– 3 –

Active Vent.......................................................................................................................21

Circulation Pump and Motor ............................................................................................13

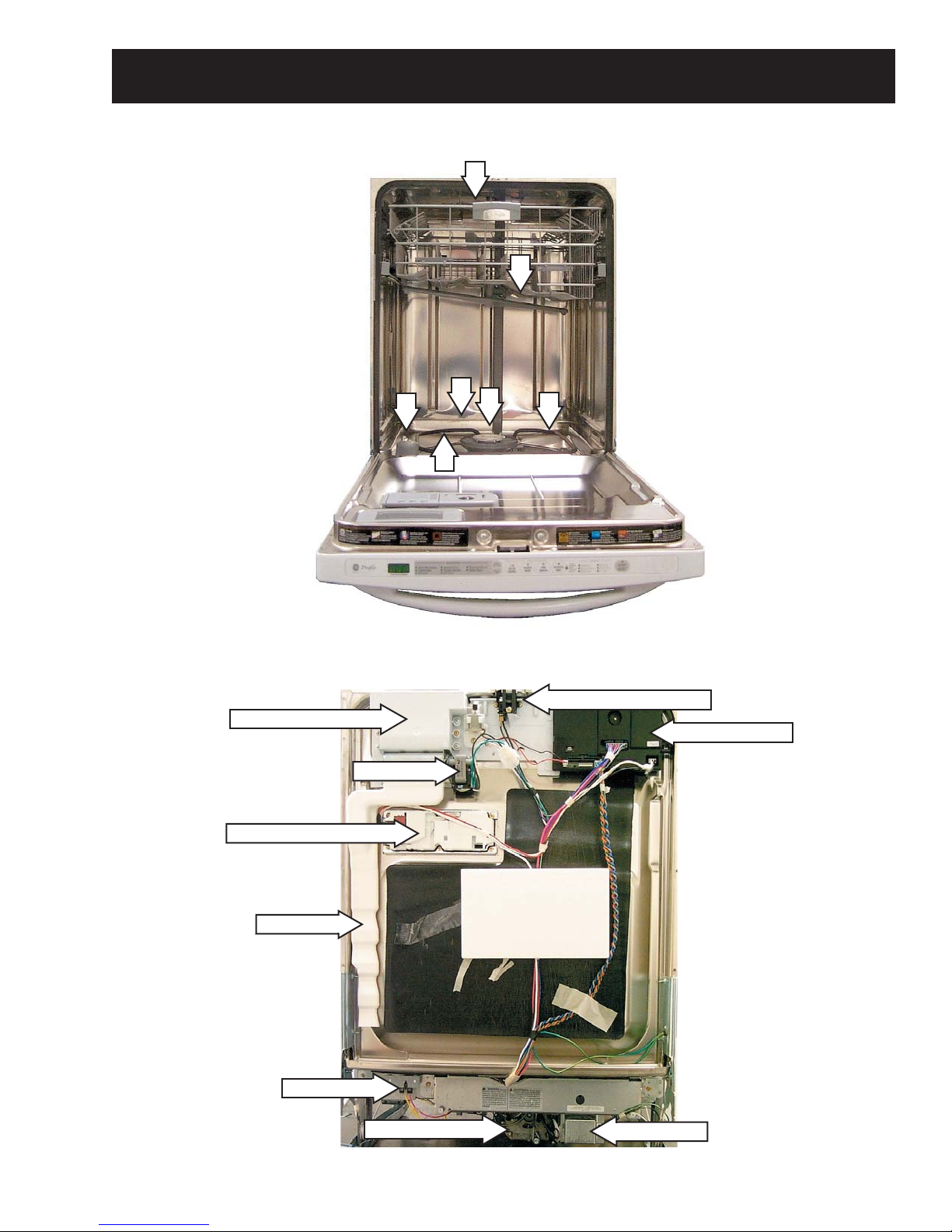

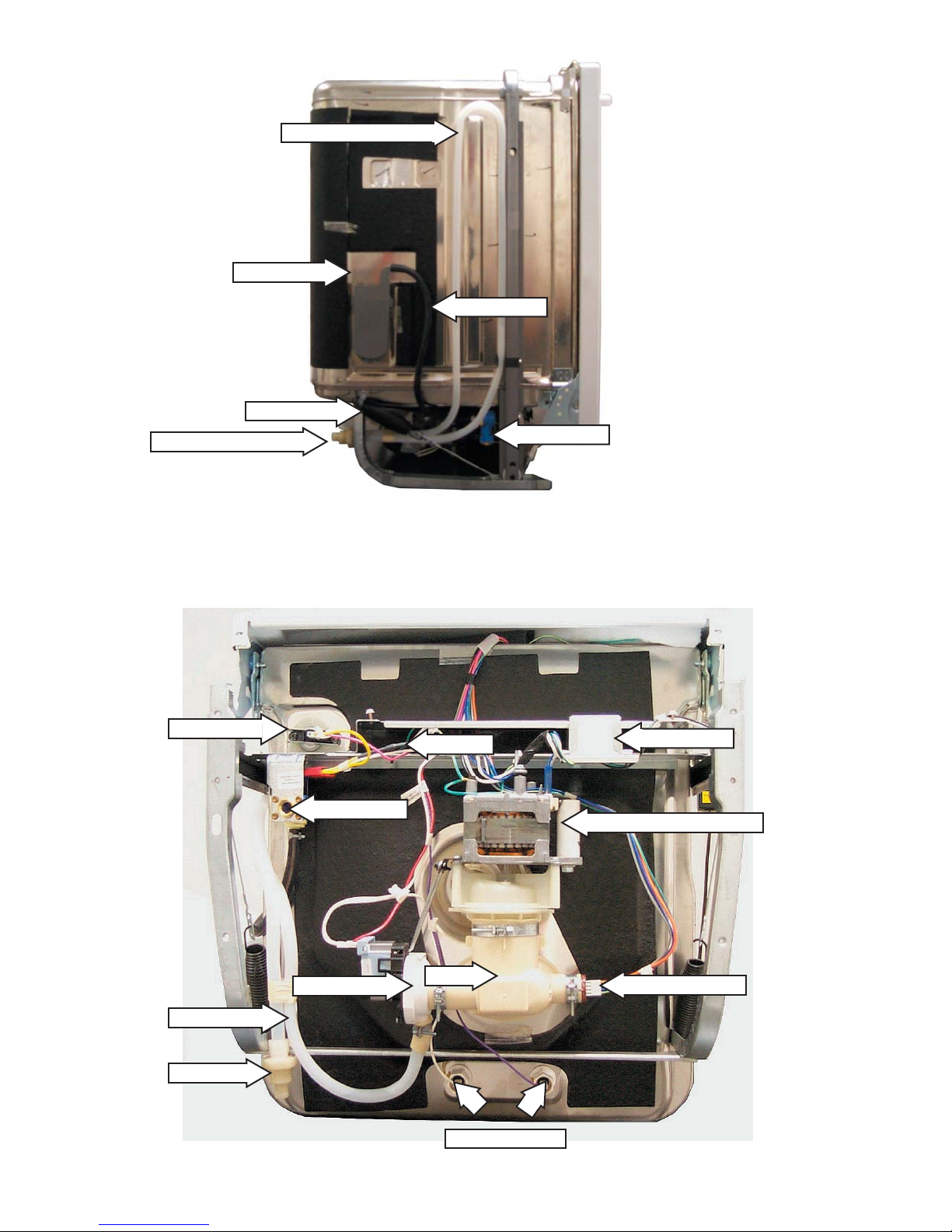

Component Locator Views.................................................................................................9

