30" RADIANT SLIDE-IN CONVECTION RANGE

SURFACE UNIT SWITCHES

HOT SURFACE INDICATOR LIGHT

When glass temperature reaches 150°F, the hot surface indicator light is activated

to alert consumer that glass surface is too hot to touch. The hot surface indicator

light is turned on by an additional set of contacts within the temperature limiter.

229C4059P536

RADIANT HEATING ELEMENT SYSTEMS

Heating Elements: The radiant heating element consists of a resistance

ribbon attached to microporous insulation with molded ceramic fiber walls in

a corrosion-protected metal tray.

The Heating Elements come in four sizes:

• 6″– 240 Volt, 1200 Watts

• 12″– 240 Volt, 3000 Watts (Tri Ring 6″, 9″or 12″)

• Bridge – 240 Volt, 2600 Watts

• 6″– 240 Volt, 120 Watts

CONTROL PANEL ASSEMBLY

Replacing Infinite Switches

1. Remove the two screws holding the

infinite switch.

2. Remove steel control panel insert by

removing 4 screws.

3. From the rear of the control panel

assembly, unplug wires and remove

infinite switch.

4. Repeat steps in reverse order to

reassemble the unit.

Removing Faceplate

1. Turn the power off to the unit.

2. Remove all knobs.

3. Unscrew all faceplate retainers while

holding the faceplate against the

control trim. The retainers must only

be hand-tightened.

4. Move the faceplate 3 inches away

from the control panel and unplug the

harness from the panel.

5. Repeat steps in reverse order to

reassemble the unit.

DUAL CIRCUIT CONTROL

The left-front element has two cooking zones:

• To use the bridge, push to turn the control knob clockwise to desired setting.

• To use the 8

″

cooking area, push to turn the control knob counterclockwise to desired

setting.

When a cooking zone is activated, coils beneath the zone radiate heat through the glass

cooktop to the utensil. The red glow of the coils will be visible through the glass. It will

take the cooking zone on the glass surface a few moments to heat up. The coil cycles on

and off to maintain your selected control setting.

