Digitrax DS78V User manual

© 2021 Digitrax, Inc. www.digitrax.com— 1 —

Features:

▪8 output channel LocoNet based Stationary decoder for operating eight

9G-type servo motors for turnout or general motion control.

▪Plug-in connectors for simple and easy installation and service.

▪User dened 8 consecutive switch (SW) addresses in 2000+ SW range.

▪Stabilized 5 Volt servo drive voltages.

▪Easy setup with Option Switches (OPSW) or LocoNet CV programming.

▪Power input from 2mm DC jack, or DCC track voltage, 10V min to 20V max.

▪16 easy to setup System Routes, with 8 SW Entries each.

▪16 input control lines; 8 for Output/SW change and 8 Sensor/DS inputs.

▪Additional advanced LocoNet Conguration modes using DT602 throttles.

Parts List

1 DS78V Stationary Decoder 2 10-pin pluggable input cables

1 Instruction Sheet

1.0 DS78V Quick Start - Eight servos, Thrown/Closed

The DS78V is simple to install and begin using on your LocoNet based layout.

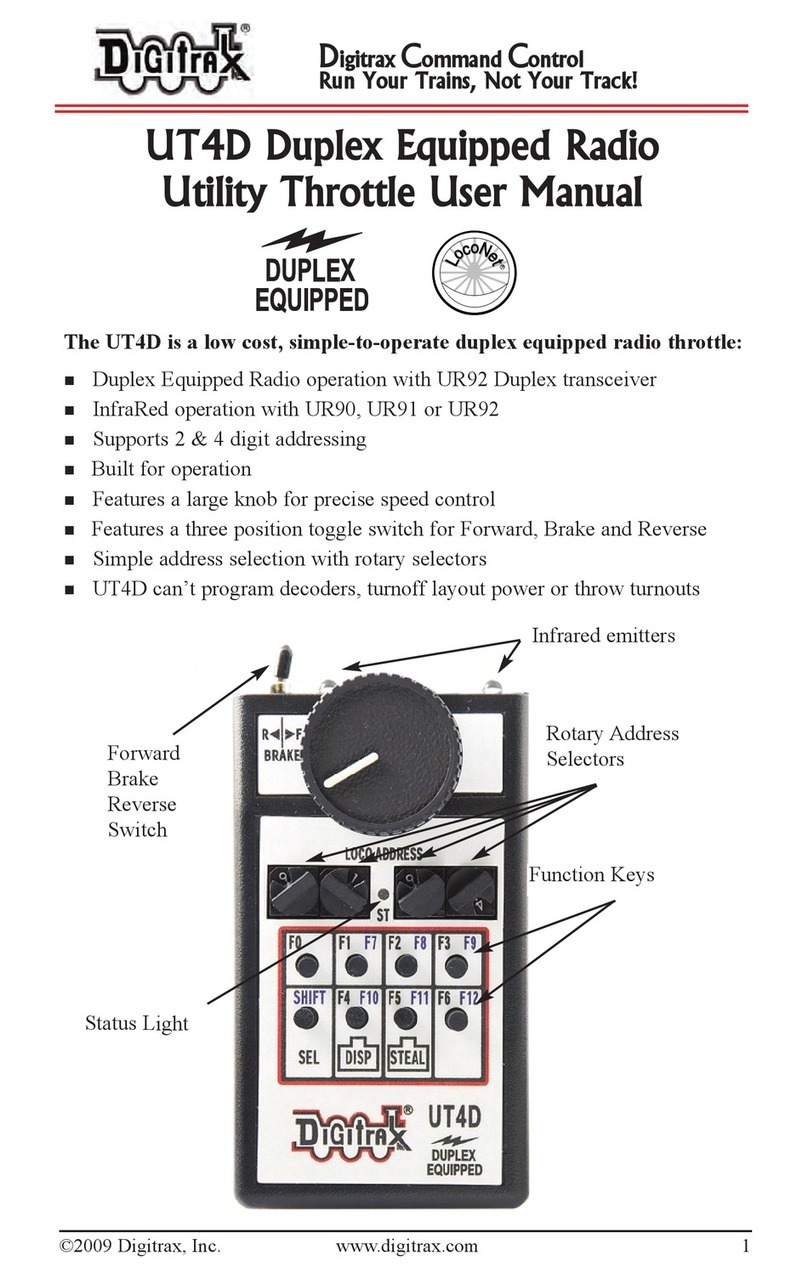

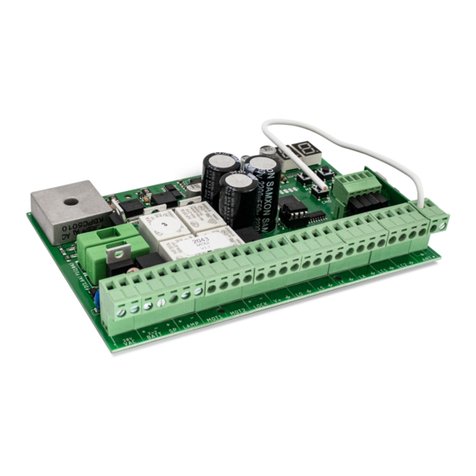

1. Figure 1 shows the recommended connections to operate the DS78V on

a LocoNet layout and to control up to eight mounted servos, like Digitrax

DSXSV9's.

2. Connect a PS14 or similar DC 12V power supply to the DS78V via the DC

power jack. When powered the green ID LED should light and will briey

wink OFF every 2 secs as a product 'heartbeat' showing the DS78V is opera-

tional. Alternatively, power from DCC feeder wires to the TKA/B terminals.

3. Plug in an active LocoNet to a DS78V RJ12 connector. The red OPS LED

will light up showing connection. Any good LocoNet message seen will cause

the DS78V OPS LED to blink OFF briey. With no LocoNet the unit will

respond to switch commands from a DCC track connection.

4. Press and hold down the ID button for about 3 seconds until the RTS and

OPS LEDs blink alternately, then release the ID button.

5. From your system send a SW command to set the Base Board address at this

SW#. The OPS and RTS LEDs will stop blinking showing the DS78V has set

