Fig.10: Manually guided cutting

15/222

GB

Fig.12: Bevel cutting and strip cutting with two torches

noTE: in case when two torches are to be used too close to eachother, the required distance can be

adjusted this way that the first torch holder is directed to the front and the second one to the back of the

machine.

5. MaInTEnanCE

5.1. daily

•Continuously check the tightness of the nozzle-torch seat

•Wipe gCE proFIT®with a cloth to clean it from slag and metal oxides.

•check if there are damages in the hoses and electric cable. Exchange damaged parts.

•Lubricate the spindle of rotating wheel with shell “vitrea 31” or its equivalent.

5.2. monthly

•Make sure that vertical and horizontal torch movement is going well and all hand wheels are functional.

•clean torch rack, distance adjustment bar and all parts of the torch holder.

•check tightness the gas hoses and gas manifold incl. adjustment valves. tighten leaking connections and

replace the damaged parts.

5.3. quarterly

•dismount the clutch lever and screws and separate the upper part of the machine body from the lower part.

(make sure that motor cables are not stretched).

•clean the interior parts of the machine carefully without damaging the speed control unit.

16/222

GB

•

lubricate the engine connection parts, gears and clutch with a

molybdenum-disulphide based lubricant as a precaution.

•

reinstall body lids without compression any cables. connect

clutch lever.

•

Lubricate front and rear wheel bearings components.

•

Check if machine works properly and check gas tightness before

starting operating gCE proFIT

®

.

voltage changing

a proper transformer for 240v and 110v aC is installed within the

machine. the machine

is set for the voltage specified on the

identification label placed on the body of the machine. Following this

instruction to change the voltage of the machine:

•

dismount clutch lever and screws and separate upper part of the

machine body from

the lower part.

•

Change the position of electric cable from the switch panel as

shown in Figure 13.

•

Mount the upper and lower lids of the body together after closing

them.

•

Change the voltage marking on the

identification labels.

when separating the upper and lower parts of the body, make

sure that motor cables are not stretched.

note:

it is useful to mark on the identification shield the new voltage

value after changing . connecting machine to a wrong voltage can

lead to failures or caused dangerous conditions for the operator.

ELECTRICaL DIaGRaM

6.

Fig.13: Changing of the voltage

240V-110

V

110

v

v

240

7.

TRoUBLE SHooTInG

8.

v Control panel

240

110

v Control panel

17/222

GB

Failure

Cause

Repair

drive wheel

does not turn

Cable connections are loose

check the solder of the cables.

defective commutator

check the cable connection.

check the commutator with a test

device.

Failure of the main electric cable

Check the main electric cable with a

test device.

defective motor

check it with a test device. check if the

motor spindle rotates.

Ragged

Cutting

Surface

(see also

adjustment

recommendation

below)

a ragged surface

unfitting rail

Make sure that the surface to be cut is

smooth enough for the rail to fit

Rotating speed of the motor is

wrong

check or replace the control units.

External vibration

Stop vibrations

Wrong cutting parameters

adjustments

check the speed of cutting with the

ruler.

abnormal delays in propulsion

gear component

repair it or get it repaired.

distortion of the torch

replace it.

9. storage, carrying and transPortation

9.1. Packing

gCE proFIT®is surrounded by preservations all around

the box. cutting machine body is in the box separated

from the accessories; the box is divided into two parts.

9.2. SToRaGE

If the cutting machine is not going to be used for a long

time, keep the electric components, torch and nozzles

in the box to protect them from dust, humidity and other

impurities.

9.3. carrying

keep the product in the box to prevent failures arising

from shocks and vibrations during carrying.

9.4. TRanSPoRTaTIon

keep the product properly in its box to prevent it from

damages during transportation.storage, carrying and

transportation

Fig 14. An example of packing

18/222

GB

10. safety instruction

10.1. PRECaUTIonS oF oPERaTIon anD USInG

•Fix the machine position and install the machine properly before starting to use and check.

•Make sure that the switch is in “middle” position before inserting the plug into power socket.

•keep these operating and safety instructions with you when operating the machine.

•do not carry the machine while flame is on.

•prevent metal pieces or burr fall if the machine is working above the floor level.

•be very careful when transporting the machine to another place.

10.2. Protection Precautions regarding electricity system

•check the network voltage power before starting using. Maximal voltage variations should be ±10% of

the specified voltage. Machine shall not be used with different voltage.

use cutting machine only with the specified voltage.

•Earthen the cable of your machine.

•Send the machine to the authorized Service or the dealer you bought the machine from when following

situation happen:

•broken or worn cables.

•if water drips from your machine or if water leaks into the machine.

•if you see there is something wrong about operation in spite of proper operation.

•if the machine breaks down.

•complicated fault requiring repair.

