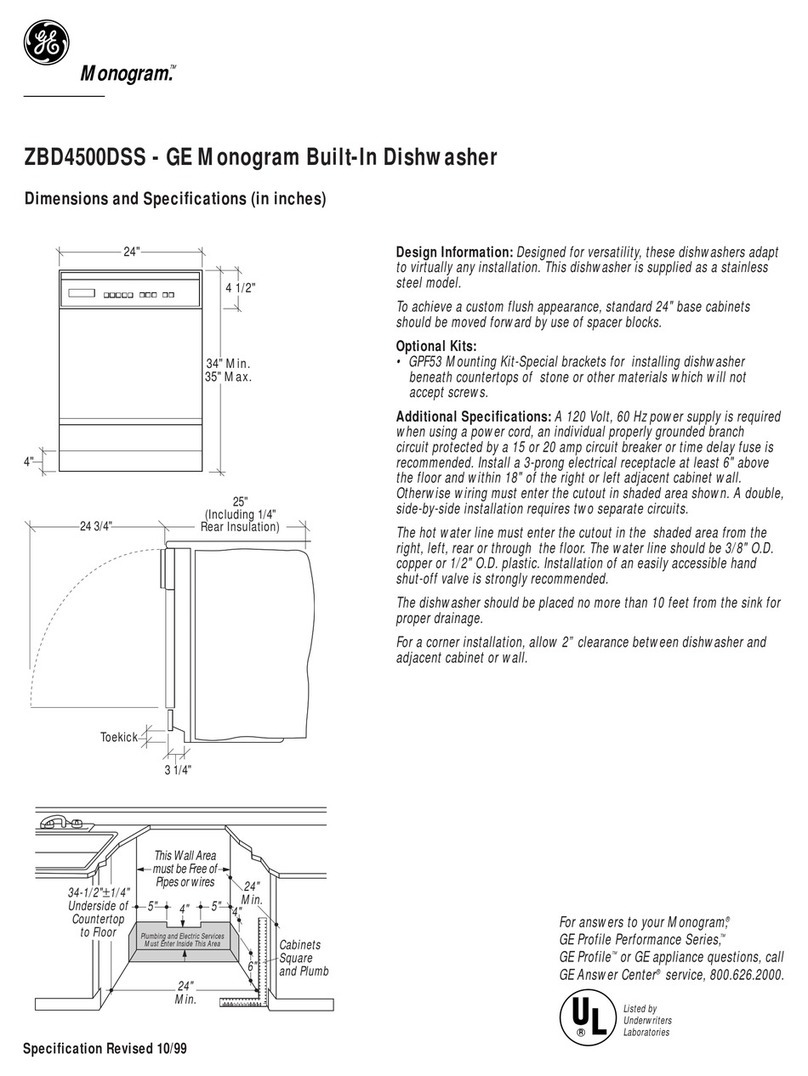

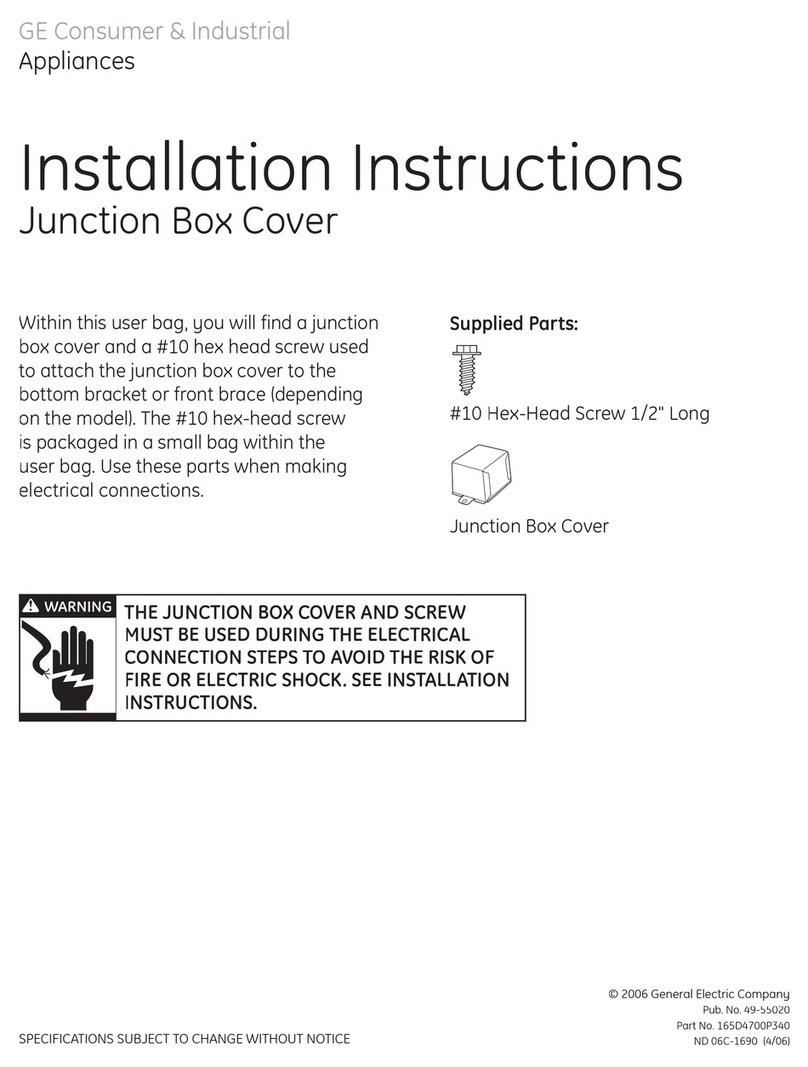

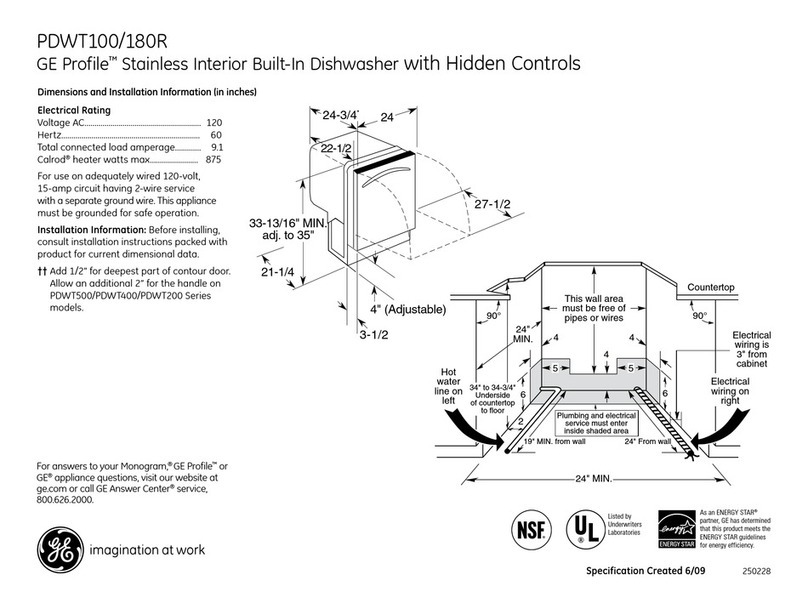

