Table of content Page

1IMPORTANT SAFETY INSTRUCTIONS .............................................................................................................................6

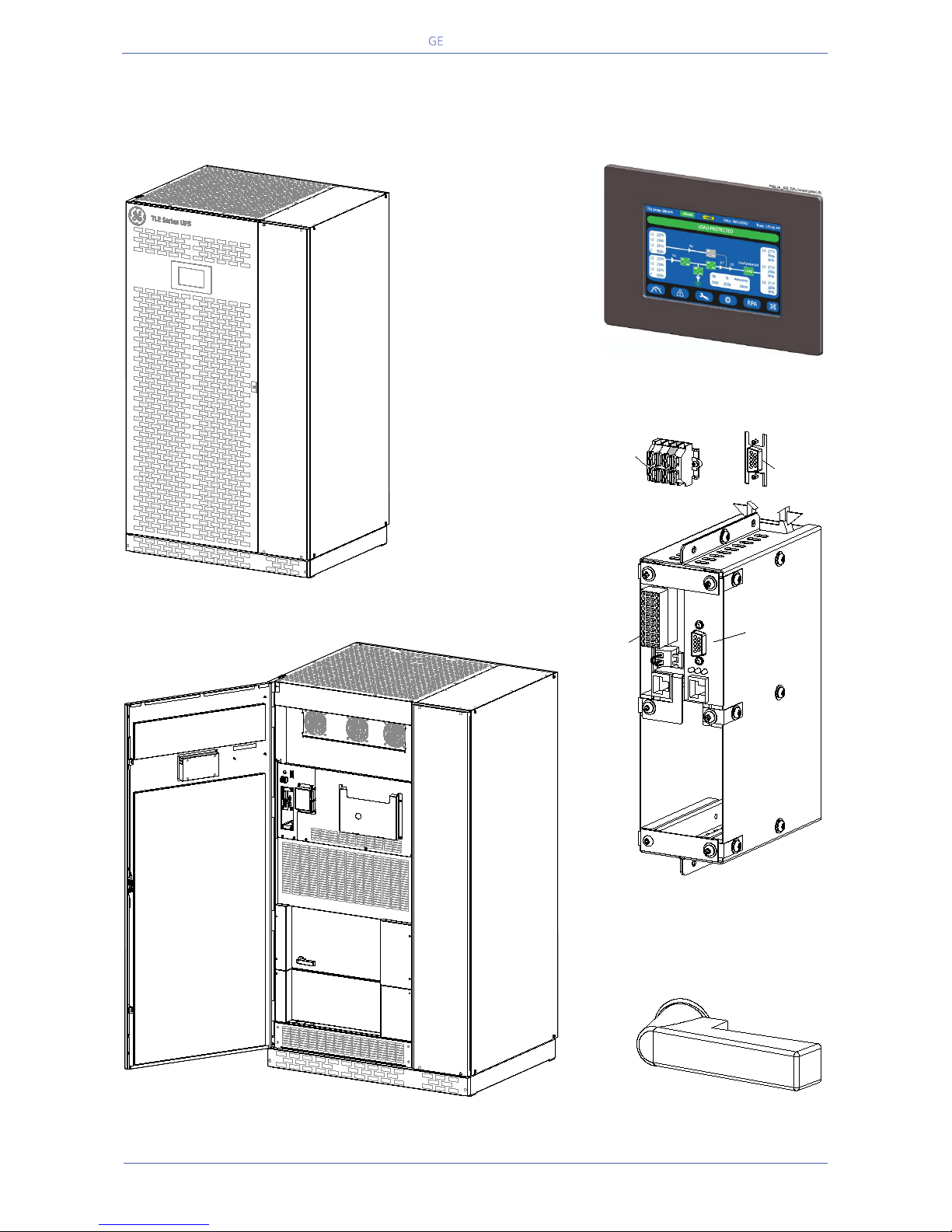

2LAYOUT...............................................................................................................................................................................9

