Techno CNC Systems Titan NK105G3 User manual

1Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series Manual

NK105G3

Techno CNC Systems, LLC ©2019

This document will provide a quick guide to the set up and operation of the Techno Titan Series

CNC router equipped with the NCstudio G3 controller.

TITA

N

Series CNC Router Manual

2Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series Manual

NK105G3

TABLE OF CONTENTS

Forklift Guide ............................................................. Page 3

Safety Instructions ............................................................. Page 4

Colleting Guidelines ............................................................. Page 5

1. Techno Titan Series Quick Setup ........................................... Page 6

Techno Titan Series Installation ..........................Page 7

2. Vacuum Pump Installation ............................................ Page 10

3. Enabling the Titan Series ............................................ Page 11

4. Titan Series Start Up ............................................ Page 12

5. NK105G3 Controller ............................................ Page 13

Single Keystroke Functions ............................................ Page 14

Movement Keys ........................... Page 15

Shift Commands / Combination Keystrokes ........................... Page 16

Execution Keys and Menu Navigation ........................... Page 17

6. Operating Tutorials

6.1- Switching Movement to Step or Jog ......... Page 18

6.2- Jogging the Machine and Changing from High/Low J Page 18

6.3- Stepping the machine ........................... Page 18

6.4- Modifying the Jog Speed and Step Size ........................... Page 19

6.5- Feedrate Override ........................... Page 19

6.6- Adjusting the XYZ Position/WCS/User Origin ......... Page 20

6.7-LoadingaG-codele .............................................Page21

6.8- Running a G-code File ........................... Page 22

7. Advanced Tutorials

7.1- Alternating bet. Override/Programmed Feedrates ..............Page 23

7.2-SettingOverridespeedforaG-codele .............Page24

7.3- Manually Changing Tools ............. Page 26

7.3.1- Removing and Inserting tools into the Spindle ............. Page 26

7.3.2- Using The Automatic Toolchanger Function ............. Page 27

7.3.3- Tool Change Parameters and Settings ............. Page 28

7.4- Setting Tool Lengths ............. Page 29

7.4.1- Tool Length Measuring Settings ............. Page 29

7.5 How to use the 6 work coordinates ................................................. Page 30

7.6 How to use the Select functions ................................................. Page 31

4th Axis Rotary Table Set Up ................................................... .Page 32

8. Maintenance Information

8.1- Lubricating the X-Y Rack and Pinion .............. Page 33

8.2- Lubricating the X-Y-Z Rails .............. Page 33

8.3- Lubricating the Z Ballscrew .............. Page 34

8.4- Recommended Lubricants ................. Page 34

Parameter and Settings .................................................................... Page 35 - 40

Notes on G-Code .....................................................................Page 41

Becker Vacuum Pump Information ...................................................Page42-49

Troubleshooting .....................................................................Page 50

Warranty .....................................................................Page 51

3Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series Manual

NK105G3

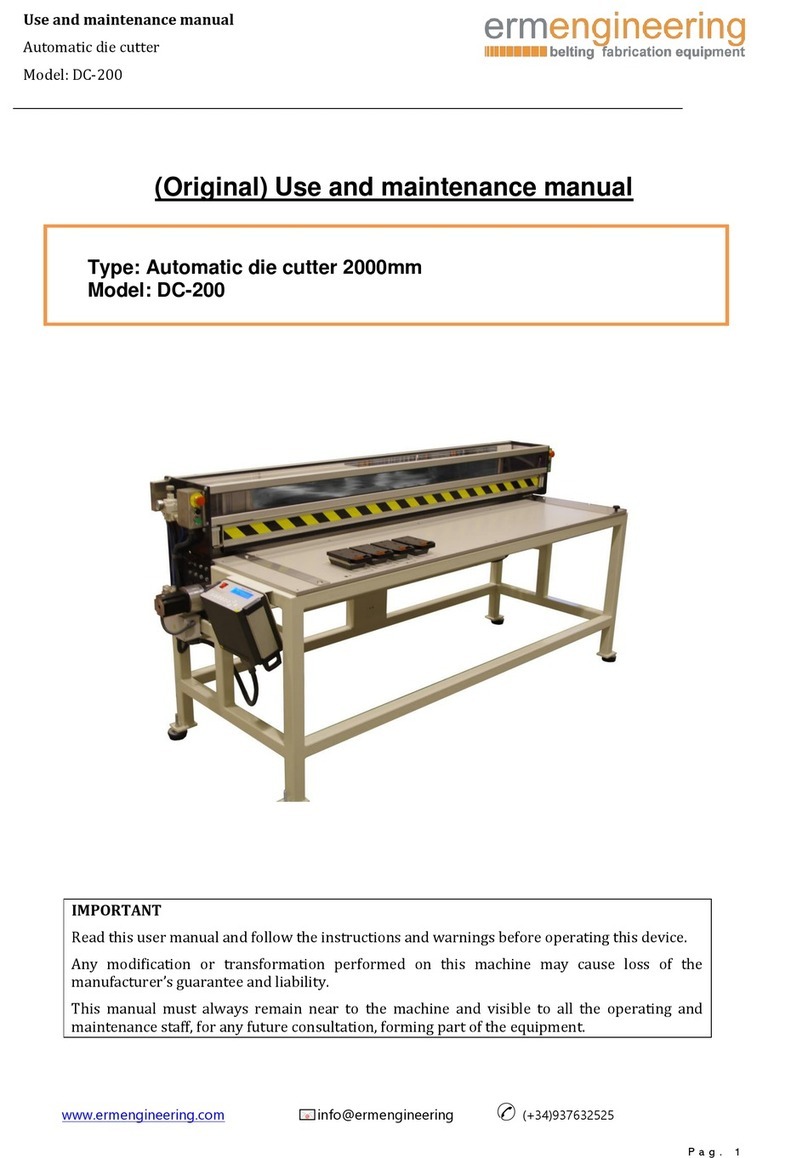

Techno CNC Systems Titan

Series Forklift Guide

SAFETY WARNING:

DO NOT LIFT MACHINE OR MOVE

MACHINE BY THE GANTRY

For safety and to prevent damage to the machine, Lift Machine Using The Forklift Tubes or Frame

ONLY

** The side of the Titan Series CNC Router may NOT have forklift tubes. Make sure forklift blades

enter through the frame of the machine only. Use blocks when lifting machine to prevent

damage to the vacuum table plumbing **

Install Leveling Feet When

Placing Machine

Cable Carrier Tray May Not Be Bolted To Frame. This SHould Be

Completed When Machine is Elevated

LIFT TITAN FROM

FRONT

1- a 5000LB CAPACITY OR LARGER FORKLIFT IS

RECOMMENDED

2-ONLY LICENSED FORKLIFT OPERATORS SHOULD

USE FORKLIFT

3-GREAT CARE MUST BE TAKEN WHEN LIFTING

MACHINE TO PREVENT INJURY AND EQUIPMENT

DAMAGE

4-WHEN LIFTING FROM FRONT, PLACE FORKS INSIDE

FORKLIFT TUBES ONLY!

5-MACHINE INCLUDES LEVELING FEET THESE

SHOULD BE INSTALLED WHEN MACHINE IS PUT

IN ITS FINAL DESTINATION

LIFT TITAN FROM

SIDE

1- a 5000LB CAPACITY OR LARGER FORKLIFT IS

RECOMMENDED

2-ONLY LICENSED FORKLIFT OPERATORS SHOULD

USE FORKLIFT

3-GREAT CARE MUST BE TAKEN WHEN LIFTING

MACHINE TO PREVENT INJURY AND EQUIPMENT

DAMAGE

4-IT IS RECOMMENDED TO HAVE FORK LIFE EXTENSIONS.

5- WHEN LIFTING MACHINE FROM SIDE PLACE WOOD BLOCKS

BETWEEN THE FORK AND STEEL FRAME TO PREVENT

DAMAGE TO VACUUM PIPING. GREAT CARE MUST BE

TAKEN WHEN LIFTING FROM SIDE TO PREVENT DAM-

AGE TO WIRING. FORKS MUST EXTEND ALL THE WAY

THROUGH FRAME.

WARNING: WHEN LIFTING FROM SIDE WEIGHT MAY BE

UNBALANCED.

6- MACHINE INCLUDES LEVELING FEET! THESE SHOULD

BE INSTALLED WHEN MACHINE IS PUT IN ITS FINAL

DESTINATION

4Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series Manual

NK105G3

1. Keepngers,hands,andallotherobjectsaway

from machine while power is on.