Installation Instructions

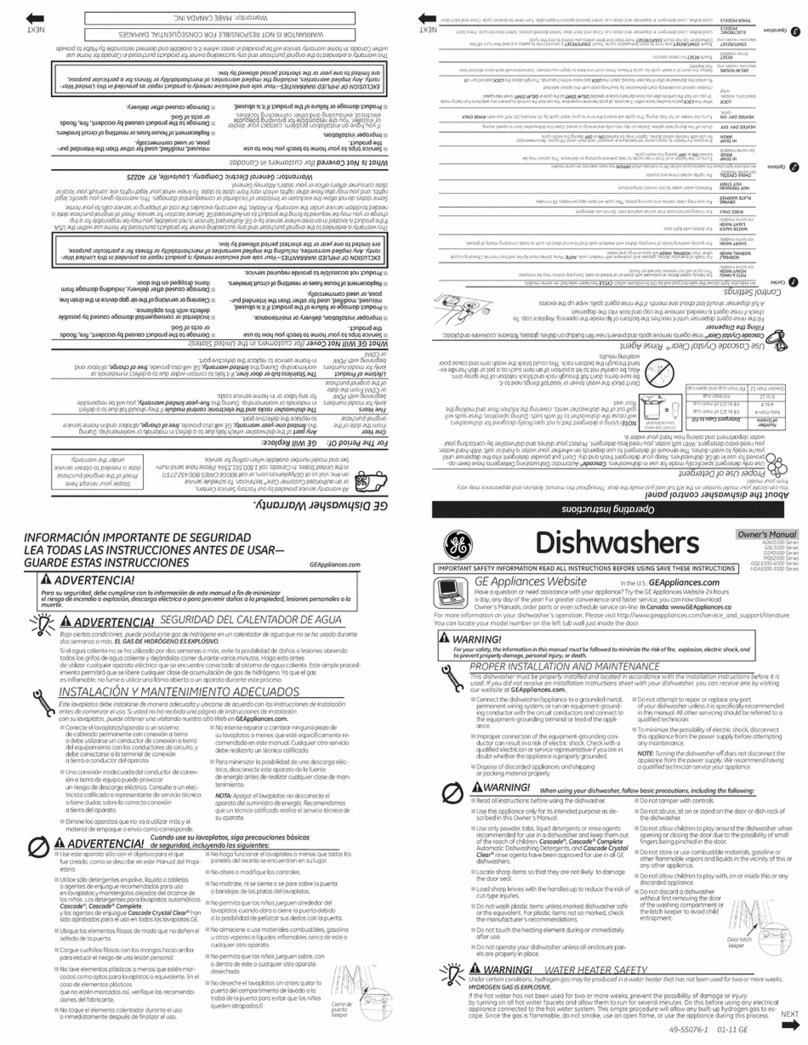

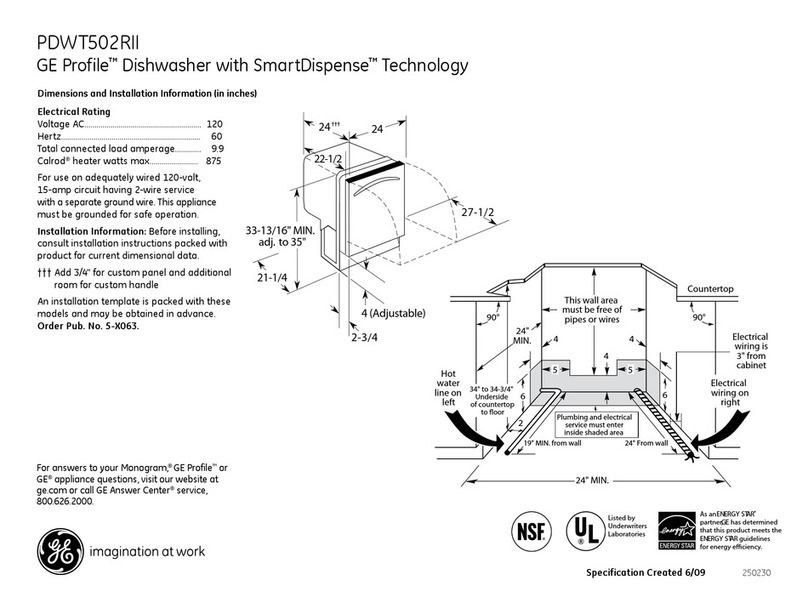

• The line may enter from either side, rear or fl oor within the

shaded area shown in Figure F.

