GDS-48 Remote Bridge Sensor Operation and Maintenance Manual, Revision 1.0

CONTENTS

1SAFETYINFORMATION.............................................................................................................................................4

2GENERALINFORMATION..........................................................................................................................................5

CATALYTICBEADSENSORS................................................................................................................................................5

INFRAREDSENSORS.........................................................................................................................................................5

PIDSENSORS.................................................................................................................................................................5

3SPECIFICATIONS........................................................................................................................................................6

4INSTALLATION..........................................................................................................................................................8

CHOOSINGALOCATION...................................................................................................................................................8

ELECTRICALCONNECTIONS...............................................................................................................................................9

5CALIBRATION..........................................................................................................................................................11

CALIBRATIONOVERVIEW................................................................................................................................................11

GENERALIZEDCALIBRATIONPROCEDURE...........................................................................................................................11

6OPERATIONANDMAINTENANCE............................................................................................................................13

SENSORREPLACEMENT..................................................................................................................................................13

7SPAREPARTS..........................................................................................................................................................15

GRAYENCLOSURE.........................................................................................................................................................15

YELLOWENCLOSURE.....................................................................................................................................................15

SENSORHEADACCESSORIES...........................................................................................................................................15

TableofFigures

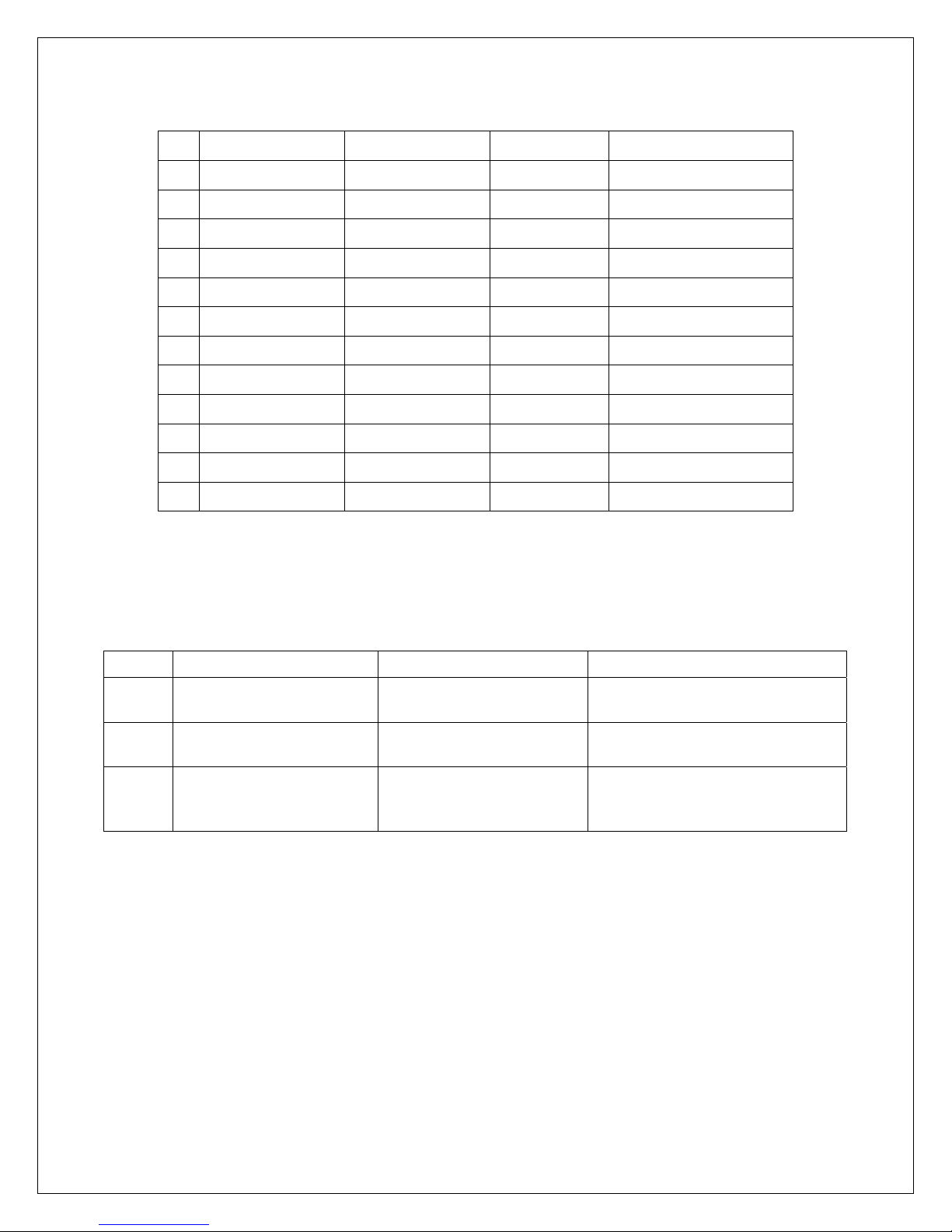

Figure3‐1:RecommendedSensorTemperatureRangesandExcitation*....................................................................7

Figure3‐2:RecommendedSensorWarmupTimes.......................................................................................................7

Figure4‐1:GDS‐48GrayEnclosure................................................................................................................................8

Figure4‐2:GDS‐48WiringConnections(GrayEnclosure).............................................................................................9

Figure5‐1:ApplyingCalibrationGastoGDS‐48..........................................................................................................12

Figure6‐1:SensorReplacement..................................................................................................................................14