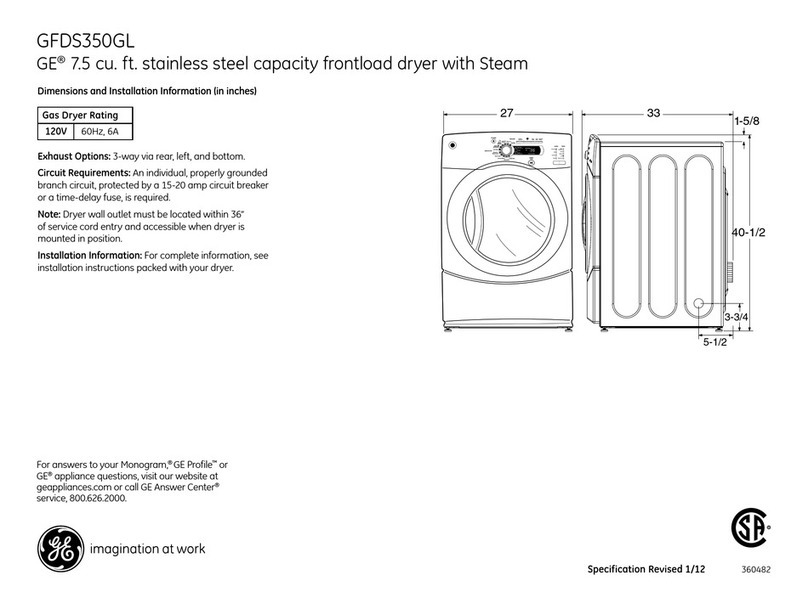

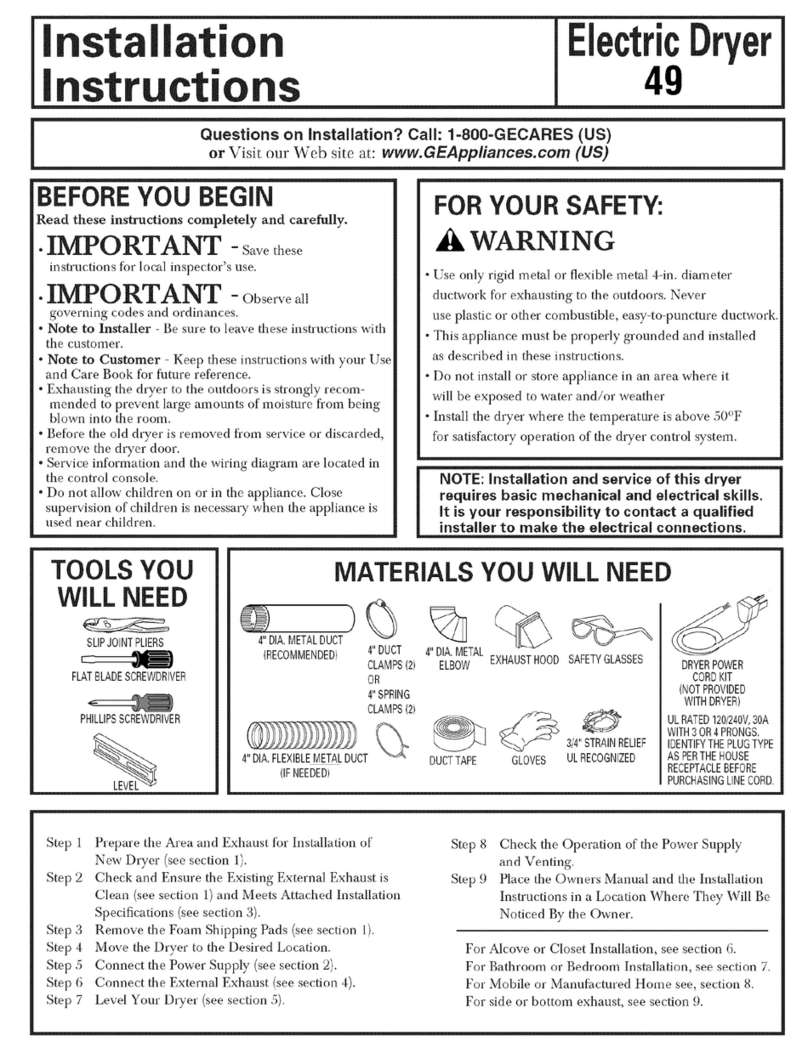

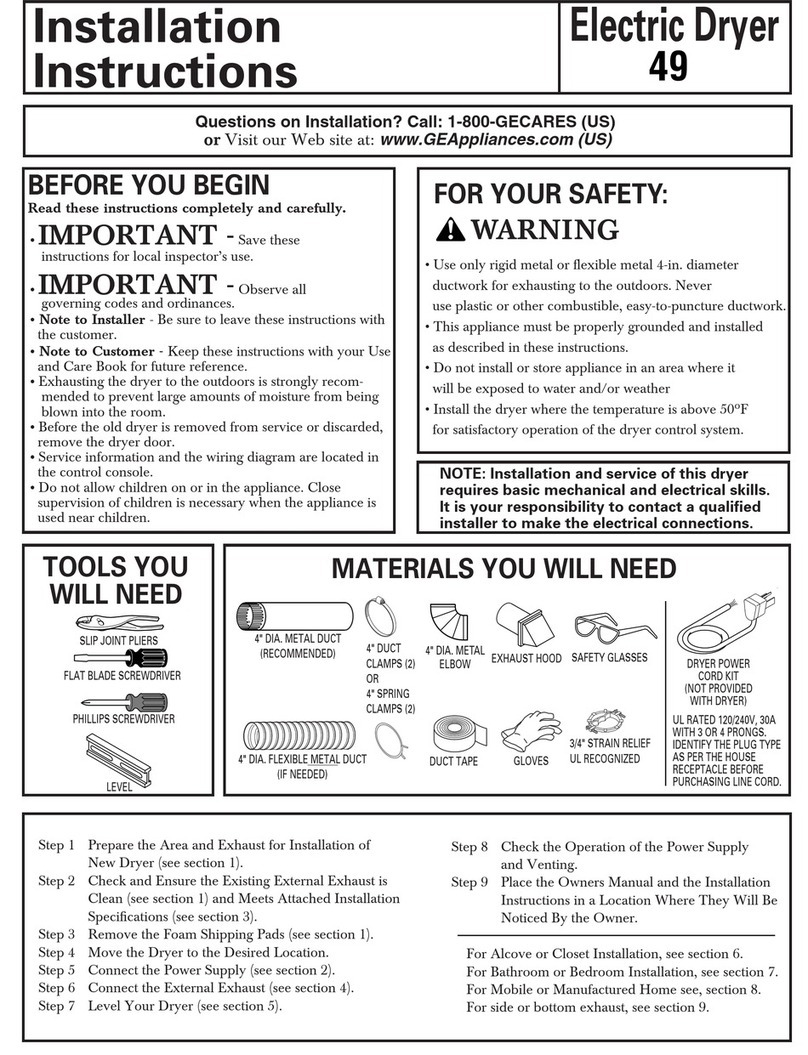

Installation Instructions

REQUIREMENTS FOR ALCOVE OR

CLOSET INSTALLATION

_- Explosion Hazard

Keepflammable materials and vapors, such as gasoline,

away from dryer.

Placedryer at least Z8"(46 cm) above the floor for a

garage installation.

Failureto do so can result in death, explosion, or fire.

, If the dryer is approved for installation in an

alcove or closet, it will be stated on a label on the

dryer back.

, The dryer MUST be vented to the outdoors. See

the EXHAUSTING THE DRYERsection.

, Minimum clearance between dryer cabinet and

adjacent walls or other surfaces is:

0" either side

3" front

3" rear

52" from floor to overhead cabinets

, Consideration must be given to provide adequate

clearance for installation and service.

, Closet ventilation openings required: 2 louvers

each 60 square inches (387 square cm), located 3

inches (7.6 cm) from top and bottom of door.

NOTE: WHEN THE EXHAUST DUCT IS LOCATED AT

THE REAR OF THE DRYER, MINIMUM CLEARANCE

FROM THE WALL iS 5.5 in.

Gas Dryers Only:

, No other fuel burning appliance shall be installed

in the same closet as a gas dryer.

, The dryer must be disconnected from the gas

supply piping during pressure testing at pressures

greater than 1,_psi (3.5 kPa).

, A 1/8 inch NPT minimum plugged tapping,

accessible for test gauge connection, must be

installed immediately upstream of the gas supply

connection to the dryer.

