1.0 Dual V4/V6 Overview

Delta Dual V4/V6

The Delta Dual V4/V6 is a packaged pump station designed to collect ground water via perimeter channel or Delta

129 detail and/or clear opening to the top of the chamber - please visit our website for water collection details.

Typically, the Dual V4/V6 would be used to collect ground water from a basement up to 150m² and/or surface water

from a light well up to 12m² to a maximum head of 7m and 9m respectively.

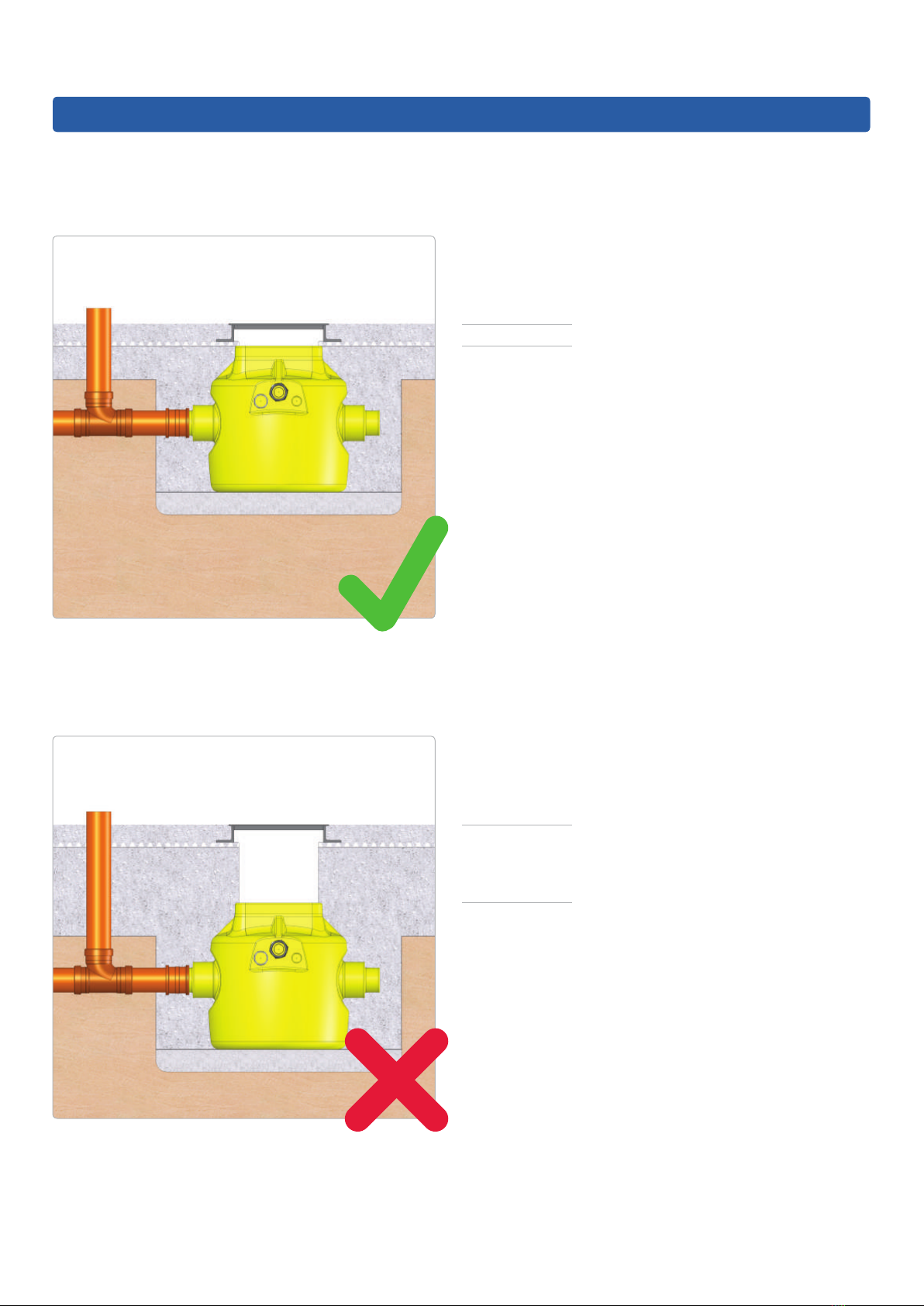

The pump station has been specically designed for below ground applications. The chamber is manufactured from

HDPE and when installed correctly, it is able to withstand hydrostatic forces encountered in high water tables.

The pump station is delivered as a complete package including, the chamber, internal pipework and two powerful

V4/V6 pumps. It is designed to be installed by contractors with competent building, plumbing and electrical skills.

The pumps operate by xed arm oats, the duty pump is set at a standard height (210mm to base of oat) and the

backup pump is set at a high level (380mm to base of oat). The high level alarm (where tted) will operate if the duty

pump fails leaving the backup pump to discharge water.

A high level alarm (DMS-270) is oered as a recommended extra to alert the property occupant when the water level

in the chamber becomes too high. A battery backup (DMS-320) is recommended to power the pumps during power

outage. Please see section 2.1 for more details about optional extras designed for the Dual V4/V6 pump station.

2.0 Parts Included

Chamber - 660 diameter

(902 across spigots) x

800mm deep

1.25” Internal Pipework

4 For technical support, please call 01279 757400

2 x V4/V6 Pumps 2” Discharge Male Iron

for temp. site installation.

2" Cable Duct Male Iron

2.1 Optional Extras

AlertMaxx High Level

Alarm (DMS-270)

2" Discharge Pipework

and various ttings

Power Plus Battery

Backup (DMS-320)