• The line may pass through the same hole as the electrical

cable and drain hose. Or, cut an additional 1-1/2" diameter

hole to accommodate the water line. If power cord with plug is

used, water line must not pass through power cord hole.

• Turn off the water supply.

• Install a hand shut-off valve in an accessible location, such as

under the sink. (Optional, but strongly recommended and may

be required by local codes.)

• Water connection is on the left side of the dishwasher. Install

the hot water inlet line, using no less than 3/8" copper tubing.

Route the line as shown in Figure F and extend forward at least

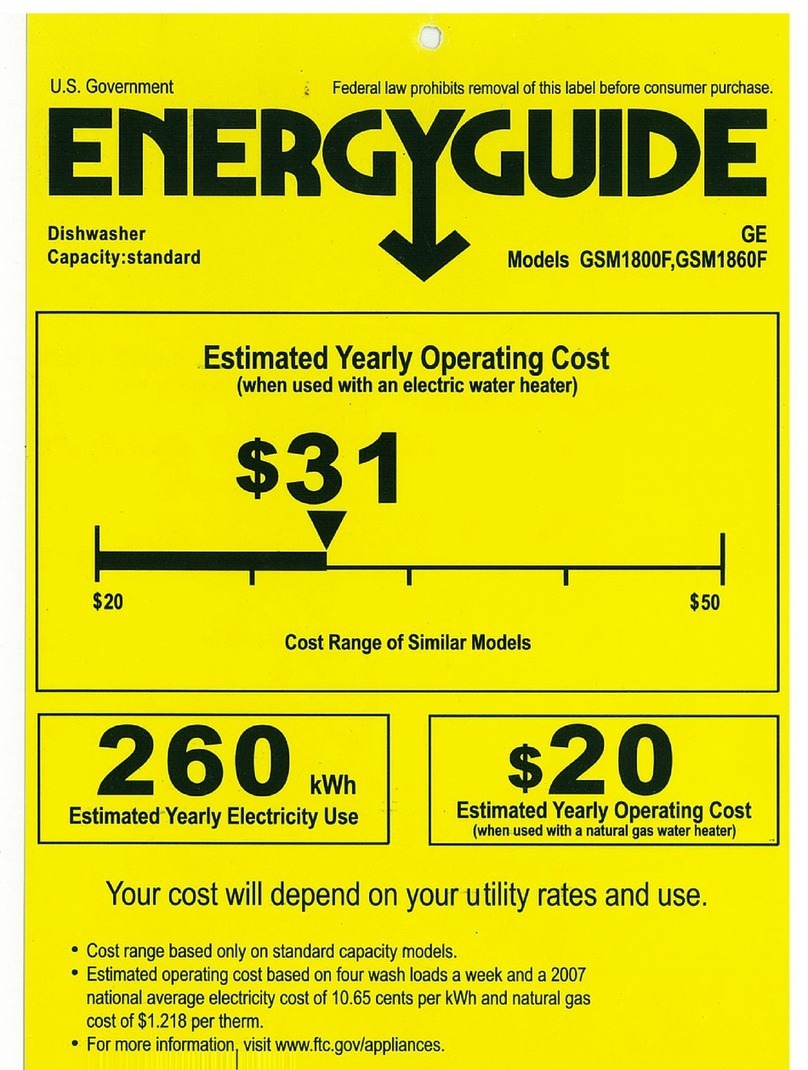

• Adjust water heater for 120°F to 150°F temperature.

• Flush water line to clean out debris.

• The hot water supply line pressure must be 20-120 PSI.

Do not remove wood base until you are ready to install the

dishwasher. The dishwasher will tip over when the door is opened

if the wood base is removed.

