Contents

4990671000 February 2008 2

Contents

Contents

1. Technical data . . . . . . . . . . . . . . . . . . . . . 5

1.1 Machine data . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . .6

1.2.1 Connection versions. . . . . . . . . . . . . . . . . . . .7

1.3 Location of lubricating points . . . . . . . . . . . . .8

1.4 Operating fluid . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5 Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

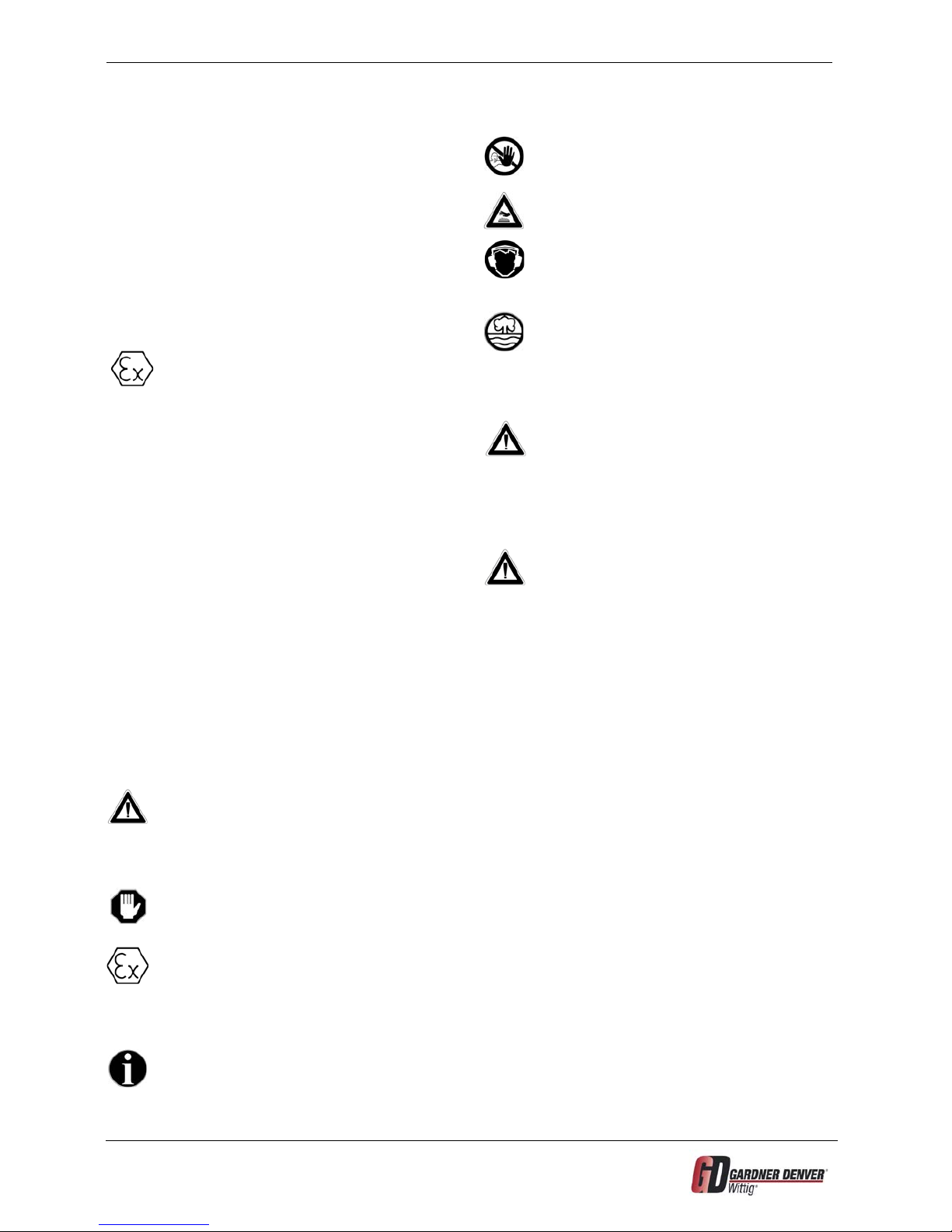

2. Safety instructions and hazard alerts . . 9

2.1 Use for intended purpose. . . . . . . . . . . . . . . .9

2.2 Acceptance and monitoring . . . . . . . . . . . . . .9

2.3 Hazard alerts and symbols. . . . . . . . . . . . . . .9

2.4 Safe working . . . . . . . . . . . . . . . . . . . . . . . . .9

3. Transport, Storage and Scope of

delivery . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.2 Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . .11