the unit's Base SW# to the SW# you just sent, which is for Servo1 control.

6. Plug in the servo 3pin connector(s) to the outputs you wish to control. The

connector brown wire will be closest to the DS78V beige case top.

7. Operate turnouts with a SW# and direction Thrown (T)/Clockwise(CW) or

Closed(C)/Counter-Clockwise(CCW) settings at the; Base SW#, or the next

consecutive 7 SW#'s now in use by this DS78V.

That’s all that’s required for installation of your DS78V on LocoNet!

DS78V

Complete Train Control

Run Your Trains, Not Your Track!

Eight Servo LocoNet Stationary/Accessory

decoder for turnout control.

© 2021 Digitrax, Inc. www.digitrax.com— 2 —

1.1 DS78V Quick Start - Eight 3-position semaphores:

To control eight servos driving 3-position semaphores using 16 switch addresses:

1. Follow the steps of section 1.0 to power on DS78V and setup the Base SW#.

2. Press and hold the OPS button for about 3 seconds until the green ID and

RTS LEDs blink alternately. Release the OPS button. The DS78V is now set-

up to congure Option Switch (OPSW) 1 to 40 by sending the required SW#

as Closed or Thrown to setup an option as T or C, as dened in Table 1.

3. Issue a SW#3 Closed command. This sets OPSW3 to Closed (C). From

factory default 2-position mode this will congure the eight servo outputs to

the 3-position Semaphore mode, each controlled by 2 SW#'s.

4. In Semaphore mode the DS78V will now respond to 16 SW consecutive ad-

dresses starting at the unit's Base SW#, in eight SW# pairs.

5. A switch command to the Base SW# will set Servo1 at: full Clockwise angle

for T (semaphore STOP/RED) and full Counter-Clockwise for C (semaphore

CLEAR/GREEN), as viewed from the arm-end of the servo

6. A switch command at Base SW#+1 will drive Servo1 to the mid-angle or Ap-

proach position (semaphore APPROACH/YELLOW) for either T or C.

7. In this way, each servo responds to a consecutive pair of switch commands:

the rst SW# as T/C and the SW#+1 for the Approach setting. For example:

Base SW#+3 sets T/C for Servo2 and Base SW#+4 for T or C sets the center

Approach angle setting for Servo2.