2. Disconnect power to all system components

when not in use, when changing accessories, and

before servicing.

3. Do not loosen, remove, or adjust machine parts or

cables while power is on.

4. Exercise care with machine controls and around

keyboard to avoid unintentional starting.

5. Make sure voltage supplied is appropriate to

specicationsofcomponents.

6. Machines must be plugged into three-pronged

grounded outlets. Do not remove the grounding

plug or connect into an ungrounded extension

cord.

7. Keep cables and cords away from heat, oil, and

sharp edges. Do not overstretch or run them

under other objects or over work surfaces.

8. Useproperxturesandclampstosecurework.

Never use hands to secure work.

9. Do not attempt to exceed limits of machine.

10. Do not attempt to use machine for purposes

other than what is intended.

11. Use machine only in clean, well-lit areas free

fromammableliquidsandexcessivemoisture.

12. Stay alert at all times when operating the

machine.

13. Always wear safety goggles.

14. Donotwearloose-ttingclothingwhen

operating machine. Long hair should be

protected.

15. Always maintain proper balance and footing

when working around the machine.

16. Maintain equipment with care. Keep cutting

tools clean and sharp. Lubricate and change

accessories when necessary. Cables and cords

should be inspected regularly. Keep controls

clean and dry.

17. Before using, check for damaged parts. An

authorized service center should perform all

repairs. Only identical or authorized replacement

parts should be used.

18. Remove any adjusting keys and wrenches before

turning machine on.

19. Do not operate the machine unattended.

20. Follow all safety instructions and processing

instructions in the MSDS for the material being

processed.

21. Use proper precautions with dust collection

systemstopreventsparksandrehazards.

22. Makesuretohaveproperreextinguishing

equipment on hand at all times.

WARNING: IMPROPER OR UNSAFE OPERATION OF THE MACHINE WILL RESULT IN

PERSONAL INJURY AND/OR DAMAGE TO THE EQUIPMENT.

READ THESE INSTRUCTIONS THOROUGHLY BEFORE OPERATING MACHINE. DO

NOT OPERATE MACHINE IF YOU ARE UNFAMILIAR WITH THESE SAFE OPERATING

INSTRUCTIONS. DO NOT OPERATE MACHINE WITHOUT KNOWING WHERE THE

EMERGENCY STOP SWITCH IS LOCATED.

PREVENT FIRE HAZARDS by using the proper feeds, speeds, and tooling while operating your

Techno machine. For example, setting feeds and speeds too low and/or using dull tool bits

createsfriction at the material.Thefriction generatesheatwhich can resultin a re that can

be drawn through the vacuum table or dust collector without warning. Fire hazard from friction

heating caused by dull tools is possible when cutting certain materials, especially composite

material such as wood composites, MDF and Particleboard. © 2012

SafetyInstructions

5Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series Manual

NK105G3

WARNING!

THE SPINDLE WILL BE DAMAGED

IF UNBALANCED EQUIPMENT IS USED.

AIR SUPPLY MUST BE FILTERED AND DRY.

6Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series Manual

NK105G3

L1 L2 L3

Fig. 1.1

Enclosure

The Techno Titan Series CNC Router is powered by 220 Volt AC. Unless specially requested, the

electronics require 3-phase power.

The Electronics are housed in the large NEMA enclosure

as shown in Figure 1.1. When unpacking the machine avoid

twisting the cable carrier that guides the cables to the

motors.

Haveasuitablyqualied

person connect the 220V

to the shown terminals.

Make sure that all local

electrical codes are obeyed.

For single phase machine,

connect power to L1 and L3

only.

1.1

1.3

I. TECHNO TITAN SERIES QUICK SETUP

Unpack the hand-

held controller

(shown in Fig 1.4)

and carefully

attach this to the

controller board.

(shown in Fig 1.5).

1.4

Fig. 1.4

Fig. 1.3

Guide the cable through the hole

on the side of the enclosure and

attach the hand-held controller to

the DB 15 terminal.

1.5

Fig. 1.5

Open the rear of the controller

using the provided key located

around the emergency stop

button or inside of the tool box.

You will now have access to the

electronics that drive the CNC.

They will be identical or like

depending on the model issued.

