TABLE OF CONTENTS

369 MOTOR MANAGEMENT RELAY – QUICKSTART GUIDE TOC–1

Table of Contents

1: INTRODUCTION ORDERING ..........................................................................................................................1-1

GENERAL OVERVIEW ........................................................................................................... 1-1

369 FUNCTIONAL SUMMARY ............................................................................................ 1-2

RELAY LABEL DEFINITION ................................................................................................... 1-3

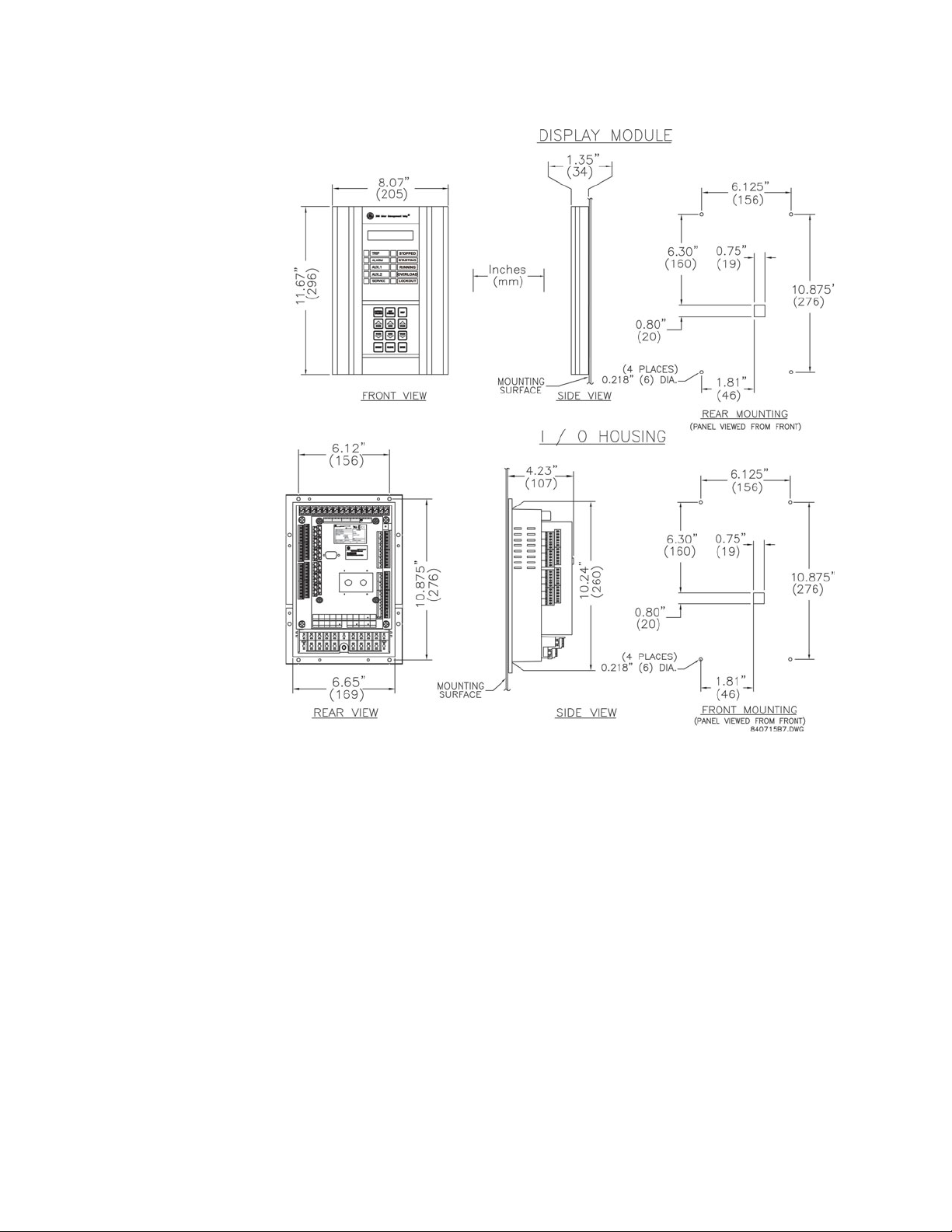

2: INSTALLATION MECHANICAL INSTALLATION .........................................................................................2-5

MECHANICAL INSTALLATION .............................................................................................. 2-5

TERMINAL IDENTIFICATION ...........................................................................................2-7

369 TERMINAL LIST ............................................................................................................ 2-7

TERMINAL LAYOUT .............................................................................................................. 2-9

ELECTRICAL INSTALLATION ...........................................................................................2-10

TYPICAL WIRING DIAGRAM ................................................................................................ 2-10

TYPICAL WIRING .................................................................................................................. 2-11

CONTROL POWER ................................................................................................................ 2-11

REMOTE DISPLAY ................................................................................................................. 2-11