8. Press and hold OPS button for about 3 seconds to now exit OPSW setup.

9. Connect linkages from the servo arms to the semaphores as needed.

12V DC in

Complete Train Control

8 servo 5

DS78V

RTS OPS ID

SW/SENSOR 5-8

4 servo 1

1/BRN SW/SENSOR 1-4

1/BRN

10 pin header cables

for 16 input line options

To DCC Track

(Optional)

LocoNet

Brown or pin1 edge

Figure 1: DS78V

System and Servo

output connections

Servo#1, at Base Board SW address +0

Servo#8, at Base Board

SW address +7 (lowest Base Board SW address is 1)

Servo examples in Thrown or

Clockwise arm orientation

as viewed from arm screw side

Brown or pin1 edge

© 2021 Digitrax, Inc. www.digitrax.com— 3 —

2.0 Setup DS78V Servo angle Adjustment mode:

The DS78V can be congured to conveniently drive all 8 servo outputs to the; T/

CW, Center or C/CCW servo angle positions for testing and installation.

1. To go to Thrown/CW position: double click the RTS button with two quick

presses and releases in less than 1 second. All servo arms will go to the T/CW

position, and just the Green RTS led will blink rapidly. To exit from adjust-

ing back to normal operation, double click the RTS button again.

2. To go to servo Center position: double click the OPS button with two quick

presses and releases in less than 1 second. All servos will go to the center

position, and just the Red OPS led will blink rapidly. To exit from adjusting,

double click the OPS button again.

3. To go to Closed/CCW position: double click the ID button with two quick

presses and releases in less than 1 second. All servos will go to the C/CCW

position, and just the Green ID led will blink rapidly. To exit from adjusting,

double click the ID button again.

4. You can enter Adjustment mode with just the 12V power hooked up, and do

not need a command station, active LocoNet or a throttle to do these servo

position adjustments.

3.0 Setup DS78V Ez-Routes:

The DS78V has 16 internal Routes with up to 8 SW# and T/C direction Entries

each. These can be set up by Ez-Routes method using the RTS button and switch

commands sent from a LocoNet throttle, connected PC or DCC track.

1. Press and hold the RTS button for about 3 seconds and the ID and OPSW

LEDs will blink alternately to show one Route can be set up. Release the

RTS button.

2. Select a switch address on your throttle between 1 and 16 and issue the

command direction for Closed. This will now be the Route Number you are

going to setup. Any previous Entries in this Route will now be replaced in

following steps.

3. Select the desired TOP Switch address between 1 and 2000 and issue a C or

T direction command. This SW# and direction is that which will trigger this

Route to be executed when seen by this DS78V

4. Now enter up to 7 more SW# and direction T or C for the other route Entries

required. The route entry ID/OPS LED will stop blinking indicating route is

full/completed.

5. If you issue a SW# and direction twice consecutively that will also end route

entry.

6. If this DS78V does not have a LocoNet connection but operates from DCC

Track power on the TKA/B terminals, then it will ignore Route Entries that

do not fall within the DS78V's Base address and next 7 servos.

7. Best practice is to set TOP SW#'s in each route in a unique "phantom" switch

range e.g. 500 and above that do not control a physical switch. This will iden-

tify the issued switch is specically a TOP or Route-start SW#.

8. Ez-Routes do not have the ability to; read back , review or edit DS78V routes

already set up. For more powerful color graphics for comprehensive DS78V

Route review and editing consider using a DT602 as noted in section 6.0

9. The green RTS LED will be steady ON if there are any routes programmed.

© 2021 Digitrax, Inc. www.digitrax.com— 4 —

4.0 Other DS78V Options: OPSW changes

The DS78V conguration and behavior can be congured using 40 OPSW's. The

Factory default OPSW settings will congure most common requirements.

1. Press and hold the OPS button for about 3 seconds until the green ID and

RTS LEDs blink alternately. Release the OPS button. The DS78V is now

setup to congure OPSW 1 to 40 by sending the required SW# as Closed or

Thrown to setup an option.

2. Send a SW# in range 1-40 as Closed/Thrown matching the valid settings

from OPSW Table 1 choices below.

3. When nished press and hold OPS button for 3 seconds to exit OPSW setup

mode. The DS78V will now restart with the new OPSW settings.

4. Factory default OPSW settings are shown in BOLD.

5. OPSW's not in this table are reserved and should be kept at Factory default T

settings for predictable operation.

6. OPSW40 =C will reset to Factory defaults on OPSW mode exit

5.0 External hardware Input lines:

The DS78V has sixteen external hardware control lines on two "SWITCH/SEN-

SOR IN" 10-pin PCB headers using plug in 10-pin ribbon cables. The 6" Factory

ribbon cable pin 1 edge should be on the right side when plugged in, as shown in

Figure 1. With Gray cable the red stripe is pin 1 edge, and for 10-color cable pin 1

is BROWN, with wire colors shown in Tables 2 and 3.

