ExhaustInformation

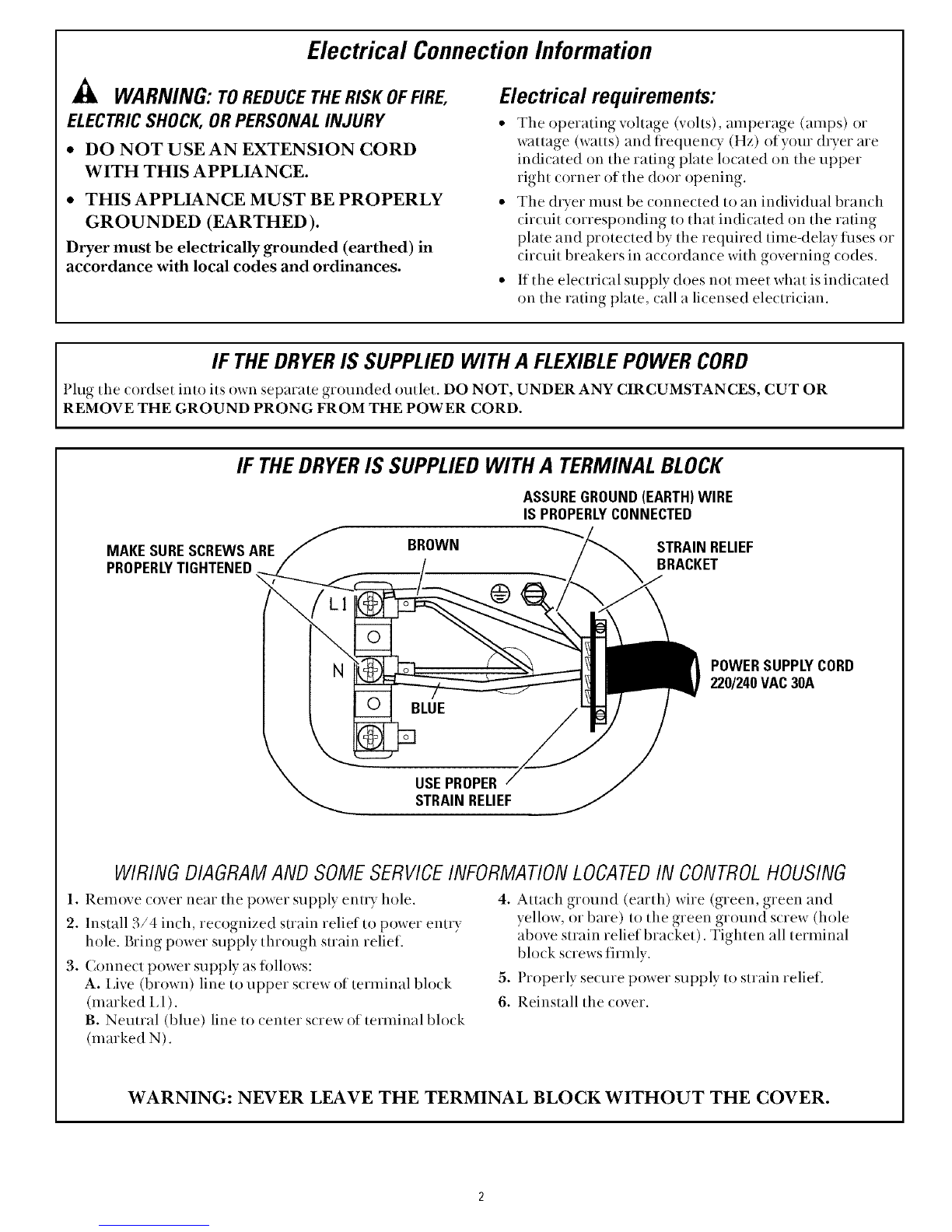

WARNING: TOREDUCE THERISK OFFIRE

AND PERSONALINJURY

•Use only metal duct for exhausting dryer to outdoors.

•Do not terminate exhanst in a chimney, any gas vent,

under an enclosed floor (crawl space), or into an attic.

The accumulated lint could create a fire hazard.

•Provide an access for inspection and cleaning of the

exhaust system, especially at turns. Inspect and clean

at least once per year.

•Never terminate the exhaust into a common duct with

a kitchen exhaust. A combination of lint and grease

could create a fire hazard.