(shown in Fig. 1.2).

The terminals for the

220 volt connection are located

at the bottom of the box

(shown in Fig.1.3)

1.2

Fig.

1.2

1.6

If the machine has a vacuum

hold down pump, there is a

matching connector that will

plug into the controller box

(shown in Fig.1.6). Vacuum Starter

Connection

Fig. 1.6

7Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series Manual

NK105G3

I.I Techno Titan Series Installation

2.1

Removethecontrollerandplaceitontheoortotheleftofthemachine.

When unpacking the controller, avoid twisting the cable carrier that guides the cables to the motors.

Carefully remove the Titan from its wood pallet. Be sure to remove the bolts from its four leveling feet

insertion holes, as well as anything stowed under the Titan during shipping.

Remove all bubble wrap, foam and strapping from the machine.

Attached the provided leveling feet to the six legs and adjust accordingly until the table is level.

2.1a

Remove the four brackets used to stabilize

the gantry during shipping using metric allen

wrenchs. (Fig. 1.1a)

Fig.1.1a

8Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series Manual

NK105G3

2.3

Take the black connector coming from the

Handheldcontroller(g2.3a,)andguideit

through the hole in the side of the control cabi-

net.

Locatethecontrollerboard(g2.3b)andattach

the block connector as shown by the red arrow.

Fig. 2.3a Fig. 2.3b

2.2

Open the back of the controller box (shown in Fig 2.2a) with the key provided. The

electronicswillnowbeexposedandcomponentsidentiedinFig2.2b.

Fig. 2.2a

Fig. 2.2b

A- Controller Board.

B- 24Volt PSU.

C- Stepper Driver.

D- 220Volt In.

9Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series Manual

NK105G3

2.4

Haveaqualiedelectricianattach208-230

Volts, 3-phase to the terminal on the bottom

of the box (Fig 2.4.)

Ifthemachinehasbeenmodiedforsingle

phase operation, then L1, L3 and GND are

used, and nothing is attached to L2.

Fig.2.4

2.5

If the machine has a vacuum table, the

Vacuum Pump should be wired to 208-

230V, 3-phase or 440V (depending on what

isspeciedontheUnit,)byaqualied

Electrician. (Fig 2.5a)

Fig. 25a

Fig. 2.5b

Fig. 2.5c

The starter box will have a round silver

connector attached to a grey cable coming

out of it, (Fig 2.5b).

This connector plugs into the socket on the

side of the machine, (Fig 2.5c).

This cable provides 220 volts to the starter

coil to turn on the vacuum.