If you use these external lines, connect the wires from the pins of Table 2 and 3

to your custom wiring by e.g. screw terminal blocks. If using a Gray non-color

ribbon cable, make sure pin 1 and counted pin numbers match Table 2/3 usage.

Alternately, plug in two DSXC4's boards with their ribbon cables, which will sup-

port up to 8 DSXCP1 fascia SW controls with servo state indicating LEDs.

Table 1: DS78V OPSW setting table:

OPSW# Default=bold Action

1,2,3,4 T,C,T,T

T,C,C,T

2 position servo (T/C)

3 position servo, (Semaphore)

6TC =Disable internal Routes

10 TC= Ignore standard LocoNet SW com-

mands ("Bushby bit")

11 TC= 16 input lines trigger Routes. [No

DSXCP1 support]

14 TC= DCC SW commands only. Ignore

all LocoNet SW#'s

15 TC= Do not echo Route SW's to Loconet.

40 TC= Factory Reset

© 2021 Digitrax, Inc. www.digitrax.com— 5 —

A +5V Reference voltage is provided on pin 10/ribbon cable BLACK wire for

setting an ON/active level, and a 0V/OFF reference level on pin 9 or the WHITE

wire. DO not draw more than 100mA from the BLACK wire. The SW/SENS

wires on pins 1/BROWN through 8/GRAY are rated for up to +16V maximum

input voltage, but best practice is 0V to 5V operation.

1. The SW1,SW2,SW3,SW4,SW5,SW6,SW7 and SW8 pins will toggle the state

of the same number output when briey connected to the +5V ON voltage

on the BLACK wire or pin10. If the DS78V is connected to LocoNet this will

occur as a SW# message to make the change and notify the system it has

occurred. Wire to momentary

press-on buttons for SW control.

2. The pins SENS1,SENS2,

SENS3,SENS4,SENS5,SENS6,

SENS7 and SENS8 will send a

LocoNet Block Occupancy or

DS message at the SW# of the

output. This will be BLOCK

OCCUPIED when the line is

above +4V and a BLOCK UN-

OCCUPIED when between 0V/

WHITE and +2V.

3. For example; if the SENS2/YEL-

LOW line of the left ribbon cable

is connected to the BLACK +5V

Reference wire, the the DS num-

ber reported will be SW# used

for Output 2R/2G. If SW10 is

the BASE address of the DS78V,

then Output2 is SW11 and the

DS message will be Block 11

OCCUPIED.

4. A disconnected SENS line will

report as UNOCCUPIED.

5. The BD4N does not plug directly

into a 10 pin header, and will

not operate. Connect the 5

wires used by the BD4N by

name via a terminal strip. More

conveniently, you may connect

the BD4N through one of two

plugged in DSXC4 boards with

ribbon cables for true plug and

play connectivity. This will also allow DSXCP1 SW control and state display.

6. These two sets of ribbon cable wires should not connect to any other voltage

levels or loads other than those dened here.

7. For OPSW11 =C: SW1 line ON starts Route1 and SENS1 starts Route2, in

order through SENS8 line that starts Route 16. An empty route is ignored.

Table 2: DS78V Input lines 1-4

Pin# Wire Color Function

1BROWN SW1 Toggle, +momentary

2 RED SENS1 occupancy level

3 ORANGE SW2 Toggle, +momentary

4 YELLOW SENS2 occupancy level

5 GREEN SW3 Toggle, +momentary

6BLUE SENS3 occupancy level

7 VIOLET SW4 Toggle, +momentary

8 GRAY SENS4 occupancy level

9WHITE 0V reference

10 BLACK +5V reference

Table 3: DS78V Input lines 5-8

Pin# Wire Color Function

1BROWN SW5 Toggle, +momentary

2 RED SENS5 occupancy level

3 ORANGE SW6 Toggle, +momentary

4 YELLOW SENS6 occupancy level

5 GREEN SW7 Toggle, +momentary

6BLUE SENS7 occupancy level

7 VIOLET SW8 Toggle, +momentary

8 GRAY SENS8 occupancy level

9WHITE 0V reference

10 BLACK +5V reference

© 2021 Digitrax, Inc. www.digitrax.com— 6 —

6.0 Advanced DT602 based DS78V conguration

To perform these advanced features, the DT602 will need to be user updated to

SubVersion 0.5 or higher, or a July 2021 or later IPL - see www.digitrax.com.