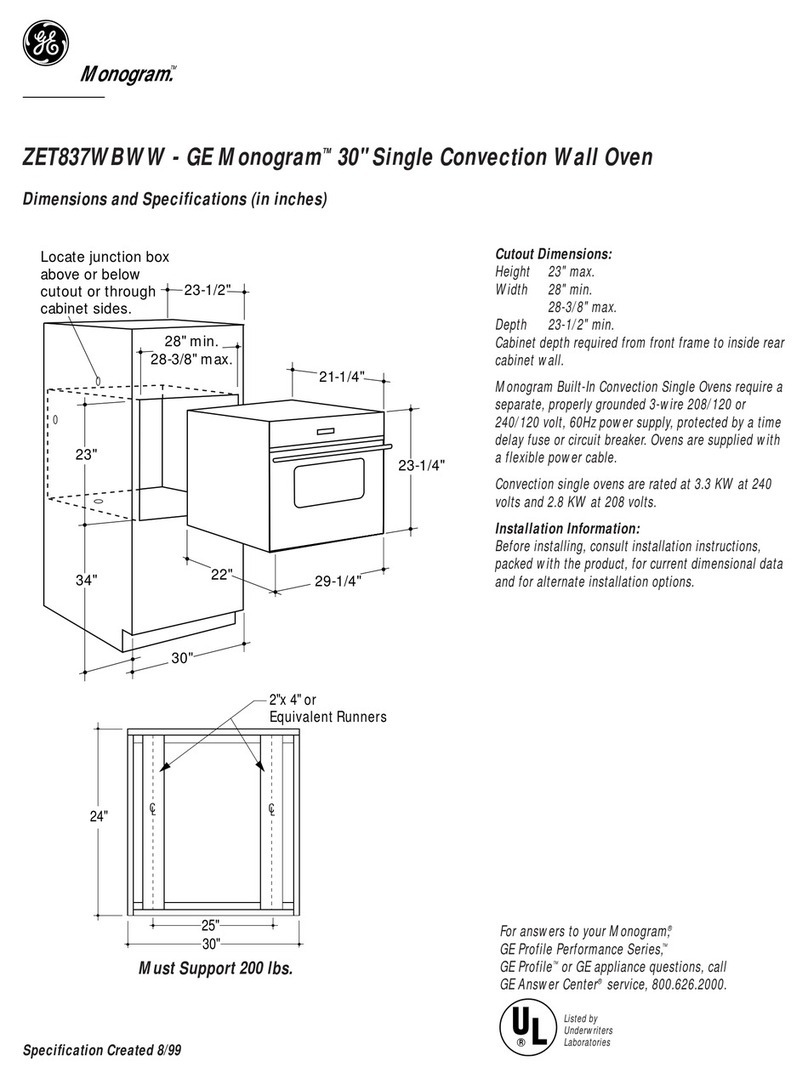

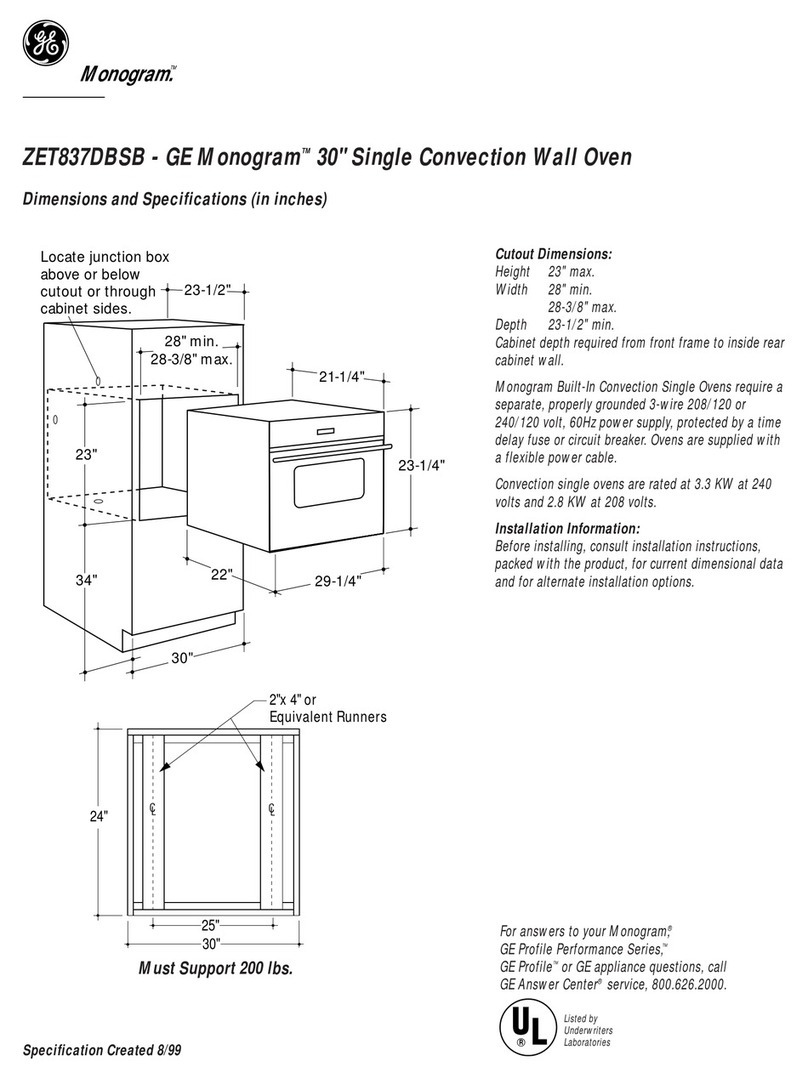

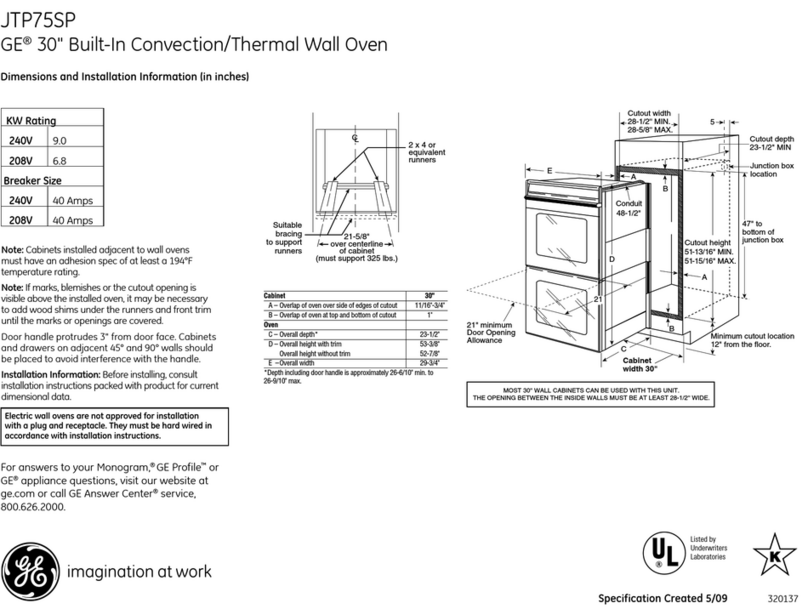

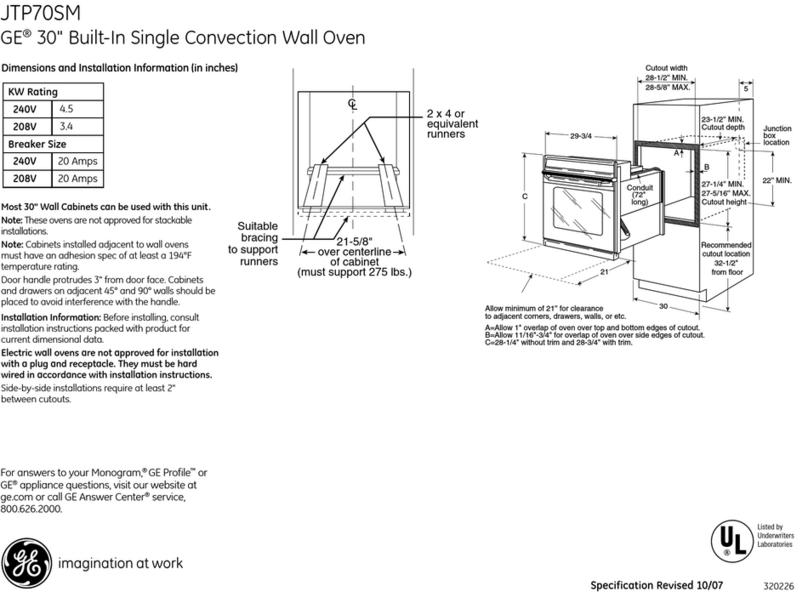

NOTE: Installation information for reference

only. See Installation Instructions shipped

with product for complete details and before

attempting to install.

Anti-tip bracket must be

attached to the floor or wall to hold either

right or left rear leg leveler. Make sure leg

leveler reengages the bracket when range is

moved for any reason.

MINIMUM CLEARANCES

Temperature Limit/Hot Light Switch

The Temperature Limit/Hot Light Switch performs two functions:

1. Turns on HOT LIGHT as soon as glass temperature reaches 150°F. The HOT LIGHT

will remain on until the glass surface above the heating unit has cooled below 150°F

(even after surface unit switch has been turned off).

2. Detects when glass temperature above a unit has exceeded its limit of approximately

1031°F and disconnects power to that unit. When glass temperature cools below 1031°F,

the unit will turn back on.

The Temperature Limit/Hot Light Switch cannot be calibrated.

REMOVABLE OVEN DOOR

COMPONENT COMPARTMENT AIRFLOW

The oven uses a fan for cooling the components. Air is pulled in by the fan

blades and circulated in the component compartment. The air is exhausted

through louvers below the control panel and out the slots above the door.

DOOR ASSEMBLIES:

The doors can be separated into two assemblies: (1) Outer assembly which

consists of handle, vent trim, outer glass, bottom trim and frame; (2) Inner