•periodically check the electricity system.

10.3. MaInTEnanCE anD ConTRoL PRECaUTIonS

•assign a competent authorized person for maintenance and control.

•remove the plug from the socket before machine body opening and machine repair.

•apply periodical maintenance to the machine.

only use the proper cutting torch and nozzles. Respect the fuel gas type when choosing torch and

nozzle.

safety suits

•safety suits (gloves, protective glasses with proper light filter, helmet, and protetive shoes) shall be

used by operator during cutting operation.

•Wet clothes can lead to electricity accidents.

•keep the clothes free of oil and grease to avoid reaction with oxygen

11.

19/222

GB

12. Precautions which shall be taken in working aREa

•keep the flame away from the gas source, keep at least 3m safety distance (gas cylinders, pipeline, and

hoses)

•do not expose acetylene cylinder, pipeline, hoses and tubes to temperatures higher than 50°c (130°F).

•oxygen does not catch fire by itself, however in case of contact with another flammable material it easily

catches fire.

•Make sure that rate of oxygen within the working area is not higher than the rate in atmosphere.

•Flame forming as a result of contact of oxygen with lubricant, grease or other hydro-carbons lead to fire

and explosions. keep all components which can be in touch with oxygen free from oil and grease.

•oxygen, propane, propylene and their mixtures are heavier than air.

•ventilate the working room sufficiently during cutting.

•keep fire extinguisher, sand, water, etc. available in working area.

•keep flammable materials away from the location of cutting and from the sparks.

it is strongly recommended using of flashback arrestors for all gases. arrestors are to be mounted at the cutting

torch inlets. it is also recommended and according to local rules also mandatory to use flashback arrestors

mounted at the pressure regulator or pipeline outlet point.

flashback arrestors for machine cutting torches en 730-1

art number

Gas

Connection (En 560)

14008408

Cutting oxygen

g3/8”

14008263

Heating oxygen

g1/4”

14008278

Fuel gas

g3/8” LH

safety labels

Relevant labels are post on the machine for

proper using. Follow the instructions as necessary

and do not take out the labels while using the

machine. Make sure that the labels are always

clean and legible.

13.

flashback arrestors

14.

20/222

GB

adjustment recommendation for Perfect machine cutting

narrowing of kerf

(divergent)

•Forward speed of torch

too fast

•distance between nozzle

and sheet metal too big

•dirty and / or damaged

narrowing of kerf

(convergent)

•Forward speed of torch

too fast

•distance between nozzle

and sheet metal too big

•Cutting oxygen pressure

too high

Concave cut surface

beneath top edge

•Cutting oxygen pressure

too high

•dirty and / or damaged

nozzle

•distance between

nozzle and sheet metal

too big Step at bottom

edge

•Forward speed of torch

too fast

•dirty and / or damaged

nozzle

Melted down top edge

with adherent slag

•Cutting oxygen pressure

too high

•Heating flame too strong

•distance between nozzle

and sheet metal too big

Lower edge rounded

•Cutting oxygen pressure

too high

•Forward speed of torch

too fast

•dirty and / or damaged

nozzle

Excessive cut drag line

depth

•Forward speed of torch too

fast or irregular

•distance between nozzle

and sheet metal too small

•Heating flame too strong

Excessive cut drag line

depth

•Forward speed of torch too

fast or irregular

•distance between nozzle

and sheet metal too small

•Heating flame too strong

Single gouges

•Forward speed of torch

too slow

•Scaled or corroded or

dirty sheet metal surface •distance between nozzle

and sheet metal too small

•Flame too weak

•Flame extinguished with

a ban

concave cut surface profile

•Forward speed of torch too

fast

•dirty and/or damaged

nozzle or nozzle size too

small for the thickness to be

cut

•Cutting oxygen pressure too

low

irregular cut surface profile

•Cutting oxygen pressure too

low

•dirty and / or damaged

nozzle

•Forward speed of torch too

fast

Edge melting on

•Forward speed of torch too

slow

•Heating flame too strong

•distance between nozzle and

sheet metal too big to too

small

•Nozzle size too big for the

thickness to be cut

string of solidified droplets

• Heating flame too strong

•distance between nozzle

and sheet metal too small

•Scaled or corroded sheet

metal surface

nozzle

Table of contents

Languages:

Other GCE Cutter manuals

Popular Cutter manuals by other brands

Alpha Professional Tools

Alpha Professional Tools ESC-150 instruction manual

JMA

JMA VOLGA BIT user manual

ICS

ICS SpeedHook 814PRO Operator's manual

Mejix

Mejix CMER 200B Original manual translation

Mul-t-lock

Mul-t-lock KC5 User's operation manual

Gastrodomus

Gastrodomus TA25K Installation, use and maintenance