6.1 Detecting all DS78V's and setting Base addresses: On

an updated DT602 plugged into LocoNet, press the; Menu>3>4 keys to enter the

Route Editor menu. If any DS78V is plugged into LocoNet, the DT602 will beep

after about one second and show "DS7x" routes at the D soft key position.

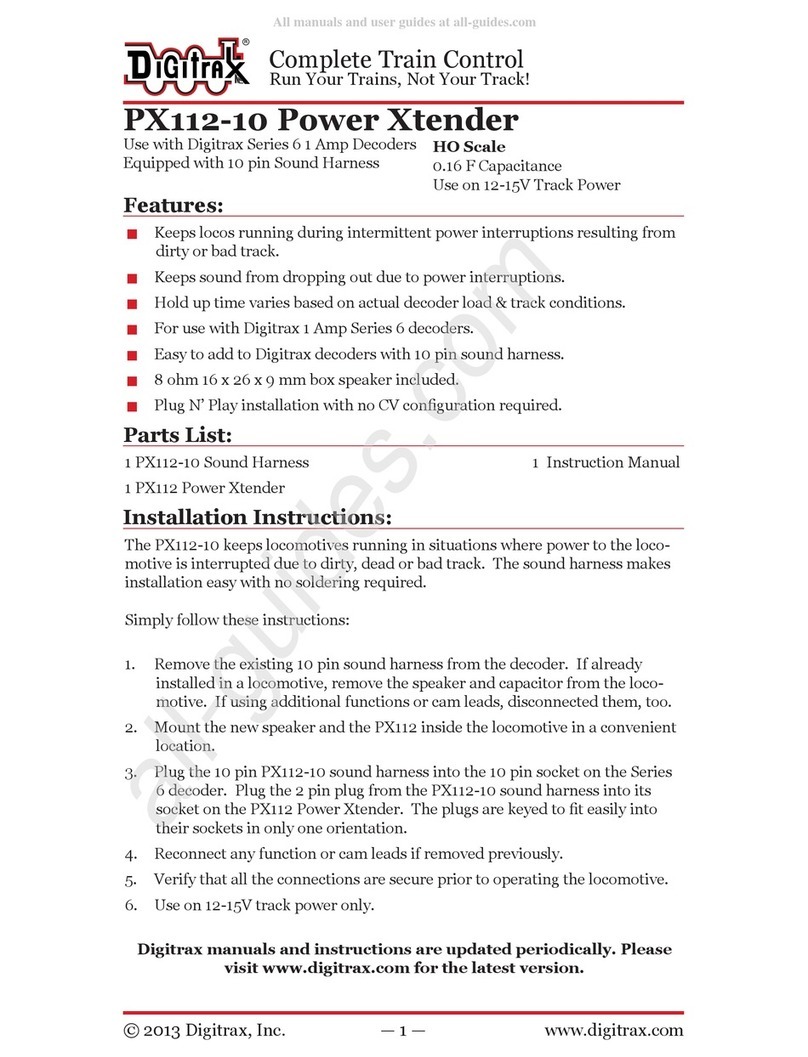

1. Press the D soft key to now enter the "Selecting DS7X device:" screen as

shown below. This example DT602 screen shows four DS78V devices detect-

ed on LocoNet, with their; Base SW address, active SW address count# and

unique device serial numbers (SN or SerNo).

2. The lowest DS78V Base address detected and sorted is SW0001, with 8

outputs and SN 9122. This is displayed in GREEN to indicate that it does

NOT conict with the 2nd DS78V SN 3122 at Base address 9. This is true

because the next free address is SW1+8 or SW0009, that 2nd DS78V SN

3122 is set at or above. You can use the LH encoder knob to scroll up and

down through the detected DS78V devices, with an underline showing the

selected DS78V.

3. The 3rd DS78V shown at Base SW17 uses

16# SW outputs, since it is congured by

OPSW's to operate 8 semaphore SW pairs

instead of 8 T/C SW turnout controls.

4. The 4th DS78V at Base Sw25 overlaps the

3rd DS78V, and so the 3rd SW base is dis-

played in RED text, since SW17+16 would

require the 4th DS78V SN9945 to have

a base address of at least Sw33 to avoid

SW# overlaps. It shows just SW25.

5. Rotate the DT602 LH encoder knob to

underline the 4th DS78V line entry after

the RED collision marked 3rd DS78V.

