vi L30 LINE CURRENT DIFFERENTIAL SYSTEM – INSTRUCTION MANUAL

TABLE OF CONTENTS

5.6 FlexLogic........................................................................................................5-165

5.6.1 FlexLogic operands........................................................................................................ 5-165

5.6.2 FlexLogic rules.................................................................................................................. 5-177

5.6.3 FlexLogic evaluation...................................................................................................... 5-177

5.6.4 FlexLogic example..........................................................................................................5-177

5.6.5 FlexLogic equation editor............................................................................................ 5-182

5.6.6 FlexLogic timers............................................................................................................... 5-182

5.6.7 FlexElements ..................................................................................................................... 5-182

5.6.8 Non-volatile latches.......................................................................................................5-187

5.7 Grouped elements .......................................................................................5-188

5.7.1 Overview ............................................................................................................................. 5-188

5.7.2 Setting group 1................................................................................................................. 5-188

5.7.3 Line differential elements............................................................................................ 5-189

5.7.4 Phase current ................................................................................................................... 5-194

5.7.5 Neutral current................................................................................................................. 5-206

5.7.6 Ground current ................................................................................................................ 5-214

5.7.7 Negative sequence current........................................................................................ 5-217

5.7.8 Breaker failure (ANSI 50BF)......................................................................................... 5-219

5.7.9 Voltage elements ............................................................................................................ 5-228

5.7.10 Supervising elements.................................................................................................... 5-235

5.8 Control elements .........................................................................................5-238

5.8.1 Overview ............................................................................................................................. 5-238

5.8.2 Trip bus ................................................................................................................................ 5-238

5.8.3 Setting groups .................................................................................................................. 5-240

5.8.4 Selector switch................................................................................................................. 5-241

5.8.5 Underfrequency (ANSI 81U)........................................................................................ 5-248

5.8.6 Frequency rate of change (ANSI 81R).................................................................... 5-249

5.8.7 Synchrocheck (ANSI 25) ............................................................................................... 5-251

5.8.8 Autoreclose (ANSI 79).................................................................................................... 5-257

5.8.9 Digital elements............................................................................................................... 5-263

5.8.10 Digital counters................................................................................................................ 5-266

5.8.11 Monitoring elements ..................................................................................................... 5-268

5.9 Inputs/outputs .............................................................................................5-282

5.9.1 Contact inputs.................................................................................................................. 5-282

5.9.2 Virtual inputs..................................................................................................................... 5-284

5.9.3 Contact outputs............................................................................................................... 5-285

5.9.4 Virtual outputs.................................................................................................................. 5-288

5.9.5 Resetting ............................................................................................................................. 5-288

5.9.6 Direct inputs and outputs ........................................................................................... 5-289

5.10 Transducer inputs/outputs........................................................................5-290

5.10.1 DCmA inputs...................................................................................................................... 5-290

5.10.2 RTD inputs .......................................................................................................................... 5-291

5.10.3 DCmA outputs .................................................................................................................. 5-292

5.11 Testing ...........................................................................................................5-296

5.11.1 Test mode function ........................................................................................................5-296

5.11.2 Test mode forcing........................................................................................................... 5-297

5.11.3 Phasor Measurement Unit test values.................................................................. 5-297

5.11.4 Force contact inputs ..................................................................................................... 5-298

5.11.5 Force contact outputs .................................................................................................. 5-299

5.11.6 Channel tests .................................................................................................................... 5-299

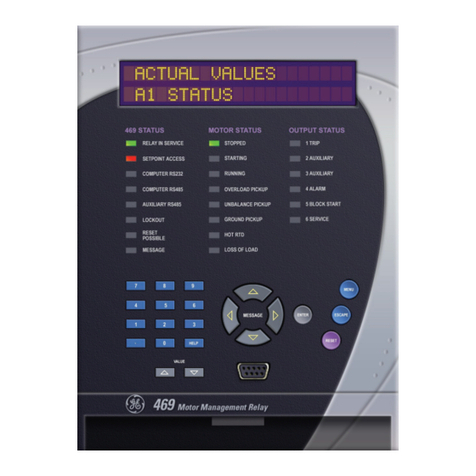

6 ACTUAL VALUES 6.1 Actual Values menu.........................................................................................6-1

6.2 Front panel........................................................................................................6-3

6.3 Status................................................................................................................. 6-4