•Do not obstruct incoming or exhausted air.

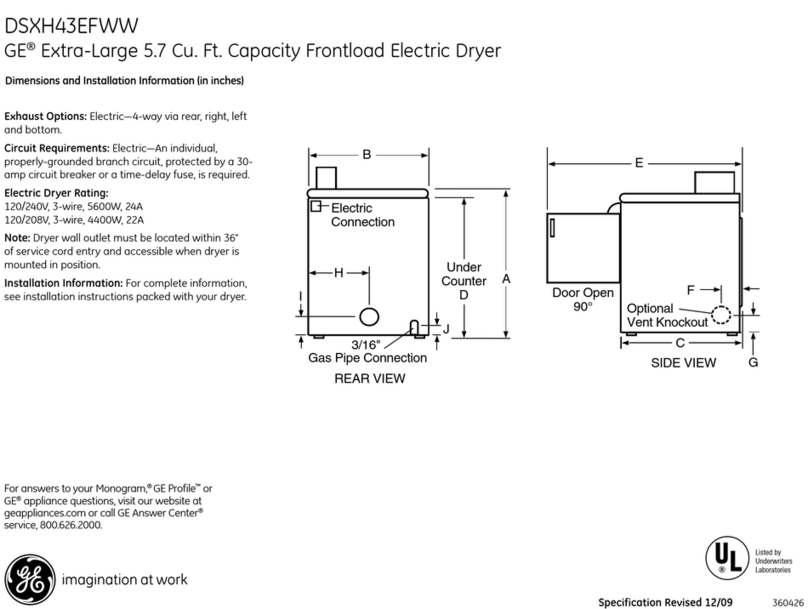

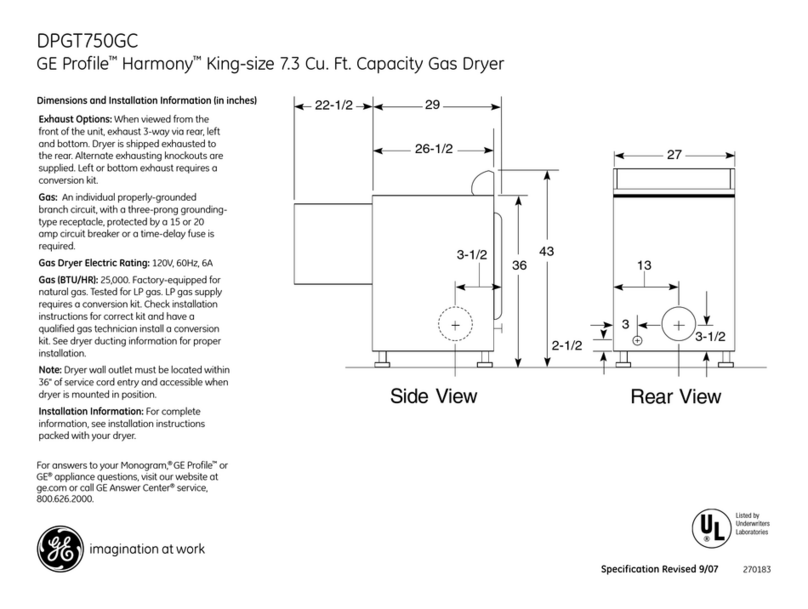

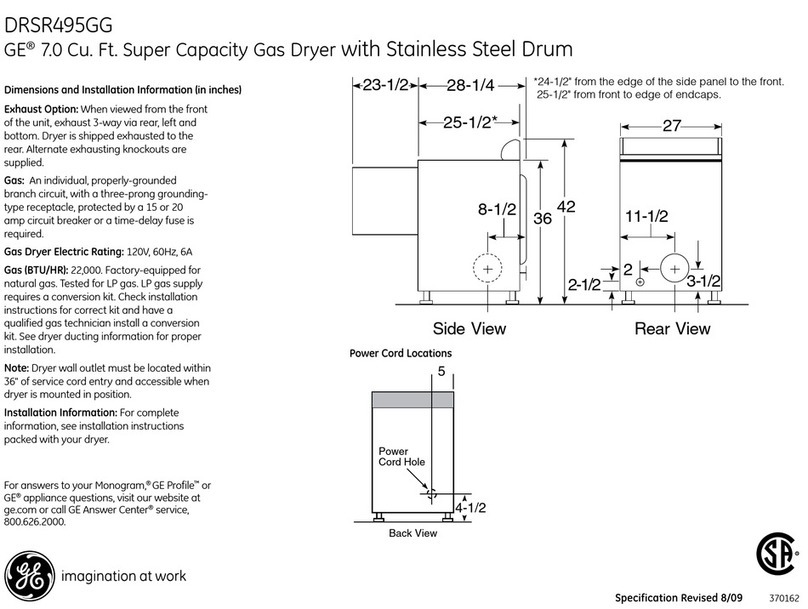

