– 3 –

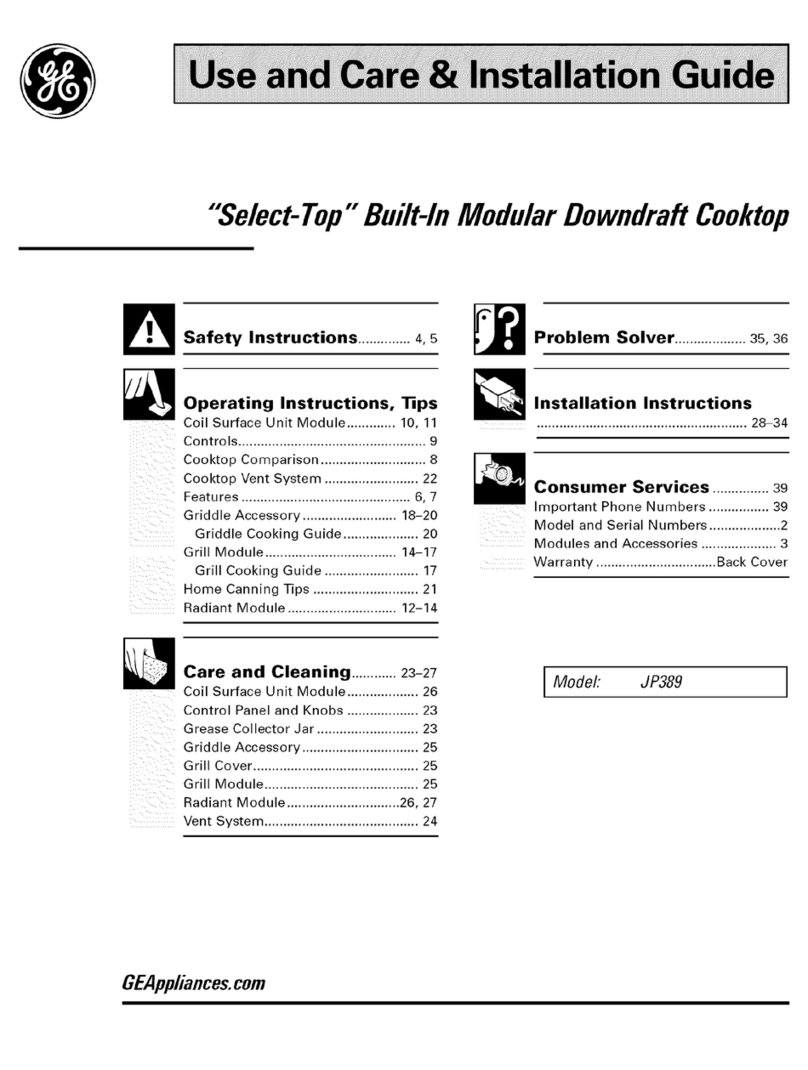

Blower Thermal Cutout....................................................................................................16

BurnerAlignment .............................................................................................................12

BurnerValve.....................................................................................................................11

Check for Proper Ignition .................................................................................................12

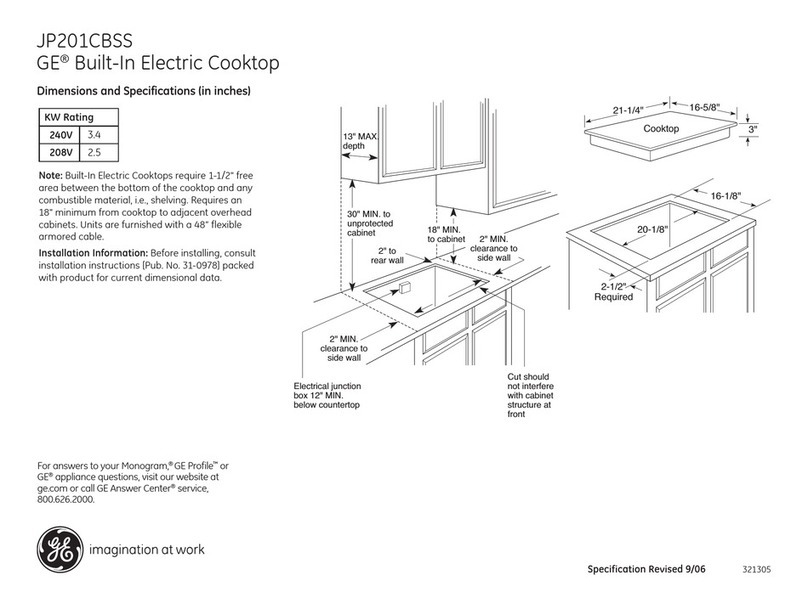

Component Access ...........................................................................................................8

Component Locator Views ................................................................................................6

Components ......................................................................................................................8

Convection Fan Assembly ...............................................................................................18

Door Assemblies ...............................................................................................................9

Flame Characteristics .....................................................................................................11

Grates ..............................................................................................................................12

GriddleLeveling ...............................................................................................................15

GriddleRemoval ..............................................................................................................14

Griddle Thermostat Adjustment .......................................................................................15

Grill Burner/Griddle Burner Ignition Systems (On Some Models) ....................................13

GrillorGriddleAirAdjustment ..........................................................................................15

GrillorGriddle Igniter Removal ........................................................................................16

Grill Removal ...................................................................................................................14

IgnitionandRe-ignition .....................................................................................................12

Introduction ........................................................................................................................4

Lock MotorAssembly.......................................................................................................19

Nomenclature ....................................................................................................................5

Orifice Conversion Kits.................................................................................................... 11

Oven Blower Motor (30-in. Range Models) ......................................................................20

Oven Blower Motor (36-in. and 48-in. Range Models) .....................................................19

Oven Door .........................................................................................................................8

Oven Light Bulbs .............................................................................................................10

Oven Select Switches .....................................................................................................17

Oven Thermostat.............................................................................................................17

Oven Thermostat Calibration...........................................................................................16

Relays, Convection Pulser Timers and Main Power Connection.....................................17

Schematics and Wiring Diagrams...................................................................................21

Simmer Orifice Burner Replacement .............................................................................. 11

Sparking...........................................................................................................................12

SparkModule ...................................................................................................................13

Surface Burner ................................................................................................................10

Surface Burner Adjustments............................................................................................ 11

Warranty ..........................................................................................................................30

TABLE OF CONTENTS