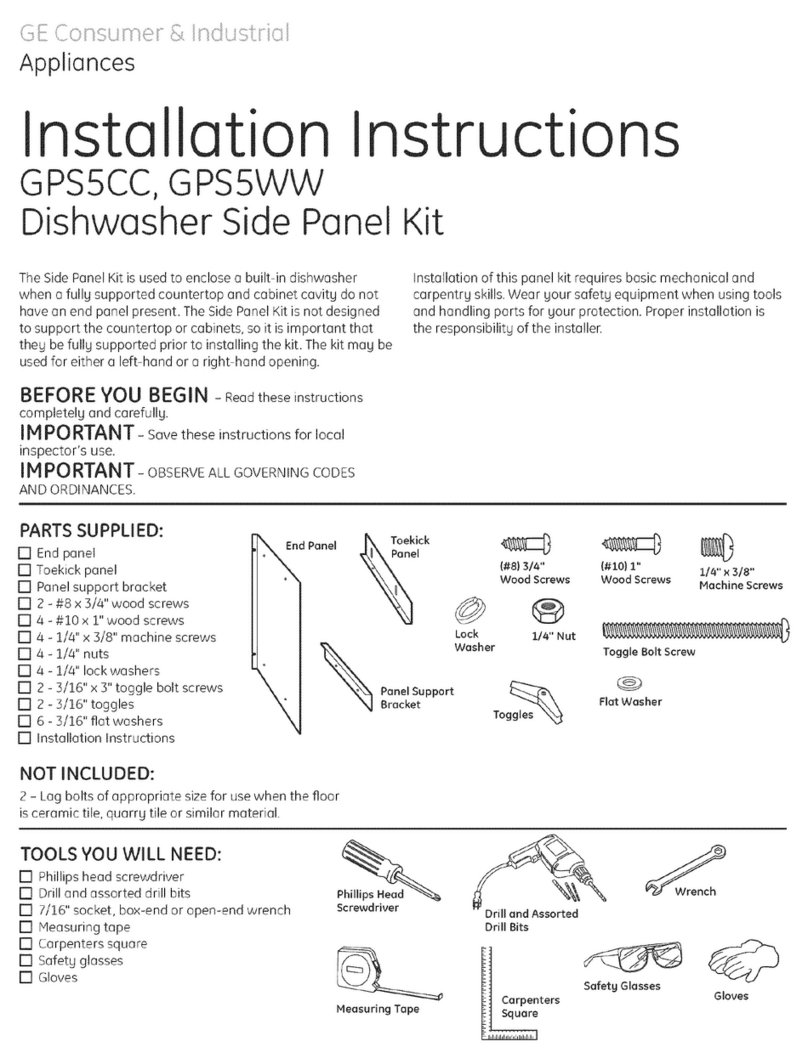

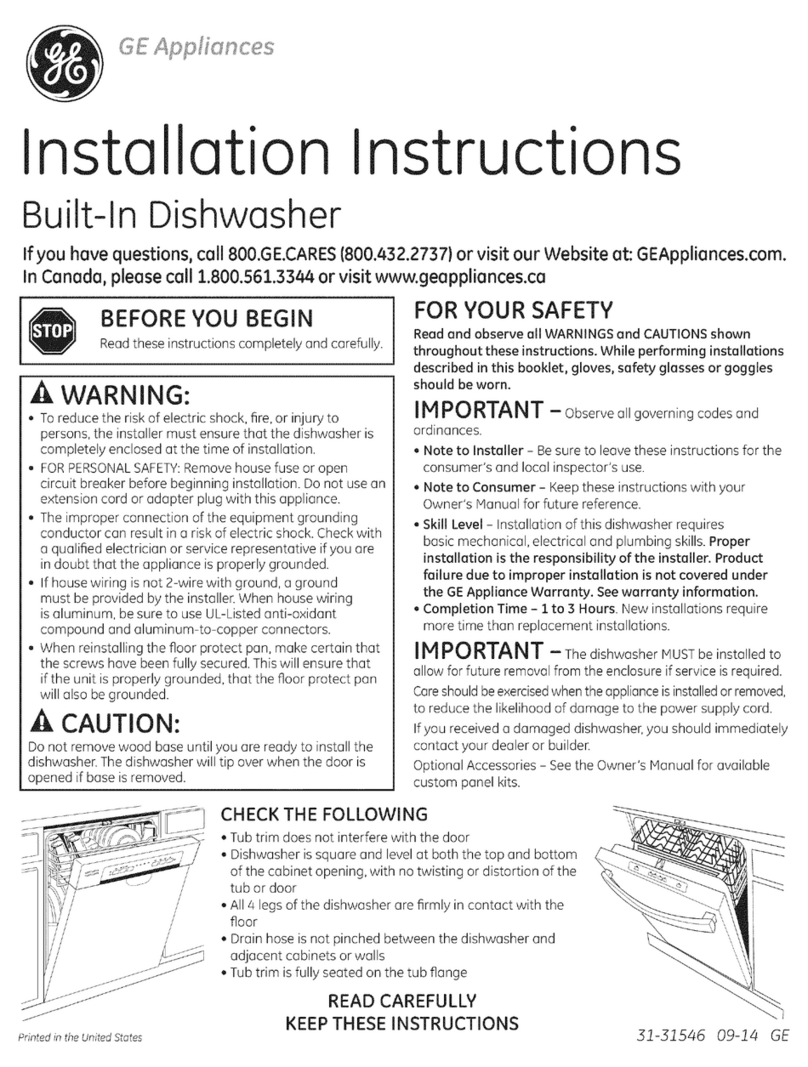

Components ....................................................................................................................11