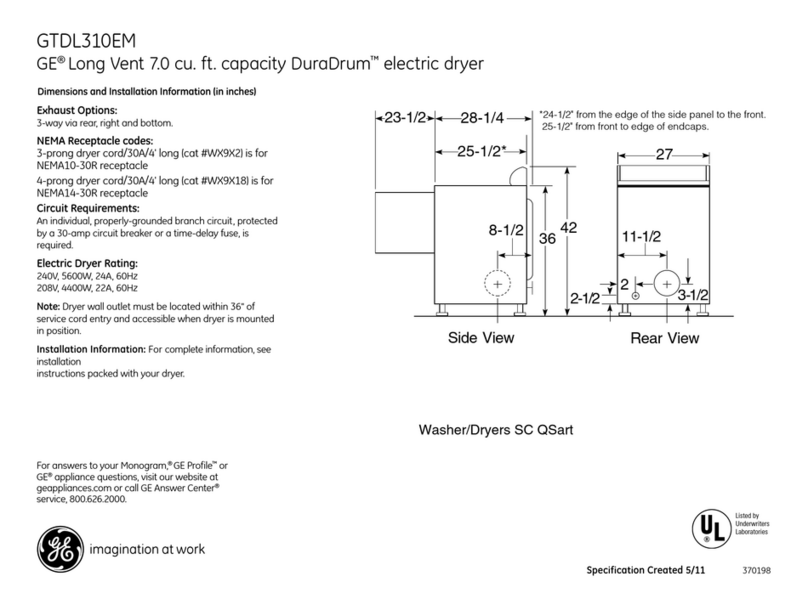

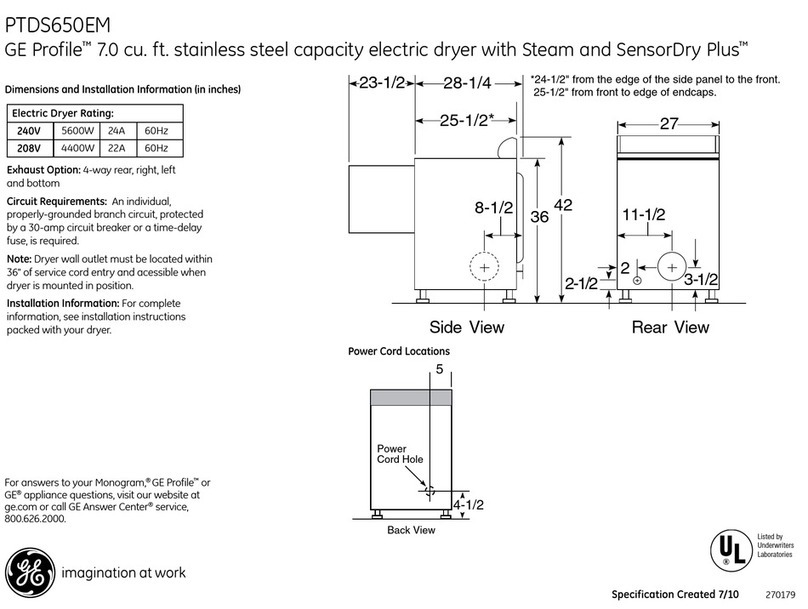

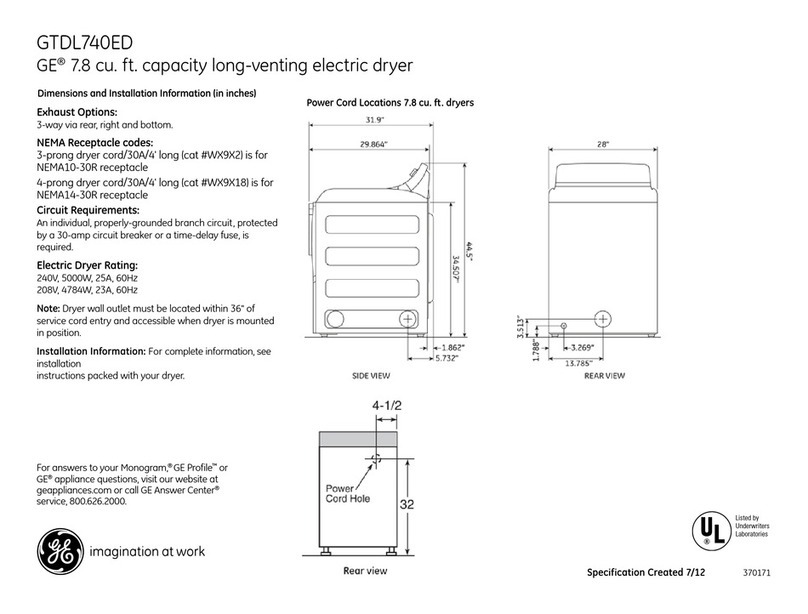

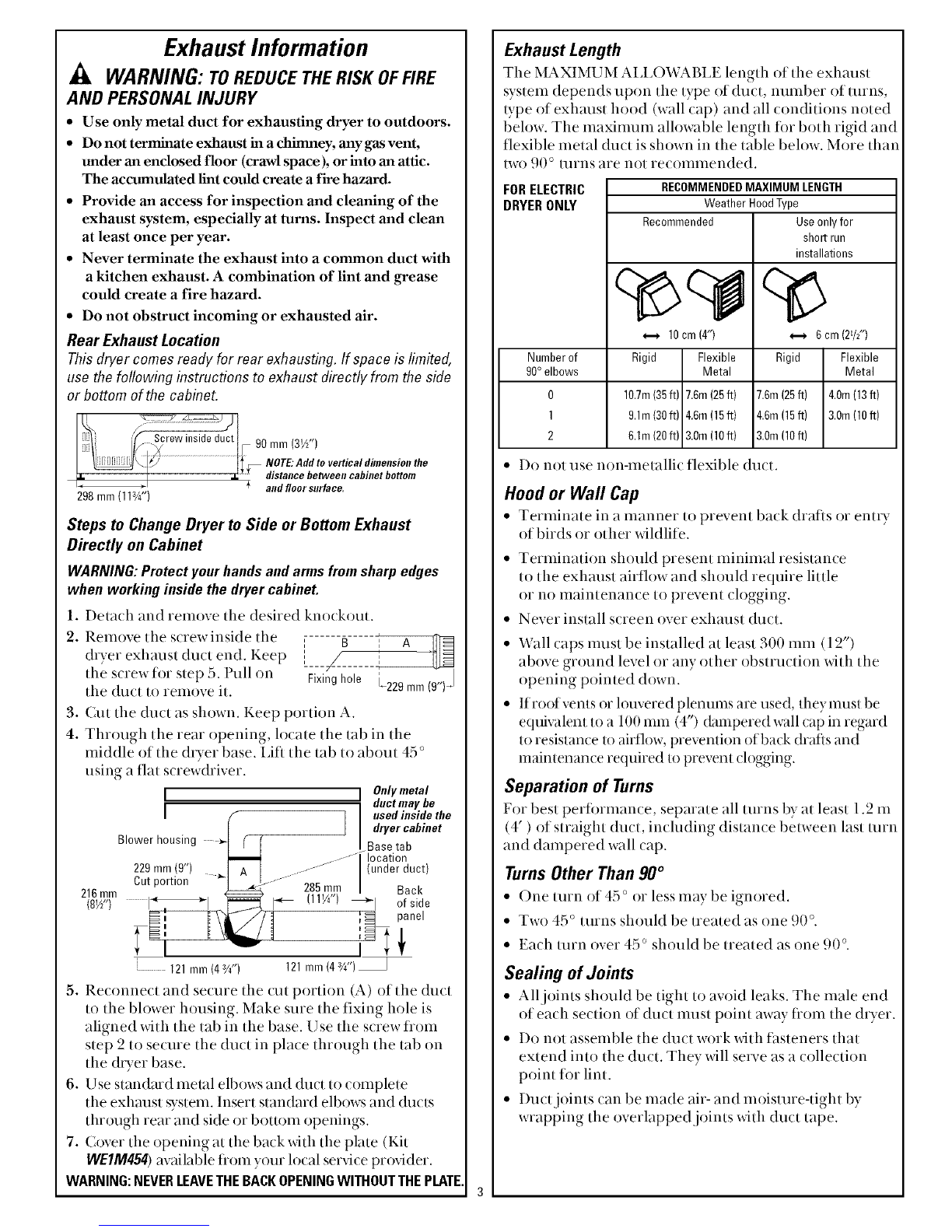

Rear Exhaust Location

Thisdryer comes readyfor rear exhausting. If space is limited,

usethe following instructions to exhaustdirectly from the side

or bottom ofthe cabinet.