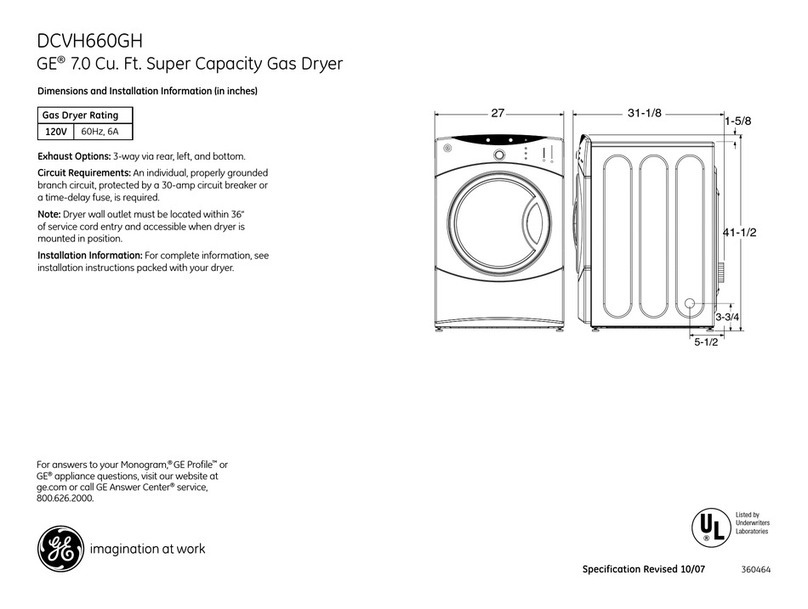

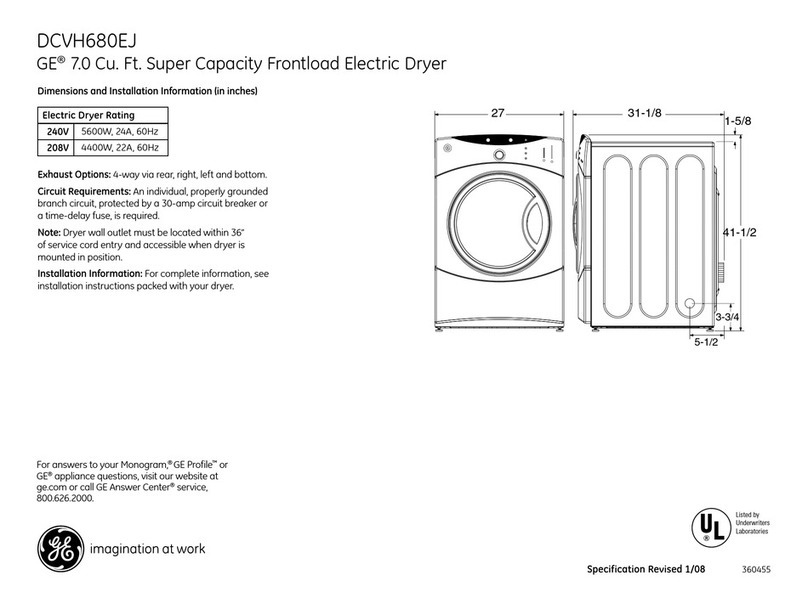

MINIMUM CLEARANCE OTHER THAN

ALCOVE OR CLOSET INSTALLATION

Minimum clearance to combustible surfaces and

for air opening are: O"both sides, 1" front, 3" rear

and 1" top. Consideration must be given to provide

adequate clearance for installation and service.

MOBILE OR MANUFACTURED HOME

INSTALLATION

, Installation must conform to the

MANUFACTURED HOME CONSTRUCTION AND

SAFETYSTANDARD, TITLE 24, PART32-80 or

Standard CAN/CSA-Z240 MH, or, when such

standard is not applicable, with AMERICAN

NATIONAL STANDARD FOR MOBILE HOME,

ANSI/NFPA NO. 50lB.

, The dryer MUST be vented to the outdoors. The

exhaust vent must be securely fastened to a

non-combustible portion of the mobile home.

, The vent MUST NOT be terminated beneath a

mobile or manufactured home.

, The vent duct material MUST BE METAL.

, KIT 14-D346-33 MUST be used to attach the dryer

securely to the structure.

, The vent MUST NOT be connected to any other

duct, vent or chimney.

, Do not use sheet metal screws or other

fastening devices which extend into the interior

of the exhaust vent.

, Provide an opening with a free area of at least

25 square inches for introduction of outside air

into the dryer room.

, See the sections for electrical connection

information.