VECTOR V1100 Wireless Adapter

4

GE Oil & Gas

PV Units.................................................................................................................................................................................. 26

PV Linearization Mode .................................................................................................................................................... 26

PV Damping Value............................................................................................................................................................ 27

PV Upper Range Value (20 mA)................................................................................................................................... 27

PV Lower Range Value (4 mA) ..................................................................................................................................... 27

Upper Fault Current ......................................................................................................................................................... 27

Upper Limit of Proportional Range........................................................................................................................... 27

Lower Limit of Proportional Range........................................................................................................................... 27

Lower Fault Current......................................................................................................................................................... 27

Automatic Burst Mode Configuration ..................................................................................................................... 28

Factory Reset ...................................................................................................................................................................... 28

Alerts ............................................................................................................................................................................................... 30

Active Alerts......................................................................................................................................................................... 30

Alert History......................................................................................................................................................................... 30

ALERT – Direct Power Out of Range ......................................................................................................................... 30

ALERT – Loop Power Out of Range ........................................................................................................................... 31

ALERT – Temperature Out of Range......................................................................................................................... 31

ALERT – Power Mode Misconfigured........................................................................................................................ 31

ALERT – Watchdog Reset .............................................................................................................................................. 32

ALERT – Stack Overflow ................................................................................................................................................. 32

ALERT – Duplicate HART Master Detected ............................................................................................................ 32

ALERT – HART Devices Count Exceeded................................................................................................................. 33

ALERT – HART Sub-Device Lost................................................................................................................................... 33

ALERT – Burst Packets are Being Dropped ........................................................................................................... 33

ALERT – Field Device Power Control......................................................................................................................... 34

ALERT – Wireless Capacity Denied ........................................................................................................................... 34

ALERT – Burst Message Configuration Issue........................................................................................................ 34

ALERT – Wired Device in Burst Mode....................................................................................................................... 35

ALERT – V1100 Failed to Join the Network ........................................................................................................... 35

ALERT – Radio Malfunction........................................................................................................................................... 35

ALERT – Variable Simulation........................................................................................................................................ 36

ALERT - Field Device Cutoff Occurred...................................................................................................................... 36

ALERT - Low Battery ........................................................................................................................................................ 36

HART DD Menu Tree................................................................................................................................................................. 37