OUTPUT RELAYS .................................................................................................................. 2-12

RS485 COMMUNICATIONS ............................................................................................... 2-12

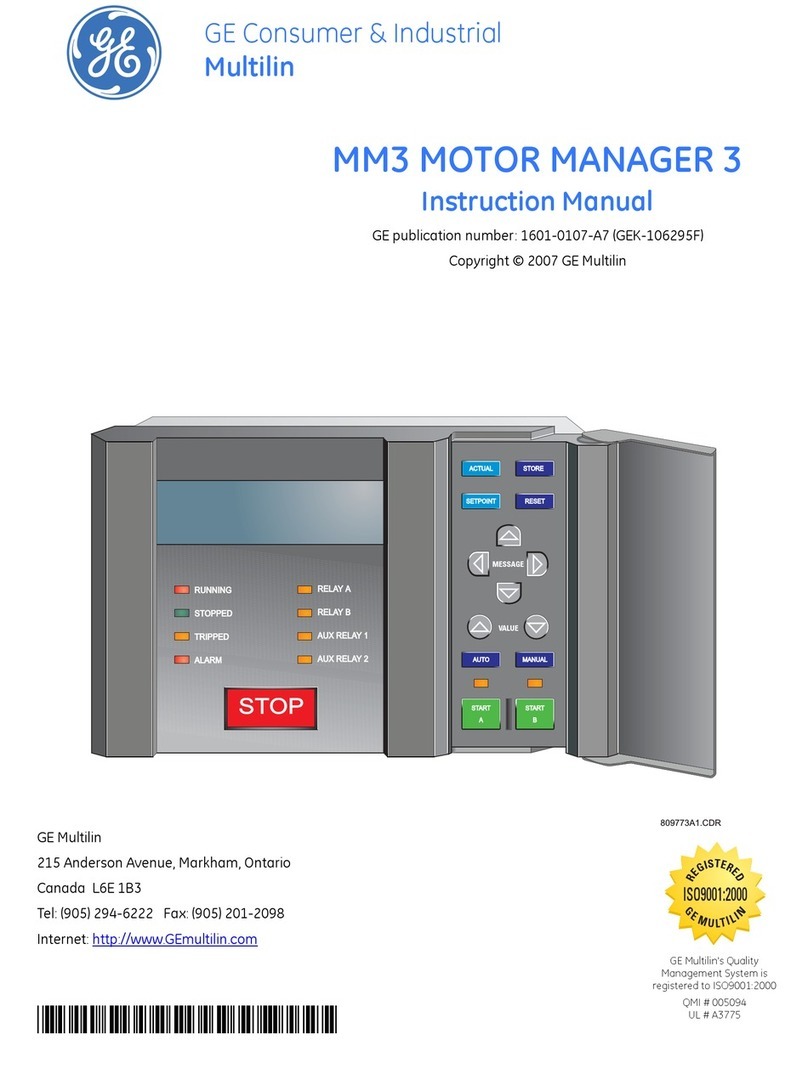

3: USER INTERFACES FACEPLATE INTERFACE ...................................................................................................3-15

DISPLAY ................................................................................................................................ 3-15

LED INDICATORS ................................................................................................................. 3-15

RS232 PROGRAM PORT .................................................................................................... 3-16

KEYPAD ................................................................................................................................. 3-16

SETPOINT ENTRY .................................................................................................................. 3-17

ENERVISTA 369 SETUP INTERFACE .............................................................................3-18

HARDWARE AND SOFTWARE REQUIREMENTS ................................................................. 3-18

INSTALLING ENERVISTA 369 SETUP ............................................................................... 3-18

CONNECTING ENERVISTA 369 SETUP TO THE RELAY .............................................3-21

CONFIGURING SERIAL COMMUNICATIONS ....................................................................... 3-21

USING THE QUICK CONNECT FEATURE ............................................................................ 3-23

CONFIGURING ETHERNET COMMUNICATIONS ................................................................. 3-23

CONNECTING TO THE RELAY .............................................................................................. 3-25

4: KEYPAD SETPOINTS OVERVIEW ...........................................................................................................................4-27

KEYPAD SETPOINTS MAIN MENU ...................................................................................... 4-27

369 SETUP USING THE KEYPAD .....................................................................................4-31

KEYPAD SETPOINT ACCESS ................................................................................................ 4-31

S2 SYSTEM SETUP USING THE KEYPAD .......................................................................4-32

DESCRIPTION ........................................................................................................................ 4-32

EXAMPLE: CT/VT SETUP .................................................................................................... 4-32

S3 OVERLOAD PROTECTION ..........................................................................................4-34

DESCRIPTION ........................................................................................................................ 4-34

OVERLOAD CURVES ............................................................................................................ 4-35

OVERLOAD ALARM .............................................................................................................. 4-39

S4 CURRENT ELEMENTS ..................................................................................................4-40

DESCRIPTION ........................................................................................................................ 4-40