6. Press the numbers 3 then 3 then press the

soft key "Chng Adr" , A. The 4th DS78V

will change to Base SW33. The 3rd DS78V

info now shows all GREEN because there

are now no SW overlaps of DS7x devices

after it. This "Chng Adr" to 33 for the 4th DS78V Base SW# just cleared the

3rd DS78V's active SW range (minimum is: 17+16 =33), xing the problem.

7. To identify the actual underlined fourth physical DS78V on the layout; press

the F soft key "Ident" and just this DS78V will blink its ID/OPS/RTS leds for

3 seconds. Press "X" to exit any DT602 advanced mode.

8. This advanced DT602 capability allows you to setup all DS7x family devices,

like the DS78V and DS74, in position on a LocoNet layout, quickly and con-

veniently, even if all devices are initially at factory-default Base SW1.

9. If you are using other types of non-DS7x family Switch control decoders, you

will have to note their active SW addresses and manually ensure the DS78V's

are congured to not overlap these.

CsRt

Selecting DS7X device:

Device: Base+Out# SerNo

DS78V Sw0001+8 # 9122

DS78V Sw0009+8 # 3122

DS78V Sw0017+16# 2500

DS78V Sw0025+8 # 9945

DS7x device select: LH knob

Chng adr

Ident

© 2021 Digitrax, Inc. www.digitrax.com— 7 —

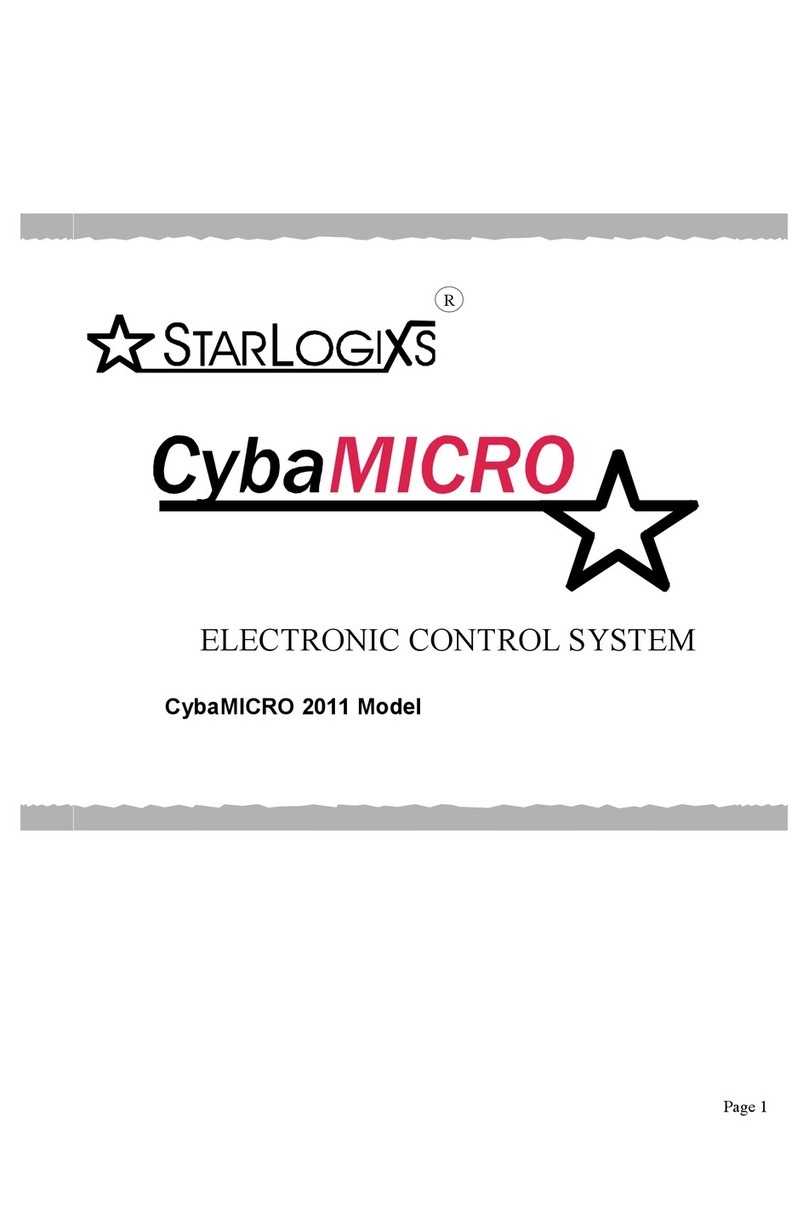

6.2 Reading and Editing a DS78V's routes: As for section 6.1,

using a suitable DT602 plugged into LocoNet, press the; Menu>3>4 keys to enter

Route Editor menu. If any DS78V is on LocoNet, the DT602 will beep after

about one second and show "DS7x" routes at the D soft key position.