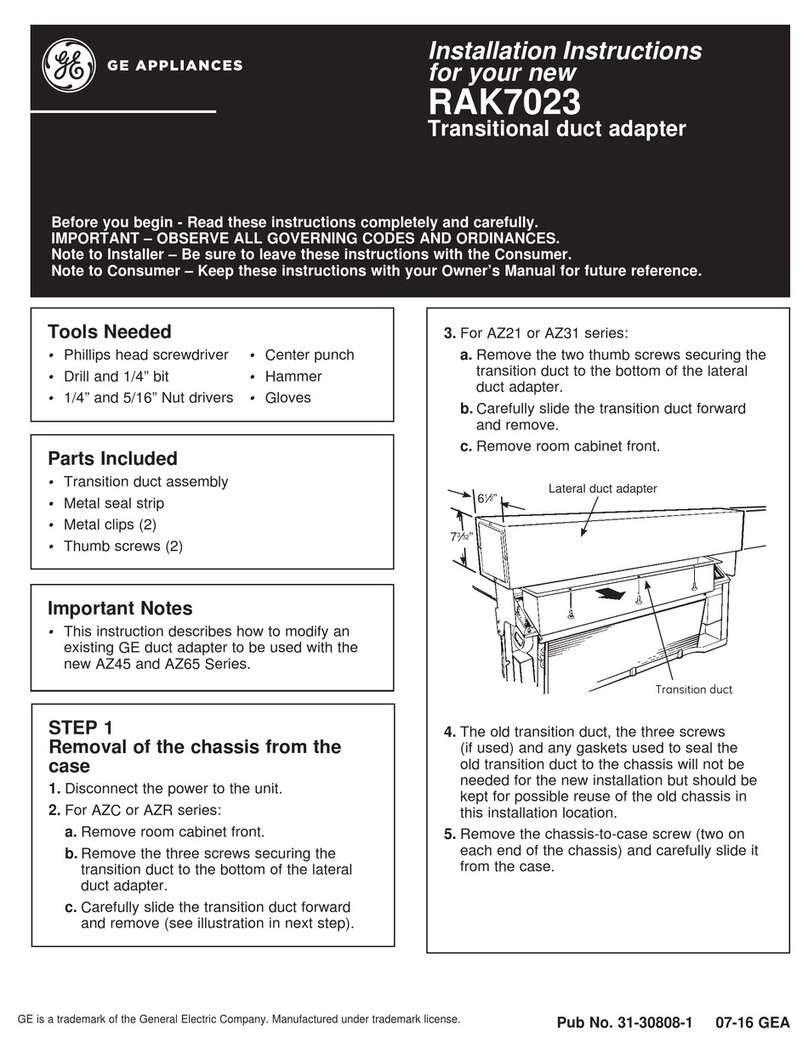

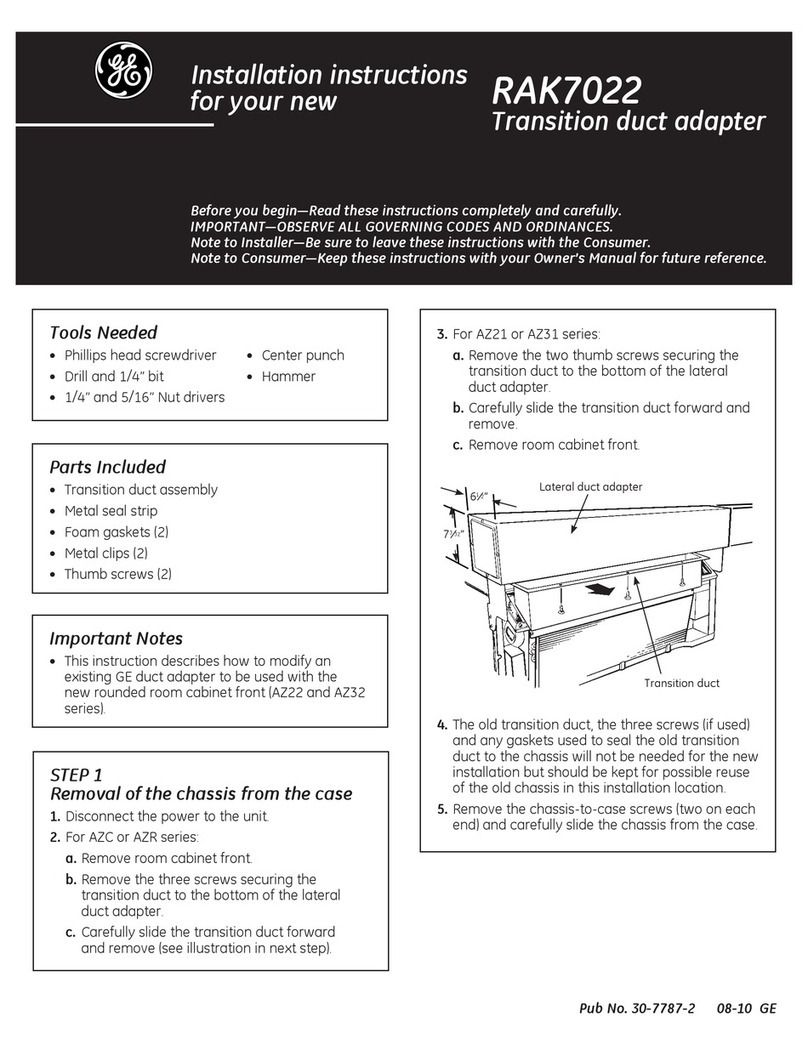

Installation .......................................................................................................................................................................................... 39