10 Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series Manual

NK105G3

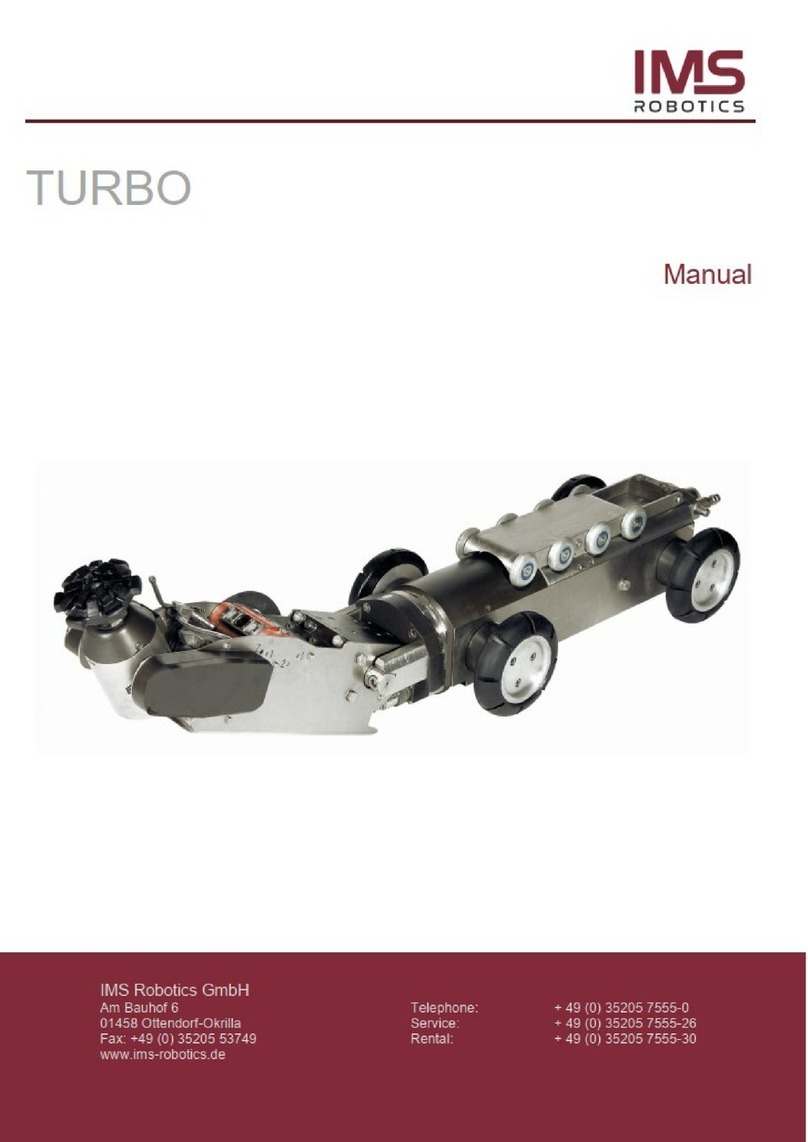

III. Vacuum Pump Installation

Matching connector that will plug into the

controller box (shown left)

WARNING: DirectionofPumpRotationiscritical.BrieystartPumpandcheckrotation

(arrow on casing). Exchange phases if rotation is incorrect. IF YOU RUN THE PUMP/BLOWER

CONTINUOUSLY IN THE WRONG DIRECTION,

THE VANES WILL BE DAMAGED.

NOTE:

The cover was

removed from Motor

Starter.

YouwillneedtohavetheelectricianconnectACpower(208-230V3PH)asspeciedonthe

unit to the Motor Starter at L1, L2, L3 and Ground (PE).

3 Phase Control Box

Pump/Blower Motor

Starter Box & Connector

The starter box will have a round silver

connector attached to a black cable

coming out of it.

This connector plugs into the socket on the

side of the machine,

This cable provides the signal to the starter

coil to turn on the vacuum.

L1,L2,L3

11 Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series Manual

NK105G3

Make sure wire conduit

is properly attached as

shown in photos - any

exposed wiring could be

damaged and cause harm

to the machine

Make sure to attach a ground wire from the

ground lug on the back of the machine to a

grounding rod.

12 Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series Manual

NK105G3

Once power is connected, turn the machine on by

turning the main power disconnect switch to the

vertical, “ON”, position.

Vacuum Pump ON/OFF

Press the Vacuum Pump button to turn on the vacuum pump. The operator can usually tell by the

sound of the pump whether its rotating in the correct direction due to the sound of the pump. If the

pump sounds like it is clicking and not making a humming noise then it is most likely running in the

wrong direction.

Flow of vacuum from the pump to the table is controlled by the gate valve

button(s) on the front of the machine.

Power is now applied to the controller box. The red light on Power OFF will now light up indicating the

machine is powered, but the controller and motors are not yet enabled.

Tocheckvacuumpumprotationandtestonando,rstensurepowerisconnectedtoboththe

vacuum pump starter box as well as the controller cabinet.

Gate Valve

When the gate valve is pressed, the operator should be able to feel air being pulled through the ports

on the table. Please remove black plugs before operation.

If the air blows out after pressing the “Gate Valve” button, this means that the pump is wired

backwards. Please exchange any two power leads. (Swap L1 with L2)

13 Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series Manual

NK105G3

1

A

2345678

1 2 345678

B

C

D

E

F

A

B

C

D

E

F

Dept. Technical reference Created by Approved by

Document type Document status

Title DWG No.

Rev. Date of issue Sheet

11/21/2018

1/1

BP002

Becker Pump Assembly

Bob Valentine

2" NPT Street Elbow

2" NPT x 8" Long Steel Nipple

2" NPT Female Steel Tee Fitting

2" NPT Plastic Angled Barb Fitting

2" NPT x 6" Long Steel Nipple

Secondary Vacuum Pump Filter Unit and Cannister

Becker Pump Vacuum Gauge

2" NPT to 3

8" NPT Reducer w/. 3

8" NPT to 1

4" NPT reducer

2" NPT Closed Nipple

14 Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series Manual

NK105G3

Once the main power switch has been engaged the controller is activated by pressing the

green on switch on the front of the controller.