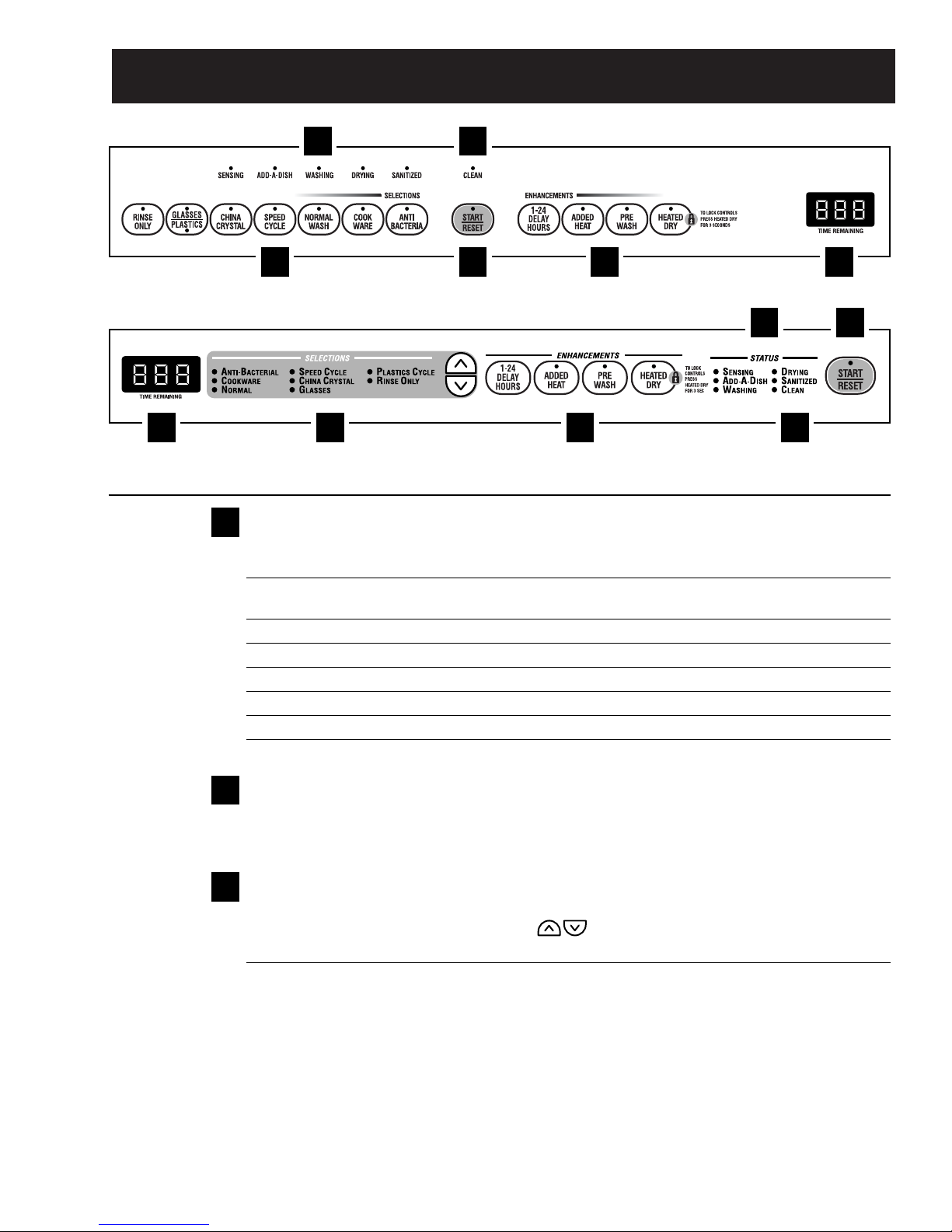

Control Features................................................................................................................5

Control Module ................................................................................................................19

Control Module Board......................................................................................................19

Demo Mode .....................................................................................................................14

Detergent/Rinse Module .................................................................................................20

Door Interlock Switch ......................................................................................................20

Door Panel ......................................................................................................................18

Drain System ...................................................................................................................16

Factory Test Mode ...........................................................................................................23

Fan...................................................................................................................................21

Fill Funnel ........................................................................................................................12

Heating Element ..............................................................................................................14

Lower Spray Wash Arm, Fine Filter, and Inlet Cover.......................................................12

Main Conduit ...................................................................................................................12

Membrane Keypad ..........................................................................................................18