4. Installation . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 System setup with cooler in main flow . . . . .12

4.2 System setup with cooler in side flow . . . . .13

4.3 Point of installation and fastening . . . . . . . .15

4.4 Connections and piping . . . . . . . . . . . . . . . .15

4.5 Protection against intake of dirt and

residue . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.5.1 Suction line. . . . . . . . . . . . . . . . . . . . . . . . . .16

4.5.2 Vacuum filter . . . . . . . . . . . . . . . . . . . . . . . .16

4.5.3 Safety dome . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.5.4 Safety bowl. . . . . . . . . . . . . . . . . . . . . . . . . .16

4.6 Safety and monitoring instruments. . . . . . . .16

4.6.1 Vacuum gauge . . . . . . . . . . . . . . . . . . . . . . . 17

4.6.2 Vacuum filter . . . . . . . . . . . . . . . . . . . . . . . .17

4.6.3 Non-return valve. . . . . . . . . . . . . . . . . . . . . .17

4.6.4 Thermometer . . . . . . . . . . . . . . . . . . . . . . . .17

4.6.5 Safety valve . . . . . . . . . . . . . . . . . . . . . . . . .17

4.6.6 Pressure gauge . . . . . . . . . . . . . . . . . . . . . .17

4.6.7 Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.6.8 Bellows. . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.6.9 Speed monitor . . . . . . . . . . . . . . . . . . . . . . .18

4.7 Operating fluid . . . . . . . . . . . . . . . . . . . . . . . 18

4.7.1 Operating water back-cooling and

storage tank . . . . . . . . . . . . . . . . . . . . . . . . .18

4.7.2 Cell Ventilation . . . . . . . . . . . . . . . . . . . . . . .19

4.8 Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.8.1 Drive by hydraulic motor . . . . . . . . . . . . . . .19

4.8.2 Drive by flexible clutch . . . . . . . . . . . . . . . . .19

4.8.3 Drive by propeller shaft . . . . . . . . . . . . . . . .19

4.9 Drive by Vee belt . . . . . . . . . . . . . . . . . . . . . 20

5. Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1 Testing the system . . . . . . . . . . . . . . . . . . . .22