assembly which consists of inner panel, gasket, glass panels and insulation.

The assemblies are held together by 2 screws on each side, along with 4

screws across the bottom.

CAUTION: Care must be taken when mounting door handle not to overtighten

handle screws. Overtightening screws can damage handle. Hand-tighten

screws (do not use electric driver). Make sure handle fits snuggly to door

panel.

SELF-CLEAN DOOR GASKET:

The door gasket is attached to the inner door

panel by a chain of spring clips.

1.

Locate spring clip at center of gasket and insert in hole on inner door panel near top.

2. Install gasket by bending at 90°beside clip and rocking into hole.

3. Tuck loose ends into slot at the bottom of inner panel.

CONTROL PANEL REMOVAL

The control panel contains the ERC and infinite switches.

To service:

1. Remove faceplate (reference section on control panel assembly).

2. Remove screws (from bottom) securing control panel to vent trim.

3. Remove steel control panel insert by removing 4 screws.

4. Detach from main harness by unplugging the 15-pin and 9-pin connector blocks.

5. Remove 5 screws securing the control panel to the maintop assembly.

6. Control panel can now be removed.

COOKTOP REMOVAL

Before removing the cooktop, the control panel must first be removed (reference section on

control panel removal). The cooktop is fastened to the body side extensions with two (2)

screws. Remove the 2 screws and slide the cooktop assembly forward. Lift the cooktop off.