Middle Spray Arm ............................................................................................................11

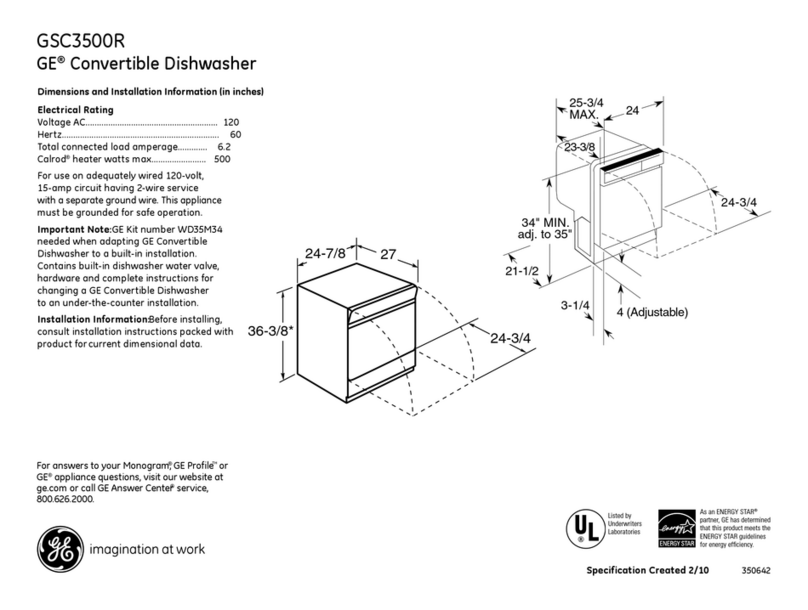

Nomenclature ...................................................................................................................4

Schematic........................................................................................................................26

Service Mode...................................................................................................................22

Strip Circuits ....................................................................................................................25

Transorb ..........................................................................................................................17

Troubleshooting ..............................................................................................................24

Turbidity Sensor...............................................................................................................15

Upper Spray Arm .............................................................................................................12

Using the Dishwasher with the Upper Rack Removed.................................................... 11

Wash Cycles....................................................................................................................13

Warranty .........................................................................................................................27

Water Valve and Flood Switch ........................................................................................16

Water Valve Test .............................................................................................................17

Table of Contents