5.2 Operating liquid . . . . . . . . . . . . . . . . . . . . . .22

5.3 Stop slide and shut-off valves . . . . . . . . . . .22

5.4 Direction of rotation . . . . . . . . . . . . . . . . . . .22

5.5 Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

5.6 Inspection of speed, vacuum and pressure .22

5.6.1 Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

5.6.2 Vacuum and vacuum gauge . . . . . . . . . . . .22

5.6.3 Pressure at pressure gauge. . . . . . . . . . . . .22

6. Operation . . . . . . . . . . . . . . . . . . . . . . . . 23

6.1 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

6.2 Regular inspections . . . . . . . . . . . . . . . . . . .23

6.2.1 Safety valve . . . . . . . . . . . . . . . . . . . . . . . . .23

6.2.2 Water stop valve . . . . . . . . . . . . . . . . . . . . .23

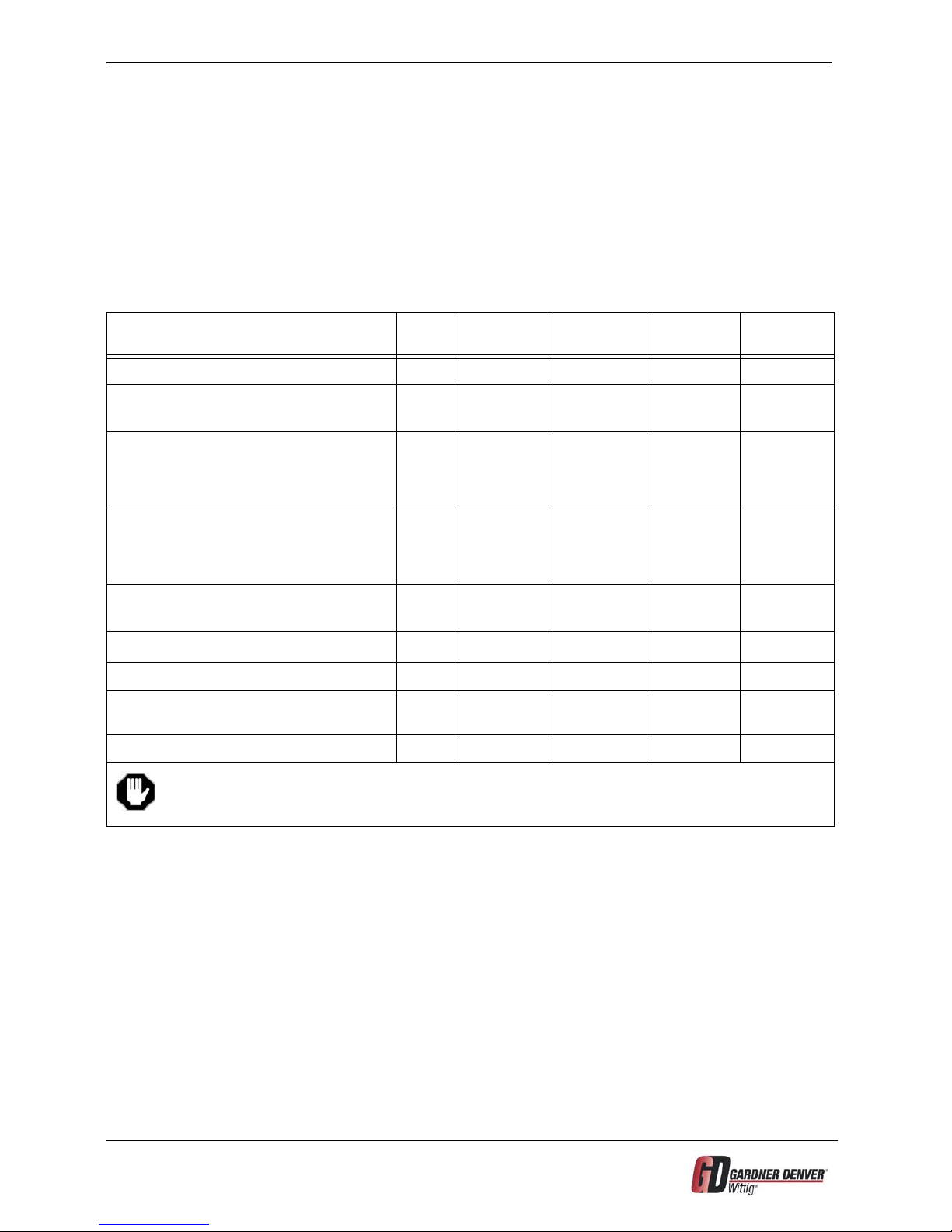

6.2.3 Inspection intervals . . . . . . . . . . . . . . . . . . .24

6.3 Operating the liquid ring pump . . . . . . . . . . . 24

6.3.1 Operating water consumption and control . .24

6.4 Possible faults by the operator . . . . . . . . . . .25

6.5 Extended period of non-use . . . . . . . . . . . .25

6.6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . .26

7. Maintenance . . . . . . . . . . . . . . . . . . . . . 28

7.1 Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . .28

7.2 Maintenance, maintenance

schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

7.2.1 Water back-cooling with air . . . . . . . . . . . . .28

7.2.2 Liquid ring pump . . . . . . . . . . . . . . . . . . . . . .28

7.2.3 Vacuum filter (GDD types) . . . . . . . . . . . . . .28

7.2.4 Vee belts and Vee belt tension. . . . . . . . . . .29

7.2.5 Non-return valve . . . . . . . . . . . . . . . . . . . . . .29

7.3 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . .29

7.3.1 Antifriction bearings . . . . . . . . . . . . . . . . . . .29

7.3.2 Shaft seal . . . . . . . . . . . . . . . . . . . . . . . . . . .30

8. Spare parts . . . . . . . . . . . . . . . . . . . . . . 31

8.1 Spare parts. . . . . . . . . . . . . . . . . . . . . . . . . .31

9.