Figure 4.1a shows the buttons and their functions.

Emergency

Stop

Power

Enable

Power

Disable Spindle Inverter

Readout

Vacuum

Pump ON/OFF

USB

Port

Fig. 4.1a

IV. Enabling the Titan Series Machine

Control Panel Functions

4.1

Turn the machine on by turning the

main power control switch to the

upright position (Fig 4.2a)

Fig. 4.2a

Fig. 4.2c

Power is now applied to the

controller box. The red light

will now light up indicating the

machine is powered, but nothing is

enabled such as the controller and

motors(Fig 4.2b)

Press the green button to apply

power to the controller and enable

the motors. (Fig 4.2c)

Fig. 4.2b

(Note that the red POWER button

will remain lit if the Emergency

Stop is pressed during

operation.)

4.2 Powering On

IMPORTANT: DOORS MUST BE CLOSED FOR POWER TO ENABLE.

Open/Close

vacuumow

15 Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series Manual

NK105G3

Whenthemachinerstpowerson,

the display on the controller will light

up and say “Starting System”. (Fig.

4.1a)

Once the system has booted it will

ask the user “Back to reference

point?” Fig 4.2b

Fig. 4.1a Fig. 4.2b

Thisisalsoknownas‘homing’themachine.Itreferstotheprocessofthemachinendingitsmechani-

cal home position.

From this point, the user has two options;

Home the machine or cancel the homing process. We recommend that you home the machine every

time you start up.

Press “ESC” will skip the homing process.

WARNING:Therewillbenoreferencepositionandbreakpoints,osetsandall

functions that rely on a reference position will be invalid.

Once the machine has moved to the its home position on each axis, it will stop and enter an IDLE state

and will be ready to use.

You should test all machine functions before beginning to cut. The functions are displayed in the next

section.

Pressing“OK”willinitiatethehomingprocess.Themachinewillrstmovethe

Z-axis to the top of travel and then the X and Y axis will move simultaneously until

both are at the home / reference position at the front left corner of the machine

bed.

NOTE: The homing procedure can be aborted at anytime by pressing ESC.

ADVANCED HOMING:

If you hit “ESC” by accident, or would like to reindicate the axes, there are two ways to “Home” again.

1) Press Menu > 3. Operations > 1. Back REF Point > 1. All Home

2) Shortcut

+

4.3 Titan Startup

16 Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series Manual

NK105G3

Handheld Controller Layout

The layout of the NK105G3 handheld controller.

Status

Lights

Execution

Keys

Output

Keys

Movement

Keys

Function

Keys

Menu

&

Navigation

Keys

5. NK105G3 Controller

17 Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series Manual

NK105G3

Single Keystroke Functions on the Handheld Pendant

18 Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series Manual

NK105G3

Movement Keys

All the movement type keys are colored yellow. They will work in both

Jog and Stepping modes.

19 Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series Manual

NK105G3

Shift Commands / Combination Keystrokes

To use the shift commands, you must press and hold the shift key and then select a second key.

When it reads X1 Y1 Z1, that is relative. When it reads X* Y* Z*, that means absolute.

20 Call: 1-631-648-7481 or Visit: support.technocnc.com

Titan Series Manual

NK105G3

Execution Keys and Menu Navigation

Use the arrows to navigate menus, move cursors and in

conjunctionwithotherkeystoperformspecicfunctions.

Controller

Power

Controller

Communication

Job

Running

Spindle

ON

Dust Shroud

Up / Down

Alarm

Chuck

Open / Close

Status Lights and Indicators

Pop Up Pins

Table of contents

Other Techno CNC Systems Cutter manuals

Popular Cutter manuals by other brands

Jenlis

Jenlis Weed Razer Pro product manual

PSI Matrix

PSI Matrix PP 803 installation guide

Hypertherm

Hypertherm Powermax30 AIR manual

Logan Graphic Products

Logan Graphic Products ARTIST CLASSIC Instruction and operation manual

iWeld

iWeld CUT 85 CNC LCD user manual

Land Pride

Land Pride RCD1884 Operator's manual