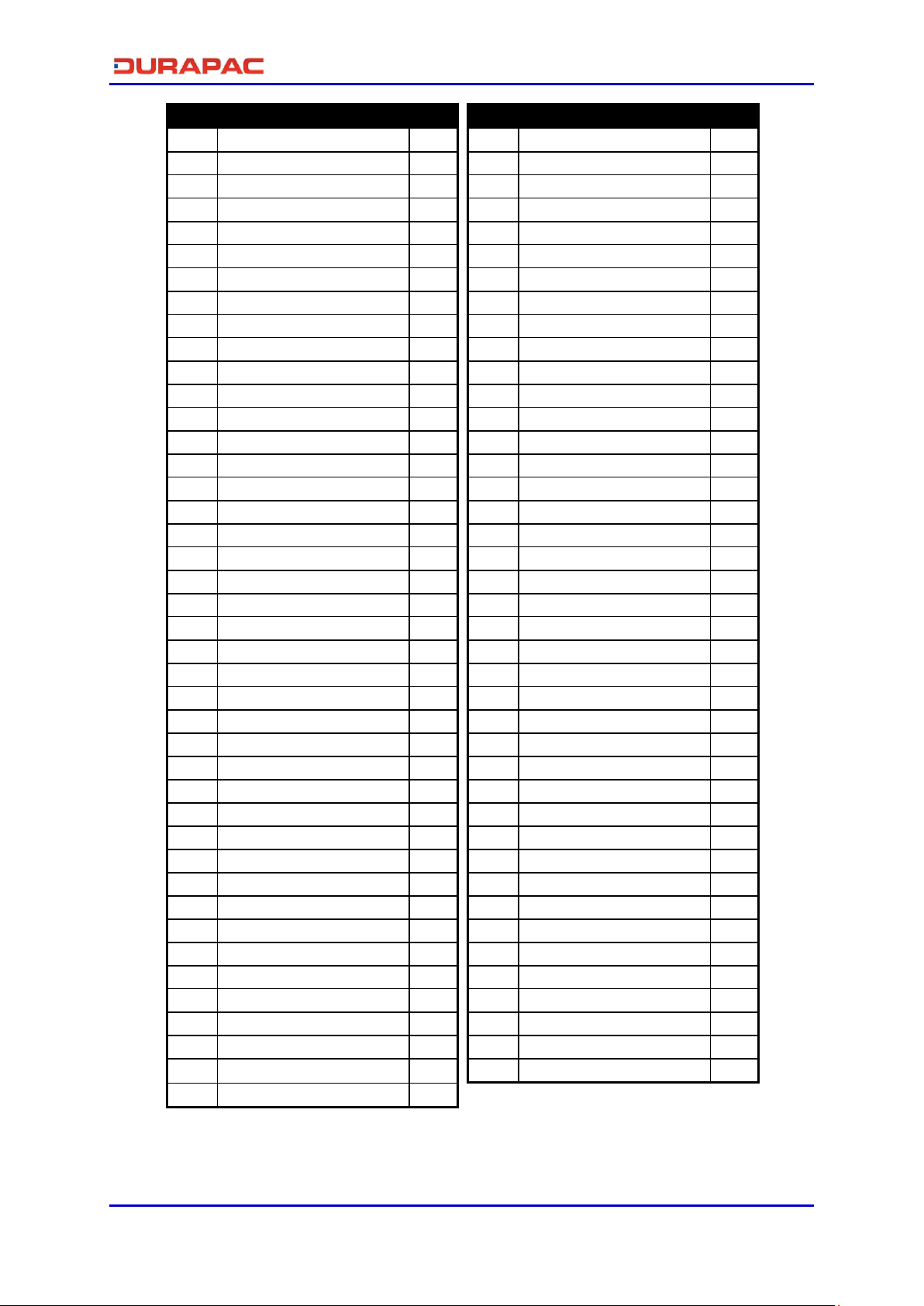

Item Description Qty Item Description Qty

1 Blade guide 1 44 O-ring 1

2 Fixing blade 1 45 Compression spring 1

3 Blade guide 1 46 Ball 3

4 Screw 4 47 Ball seat 1

5 Chain 1 48 O-ring 2

6 Hook 1 49 Back-up ring 2

7 Locating plate 2 50 Valve screw 1

8 Moving blade 1 51 O-ring 1

9 Dust seal 1 52 Ball 1

10 Cylinder cover 1 53 Screw 1

11 Spring washer 1 54 Solid filter 1

12 Hex. nut 1 55 Oil screen 1

13 Screw 2 56 Push-in fastener 1

14 Blade guide 1 57 Extension tube 1

15 Ball 2 58 Spring pin 1

16 Compression spring 1 59 O-ring 1

17 Screw 1 60 Valve screw 1

18 Arresting lever 1 61 Compression spring 2

19 Buckle 1 62 Screw 1

20 Screw 1 63 O-ring 1

21 Spring pin 1 64 Valve screw 1

22 Hinge pin 1 65 Oil reservoir 1

23 Compression spring 1 66 Magnetic bar 1

24 Locating screw 1 67 Filler cap 1

25 Main piston 1 69 Fibre glass pipe 1

26 Back-up ring 1 70 Handle grip 1

27 O-ring 1 71 Insulation cap 1

28 Valve screw 2 72 Cap 1

29 Compression spring 2 73 Spring pin 1

30 Ball 2 74 Hinge pin 1

31 Cylinder body 1 75 Bushing 4

32 Compression spring 1 76 Crescent 2

34 Pump piston 1 77 Arresting pin 1

35 Back-up ring 1 78 Conical pin 1

36 O-ring 1 79 Torsional spring 1

37 O-ring 1 80 Guide bolt 1

38 Back-up ring 1 81 Release pin 1

39 Locating screw 1 82 Fibre glass pipe 1

40 Release valve stem 1 83 Spring pin 1

41 O-ring 1 84 Handle grip 1

42 Relief valve set 1 85 Washer 1

43 Compression spring 1