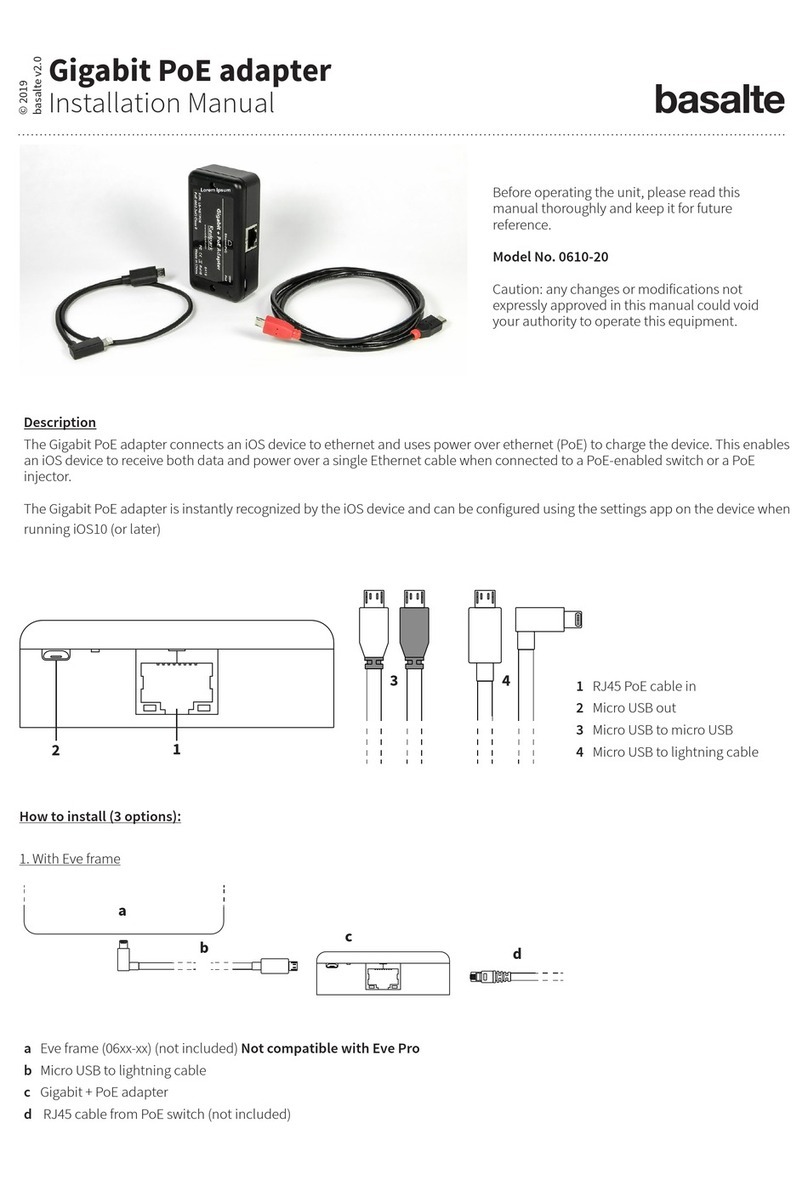

VECTOR V1100 Installation to Field Device................................................................................................................... 39

Field Wiring .................................................................................................................................................................................. 40

Antenna Positioning................................................................................................................................................................. 41

Typical Options........................................................................................................................................................................... 42

VECTOR V1100 as a Standalone Wireless HART Router (Repeater) .......................................................... 42

VECTOR V1100 with a 4-20 mA Analog Only Non-HART Field Device...................................................... 42

VECTOR V1100 with a HART Enabled Field Device............................................................................................ 42

VECTOR V1100 with HART Field Devices in Multi-Drop Mode ...................................................................... 45

VECTOR V1100 with a 4-20 mA Field Device with Battery Powered Operation .................................. 47