1. Press the D soft key to now enter the

"Selecting DS7x device:" screen,

2. Rotate the LH encoder knob to under-

line the DS78V to edit routes for.

3. Now press DOWN the LH encoder knob

to read in and display the Routes of the

selected DS78V, as shown in adjacent

"EDIT DS7X Rt#:" screen.

4. The LH encoder knob now selects a

Route# and the RH encoder selects the

black outlined Entry# to edit. Soft A key

will toggle the entry from T to C direc-

tion choice. Numeric keys will change

the SW# in the outlined Entry position.

"Add" soft key allows inserting another

entry at current position and "Delete"

will remove the current entry. The "SW

test" soft key will send just the outlined

switch# and direction to LocoNet.

5. After edit of any Route is complete be sure to press the "Save" soft key to

update this DS78V Route to non-volatile memory. Press "X" to exit.

6. With LocoNet connected DS78V routes have System wide control ability.

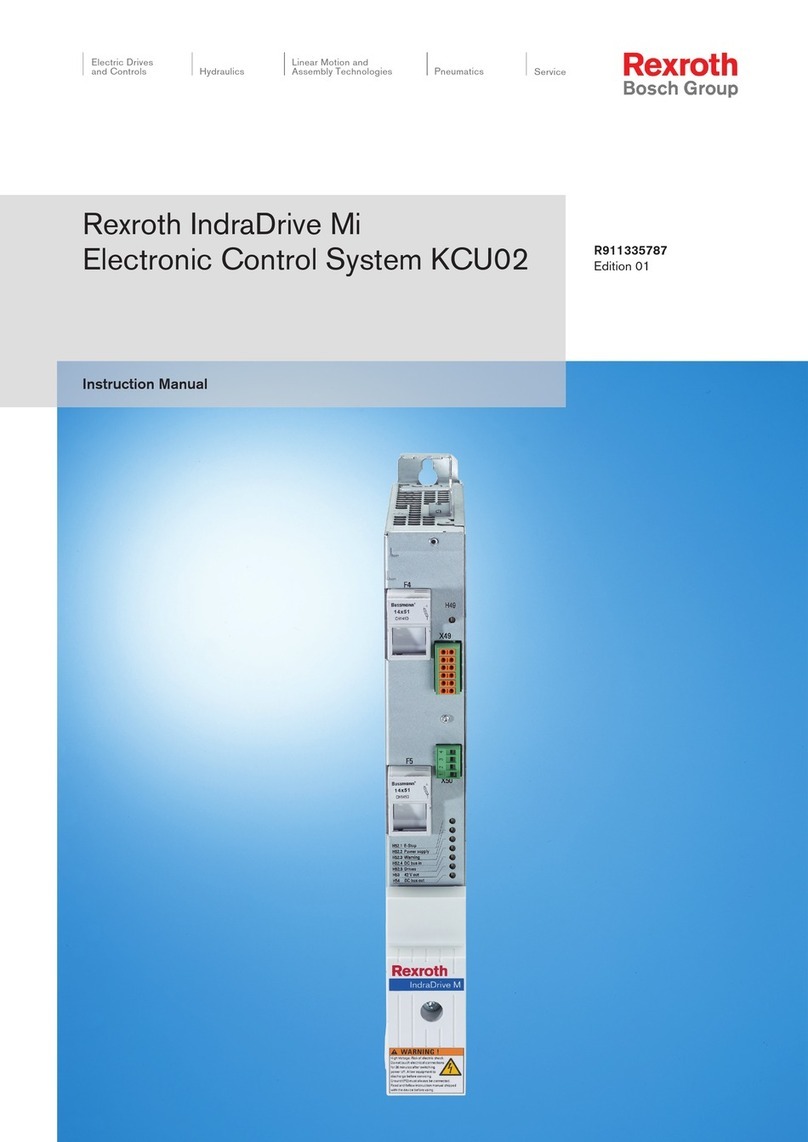

6.3 Programming DS78V CVs on LocoNet: As for section 6.0,

with a suitable DT602, press the; Menu>2>1 keys to enter Operations Mode

programming.

