– 4 –

Front Control Console.........................................................................................................................................................32

Front Control UI, Light Pipe and Buttons....................................................................................................................33

Pocket Handle (Front Control Only)...............................................................................................................................33

Top Control Panel, UI, Light Pipe and Buttons.........................................................................................................33

Top Control Console Cover...............................................................................................................................................35

Outer Door Panel...................................................................................................................................................................35

Hinges........................................................................................................................................................................................35

Inner Door Panel...................................................................................................................................................................36

Door Strike................................................................................................................................................................................36

Door Gasket.............................................................................................................................................................................36

Vent Parts.................................................................................................................................................................................37

Detergent Dispenser...........................................................................................................................................................38

Floor Protect Pan...................................................................................................................................................................39

Sump Module..........................................................................................................................................................................41

Sump Gasket...........................................................................................................................................................................43

Installing Sump Module.....................................................................................................................................................43

Electronic Controls..........................................................................................................................................................................44

Consumer Error Mode.........................................................................................................................................................44

On the Main Control Board CSM....................................................................................................................................46

Service Mode...........................................................................................................................................................................47

Diagnosing Electronic Control Boards........................................................................................................................48

Main Control Diagnostics..................................................................................................................................................48

UI Diagnostics.........................................................................................................................................................................50

Inverter Control Board........................................................................................................................................................51

Inverter and Motor Diagnostics.....................................................................................................................................52

WiFi Connect.....................................................................................................................................................................................56

Tub Lighting........................................................................................................................................................................................58

Fill System...........................................................................................................................................................................................59

Water Level..............................................................................................................................................................................59

Diagnostics..............................................................................................................................................................................60

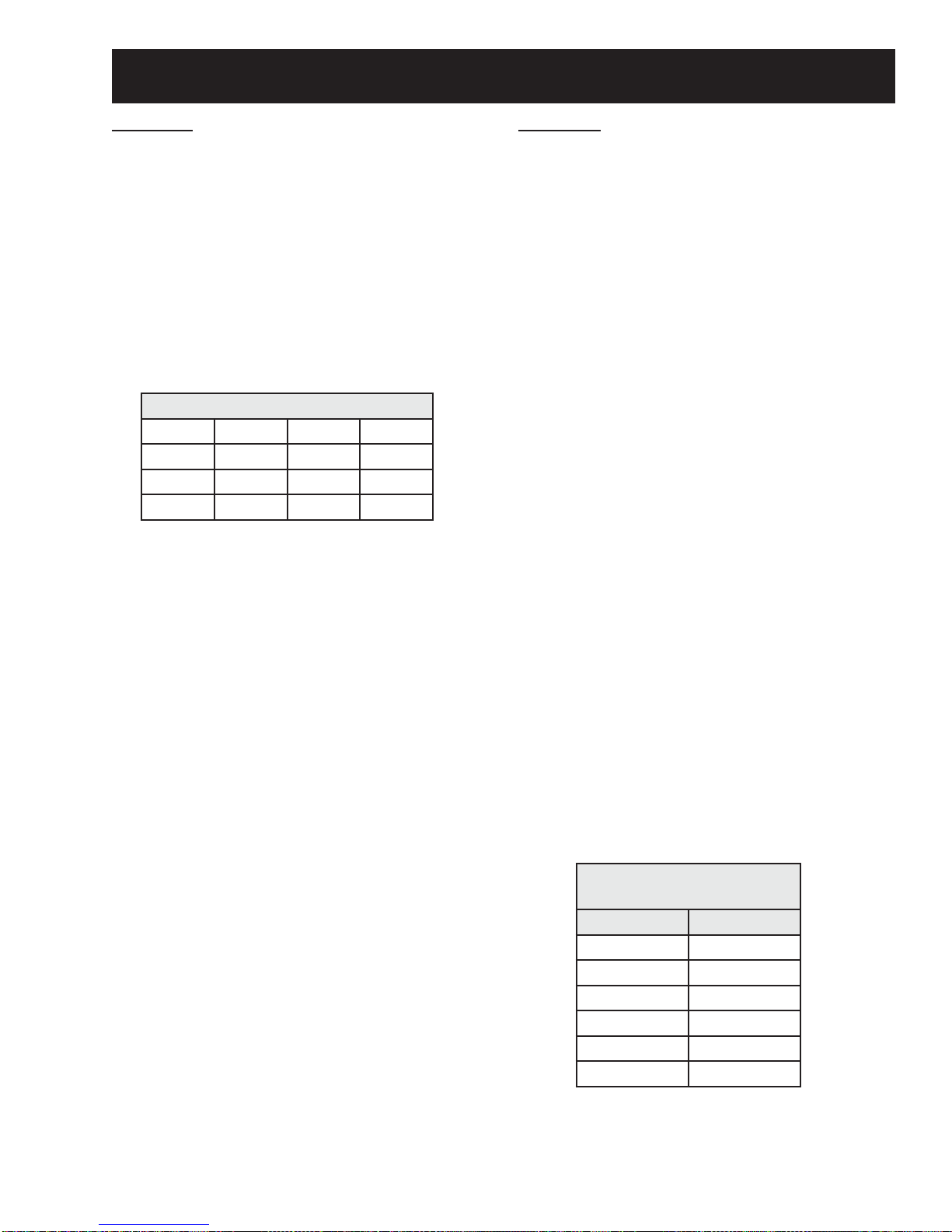

Flood Float and Switch.......................................................................................................................................................61

Air Gap.......................................................................................................................................................................................61

Water Valve Removal..........................................................................................................................................................62

(Continued next page)