GEI-83910

TABLE

OF

CONTENTS

PAGE

INTRODUCTION

........................

. . . . . . . . . . . . . . . . . . . . .

..

.......

3

APPLICATION

..............................

. . . . . . . . . . . . . 3

RATINGS

..........................

.........

4

COILS

.........

.......

...................................

4

CONTACTS

................

.......................................

4

CHARACTERISTICS

.........

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

OPERATING PRINCIPLES

....

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

PiCKUP.................

..........................

......

........

5

OPERATING

TIME

...................................................

5

BURDEN

................

..........................................

5

CALCULATIONS

OF

SETTINGS

...............................................

5

TWO-TERMINAL

LINE

......................................................

6

THREE-TERMINAL

LINE.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

6

CONSTRUCTION

...............

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

7

CARRIER-START UNIT (G-1)

.................................................

7

TRIP UNIT (G-2)

...........

. . . . . . . . . . . . . . . . . . . . . . .

..

..................

8

DIRECTIONAL UNIT (GD)

...................................................

8

AUXILIARY

UNIT (GD1X)

...................................................

8

SEAL-IN UNIT

(SI)

...................

. . . . . . . . . . . . . . . . . . . . . . 9

RECEIVING,

HANDLING,

AND

STORAGE

..

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

9

ACCEPTANCE

TESTS

............................................................

9

VISUAL INSPECTION

................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

10

MECHANICAL

INSPECTION

................................................

10

ELECTRICAL

TESTS

........................................................

10

Upper-Unit

Pickup

(G1)

........................

...............

10

Middle-Unit

Pickup

(G2)

...........

. . . . . . . . . . . . . .

11

Bottom-Unit

Pickup

(GD)

...........

. . . . . . . . . . . . . . . . . . .

..

11

Bottom-Unit-Core

Check (GD)

.......

. . . . . . . . . . . . .

..

11

GD1X

Unit

Pickup

........................

. . . . . . . . . . . . . . . . . . . . .

..

11

INSTALLATION PROCEDURE

..........

.......................................

11

RELAY SETTINGS

..................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

11

CARRIER-PICKUP-START UNIT (G1)

....

...................................

12

CLUTCH

ADJUSTMENT........

....................................

12

TRIP UNIT (G2)

..........................................................

12

CLUTCH ADJUSTMENT

....................................................

13

DIRECTIONAL UNIT (GD)

........................

. . . . . . . . . . . . . . . . .

..

13

PERIODIC

CHECKS

AND

ROUTINE

MAINTENANCE.

.

..

. . . . . . . . . . . . .

..

13

MECHANICAL

CH

ECKS

.............................

14

ELECTRICAL

TESTS

.............

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

14

SERVICING

....................................................

. . . . .

..

14

MECHANICAL

ADJUSTMENTS

.......................................

14

ELECTRICAL ADJUSTMENTS . . . . . . . . . . . . . . . 15

RENEWAL

PARTS...

..........

......................................

16

LIST

OF

FIGURES......

........

..........................

17

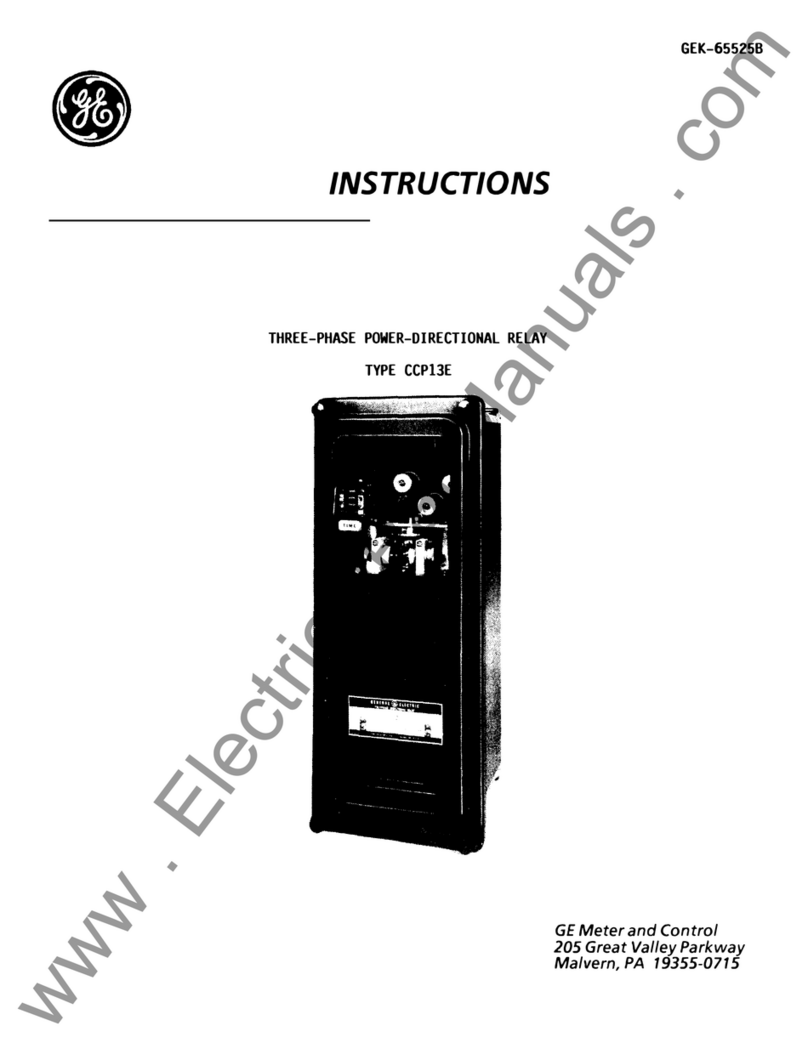

(Cover

Photo

8029772)

)