298mm(1PA")

90 mm (31/2'')

NOTE:Add to vertical d#aension the

distance between cabinet bottma

and floor surface,

Steps to Change Dryer to Side or Bottom Exhaust

Directly on Cabinet

WARNING:Protectyourhandsand armsfromsharpedges

when workinginsidethe dryercabinet.

1. Detach and remove the desired knockout.

2. Remove the screwinside the ,, B A

dryer exhaust duct end. Keep i 1

the screw for step 5. Pull on Fixinghole L229 mm

the duct to remove it.

3. Cut the duct as shown. Keep portion A.

4. Through the rear opening, h)cate the tab in the

nfiddle of the (hTer base. Lift the tab to about 45 °

using a fiat s(rewdriver. Onlymetal

I;duct may be

I1Iused inside the

[ I dryer cabinet

Blower housing ........i%:

,29mm,9",J ,

Cut portion 285 rnm

216mm (11%")_1

(8V[') of side

121 mm(4aA") 121mm(4W')

5. Reconnect and secure the cut portion (A) of the duct

to the blower housing. Make sure the fixing hole is

aligned with the tab in the base. Use the s(iew flOln

step 2to secure the duct in place through the tab on

the &Ter base.

6. Use standard metal elbows and duct to complete

the exhaust system. Insert standard elbows and ducts

through rear and side or bottom openings.

7. (over the opening at the back with the plate (Kit

WEIM454)available flOln your h)cal serxfce prox4der.

WARNING:NEVERLEAVETHEBACKOPENINGWITHOUTTHEPLATE.

Exhaust Length

The MAXIMUM AIA_€)'v\LMH_Elength of the exhaust

system depends upon the type of duct, number of turns,

type of exhaust hood (wall cap) and all conditions noted

below. The maximum allowable length fin both rigid and

fexible metal duct is shown in the table below. More that

two 90 o turns are not recommended.

FORELECTRIC

DRYERONLY RECOMMENDEDMAXIMUM LENGTH

Weather HoodType

Recommended Use onlyfor

Numberof

90°elbows

0

1

2

• Do not use non-metallic flexible duct.

10cm(4")

Rigid Flexible

Metal

10.7m(35ft) 7.6m(25ft)

9.1m(30ft) 4,6m(15ft)

6.1m(20ft) 3.0m(10ft)

shortrun

installations

_--_ 6cm (2W')

Rigid Flexible

Metal

7.6m(25ft) 4.0m(13ft)

4.6m(15ft) 3.0m(10ft)

3.0m(10ft)

Hood or Wall Cap

• Terminate in a manner to prevent ba(k drafts or enu T

of birds or other wildlife.

Termii_ation should present mildmal resistan(e

to the exhaust airflow and should require little

or no maintenan(e to prevent (logging.

Never install s(reen over exhatlst (hi(l,

Wall caps must be installed at least 300 mm(12")

above ground level or any other obstruction with the

opening pointed down.

If root vents or louvered plenums are used, they must be

equivalent to a 100 mm (4") dampered wall cap in regard

to resistance to airflow, prevention of back drafts and

maintenance required to prevent clogging.

Separation of Turns

For best performance, separate all turns by at least 1.2 m

(4') of straight duct, including distance between last turn

and dampered wall cap.

Turns Other Than 90 °

• One turn of 45 ° or less may be ignored.

• Two 45° turns should be treated as()tie 90 °.

• Each turn over 45 ° should be treated as one 90 °.

Sealing of Joints

• All joints should be tight to avoid leaks. The male end

of each section of duct must point mvay fiom the dtTer,

• Do not assemble the duct work with tasteners that

extend into the duct, They will serve as a collection

point lot lint.

• Duct joints can be made air- and moisture-tight by

wrapping the overlapped joints with duct tape.