1. Press the F "SWITCH" soft key to enter the "Ops Switch" mode program-

ming screen as shown adjacent. This

example screen shows CV11 selected for

a DS78V with BASE address of SW1.

2. Use the LH and RH encoder knobs to

select the SW#/ADR of the DS78V to

modify a CV on. A DS78V's CV11 to

CV15 access the 40 OPSW bit settings.

3. For example; press the "CVDATA" soft

key at CV11 to change to CV data entry,

press the number 6 then press "WRITE".

This now congures the 8 OPSW bits of

CV11 to 6, forcing this DS78V to change

to semaphore mode with eight 3-posi-

tion outputs. A value of 02 in CV11 sets

default 2-position mode.

4. Be careful changing the values in

CV11,12,13,14 and CV15 since the 8 bit

data number 0-255 in these CV's actu-

EDIT DS7X Rt#: 01 of 16

Entry# TOP of 8

0100c

0224t

Thrown Add Save

Delete

DS7X Edit: LH knob selects

SW testCS Rt

DS78V

Sw0009+8 # 3122

CV Program Menu A:

CV Number:

CV data:

0011

0000

Ops Switch ADR: 0001

LOCO

CVNUM CVDATA DONE

© 2021 Digitrax, Inc. www.digitrax.com— 8 —

8.0 Warranty & Repair

Digitrax gives a one year Warranty against material and manufacturing defects

on the DS78V.

Visit www.digitrax.com for instructions for

returning items for repair. Please return

warranty items directly to Digitrax -

DO NOT return items to place of purchase.

Digitrax, Inc. reserves the right to make changes

in design and specications, and/or to make addi-

tions or improvements in its products without im-

posing any obligations upon itself to install these

changes, additions or improvements on products

previously manufactured. IPL capable products

like the DS78V & DT602 may be user updated

with the latest IPL les that are available for free

on the product specic information pages of the

www.digitrax.com web site. The newest features

are documented on the product pages of the

website.

Digitrax, Inc. is not responsible for unintentional

errors or omissions in this document.

ally each control 8 individual OPSW bits. OPSW1 is ls bit of CV11, through

OPSW8, as ms bit of CV11.

5. The DT602 does not indicate to the DS78V when programming is complete.

After nishing CV changes, best practice is to POWER cycle the DS78V to

save changes. Alternately, you can WRITE CV7 to 00 to restart that DS78V.

7.0 Set up Notes:

1. The DS78V manages servo supply voltages at 5V.

2. In all output modes a 300mA /12 to 14V DC supply should suce.

3. Using DigiIPL II version 2.9.1 or later on a PC will display a Sub-version

number that conrms the last downloaded IPL/update#, since the DS78V

does not have a LCD display to show this last IPL download info

4. The OTA and OTB screw terminals are connected to TKA and TKB wires and

allow DCC track feed wires to daisy-chain between multiple DS78V's.

5. A connected DSXCP1 will ash red/green while its servo is moving.

Regulatory Information Declaration of Conformity: “This device complies with part 15 of the

FCC Rules for a Class B digital device. Operation is subject to the following two conditions: (1)

This device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.”

These limits are designed to provide reasonable protection against harmful interference in a residen-

tial installation. This equipment generates uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to radio com-

munications. However, there is no guarantee that interference will not occur in a particular installa-

tion. If this equipment does cause harmful interference to radio or television reception, which can

be determined by turning the equipment off and on, the user is encouraged to try to correct the inter-

ference by one of the following measures: Reorient or relocate the receiving antenna. Increase the

separation between the equipment and receiver. Connect the equipment into an outlet on a circuit

different from that to which the receiver is connected. Consult the dealer or an experienced radio/

TV technician for help

307-DS78V-0000

2443 Transmitter Road

Panama City, FL 32404

www.digitrax.com

Need Support?

helpdesk.digitrax.com

Made in the USA

Table of contents

Other Digitrax Control System manuals

Popular Control System manuals by other brands

Motorline professional

Motorline professional MC62 User's and installer's manual

Siemens

Siemens SINUMERIK 840D sl Commissioning manual

Proteco

Proteco BARRY user manual

Micronix

Micronix MMC-200 Series Reference manual

Devolo

Devolo Home Control First steps

Electronics Line

Electronics Line Commpact installation manual