Heating Element

Micro Porous

Insulation

Ceramic Fiber

Molded Walls

Metal Tray

WARNING

•All ranges can tip

•Injury to persons could result

•Install anti-tip bracket

packed with range

•See Installation Instructions

Adjacent Cabinet

Or Final Location

Of Range Side Panel Wall

Floor-Wood

Bracket

Side

Rear

Leveling

Leg Floor-Concrete

AttachmentToWall

Bracket Wall

Plate

Screw Must

EnterWood

Or Metal

The electronic range control system

consists of the control, key panel,

oven sensor and door lock assembly.

The key panel (control panel) and

electronic control are separate

components but must be tested together.

OVEN SENSOR AND LOCK

SWITCH CONNECTOR

BAKE

RELAY BAKE

L1

"L1"

BLACK

BROIL

RELAY

L1

BROIL

*Approximately 25% on time in Bake.

Bake & Broil relays cannot be on at same time.

There is approx. 1 min. of dead time between

bake and broil unit operation after preheat.

Bake and broil units operate sequentially during first

(preheat)cycle.

** 1 second dead time between bake and broil

units while calling for heat in clean.

"L2"

RED

"L1"

BLACK

L1 BROIL

"L2"

RED

BROIL

RELAY

2700W/16.8

3600 W / 16

BAKE & TIME BAKE*,

BROIL & CLEAN-UNTIL

AFTER 750˚F IS REACHED

3600W/16.4

14.2A

15A

15A

BK

BR

BR

DLB

RELAY

DLB

RELAY

**If convection fan is not working,

make the following checks:

•Check the voltage from terminal CF

to N on control—it should read

120V in Conv Bake or Roast mode.

If not, replace the control.

•If voltage is OK, check the

convection fan motor. It reads

approximately

15–20Ωat room temperature.

Check to make sure the fan shaft is

not rubbing on the oven liner.

L2

L1

N

L1-1

L1-1 CF

M

CONV.

BAKE

**CONV.

FAN

DOOR

SW.

2500W

22

CONVECTION BAKE

NO C

L2

L1

N

L1-1

L1-1 CF

M

BROIL

**CONV.

FAN

DOOR

SW.

4000W

14.4

CONVECTION ROAST

NO C

240V.

240V.

10.4A 10.4A

15A 15A

CONV-1

BROIL-1

**Convection Fan Not Running

DLB

RELAY

DLB

RELAY

P2

S1

S2

4

2

P1

EGO

TOP

DUAL VOLTAGE SENSITIVE

4

2

P1 P2

L2

L1

S2

Indicator

Light

Load 1

4a

S1

Load 2

4a

KEY PANEL

IMPORTANT SAFETY NOTICE: This information is intended for use by

individuals possessing adequate backgrounds of electrical, electronic

and mechanical experience. Any attempt to repair a major appliance may

result in personal injury and property damage. Neither the manufacturer

nor the seller can be responsible for the interpretation of this information

or assume any liability in connection with its use.

DISCONNECT POWER BEFORE SERVICING

IMPORTANT: RECONNECT ALL GROUNDING DEVICES. All parts of this

appliance capable of conducting electrical current are grounded. If

grounding wires, screws, straps, clips, nuts or washers used to complete

a path to ground are removed for service, they must be returned to their

original position and properly fastened.

GROUNDING SPECIFICATIONS

Ground Path Resistance 0.10Ω Max.

Insulation Resistance 250KΩMin.

INSTALLATION REQUIREMENTS

Power Supply: This appliance must be supplied with proper voltage and

frequency, and connected to an individual, properly grounded branch

circuit, protected by a circuit breaker or time-delay fuse, as noted on rating

plate. Wiring must conform to the National Electrical Codes. The rating plate

is located on the lower front frame above the storage drawer.

Overcurrent Protection Ranges

236V

12.4

15.4

21.4

208V

___

12.4

17.4

NEC Maximum Kilowatt Rating

Rating

35 Amp

40 Amp

50 Amp

240V

12.4

16.0

22.0

REMOVABLE OVEN DOOR

The door is very heavy. Be careful when removing

and lifting the door. Do not lift the door by the handle.

To Remove:

1. Fully open the door.

2. Push the hinge locks down toward the door frame,

to the unlocked position. Atool, such as a small

flat-blade screwdriver, may be required.

3. Firmly grasp both sides of the door at the top.

To Replace:

1. Firmly grasp both sides of the door at

the top.