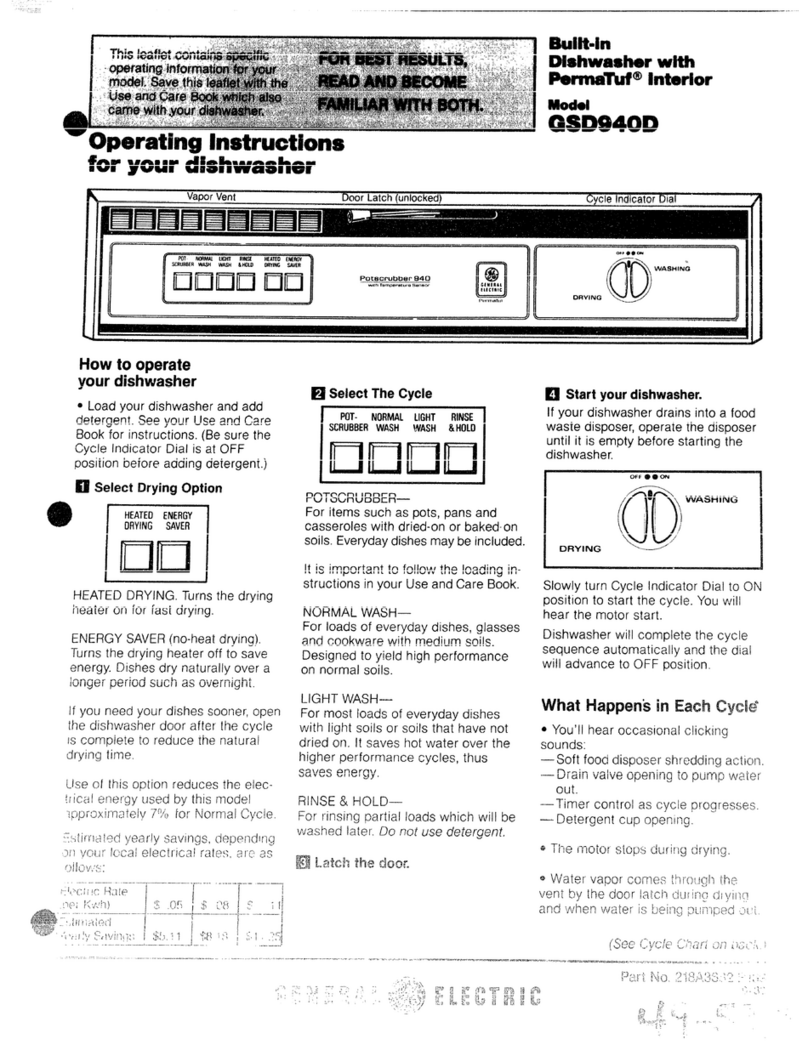

STEP 2–CHECK DOOR BALANCE

• With dishwasher on the wood skid, check the door balance by

opening and closing the door.

• If the door drops when released, increase the spring tension. If

the door rises when released, decrease the tension.

Increase or decrease tension

as shown. Adjust both springs

to the same tension setting

If door spring adjustment is necessary, check door opening

and closing. If door does not open easily or falls too quickly,

check spring cable routing. The cable is held in place by

“shoulders” on the pulley. Check to be sure cable has not slipped

over the pulley shoulders.

STEP 3– REMOVE WOOD BASE,

Do not kick off wood base!

• Move the dishwasher close to the installation location and lay

• Remove the four leveling legs on the underside of the wood

base with an adjustable wrench or 15/16" socket.

• Screw leveling legs back into the dishwasher frame,

approximately 1/8" from frame as shown.

Increase

Spring

Tension

Decrease

Spring

Tension

Correct

Incorrect

Insert Hook

Over Bracket

05A-1182N

6"

661Dia56

5" 5" 4"

Cabinet Face

Shut-off

Valve

4"

2" From Floor

19" From Wall

2"

From

Cabinet

1-1/2" Dia.

Hole

Hot

Locate the items in the installation package and set aside for use

Screw kit – Steps 5 or 18 and 15

Side mount kit (some models) – Step 12

Junction box cover – Step 5 or 18

Drain hose and clamp – Step 7

Trim pieces (some models) – Step 11

Owner's Manual - Steps 19 and 22

Product Samples and/or coupons – Step 22