2.1 LAYOUT TLE SERIES 160 - 220 - 225 - 250....................................................................................................................................................... 9

2.2 LAYOUT TLE SERIES 300 - 400 - 500................................................................................................................................................................ 11

3ENVIRONMENT................................................................................................................................................................13

3.1 RECYCLING INSTRUCTIONS.................................................................................................................................................................................. 13

4INSTALLATION.................................................................................................................................................................14

4.1 TRANSPORT................................................................................................................................................................................................................. 14

4.1.1 Dimensions and weights TLE Series 160 - 500 ........................................................................................................................................................... 15

4.2 DELIVERY...................................................................................................................................................................................................................... 16

4.3 STORAGE...................................................................................................................................................................................................................... 16

4.3.1 Storage of the UPS.................................................................................................................................................................................................................... 16

4.3.2 Storage of Battery..................................................................................................................................................................................................................... 16

4.4 PLACE OF INSTALLATION...................................................................................................................................................................................... 17

4.4.1 UPS location ................................................................................................................................................................................................................................. 17

4.4.2 Battery location.......................................................................................................................................................................................................................... 20

4.5 VENTILATION AND COOLING............................................................................................................................................................................... 21

4.6 UNPACKING................................................................................................................................................................................................................ 22

4.7 ELECTRICAL WIRING ............................................................................................................................................................................................... 24

4.7.1 Utility input connection........................................................................................................................................................................................................... 24

4.7.2 Input/output over current protection and wire sizing............................................................................................................................................. 25

4.7.3 Data for Input/output and battery over current protection and wire sizing ............................................................................................... 26

4.7.4 Installation requirements....................................................................................................................................................................................................... 29

4.8 WIRING CONNECTION............................................................................................................................................................................................ 32

4.8.1 TLE Series 160 - 200 - 225 - 250 Power connection with Common Input Utility..................................................................................... 35

4.8.2 TLE Series 160 - 200 - 225 - 250 Power connection with Dual Input Utility............................................................................................... 37

4.8.3 TLE Series 300 - 400 - 500 Power connection with Common Input Utility ................................................................................................. 40

4.8.4 TLE Series 300 - 400 - 500 Power connection with Dual Input Utility........................................................................................................... 42

4.8.5 Use of TLE Series 160 - 500 in eBoost™ Operation Mode..................................................................................................................................... 45

4.8.6 Use of TLE Series 160 - 500 as frequency converter ............................................................................................................................................... 46

4.9 RPA PARALLEL SYSTEM CONNECTION ............................................................................................................................................................ 47

4.9.1 Power wiring of parallel units.............................................................................................................................................................................................. 47

4.9.2 Parallel control bus connection.......................................................................................................................................................................................... 48

4.9.3 Control bus cable location .................................................................................................................................................................................................... 50

4.10 “EPO - EMERGENCY POWER OFF” COMMAND CONNECTION ............................................................................................................... 52

5CUSTOMER INTERFACE..................................................................................................................................................54

5.1 SERIAL PORT J35µP - RS232 (SUB D, FEMALE 9 PIN)................................................................................................................................. 55

5.2 CUSTOMER INTERFACE BOARD.......................................................................................................................................................................... 56

5.2.1 Connector J1 – RJ45 8P8C .................................................................................................................................................................................................... 57

5.2.2 X1 terminal block - Output signals on voltage-free contacts ............................................................................................................................. 57

5.2.3 X1 terminal block - Programmable input free contacts......................................................................................................................................... 57

5.2.4 X2 terminal block – “EPO - Emergency Power Off” ................................................................................................................................................... 58

5.2.5 X1 terminal block - Gen Set Signaling (GEN ON)......................................................................................................................................................... 58

5.2.6 X1 terminal block - AUX external Maintenance Bypass......................................................................................................................................... 59

5.2.7 X1 terminal block - eBoost/IEMi control signal........................................................................................................................................................... 59

6NOTES...............................................................................................................................................................................60

6.1 NOTES FORM.............................................................................................................................................................................................................. 60