2. With the door at the same angle as the

removal position, seat the indentation of

the hinge arm into the bottom edge of the

hinge slot. The notch in the hinge arm must

be fully seated into the bottom of the slot.

Removal position

Push hinge locks up to lock

3. Fully open the door. If the door will not fully open,

the indentation is not seated correctly in the

bottom edge of the slot.

4. Push the hinge locks up against the front frame of

the oven cavity, to the locked position.

5. Close the oven door.

4. Close door to the door removal position, which is halfway

between the broil stop position and fully closed.

5. Lift door up until the hinge arm is clear of the slot.

Bottom Edge

of Slot Hinge Arm

Indentation

Hinge Arm

Hinge

Lock

Key Panel Test

Press each pad on the key panel followed by the Clear/Off pad. If the key panel is

functioning properly, the following should occur:

•Bake, Broil, Convection Bake, Convection Roast, Clean, Timer, Clock, Stop Time and

Cook Time Modes –Audible tone plus display showing mode of operation selected.

•Clear/Off –Audible tone and display shows time of day.

•Probe –Audible tone and response if meat probe is plugged in.

•Numerical Pads –Audible tone. Can only be used after another function has been

selected.

Glass Touch Models ONLY –Lock Reference Command

When the control panel is accessed, the signals used by glass touch control may

be adversely affected. To compensate for this change in signals, the following

procedure must be followed every time the control panel is accessed.

1. Make sure power to the range is turned off.

2. Completely close the range control panel and return the range to its normal

installation.

3. Apply power to the range.

Steps to Follow if the Control is NOT Replaced

Step

4

5

6

7

Key presses (Digi-pad)

Bake & Broil

9 & 0

1 & 5

6 & 8

Key presses (Slew-pad)

Bake & Broil

Hour Down & Minute Down

Temp Up & Minute Up

Hour Down & Minute Up

Action

Enter SF

Reset control

Reset LOCK REF

Acknowledge

LOCK REF

Steps to Follow if the Control IS Replaced

Step

5Key presses (Digi-pad)

6 & 8 Key presses (Slew-pad)

Hour Down & Minute Up Action

Acknowledge

LOCK REF

Accessing the control panel area and replacing the control:

4. After power is applied to the range, the control will briefly display all segments,

briefly display “LOC REF,”display all segments for 30 seconds, and then display

“LOC REF.”

5. Acknowledge the “LOC REF”command by pressing the 6and 8or the HOUR

DOWN and MINUTE UP keys at the same time. The control should then display

the time of day.

6. The oven should be ready for normal operation.

7. If steps 4–6 do not occur as described, repeat the process or follow steps

1–9 in the section above.

8. Test the functionality of the glass touch control, especially the CLEAR/OFF

and/or CANCEL key(s).

KEY PANEL (cont.)

Slot

Hinge Lock

Pull hinge locks down to unlock

Accessing the control panel area but not replacing the control:

4. Enter Special Functions mode by pressing the Bake and Broil keys at the same

time.

5. Reset the control by pressing the 9 and 0 or the Hour Down and Minute Down

keys for 3 seconds at the same time.

6. Approximately 20 seconds after the time of day is displayed, press the 1and 5 or the

TEMP UP and MINUTE UP keys. The control should briefly go blank, briefly display

all segments, briefly display “LOC REF,”display all segments for 30 seconds, and

then display “LOC REF.”

7. Acknowledge the “LOC REF”command by pressing the 6 and 8 or the HOUR

DOWN and MINUTE UP keys at the same time. The control should then display the

time of day.

8. The oven should be ready for normal operation.

9. Test the functionality of the glass touch control, especially the CLEAR/OFF and/

or CANCEL key(s).

TRI-RING CIRCUIT CONTROL

The right-front element has three cooking zones:

•To use the large 12

″

cooking area, push to turn the control knob clockwise to desired

setting.

•To use the small 6

″

cooking area, push to turn the control knob counterclockwise to

desired setting.

•To use the 9

″

cooking area, push to turn the control knob either clockwise or

counterclockwise to the zone between the zones for 6

″

and 12

″

elements on the

control panel. Release the knob at the desired setting.

1

2

3

4

5

6

7

8

SENSOR

1100 @ RM

2650 @ 865

˚

F

*NOT ON ALL MODELS

UNLOCK

SW. 2

LOCK

SW. 1

MEAT PROBE*

50K @ RM

CONTROL

CONNECTOR

PLUG

THERMAL

SWITCH

OPEN 240

˚

F

CLOSES 190

˚

F

THERMAL

SWITCH

OPEN 169˚F

CLOSES 140˚F